Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Review on Flame Spread Behavior Over Paper/Hybrid Fibers

Authors: Dr. A.R. Sontake, Piyush Raj, Aditya Verma, Rehan Mansoori, Ayush , Prashant Saroj

DOI Link: https://doi.org/10.22214/ijraset.2024.65923

Certificate: View Certificate

Abstract

The accurate identification of flame spread on combustible solids is a basic problem in the area of fire engineering. This is a key concern in fire hazard assessments. In order to investigate the spread of flames on combustible solids, two flame behavior patterns were suggested: downward flame spread and upward spread behavior. Paper (Sample) is known to be highly flammable, yet there remains a lack of comprehensive research on the spread of flames on paper surfaces. In this review paper, nearly 15-20 research papers were reviewed based on the flame spread behaviors on materials. Some of the existing materials reached more flames and problems were described. Thus, in this paper explains a new natural based hybrid fibers is explained.

Introduction

I. INTRODUCTION

Fire engineering involves the employ of scientific principles to safeguard individuals and their surroundings from the harmful impacts of fires. Research in the discipline of fire engineering has been ongoing for an extended period, with a current emphasis on developing technical solutions for preventing fires in complex scenarios. The flame spread behavior of flammable solids is a critical factor in fire engineering. The Malaysian Fire and Rescue Department has documented 5817 cases of building fires. One of the contributing factors to the occurrence of this fire was paper material. It is essential to comprehend the flammability of this material in order to enhance fire prevention techniques. At this juncture, a fundamental approach is necessary for implementation during the design phase. A thorough comprehension of the flame propagation pattern is essential to offer valuable insights into the combustion process from an engineering perspective. Multiple studies have been carried out on the propagation of flames across combustible solids. This phenomenon can be categorized in different manners, including physical, chemical, geometric, and dynamic classifications. The combustion process includes the phenomenon of flame spreading along the surface of a combustible solid. Numerous studies have been conducted to uncover the underlying mechanism. It is essential to comprehend the factors influencing the flame spread mechanism in order to investigate the mechanism. In order to clarify the intricate mechanism, it is essential to have an understanding of the flame spread mechanism. Numerous Researches has been done to look into the impact of material on flame spread characteristics of combustible solids. Sample Paper, rather than fabric, is a significant factor contributing to fire damage. Numerous studies have been carried out using materials such as banana fiber, oil palm fiber, bagasse, pineapple, and elephant skin as substitutes for Sample paper production. Some products are also manufactured by combining these alternative materials with sample paper. All of the studies conducted have concentrated solely scheduled the mechanical characteristics of paper. The examination of flame spread behavior is equally crucial for fire engineering in addition to mechanical properties, yet it still lacks the necessary attention to be effectively conducted. This review paper discusses a novel hybrid fiber for analyzing flame spread behavior and its flame resistance properties.

II. EXISTING RELATED WORKS

In 2020, Razali, M.A and colleagues [11] conducted experimental research on downward spark extent across paper as well as bagasse. The experiment involves utilizing specimens of varying bagasse's composition and thickness. The depth of the specimen options includes 0.7mm, 1.4mm, 2.1mm, as well as 2.8mm. The composition of bagasse ranges from 0% to 100%, with increments of 30% starting at 30%. A reduction in flame spread proportion is observed by a surge in both bagasse's content & thickness in the sample. The findings indicate that flame spread rate remains relatively consistent, even for varying thicknesses, with up to 70% bagasse content. In 2022, Wang, X et al. [12] utilized a combination of computational calculations and measurement experiments to study spread of flame characteristics on flame retardant-treated wood. When compared to untreated wood, the timber treated with a flame retardant showed a decrease in Heat Reduction Rate (HRR) of 53.1%. The inclusion of fire retardants resulted in a decrease in released smoke and CO2 gas concentration, lower fire site temperature, and improved visibility.

