Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Review on the Performance of Natural Fiber Reinforced Polyester and Epoxy Matrices

Authors: Sravanthee S, A. Prabhu Kumar

DOI Link: https://doi.org/10.22214/ijraset.2024.63448

Certificate: View Certificate

Abstract

Natural fiber reinforced polymer matrix composites have gained significant attention in recent years due to their eco-friendly nature and potential applications in various industries. Hand layup is a widely employed manufacturing method for these composites, offering flexibility and cost-effectiveness in producing complex shapes and structures. This review explores the characteristics of natural fibers, the properties of the resulting composites, and the process of hand layup. The integration of natural fibers with polymer matrices through hand layup is discussed in terms of mechanical performance, environmental impact, and economic feasibility. Challenges and future prospects in the field are also highlighted to guide further research and development efforts.

Introduction

I. INTRODUCTION

Natural fiber reinforced polymer matrix composites have emerged as promising alternatives to traditional synthetic fiber composites due to their inherent sustainability, low cost, and satisfactory mechanical properties. The use of natural fibers such as jute, hemp, flax, and bamboo offers several advantages including biodegradability, renewability, and carbon neutrality compared to synthetic fibers like glass or carbon. These fibers, when combined with polymer matrices such as epoxy or polyester, create composite materials that find applications in automotive, construction, aerospace, and consumer goods industries.

Among various manufacturing methods for these composites, hand layup remains a preferred choice for small-scale production and prototyping. Hand layup involves manually placing fiber layers within a mold and saturating them with a resin matrix, followed by curing to achieve the final composite structure. This method allows for flexibility in design, ease of handling complex shapes, and reduced initial investment in equipment, making it suitable for initial explorations and custom fabrications.

This paper reviews the current state of natural fiber reinforced polymer composites produced via hand layup, focusing on the mechanical, thermal, and environmental properties of these materials. It discusses the influence of fiber orientation, resin selection, and processing parameters on the final composite performance. Furthermore, challenges such as fiber-matrix adhesion, moisture absorption, and recycling issues are addressed to provide a comprehensive understanding of the practical implications of using these composites in industrial applications.

II. NATURAL FIBERS

Natural fibres are gaining a lot of priority over synthetic fibres due to many of their remarkable advantages like low cost, less processing requirements, biodegradability, high stiffness, high strength, lightweight, abundant availability and many more. They are likely to replace the synthetic fibres in the coming time.

Here are a few significant characteristics of natural fibres.

- They are eco-friendly as they require less energy and emit less CO2 ,during their production.

- They are highly resistant to electricity

- They have good thermal and insulating properties

- They do not cause irritation and allergic reactions when contacted with bare skin

- They are a renewable resource

- They are biodegradable and when burnt, they do not emit poisonous gases

- They are cheap and abundant

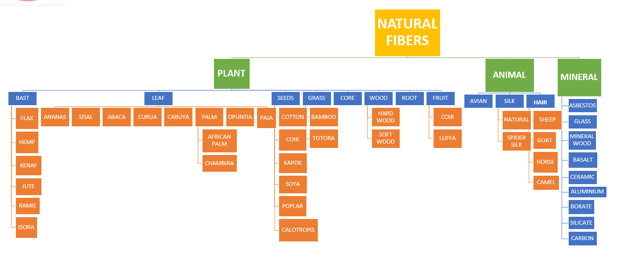

Natural fibers may be broadly classified as under:

However, they suffer from certain pitfalls like

- They have low strength and stiffness

- They absorb water and shape out easily

- They are not durable

- They are less compatible with other materials

- They undergo wrinkling and need heat in the form of ironing or steaming, to regain their shape

- They undergo shrinkage due to heat or moisture

- They undergo pilling, which means the formation of small balls on the surface due to repeated washing, especially in case of textiles.

- Although cheap, they require a lot of laborious effort to grow and harvest.

