Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Review on Investigation of Petrol and Ethanol Blend as fuel on Performance of Spark Ignition Engine

Authors: Prasad Nimbalkar, Rahul Baisane, Onkar Mutekar, Darshan Chavan, Sachin Mutalikdesai

DOI Link: https://doi.org/10.22214/ijraset.2024.59763

Certificate: View Certificate

Abstract

Finding substitute fuels has been more popular in recent years as a response to escalating pollution levels and fuel shortages. The goal of this research is to find the ideal gasoline to ethanol ratio that will maximize engine performance and reduce emissions in spark ignition engines. In order to analyse the performance of different blending ratios, the research looks at metrics such carbon monoxide (CO) emissions, brake power (BP), brake specific fuel consumption (BSFC), and brake thermal efficiency (BTE). Blends of gasoline and ethanol with a 15% ethanol content greatly increase engine thermal efficiency at higher engine speeds. E12 mixes of gasoline and ethanol boost engine braking power while lowering CO emissions and break-specific fuel usage. Blends of gasoline with ten to fifteen percent ethanol present a possible substitute.

Introduction

I. INTRODUCTION

Transportation has become an absolute necessity in the twenty-first century, and meeting this demand necessitates the availability of appropriate transportation fuel. Until now, there has been an excessive usage of petrol or diesel for transportation, resulting in the world's current energy crisis. Furthermore, the use of fossil fuels in SI engines has significantly increased atmospheric pollution. The major pollutants released as vehicle/fuel emissions are carbon monoxide (CO), nitrogen oxides (NOx), photochemical oxidants, air toxics, namely benzene (C6H6), aldehydes, 1, 3 butadiene (C4H6), lead (Pb), particulate matter (PM), hydrocarbon (HC), sulphur oxides (SO2), and polycyclic aromatic hydrocarbons (PAHs). So, to reduce pollution, energy crises, and also to avoid the use of fossil fuels, the hunt for alternative.

Hamza Afser Delvi. [1] The study aims to investigate the performance, combustion, and emission characteristics of E25, E30, and E35 ethanol-gasoline blends on a single-cylinder, four-stroke spark ignition engine. Using an eddy current dynamometer and exhaust gas analyser, tests were conducted under various load, engine speed, and compression ratio conditions. Results showed improved engine performance, with E25 consuming less fuel than other blends at maximum speed (BSFC of 0.32 kg/kW-hr) and increased thermal break efficiency compared to gasoline (maximum BTE of 27.87% for E35 blend). Mrs. Rana Ali Hussein [2] The study investigates the impact of ethanol (E10 to E30) and methanol (M10 to M30) additives to gasoline on a one-cylinder, four-stroke, 11 kW IC engine's combustion characteristics and performance. Tests covered brake torque, power, thermal efficiency, fuel consumption, and flue gas analysis (CO, HC, CO2) at engine speeds from 1,500 to 3,000 RPM. Results favoured E10, showing improved thermal performance and reduced HC and CO with higher ethanol content, while methanol-gasoline blends performed less favourably than ethanol-gasoline blends. Mortadha K. Mohammed [4] The study found that increasing ethanol concentration improved power, brake specific fuel consumption, and thermal efficiency but reduced volumetric efficiency. Ethanol also reduced harmful exhaust gases, with higher ethanol content leading to fewer emissions. Additionally, ethanol blends had higher research octane number and motor octane number, despite a lower heating value compared to pure gasoline, enhancing overall engine performance. Abdul Manan Khan [6] an experimental investigation was conducted on a spark-ignited single-cylinder engine using various ethanol-gasoline blends (E-0 to E-14). A CAD model was used to prepare a test bench, and an experimental setup with additional devices was created. Analysis of gasoline outcomes identified optimal operating conditions. Cost-economic analysis showed that the running cost of E10 ethanol-gasoline blend is lower than high-octane gasoline. Kamble A. G [7] an experiment evaluated ethanol-petrol blends (E5, E8, E10, and E12) on a spark-ignited engine, recording performance variables. Two decision-making methods ranked the blends, with E10 ranked highest, followed by E5, and E8 and E12 ranked lower. O. C. Nwufo [8] A study on a spark ignition engine using ethanol-petrol blends, including ethanol from raffia trunks, showed improved combustion, reduced emissions, and enhanced engine performance.

