Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Research on Effect of Metal Coupling on Rusting of Iron

Authors: Falguni S. Bhavsar, Sanskruti Soitkar, Ayush Patil, Venu More, Pankaj Bhagat

DOI Link: https://doi.org/10.22214/ijraset.2024.65842

Certificate: View Certificate

Abstract

This research reinforces the importance of material selection and galvanic coupling in preventing or controlling corrosion in real-world applications. So metal coupling has become the most important research going on regarding various issues of corrosion. So this project is regarding one of the most remarkable techniques “METAL COUPLING” for prevention of corrosion. In this project we are looking forward to investigate the effect of the metal coupling on the rusting of iron, so here we have taken the metal strips of zinc, copper, and aluminium. Metal coupling affects the rusting of iron according to the ECS series, if the nail is couple with the more electropositive element or metal like zinc and Aluminium rusting is prevented but if on the other hand It is couple with less electropositive metal like copper and nickel the rusting is facilitated.

Introduction

I. INTRODUCTION

We can see number of examples of rusting in our daily life. Rusting of iron is very common as iron reacts easily with atmospheric oxygen undergoing corrosion. Position of metals in electrochemical series decides the metal undergoing corrosion by formation of rust. Iron is chemical element it is by mass the most common element on Earth forming outer and inner Core it is M.P=1811K B.P=3134K It has been the most favourable and prior material in the manufacturing ,construction and transport sector as well.

A. Galvanic series

The Galvanic Series is a list of metals and alloys arranged in order of their tendency to corrode (or oxidize) when placed in an electrolyte. It provides a comparison of the electrochemical reactivity of various metals, helping to predict which metals will corrode and which will remain protected when they are in contact.

B. Applications of the Galvanic Series

1) Material Selection:

Example: Avoid coupling copper pipes with steel in plumbing systems.

2) Sacrificial Protection:

Highly anodic metals (like zinc or magnesium) are used as sacrificial anodes to protect less reactive metals.

Example: Zinc coatings in galvanization protect iron structures.

3) Marine Engineering:

Helps in designing ship hulls, offshore structures, and pipelines exposed to seawater to minimize corrosion risks.

Understanding the galvanic series is essential for effective corrosion prevention and management in engineering and material science.

- Metal Corrosion Characteristics: Corrosion primarily occurs on the surface of metals through chemical reactions. It affects key properties such as strength, plasticity, toughness, and other mechanical characteristics.

- Economic Impact: Corrosion significantly increases costs for industries due to damage control and maintenance.

- Effects of Rusting on Iron: Causes iron to become flaky and weak, reducing its structural integrity.Deteriorates the length, appearance, and permeability of the metal.

In structural applications (e.g., bridges, buildings, ships), rusting can lead to corrosion fatigue.

- Hazardous Impact of Rust: Rust formation increases the overall weight due to iron oxide accumulation, while the metal itself loses weight. This added weight is problematic in industries where weight is a critical factor, such as automotive and aerospace .

- Vulnerability to Rusting: Iron rusts if protective layers (like zinc coatings) are damaged or worn, exposing it to corrosive elements.

C. Rusting of iron

It refers to the formation of rust. A mixture of iron oxide at the surface of iron objects of structures. It is formed due to redox reactions between oxygen and iron in an environment containing water.

Rusting may be explained by an electrochemical mechanism. In

the presence of moist air containing dissolved oxygen or carbon dioxide, the commercial iron behaves as if composed of small electrical cells. At the anode of the cell, iron passes into solutions of ferrous ions. The electron moves towards the cathode and forms hydroxyl ions. Under the influence of dissolved oxygen, the ferrous ion and hydroxyl ions interact to form rust, i.e., hydrated ferric oxide.

D. Methods of Prevention of Corrosion and Rusting

Preventing corrosion is of utmost importance in order to avoid huge losses. The majority of the structures that we see and use are made out of metals. This includes bridges, automobiles, machinery, household goods like window grills, doors, railway lines, etc. While this is a concerning issue, several treatments are used to slow or prevent corrosion damage to metallic objects

- Galvanization: It is the most known technique of prevention of corrosion. Basically known as the process in which there is an application of protective zinc coating to iron or steel that helps prevent premature corrosion and rust. A metal provided anti-corrosion properties to the same. The absence of protective zinc coating exposes the elements and increases the chance of oxidizing, resulting in faster corrosion.

- Electroplating: It Is the process of coating a material (typically a metal) with a thin layer of another metal using an electrical current. It is commonly used to improve appearance, prevent corrosion, reduce friction, or enhance surface properties like hardness.

II. CONNECTING CONCEPTS WITH REALITY

Looking forward towards the recent issue of industrial loss due to corrosion and rusting.