III. PERFORMANCE OF DIFFERENT NATURAL FIBERS WHEN USED IN COMPOSITES

- Animal Fiber: Chicken feather fibers are treated with certain metal oxides and are mixed i.e. reinforced with polyester resins by hand lay-up process. Compounds like ZnO3, CaCO3, and Al2O3 were added to the matrix. It helps in the enhancement of mechanical properties of the composites[1]. Mohair is the animal fiber. Different laminates of similar and hybrid layers by hand lay-up process in a closed mold at a constant fiber weight fraction (number of layers), mold pressure, curing time and temperature. The highest impact strength and the hybrid laminates of the mat and woven fabrics offer satisfactory strength[5]. Another study uses different mohair fibre textiles and were tested to see which one provides the best characteristics. The three most commonly used locally-made mohair fabrics (woven, knitted and pressed mat) were selected as reinforcement in polyester resin. Nine different laminates of similar and hybrid layers were made by hand lay-up in a closed mold at a constant fibre weight fraction, mold pressure, curing time and temperature. The results showed that the composite laminate of mat fabric reinforced polyester provides the maximum tensile strength, elongation, flexural strength and thermal insulation[64]. Another study considers EpoxyResin matrix reinforced with Emubird feather,Kusha grass,Copper wire for fiberlengths rangingfrom10to50 mm,andfiberweight percentagesvarying from1to5%. The study analyzes the flexural characteristics of epoxy composites fabricated with different natural fibers. Flexural strength variations were observed with changes in fiber length and weight percentage. Emu feather composites showed a decrease in flexural strength with increased fiber length and loading, while kusha grass and copper fiber composites exhibited increased flexural strength with the same parameters [101].

- Natural Fiber: Acacia tortilis fibers were extracted using manual extraction methods and alkali treated at 10 wt% and 20 wt%. Tensile, flexural strength, Young’s modulus, Extension were observed for different combinations[9]. Rattan fibre and unsaturated polyester resin are combined by GP-7150 using hand layup technique. Mechanical properties including tensile, flexural, density and hardness were studied[11].

- Vegetable Fiber: Optimizing the delamination failure in bamboo fiber reinforced polyester composite. a partially ecological composite was made, using natural fibers as reinforcement (bamboo fiber), in the polyester resin matrix to form a composite, seeking to improve the mechanical behavior among its class of material. Speed, feed and drill diameter using gray relational grade are studied[23].

- Bamboo Fiber: Bamboo fiber is treated with NaOH (5%/2 h). The chemical characterization of the fibers was obtained followed by the morphological characterization using Scanning Electron Microscopy (SEM) Composites with 30 mm long treated fibers and 30% kaolin showed better flexural strength. The addition of kaolin waste provided a significant improvement in tensile strength[2].

- Kenaf Fiber: Mechanical and morphological properties of woven kenaf/polyester fiber reinforced polylactic acid. Tensile stress, modulus, shear stress modulus, elongation were studied[12]. Another study explored methods to enhance the compatibility between kenaf fiber (KF) and polymer matrices by treating KF with zinc oxide nanoparticles (ZnONPs). The composite samples incorporating ZnONPs exhibited improved hydrophobicity and mechanical properties compared to untreated KF composites, with the optimal content of ZnONPs determined to be 2 wt%. Surface morphology changes and the presence of ZnONPs functional groups were observed in the treated composites[83].

- Flax Fiber: Flax fiber-polyester composite goes under hand lay-up process. Results for longitudinal modulus, transverse modulus, shear modulus, tensile strength, compressive strength, shear strength were observed[6]. Another study involved numerical and experimental analysis of a large-scale footbridge model made of flax fiber-reinforced polyester composite. The study involved modeling a multi-layered laminate using ABAQUS with embedded fiber-optic Bragg grating (FBG) sensors for strain sensing and mechanical evaluation. The results from numerical analysis were compared with load test results[75]. Another study involved epoxy matrix reinforced with jute/banana/flax in combination with uniaxial glass fibers and further testing of the samples revealed that flax combined with glass fibers demonstrated higher strength compared to those of jute and banana combined with glass fibers[101].