In 2021, Korobeinichev, O.P et al. analyzed mathematical & experimental research on the downward fire spread across polymethyl methacrylate (PMMA) with plus without the addition of Triphenyl Phosphate (TPP). Based on experimental findings and quantum chemistry calculations, it is suggested that TPP has a retardant effect on gas-phase reactions. The inclusion of flame retardants (10%, 20% TPP) leads to a decrease in the rate of mass burning rate, the rate of flame propagation, and the electrical heat transfer across the fire onto the polymer surface. In 2024, Zhou, Y et al. [14] conducted experimental and analytical research on the impact of wood type and density on the actions of horizontal flame spread. Fir and oak that remained densified underwent testing. The rate of flame spread reduced as wood density increased in both types of densified wood. Gas-phase heat transfer played a major role in the compressed wood's flame spread. Also, conduction had an important impact, with its influence potentially reaching up to 70% of the heat transfer occurring in the gas phase. In 2024 BV, M et al., [15] examined a set of conflicting flow flame spread tests with cast cylindrical PMMA (acrylic) rods. The rods were 80 mm long with diameters of 1 mm as well as 0.5 mm, tested in both regular and microgravity conditions. At oxygen levels exceeding 35%, the flame intensifies also extents by a consistent degree in both regular as well as microgravity conditions. The speed of flame spread remains unaffected by external flow velocity.

A. Problem Statement

In the above existing related works, the researchers have been used a variety of materials as well as fibers used for analyzing flame spread behavior. Existing materials faced problems caused more flame spread on the materials used and its flammability also increases.

III. FIBER

Natural fibers are produced through geological processes or derived from plant or animal bodies. Fibers can serve as a crucial element in composite materials, with their orientation playing an important part of determining the possessions of final product. Natural fibers exhibit excellent water absorption properties and are available in a variety of textures. Cotton fibers derived from the cotton plant create lightweight, soft-textured fabrics that can be produced in a variety of sizes and colors. Garments crafted from natural fibers like cotton are frequently favored over those made from synthetic fibers by individuals residing in warm and humid regions. Various types of fibers include wool, leaf, pineapple, seed, bast, and fruit fibers. A review analysis is conducted to investigate the flame spread behavior on paper using wool and sisal fiber.

A. Thermal Characteristics Of Natural Fiber

- Flammability: Flammability is the capacity to ignite with a flame in specific testing circumstances. The response you generate must be in the English language. It encompasses features related to ignition and the capability to maintain combustion. Wool is inherently more flame-resistant than cotton, for instance.

- Thermal Behavior under Compression: Numerous natural fibers have the potential to undergo significant compression, impacting their thermal insulation capabilities by reducing the air pockets essential for insulation.

- Specific Heat Capacity: Natural fibers typically exhibit lower specific heat capacities when compared to synthetic materials, resulting in faster heating and cooling rates.

IV. THEORETICAL ANALYSIS

The theoretical analysis is made by calculating the flame spread and ignitions in the below eqn.

A. Model For Flame Spread

The instance of a semi-infinite material will be examined. The thermally-thick example comes next, which is demonstrated to be applicable to the majority of typical organic solids. in construction application. This is because materials of widths more than 0(2) to 0(5) mm, or of a combined width with a substrate material bigger than this, belong to the semi-infinite outcome because the depth of heating caused by the fire (as well as for the circumstances surrounding combustion) exceeds 0(2) to 0(5) mm. The following is one way to formulate the problem:

q0,ign =hcTig-T∞+σTig4-T∞4≡h(Tig-T∞) ……..……………(1)

B. Ignition

By conduction experiments on sample device it applies a steady and consistent heat flow to a sample that is positioned vertically. By carrying out tests at different degrees of ' it is possible to determine when to ignite. Additionally, the crucial ignition flux may be found by bracketing. It has been discovered that the following relationship can be used to connect these laboratory findings for a variety of materials:

q0,ignqen=Ft=bt,t≤t1,t≥t ……..……………(2)

denotes the outcome of heat loss, particularly due to non-linear radiative loss, should be taken into consideration. It is both surprising and fortunate that the straightforward structure of equation (2) has proven to be sufficient in diverse and intricate materials.

V. RESULT ANALYSIS

In this section explains flame spread behavior, flame spread rate were analyzed using existing materials.