Here’s its brief information:

In India corrosion leads to loss worth of 100 billion in Indian industry named “JSL MD (Jindal Stainless Ltd.) every year by strategically implementing corrosion management. We can save up to 25% of corrosion cost across industries. CII and JSL signed a memorandum regarding focusing on scaling up corrosion management entities in India and abroad.

The Boiler machines are closely related to corrosion and rusting because they operate in environments that often involve high temperatures, water, and sometimes aggressive chemical conditions, all of which contribute to the processes of corrosion and rust formation. Here's how these phenomena are connected:

A. High Temperature Accelerates Corrosion:

- The elevated temperatures inside boilers accelerate chemical reactions, including those that cause corrosion.

- In high-temperature environments, water can dissociate into hydrogen and oxygen, enhancing the potential for oxidation.

B. Impurities and Scaling

- Impurities in boiler water, such as salts and minerals, can precipitate and form scales. These deposits can trap corrosive agents (e.g., oxygen and chlorine), creating localized corrosion points beneath the scale.

- This scaling also reduces heat transfer efficiency, leading to overheating and accelerated corrosion.

Corrosion and rusting, if left unmanaged, can lead to reduced efficiency, costly repairs, or catastrophic boiler failures. Thus, monitoring and preventive measures are crucial for safe and efficient operation. Looking forward towards Maharashtra the Corrosion poses significant challenges in Maharashtra, particularly due to its extensive coastline and humid climate, which accelerate the deterioration of metal structures. A notable incident highlighting this issue occurred in August 2024 when a 35-foot statue of Chhatrapati Shivaji Maharaj collapsed at Rajkot Fort in Malvan, Sindhudurg district. Investigations revealed that internal corrosion, rusting, and structural weaknesses were primary factors leading to the collapse.

The Maharashtra Public Works Department (PWD) had previously alerted the Indian Navy about rust accumulating on the statue's nuts and bolts, emphasizing the need for immediate remedial measures.

Despite these warnings, the structure failed, underscoring the critical importance of proactive maintenance and corrosion prevention strategies.

Moving towards the most well known city of Maharashtra i.e PUNE as Pune is too much crowded leading to pollution due to which harmful gases are released.

C. Temperature

Daily and seasonal temperature variations in Pune can lead to thermal expansion and contraction, weakening protective coatings on metals and causing exposure to rust.

D. Industrial Emissions

Pune has several industrial hubs (e.g., Pimpri-Chinchwad, Chakan, and Hadapsar). Factories emit sulfur dioxide (SO?) and nitrogen oxides (NO?), which combine with water to form acidic solutions. This results in acid rain, which corrodes metal surfaces and infrastructure.

And So now let’s know about the corrosion problems in my college PIMPRI CHINCHWAD COLLEGE OF ENGINEERING, PUNE(PCCOE) I have recently observed that in our college playground. As corrosion in playgrounds is a common problem that can affect the safety, durability, and aesthetics of the equipment. Understanding the causes, effects, and solutions for corrosion in playgrounds is crucial for proper maintenance and safety.

III. METHODOLOGY

A. Requirements

- Iron Nails

- Small Metal Strips (Copper, zinc, Aluminium)

- 4 Beakers

- Distilled Water

- Common Salt (Sodium Chloride)

- Sand Paper (to clean nails and metals)

- Cotton Thread

- Phenolphthalein

B. Procedure

- First of all Clean the Iron Nails and Metal strips with sandpaper to remove an oxide layer.

- Then we will setup the different Test Tubes such that:

Iron nails kept alone in beaker

Iron nail coupled with Zinc (Galvanic Protection)

Iron nail coupled with copper (Accelerated rusting)

Iron nail coupled with Aluminium (Do not Accelerate rusting)

- Wrap the different metal Strips to the iron nails using cotton thread or adhesive tape.

- Place each nail metal pair in a separate beaker containing water.

- Add a pinch of salt i.e Sodium chloride to the water to speed up the rusting process.

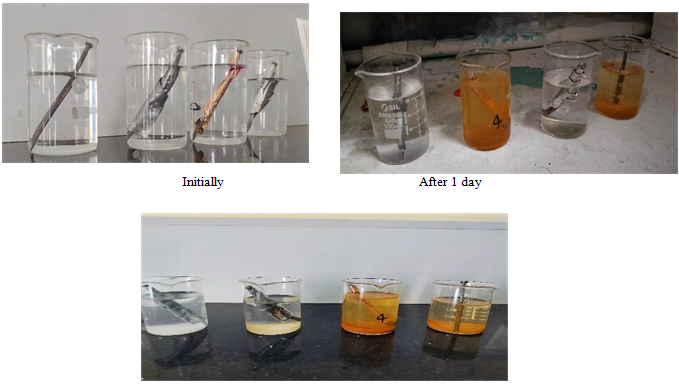

C. Results

- Control (Iron Alone): The iron nail will rust as expected, with visible reddish-brown deposits.