- Palmyra Palm Fiber: Forlong Palmyra Palm/ Borassus Flabellifer Petiole Fibre Reinforced Polyester Composites, tensile strength, tensile modulus flexural strength, flexural modulus, impact strength were observed and a significant improvement was found[15]. Another study developed a nanocomposite polymer using palm leaf stalk fiber treated with potassium permanganate (KMnO4). Mechanical tests were performed on the composites, showing superior values compared to similar natural fibers. Structural electron microscopy observations revealed the presence of matrix, reinforcement, and absence of voids due to nano powder addition[76].

- Carbon Fiber: Pultruded carbon fibre reinforced polymer strips are produced with a novel bio-based thermoset polyester for structural strengthening and tensile strength, hardness, modulus of elasticity, and strain at failure were observed[19].

- Bagasse Fiber: Effect of fiber loading on the mechanical and physical properties of “green” bagassepolyester composite were studied and flexural strength, failure at strain, young’s modulus, water absorption, chemical resistance were found[24]. Another study involving epoxy matrix reinforced with combination of old glass fiber and bagasse fiber; and epoxy matrix reinforced with combination of old glass fiber and banana fiber, composites of bagasse fiber yielded 70% more tensile strength than those of banana fiber, whereas both types of composites performed equally well in hardness and compression tests[102].

- Eucalyptus Fiber: Investigations and uses of composites reinforced with natural fibers have been growing over the last decades. These composites offer economical, technical, societal and environmental advantages. As a consequence, they became promising alternatives to replace synthetic fibers from non-renewable sources. In this way, the study of the properties of these natural composites is of utmost importance to enable its use. Comparison of tensile mechanical behavior of polymeric composites reinforced with natural eucalyptus fibers is done[43].

Comparison between tensile behavior of epoxy and polyester matrix composites reinforced with eucalyptus fibers was made and tensile strength and elastic modulus of epoxy at 30% volume, and polyester at 30% volume were observed[25]. Another study evaluated polymeric composites reinforced with eucalyptus fibers, finding minor effects on tensile properties in both epoxy and polyester matrices[87].

11. Purun Fiber: study was done on the feasibility of using Polyester (PE) waste particles from metal coating industry as a secondary raw material in concrete. Flexural, compressive strengths, Flow values of Cement paste for 56 days are observed[26]. Another work studies the properties of polyester composites reinforced with purun fiber filler at different concentrations (5%, 10%, and 15%). Purun fiber showed promise as a filler material, offering a balance of mechanical and thermal properties[78].

12. Sisal fiber: Comparative Study of Impact Strength Characteristics of Treated and Untreated Sisal Polyester Composites. Impact strengths of 3mm thickness of Treated specimen and 3mm thickness of Untreated specimen were observed[29].

Another study provided a dataset illustrating the mechanical properties of sisal, sorghum bicolor, and coconut coir reinforced polyester composites. The addition of sisal and coconut coir fiber was found to enhance the properties of the composites[81].

13. Sugar Palm Fiber and Glass Fiber Hybrid Composites: The effects of alkaline treatment and hybridization on the thermal properties of sugar palm yarn/glass fiber were investigated. The sugar palm fiber was treated with 1% of sodium hydroxide (NaOH) solution for 1 h and the ratio of matrix to reinforcement was varied. The thermal properties of the hybrid composites were analyzed using a dynamic mechanical works[44].

14. Pineapple Leaf Fibers: Lignocellulosic fibers (LCFs) obtained from plants are replacing glass fiber as reinforcement of polymer composites in engineering applications, including automobile parts. Among the promising LCFs, those from the pineapple leaf fibers (PALF) have a potential for composite reinforcement[46].

15. Indian Mallow Fiber: Randomly oriented Indian mallow fiber/polyester (IMFP) composites which are fabricated by compression moulding method by varying the fiber wt.% from 10 to 50% are taken. The prepared IMFP specimens were evaluated through various mechanical and thermal properties[49].

16. Coir and Hemp Fibers: The findings from the tensile, flexural, and impact tests revealed an enhancement in the mechanical characteristics of the fabricated composites as the proportion of coir fiber grew and the proportion of hemp fiber reduced. The hybrid composite, containing 15% coir and 5% hemp fibers, had superior mechanical properties to the binary composite system[61].