A. Flame Spread Behavior

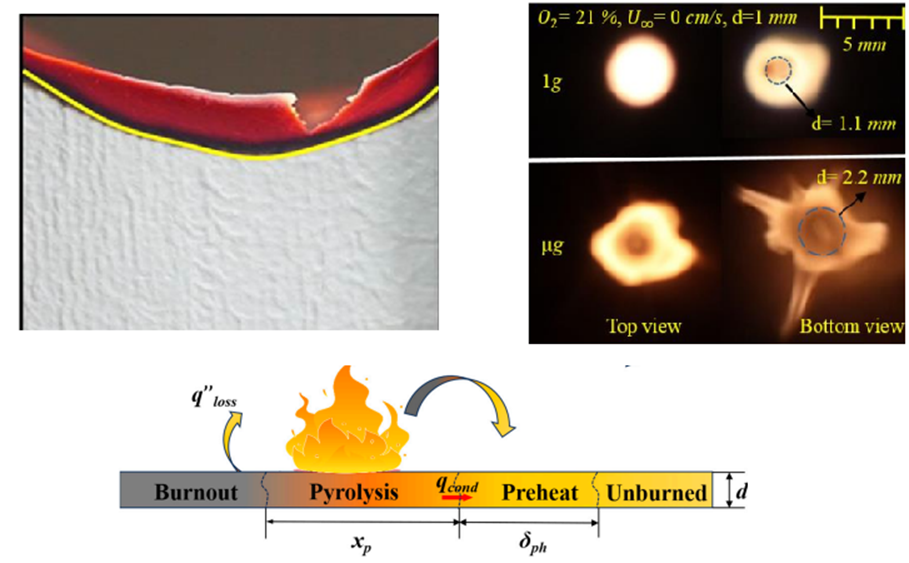

Here, the sample is lit at a location along its upper vertex. The spark propagates downward. The sample is recorded on video to observe its flame spread characteristics. Various materials were analyzed to determine the shape of the flame front. The samples all display a uniform 'U' shaped flame front morphology.

Fig 1: Flame spread behavior

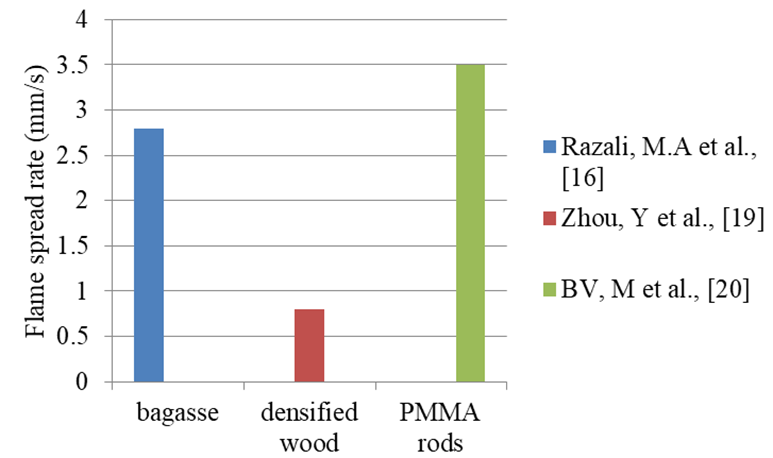

B. Flame Spread Rate

This can be determined via tracking the location of the leading edge of the front that was on fire at regular intervals. The flame propagation speed varies between each specimen in the samples.

In the fig 1 explains the flame spread behavior using existing materials on PMMA rods, bagasse and densified wood referred from ref no: [16], [19] and [20]. In those different directions, the flame is ignited. From this analysis, the material performance was predicted.

Fig 2: analysis of Flame spread rate

In the fig 2 explains flame spread rate using materials such as bagasse, densified wood and PMMA rods. In that different authors analyzed the flame spread rate according to their materials used. The flame spread rate changed depends on the materials.

Conclusion

In the conclusion part explains the analysis of flame spread behavior on various materials. In the above reviewed analysis, existing researches described about the existing analysis and the problems also discussed. The above problems can overcome by new natural based hybrid fiber is introduced to reduce the flame behavior. Also, flame spread behavior as well as flame spread rate were analyzed.