Ethanol blends were deemed suitable alternatives for spark ignition engines. Balappa Hadagali [9] Experimental investigations explored the feasibility of ethanol-petrol blends in a single cylinder diesel engine converted to spark ignition mode. Results showed lower CO, HC, and NOx emissions with ethanol blends. E75 blend exhibited improved engine performance with increased brake thermal efficiency and reduced emissions.

Venktesh Kumar [10] A feasibility study assessed the impact of unleaded fuel blends on engine performance using a four-stroke, single-cylinder, water-cooled multi-fuel engine with carburetor fuel injection. Six ethanol blends were tested, with E20 showing the best results in terms of brake power, torque, thermal efficiencies, and fuel consumption. Ahmed Abdelrazik Elshenawy [11] Researchers are exploring gasoline and ethanol blends in spark ignition engines to reduce fuel consumption and emissions. Using a MATLAB model, they found that ethanol blending up to 20% (E20) improved thermal efficiency by 3% and reduced specific fuel consumption by 7.2% compared to gasoline. Output power increased with ethanol blends, and emissions decreased significantly, demonstrating the potential of ethanol blending to enhance gasoline engine performance and reduce emissions. Sahil [12] The study investigates ethanol blends with gasoline as an alternative fuel in a spark ignition engine, focusing on engine performance improvement and exhaust emissions reduction. Parameters such as BHP, total fuel consumption, brake thermal efficiency, air-fuel ratio, volumetric efficiency, heat balance, and emissions are analyzed for E10, E20, and gasoline blends at loads of 2kg, 5kg, and 10kg.

Hyder H. Balla [13] A study on a one-cylinder, four-stroke spark ignition engine showed that increasing ethanol concentration improved power, efficiency, and reduced harmful exhaust gases, except for carbon monoxide where 30% ethanol was optimal. Ethanol blends had higher octane numbers despite a higher lower heating value for pure gasoline. Paolo Iodice [14] Ethanol can be used as an alternative fuel in spark-ignition engines to increase octane number and oxygen content in blends, reducing fossil fuel dependence and emissions. The study reviews ethanol's impact on combustion efficiency, exhaust emissions, and NOx formation in SI engines, considering ethanol production, physicochemical properties, and engine parameters. Nazrul Atan [15] The review paper focuses on ethanol-petrol blends in gasoline engines to reduce CO2 emissions and improve performance. It includes an investigation of different ethanol types (sugar cane, wheat, corn) and blending ratios, aiming to provide insights into engine efficiency and emissions reduction.

II. EXPERIMENTAL SETUP AND PROCEDURES

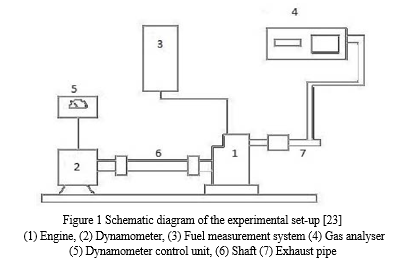

The experimental setup consisted of a single-cylinder SI engine, an electric dynamometer, a fuel measurement system, a gas analyser, combustion analysis equipment, a dynamometer control unit, a shaft, and an exhaust pipe. The tests were carried out at various engine speeds, ranging from 500 to 7500 RPM based on their requirements.

Test Method: Four stroke four cylinder carburettor type spark ignition engine is coupled to dynamometer. With the help of connection and mounted to a rigid frame with provision to monitor speed, fuel evaluation tube, and a gas analyser that can measure five gases viz. CO, CO2, NOx, HC, and O2 (NETEL) for measuring the tail pipe emissions.

The engine may warm up for the period of 20 to 30 minutes, prior to actual testing. Before starting the engine with a new fuel blend, it was allowed to run long enough to consume the residual fuel from the previous experiment. All mixtures were tested at steady speeds. The engine load was calculated using the dynamometer control. Engine speed, fuel consumption, load, and emissions were measured. After the engine reached a stable functioning condition (stationary state), an exhaust gas analyser was used to record emission parameters such as CO, CO2, HC, and NOx.