Another study considers natural resin as matrix and banana, coir were the fibers and composites were prepared using the hand layup method. Mechanical and physical properties were evaluated according to ASTM standards. The aim of the project was to manufacture and analyze the mechanical properties of a composite reinforced with natural fibers (banana, coir) and a natural resin matrix.

The study found that banana fiber is a suitable reinforcing material for composite materials due to its strong mechanical qualities, including high tensile strength, high elastic modulus, and good toughness. The stacking of fibers influenced the mechanical and physical properties of the composite. Coir fibers were also investigated for their potential use in composite materials due to their abundance, renewability, and biodegradability[95].

17. Discarded Chicken Feathers: Investigation of ways to utilize discarded chicken feathers, which are a byproduct of poultry farms, to create sustainable composite materials and such composites combine chicken feather fibers (CFF) with unsaturated polyester resin (UPR) were successful in reducing environmental pollution [62].

18. Coconut Fiber: Panels were produced using rectangular molds, and the effects of various fiber sizes, especially 2, 4, and 6 mm, were compared without fiber and continuous fiber polymer composites and investigation on the impact of varying fiber lengths on the flexural strength of coconut fiber composites with epoxy resin, revealed that the flexural strength of Natural Fiber-reinforced Polymer Composites (NFPC) varied with fiber length[72].

19. Jute Fiber: Fiber reinforced composites with jute fibers of length 5-6 mm using polyester and epoxy resins were prepared. The composites were synthesized at 18:82 fiber-resin weight percentages and tested for mechanical properties such as tensile strength, flexural strength, impact strength, and hardness. The results indicated that the jute reinforced epoxy composite exhibited better mechanical properties compared to the jute-polyester composite [73].

In another study, Cement, sand, and bricks waste were used as matrix and reinforced with Jute fibers M20 grade concrete was mixed with various volumetric percentages of 10mm long jute fibers (0.05%,0.10%,0.25%,0.50%, and 1.00%). They were tested for compressive and split tensile strength after 7 and 28days of curing. And found that the compressive strength increasedby39%[91]. Another study, in which Poly lactic acid (PLA) was the matrix material and Jute was used as fiber, performed a comprehensive exploration of jute fibre reinforced PLA matrix composite focusing on their load carrying capacity and strength through finite element analysis. The composite utilizing short jute fibres exhibited superior strength compared to the long fibre-PLA composite.

Short fibres exhibit better toughening and strengthening qualities than longer fibres due to their good adhesive surface to the matrix [93]. Another study considered Lignin-based resin (E- PCL) as the matrix which was reinforced with Mercerized jute. Composites were manufactured with the help of compression moulding. Flexural properties of jute fiber-reinforced biopolymer composite were achieved using a lignin-based resin and mercernibation approach. The study aimed to find the flexural strength and modulus of jute fiber reinforced polymer composites. Mercerized jute/E-PCL composite showed improved flexural strength (377%) and flexural modulus (72.9%) compared to neat jute/E- PCL composite. The mercerized composite exhibited excellent fiber- matrix bonding with no voids and improved thermal stability and hydrophobicity [94]. One more study involved epoxy matrix which was reinforced with chopped glass fibers and jute fibers and proved that addition of glass fibers yielded improved strength [103].

20. Banana fiber: Resin with natural fibers- jute, pineapple, and banana composites were prepared with three different thicknesses (5mm,10mm, and15mm) using the hand layup method. Temperature differences on the surfaces and surroundings of the composites (JPAB, PAJB, BPAJ) were recorded at one-minute intervals. The BPAJ composite, consisting of 50%banana,25% pineapple, and25%jute, exhibited high thermal resistance and temperature differences.

The study concluded that the percentage variation of fibers affected the heat transfer properties of the insulation. The BPAJ composite showed promising results in terms of thermal resistance and temperature differences [96]. Another study includes fabrication of banana fibre mats through pulping, drying, and hot pressing. Composite sheets were reinforced with 50% pineapple, taro,or water hyacinth fibres. Mechanical properties (tensile,yield strength, elongation, bursting strength), hydrophilicity (contact angle, water absorption), biodegradability(soil burialtest),seedling growth promotion were studied and Banana-taro composites exhibited suitable tensile strength[97].