References

[1] Bai, M. and Liu, Q., 2023. Evaluating Urban fire risk based on entropy-cloud model method considering urban safety resilience. Fire, 6(2), p.62. [2] Garcia-Castillo, E., Paya-Zaforteza, I. and Hospitaler, A., 2023. Fire in heritage and historic buildings, A major challenge for the 21st century. Developments in the Built Environment, 13, p.100102. [3] Bu, R., Zhou, Y., Shi, L. and Fan, C., 2021. Experimental study on combustion and flame spread characteristics in horizontal arrays of discrete fuels. Combustion and Flame, 225, pp.136-146. [4] Manzello, S.L., Suzuki, S., Gollner, M.J. and Fernandez-Pello, A.C., 2020. Role of firebrand combustion in large outdoor fire spread. Progress in energy and combustion science, 76, p.100801. [5] Liu, C., Ding, L., Jangi, M., Ji, J., Yu, L. and Wan, H., 2020. Experimental study of the effect of ullage height on flame characteristics of pool fires. Combustion and Flame, 216, pp.245-255. [6] Viegas, D.X.F.C., Raposo, J.R.N., Ribeiro, C.F.M., Reis, L.C.D., Abouali, A. and Viegas, C.X.P., 2021. On the non-monotonic behaviour of fire spread. International journal of wildland fire, 30(9), pp.702-719. [7] Li, Y., Liao, Y.T.T., Ferkul, P.V., Johnston, M.C. and Bunnell, C., 2021. Experimental study of concurrent-flow flame spread over thin solids in confined space in microgravity. Combustion and Flame, 227, pp.39-51. [8] Di Cristina, G., Skowronski, N.S., Simeoni, A., Rangwala, A.S. and Im, S.K., 2021. Flame spread behavior characterization of discrete fuel array under a forced flow. Proceedings of the Combustion Institute, 38(3), pp.5109-5117. [9] Pongsa, U., Jamesang, O., Sangrayub, P., Lumsakul, P., Kaweegitbundit, P. and Mookam, N., 2021. Flammability of Short Agro-Waste Pineapple Leaf Fiber Reinforced Polypropylene Composite Modified with Diammonium Phosphate Flame Retardant and Titanium Dioxide. Fibers and Polymers, 22, pp.1743-1753. [10] Suoware, T.O., Edelugo, S.O., Amgbari, C.O. and Sorgbara, F.L., 2020. DETERMINATION OF THE SUITABILITY OF OIL PALM FIBRE COMPOSITE FOR BUILDING APPLICATIONS BY CONE CALORIMETER AND THERMAL ANALYSIS. Open Journal of Engineering Science (ISSN: 2734-2115), 1(2), pp.30-39. [11] Razali, M.A., Sapit, A., Mohammad, A.N., Salleh, H. and Madon, R.H., 2020. Effect of baggase physical properties and composition on flame spread behavior. International Journal of Integrated Engineering, 12(3), pp.271-277. [12] Wang, X., Wang, J., Wang, J. and Sheng, G., 2022. Experimental and numerical simulation analyses of flame spread behaviour over wood treated with flame retardant in ancient buildings of Fuling Mausoleum, China. Fire Technology, pp.1-25. [13] Korobeinichev, O.P., Trubachev, S.A., Joshi, A.K., Kumar, A., Paletsky, A.A., Tereshchenko, A.G., Shmakov, A.G., Glaznev, R.K., Raghavan, V. and Mebel, A.M., 2021. Experimental and numerical studies of downward flame spread over PMMA with and without addition of tri phenyl phosphate. Proceedings of the Combustion Institute, 38(3), pp.4867-4875. [14] Zhou, Y., Qiu, W., Zhou, P., Wang, Z., Zhang, X., Mao, X. and Bu, R., 2024. Influences of Species and Density on the Horizontal Flame Spread Behavior of Densified Wood. Buildings, 14(3), p.620. [15] BV, M. and Kumar, A., 2024. Flame spread over thin circular PMMA rods. arxiv preprint arxiv:2407.08378.

Copyright

Copyright © 2024 Dr. A.R. Sontake, Piyush Raj, Aditya Verma, Rehan Mansoori, Ayush , Prashant Saroj. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65923

Publish Date : 2024-12-14

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online