- Iron + Zinc: Zinc, being more reactive than iron, will act as a sacrificial anode. The nail will rust less or not at all, as zinc gets oxidized instead of iron.

- Iron + Copper: Copper, being less reactive than iron, accelerates rusting. The iron nail will rust faster and more severely because copper acts as a cathode, promoting the oxidation of iron.

- Iron + Aluminium:

The effect depends on the reactivity of the metal:

Less reactive metals (e.g., aluminum): Rusting may be similar to or faster than the control setup.

The results demonstrate the principles of galvanic protection and galvanic corrosion:

- Metals higher in the reactivity series (e.g., zinc) protect iron.

- Metals lower in the reactivity series (e.g., copper) accelerate iron's rusting.

IV. OBSERVATION

As we have kept all the four beakers for 2 days containing 4 nails out of which 3 nails are wrapped with Copper, Aluminium and Zinc strips. So as expected we have observed that among all the four only 2 were rusted (alone Iron without wrapped strip and copper strip iron) and 2 of them were not rusted. As above it is mentioned copper and iron nail alone will get rusted and zinc and aluminium will not show any type of change.

Reactions:

Iron Coupled with Zinc or Aluminum :

Zinc or aluminum is more reactive than iron, so they act as the anode and oxidize preferentially.

for zinc:

Zn→ Zn2+ + 2e−

for aluminium:

Al → Al3++ 3e−

Iron becomes the cathode, where oxygen reduction occurs:

O2+ 2H2O + 4e−→ 4OH−

Iron Coupled with Copper (Less Reactive Metal):

Copper is less reactive than iron, so it becomes the cathode, where oxygen reduction occur

O2 + 2H2O + 4e−→4OH−

Iron oxidizes more rapidly as it acts as the anode:

Fe (s)→Fe2++ 2e−

Conclusion

The reactivity of the metal coupled with iron determines whether it will protect or accelerate the rusting process. Metals higher in the electrochemical series (like zinc and aluminum) protect iron through sacrificial corrosion. Metals lower in the series (like copper) accelerate rusting by forming galvanic cells. This principle is used in galvanization to protect iron and steel structures.

References

[1] N.C. Hosking & M.A. Ström & Philip H. Shipway & C.D. Rudd,Corrosion resistance of zinc–magnesium coated steel, Volume 49, Issue 9 https://doi.org/10.1016/j.corsci.2007.03.032 [2] Zaki Ahmad 2 September 2007., BASIC CONCEPTS IN CORROSION,. https://doi.org/10.1016/B978-075065924-6/50003-9 [3] John X.J. Zhang, Kazunori Hoshino,in (Second Edition), Fundamentals of nano/microfabrication and scale effect, 2019 https://www.sciencedirect.com /topics/materials-science/electroplating [4] Modulation of improved lignin structure for conversion of iron oxides on the metal artifact .Iiyana Syafawati Osman, Nur Hanani Hazirah Elias, Mokhtar Saidin, Shaiful Shahidan, Ahmad Fadly Jusoh, Nicolas Brosse c, Isabelle Ziegler-Devin, Mohamad Nasir Mohamad Ibrahim ,Pandian Bothi Raja, Djalal Trache,M. Hazwan Hussin, Volume 222, Part 5, 15 December 2024 https://doi.org/10.1016/j.indcrop.2024.120015 [5] The coupling mechanism of shrinkage defects and graphite on the corrosion resistance of ductile iron Tianqi Chen, Bingqin Wang, Liang Sun, Chao Liu, Xuequn Cheng, Xiaogang Li [6] Volume 227, February 2024, https://doi.org/10.1016/j.corsci.2023.111798 [7] Camila Pucci Couto, Francesco Andreatta, AlexLanzutti, Isolda Costa, Zehbour Panossian, Herman Terryn, Jesualdo Luiz Rossi, Reynier I. Revilla, Volume 185, June 2021, https://doi.org/10.1016/j.corsci.2021.109435 [8] Emmanuel Chukwuebuka Gugua, Chika Oliver Ujah, Christian O. Asadu, Daramy Vandi Von Kallon, Benjamin Nnamdi Ekwueme Volume 7, December 2024, Electroplating in the modern era, improvements and challenges., https://doi.org/10.1016/j.hybadv.2024.100286 [9] An Li, Qi Wang, Ruirun Chen, Xin Ding, Yanqing Su, Hengzhi Fu, Application of alloying for enhancing the corrosion resistance of titanium alloys: A review, Volume 42, January 2025, https://doi.org/10.1016/j.mtcomm.2024.111111

Copyright

Copyright © 2024 Falguni S. Bhavsar, Sanskruti Soitkar, Ayush Patil, Venu More, Pankaj Bhagat. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65842

Publish Date : 2024-12-10

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online