Epo?y matrix was reinforced with banyan and banana fibers and the manufacturing process involved extraction, treatment, and preparation of natural fibers, followed by their incorporation into composites using techniques like hand lay-up and resin transfer molding. The characteristics evaluated include mechanical properties such as tensile strength, bending strength, impact strength, and fracture toughness of the composite materials. Banana fibers, exhibit enhanced(better) mechanical properties compared to traditional composites[98].

Epoxy Resin(LY556) &Hardener(HY951) and banana fiber (continuous)and Glass Fiber (Chopped strands mat of 450GSM) were considered for the study. Banana fiber was treated with sodium hydroxide (NaOH) to produce treated hybrid composites. Samples with treated and untreated banana fiber alongside pure epoxy resin and glass fiber were prepared with different fiber weight volume percentages. The study investigated the mechanical properties of banana- glass fiber reinforced epoxy hybrid composites. Treated banana fiber exhibits better tensile, flexural, and impact properties compared to untreated fiber[100].

21. Peach Palm Fibers: Studies on bi-dimensional orientation of peach palm fibers, revealed that the oriented fibers offer superior mechanical properties compared to randomly oriented ones[85][90].

22. Sugar Palm/Glass Fiber Hybrids: Analysis of thermal properties of sugar palm (SP)/thermoplastic polyurethane (TPU) hybrid composites with glass fiber (GF) was performed and changes in thermal behavior based on fiber weight fractions were observed[88].

23. Bio-Based Resin in CFRP: High-performance CFRP composite strips using a bio-based unsaturated polyester (UP) resin were developed, offering excellent mechanical properties for structural strengthening[89].

24. Agave fiber: A polymer matrix like polyester, epoxy etc., was considered and Natural fibres(specifically agave fiber) were used as reinforcing material. The composite material is fabricated with various fibre orientations such as 0°,45°,and90°. The material characteristics including tensile, flexural, and impact strength are calculated. And found that high specific strength, high resistance to corrosion, high stiffness and strength were obtained [92].

25. Vakka fibers: Unsaturated polyester resin of grade ECMALON4411 reinforced with Vakka, sisal, bamboo, banana fibers were considered. Unidirectional composites were prepared using handlay- up method. Fibers were extracted through retting and mechanical procedures. The study investigated the tensile, flexural, and dielectric properties of the composites. Vakka fibers, being lightweight, renewable, and underutilized, are investigated alongside established fibers for their potential in lightweight structural applications. Vakka fiber composites demonstrated superior tensile strength and modulus compared to sisal and banana composites, with results at higher volume fractions of fiber. The composites also exhibit lower density, making them attractive for lightweight materials[99].

26. Composite Properties Investigation: A new polymeric composite materials from the flamboyant pod (Delonix Regia), an agricultural waste, with polyester as a matrix is used to investigate the properties and application areas[31].

27. Biocomposites and Mechanical Properties: Biocomposites reinforced by natural plant fibers tend to be brittle, moisture sensitive and have limited strength. Wood cellulose nanofibers (CNF) were therefore used to reinforce an unsaturated polyester matrix (UP) without the need of coupling agents or CNF surface modification. The nanostructured CNF network reinforcement strongly improves modulus and strength of UP but also ductility and toughness. A template-based prepreg processing approach of industrial potential is adopted, which combines high CNF content (up to 45 vol%) with nanoscale CNF dispersion[37].

28. Physical and Mechanical Properties Investigation:Physical and mechanical properties of flamboyant (Delonix Regia) pod filled polyester composites. Density, water absorption, elongation at break, flexural strength, flexural modulus, tensile strength, tensile modulus, hardness are observed[27].

29. Flame Retardant Properties Investigation: Effect of Magnesium Hydroxide on the Flame Retardant Properties of Unsaturated Polyester Resin. Mass loss rate, Heat release rate for samples without magnesium hydroxide, the HRR peak of the samples contained 35%, 45% and 55% of magnesium hydroxide was decreased, while SEAav significantly reduced[30].

a. Comparative Studies:

Khalil Ahmed et al. [36] This paper presents the comparative results of a current study on unsaturated polyester resin (UPR) matrix composites processed by filament winding method, with cotton spun yarn of different mass irregularities and two different volume fractions. Physical and mechanical properties were measured, namely ultimate stress, stiffness, elongation%.