III. RESULT AND DISCUSSION

The study examines engine speed's impact on Brake specific fuel consumption. From figure 2 The BSFC increases with higher ethanol percentage in the gasoline blend due to increased power production at higher speeds. However, BSFC decreases as engine speed increases for all blends, with the E25 blend showing the most reduction at 1800 rpm. On the other hand, BTE increases with engine speed for all blends, reaching a maximum at 1800 rpm, with the E35 blend showing the highest BTE at 27.87%.

BSFC decreases with higher ethanol proportions in ethanol-gasoline blends, showing significant differences compared to pure gasoline. Similarly, BSFC increases with higher methanol ratios in methanol-gasoline blends. Engine speed has an impact, with BSFC generally decreasing as speed increases, possibly due to improved thermal efficiency.

The study's findings highlight the intricate relationship between engine speed, ethanol percentage in gasoline blends, and brake specific fuel consumption (BSFC). The observed increase in BSFC with higher ethanol percentages in gasoline blends is attributed to the enhanced power production at higher engine speeds. However, a notable trend emerges as engine speed increases, leading to a reduction in BSFC across all blends, with the E25 blend demonstrating the most significant decrease at 1800 rpm. Conversely, brake thermal efficiency (BTE) shows an opposite trend with engine speed, increasing as speed rises for all blends and peaking at 1800 rpm. The E35 blend stands out with the highest BTE at 27.87%, indicating its efficiency under these conditions.

These findings underscore the impact of ethanol proportions in gasoline blends on engine performance parameters. The study also suggests that higher ethanol proportions contribute to lower BSFC, especially when compared to pure gasoline. Additionally, the influence of engine speed on BSFC highlights the role of improved thermal efficiency at higher speeds, further emphasizing the complexity of optimizing fuel blends for enhanced engine performance.

Figure 3 indicates that adding methanol to gasoline boosts brake thermal efficiency (BTE), Brake thermal efficiency (BTE) measures how efficiently an engine converts input energy into output power. Figure 3(a) shows that as engine speed increases, BTE also increases for all blends, peaking at 1800 rpm. The highest BTE recorded was 27.87% for the E35 blend. Compared to gasoline, BTE at 1800 rpm improved by 2.32%, 10.93%, and 19.92% for E25, E30, and E35 blends, respectively. Demonstrate how brake thermal efficiency (BTE) changes with different fuel blends and engine speeds. BTE increases with ethanol blends compared to pure gasoline, especially at higher speeds. On the other hand, methanol blends show a decrease in BTE compared to gasoline due to reduced latent heat in the fuel mixture with higher ethanol percentages. Therefore, E10 has better BTE than E20 and E30 blends.

The analysis of Figure 3 reveals crucial insights into the impact of fuel blends and engine speed on brake thermal efficiency (BTE). The data indicates that adding methanol to gasoline can indeed enhance BTE, which measures how effectively an engine converts input energy into output power. Specifically, as engine speed increases, BTE also increases across all blends, reaching its peak at 1800 rpm. The highest BTE recorded in the study was 27.87% for the E35 blend. Comparing these blends to pure gasoline, significant improvements in BTE were observed, with E25, E30, and E35 blends showing enhancements of 2.32%, 10.93%, and 19.92%, respectively, at 1800 rpm.Ethanol blends demonstrated higher BTE compared to pure gasoline, especially at higher engine speeds. This improvement can be attributed to the characteristics of ethanol, such as its higher octane rating and oxygen content, leading to more efficient combustion. In contrast, methanol blends exhibited a decrease in BTE compared to gasoline, primarily due to the reduced latent heat in the fuel mixture as ethanol percentages increased. This finding highlights the importance of the specific ethanol blend ratio, with E10 showing better BTE than E20 and E30 blends, emphasizing the need for careful consideration when blending fuels for optimal engine performance.