Fabio de Oliveira Braga et al. [40] A multilayered armor system (MAS) is intended to personal protection against high kinetic energy ammunition. MAS layers are composed of materials such as a front ceramic and a back composite that must show both high impact resistance and low weight, usually conflicting characteristics. Synthetic fiber fabrics, such as Kevlar™ and Dyneema™, are the favourite materials to back the front ceramic, due to their high strength, high modulus and relatively low weight. Among the tested materials, the 30 vol.% fiber composites were found to be the best alternative to Kevlar™.

b. Materials and Processing Techniques:

Rulin Yanga et.al. [28] Recycling routes, including biodegradation, mechanical recycling, and chemical recycling for polymer materials that are easy to sort and have good thermal stability, melting and reformation are preferred, while composting should be prioritized for materials with good biodegradability.

FemianaGapsari et al. [35] Natural fiber reinforced composites are usually added with fillers to improve their performance. This study describes the successful development of timoho fiber (TF)-reinforced polyester composites combined with iron powder (IP) filler. Composite fabrication used hot press method. Flame, thermal, mechanical, and morphological characteristics were analyzed to determine the effect of variations on the volume fraction of IP filler in polyester composites with 30% (wt) TF. The results showed that the PTF composite had the highest tensile strength

c. Material Characterization and Investigation:

Binu P P et al. [39] A series of glass fiber reinforced polyester nanocomposites have been prepared with varying compositions and Cloisite15A as nanofiller.. The effects of nanoclay content on the mechanical, dynamic mechanical and thermal properties of nanocomposites were studied. Tensile testing, Impact testing, Dynamic Mechanical Analysis and Thermogravimetric analysis are employed to investigate mechanical and thermal characteristics. The fractured surface isanalyzed by Scanning Electron Microscopy(SEM) to indicate brittle nature of fracture for pure polyester reinforced with glass fiber mat, Whereas the fracture changed to ductile nature by the addition of nano clay.

Chinnappa Arumugan et al. [42] Silver nanoparticles (AgNPs@PVA) were prepared and nanobio-composites were made using unsaturated polyester resin, woven kenaf fiber (untreated and treated with NaOH, formic acid, acetic anhydride, hydrogen peroxide and KMnO4) and 2% AgNPs@PVA. In the FT-IR spectrum the band at 1736 cm−1 due to lignin disappeared completely for the fiber treated with 5% NaOH. The intensity of the above band was found to decrease in the order of KMnO4 > H2O2 > Ac2O > Untreated > HCOOH > NaOH treated fibers. This study, suggests that the material studied here could be good replacement for automotive interior (side panels, seat frames, central consuls) and exterior parts (door panels, dash boards).

d. Wear Properties Investigation:

E.O. Achukwu et al. [33] This study addresses the experimental investigation on physico-mechanical and Taguchi-designed sliding wear properties of novel Himalayan agave fiber (fiber's sizes of 3 mm, 5 mm, 7 mm and fiber's loading of 5 wt.%, 7 wt.% and 9 wt.%) reinforced polyester composites. The tensile and impact strength were observed to increase with increase in fiber's size and loading whichledto maximum tensile and impact strength.

e. Application Studies:

Aidy Ali et al. [32] In this study, researchers developed a laminated woven bamboo/woven E-glass/unsaturated polyester composite to withstand ballistic impact from bullets in shooting tests. The aim was to understand how the woven bamboo arrangement affects ballistic resistance properties. The study focused on the ballistic limit test known as NIJ V50, which qualifies materials for use in combat armor panels. These findings provide a strong basis for engineers to consider green composites as potential replacements for synthetic composites in certain engineering applications.

f. Delamination Studies:

N. Abilash et al. [38] Delamination is represented to be the most prevalent failure in composite structures. The characteristics of a composite material are determined by how it behaves while machining. Drilling is the most predominant machining process because of its cost effectiveness when compared with other processes. This research mainly emphasizes on the critical parameters by varying its speed, feed, and diameter of the cutting tool, their contribution to delamination was analyzed. Reduced delaminations were identified by varying the speed and feed rate.

g. Impact Toughness of Polyester Matrix Composites:

Veronica Scarpini Candido et al. [45] The fibers extracted from the sugarcane bagasse have been investigated as possible reinforcement for polymer matrix composites. The use of these composites in engineering applications, associated with conditions such as ballistic armor, requires information on the impact toughness.