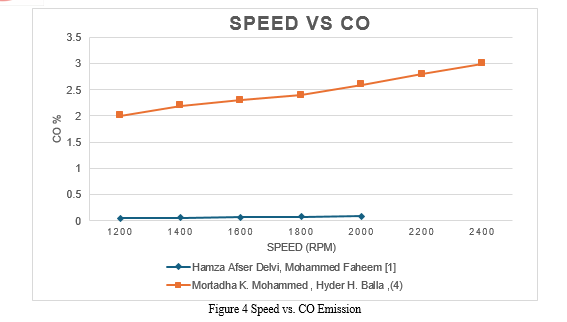

Figure 4 indicates that adding methanol to gasoline. The CO emission decreases as the ethanol percentage in the fuel blend increases, indicating more complete combustion. At 1800 rpm, CO concentrations were reduced by 11.11%, 25.92%, and 40.74% using E25, E30, and E35 blends compared to gasoline, respectively. This reduction is due to ethanol's lower carbon content compared to gasoline. At a compression ratio (C.R) of 9:1, CO concentration increases, but it decreases at a C.R of 10:1 with increasing ethanol percentage in gasoline. At a C.R of 10:1, CO concentrations using E25, E30, and E35 were reduced by 8.82%, 16.66%, and 28.43%, respectively, compared to gasoline.

The analysis from Figure 4 highlights the impact of adding methanol to gasoline on CO emissions in the fuel blend. As the ethanol percentage increases, there is a notable decrease in CO emissions, indicating more efficient and complete combustion. This reduction in CO concentrations is significant, with reductions of 11.11%, 25.92%, and 40.74% observed at 1800 rpm using E25, E30, and E35 blends, respectively, compared to gasoline. The lower carbon content in ethanol plays a key role in this reduction, as ethanol burns cleaner than gasoline.

Additionally, the effect of compression ratio (C.R) on CO emissions is evident. At a C.R of 9:1, CO concentration increases, likely due to the higher pressure leading to incomplete combustion. However, at a C.R of 10:1, CO concentrations decrease with the increase in ethanol percentage in gasoline. Specifically, using E25, E30, and E35 blends at a C.R of 10:1 resulted in reductions of 8.82%, 16.66%, and 28.43% in CO emissions, respectively, compared to gasoline.

Overall, these findings demonstrate that blending methanol with gasoline can lead to reduced CO emissions, especially at higher ethanol percentages and specific compression ratios. This indicates the potential for cleaner and more efficient combustion in engines using ethanol-gasoline blends.

Conclusion

Here are the summarized conclusions from the analysis: 1) Ethanol-gasoline blends improve engine performance without engine modifications. 2) Brake specific fuel consumption decreases with engine speed but is higher for Gasohol blends compared to gasoline, with E30 consuming the most fuel at maximum speed and E25 the least. 3) Brake thermal efficiency increases with ethanol proportion, with E35 offering the highest efficiency at 1800 rpm. E25 has lower efficiency at maximum speed but all blends show improvement over gasoline. 4) CO and HC emissions decrease significantly with ethanol addition, while CO2 emissions increase due to improved combustion efficiency. 5) Ethanol-gasoline blends reduce flue gas emissions (CO, CO2, HC, NOx), with E10 recommended for future use to enhance engine performance and reduce emissions.

References

[1] Hamza Afser Delvi1 , Mohammed Faheem, Sher Afghan Khan, Kiran Kumar , Mohammed Kareemullah,Effect of Ethanol-Gasoline Blends on Performance, Combustion and Emission Characteristics of Spark Ignition Engine, ISSN: 2289-7879 [2] Mrs. Rana Ali Hussein , Mr. Atheer Saleh Hassoon , Dr. Audai Hussein Al-Abbas, [3] Experimental Study into Combustion Characteristics of IC Engines Operated with Blended Fuels, IOP Conf. Series: Materials Science and Engineering 433 (2018) 012053 doi:10.1088/1757-899X/433/1/012053 [4] Puli Danaiah, P. Ravi Kumar, D. Vinay Kumar, Effect of Methanol Gasoline Blended Fuels on the Performance and Emissions of SI Engine, International Journal of Ambient Energy, 34 (4), 2013, pp.175-180. [5] Hyder H. Balla , Zaid Maan H. Al-Dulaimi , Zaid S. Kareem , Mudhaffar S. Al-Zuhairy d, Effect of ethanol-gasoline blends on SI engine performance and emissions, Case Studies in Thermal Engineering 25 (2021) 100891 [6] k. srinivasa rao1 , p. gopinadh chowdary2 , g. jamuna rani3 & g. srivalli, t ,performance and emission characteristics of a turbocharged si engine using petrol-ethanol fuel (ijmperd) issn(p): 2249-6890; issn(e): 2249-8001 vol. 9, issue 3, jun 2019, 463-470 [7] Abdul Manan Khan , Ghulam Hassan Askari , and Dr. Zaheer Ahmed, The Performance and Cost Analysis on Bio Fuel Blends for Internal Combustion Engine, MATEC Web of Conferences 381, 01012 (2023) [8] Kamble A. G., BhosaleV. A., Naranje V. G., Selection of blends of ethanol with petrol for SI engine using TOPSIS and VIKOR methods, 2178 (2022) 012037 [9] O. C. Nwufo, C. F. Nwaiwu, C. Ononogbo, J. O. Igbokwe, O. M. I. Nwafor & E. E. Anyanwu ,Performance emission and combustion characteristics of a single cylinder spark ignition engine using ethanol–petrol-blended fuels, DOI: 10.1080/01430750.2017.1354318 [10] Balappa Hadagali, N.R. Banapurmath, Kirankumar B., V.S. Yaliwal, Performance of Petrol-Ethanol Blended Spark Ignition Engines, ISSN: 2277-3878 [11] Blends Venktesh Kumar, Assistant Professor, Performance Analysis of Gasoline Engine with Different Ethanol, Gopal Narayan Singh University, Jamuhar, Sasaram, Bihar, India [12] Ahmed Abdelrazik Elshenawy , Sayed M Abdel Razik and M S Gad, Modeling of combustion and emissions behavior on the effect of ethanol–gasoline blends in a four stroke SI engine ,Advances in Mechanical Engineering 2023, Vol. 15(3) 1–16 [13] Sahil (M.tech Scholar, D.A.V.I.E.T, Jalandhar) Mr. Gurveen Singh (Assistant professor at D.A.V.I.E.T, Jalandhar) & Mr.PankajSadana (Assistant professor at D.A.V.I.E.T, Jalandhar, Investigation of Ethanol blends in S.I Engine,ISSN: 2320-2882 [14] Hyder H. Balla, Mortadha.K. Mohammed, Zaid Maan H. Al-Dulaimi, Al-Zuhairy Mudhaffar S., Zaid S. Kareem, Mohammed Saad Abbas, EFFECT OF ETHANOL-GASOLINE BLENDS ON SI ENGINE PERFORMANCE AND EMISSIONS, 100891. [15] Paolo Iodice, Amedeo Amoresano, Giuseppe Langella,A review on the effects of ethanol/gasoline fuel blends on NOX emissions in spark-ignition engines, 1465-1480 [16] Nazrul Atan, Azizul Mokhtar, Najib Rahman , Amir Khalid, Experimental Investigation on Ethanol-Petrol Blends Operating with a Petrol Engine: An Overview, Vols 773-774 (2015) pp 465-469 [17] I.Vimalkannan, A.Pradeep,K.S.Babulal,P.Muthukumar, Performance and Emission Characteristics of a Four Stroke Petrol Engine Using Ethanol and Petrol Fuel Blends, ISSN 0973-4562 Vol. 10 No.56 (2015) [18] Dr. N. S. Poonawala b , Dr. Mahesh P. Nagarkar, [19] AN OVERVIEW ON ETHANOL USE IN IC ENGINE AS ALTERNATIVE FUEL Mr. Ravindra Deshpande a ISSN NO: 2347-3150 [20] Praveen Srivastava, Prakhar Chansauria, Abhishek Kumar Jain, EFFECTS OF GASOLINE ETHANOL BLENDS ON PERFORMANCE OF SI ENGINE: A TECHNICAL REVIEW, IJARIIT (ISSN: 2454-132X) [21] Thang Nguyen Minh1,2, Hieu Pham Minh2, Vinh Nguyen Duy3, A review of internal combustion engines powered by renewable energy based on ethanol fuel and HCCI technology ,DOI: 10.3934 [22] Mortadha K. Mohammed a,**, Hyder H. Balla a,b,* , Zaid Maan H. Al-Dulaimi b , Zaid S. Kareem c , Mudhaffar S. Al-Zuhairy d, Effect of ethanol-gasoline blends on SI engine performance and emissions, 100891

Copyright

Copyright © 2024 Prasad Nimbalkar, Rahul Baisane, Onkar Mutekar, Darshan Chavan, Sachin Mutalikdesai. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59763

Publish Date : 2024-04-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online