Charpy tests were performed in ASTM standard specimens of polyester matrix composites, reinforced with 10, 20 and 30 vol% of continuous and aligned sugarcane bagasse fibers, in order to evaluate the impact energy.

h. Functionalization of Composite Materials:

Anderson Oliveira da Silva et al. [47] Functionalization of composite materials by ionizing radiation is considered an environmentally friendly technology to improve the compatibility of natural fibers with a polymer matrix. However, depending on the dose, it might also cause degradation. In particular, the effect of ionizing radiation on hybrid polymer composites reinforced with both naturals and synthetics fibers still needs more attention.

i. Water Absorption Behavior of Woven Fan Palm Fiber Composites:

Kusmono et al. [48] This study aims to investigate the effect of silane, alkali, and a combination of alkali–silane treatments on the water absorption behavior, mechanical and thermal properties of woven fan palm fibers (WFP)-reinforced unsaturated polyester composites. Maximum moisture content (Mm) and diffusivity (D) values of treated WFP composites immersed in 3.5% NaCl solution both at room temperature and 60° C were found to be lower than those of untreated WFP composite.

j. Optimization of Alkali Treatment for Natural Fiber Reinforced Polyester Composites:

Abiola John Adeyi et al. [63] Studies on modeling and optimization of alkali treatment, investigation of experimental uncertainty and sensitivity analysis of alkali treatment factors of natural fibers. In this contribution, response surface methodology (RSM) was employed to investigate and optimize the effect of varied treatment factors (sodium hydroxide concentration (NaOH) and soaking time (ST)) of the alkali treatment of Ampelocissuscavicaulis natural fiber (ACNF) on the tensile strength (TS) of alkali treated ACNF reinforced polyester composite.

k. Mechanical Properties of Crocheted Fabrics of Miriti Fibers in Polyester Matrix:

AltairleyM.Freires et al. [65] includes experimental investigation of the mechanical properties of composites reinforced with crocheted fabrics of miriti fibers (Mauritia flexuosa) in a polyester matrix. The fabrics were manufactured under different grammages, with and without alkaline fiber treatment. The composites were produced using two different viscosity conditions of the polyester matrix and part of these underwent post-cure treatment at 60 °C. In order to evaluate the effects of the input variables, the samples were produced by manual lamination with curing under vacuum, following a complete factorial.

l. Valorization of Chemical Compounds from Thermal Decomposition of Fiber Reinforced Plastic Waste:

A. Serras-Malillos et al. [66] Valorisation of chemical compounds derived from the thermal decomposition of the plastic matrix in fibre reinforced plastic waste is claimed as crucial for cost-effective recycling of this waste. The study validated the application of a thermal treatment (900?°C) to the volatiles generated from the pyrolysis of four end-of-life glass fibre reinforced polyester waste in a fixed bed tubular reactor placed in series with the pyrolysis reactor. Thermal treatment of pyrolysis volatiles' improves current scenario by transforming the hazardous liquids and low quality.

m. Overview of Natural Fiber Composites and Their Applications:

Sivasubramanian Palanisamy et al. [67] Natural fiber composites (NFCs) as alternatives to traditional materials such as fiberglass. By examining fibers like abaca, bamboo, banana, coir, flax, hemp, jute, kenaf, pineapple leaf (PALF), sisal, and others,

we emphasize their lower weight, cost-effectiveness, competitive mechanical properties, commendable specific strength, and potential for biodegradability. NFCs offer practical and eco-friendly substitutes for conventional composite fibers in industries like construction, automotive, and packaging.

n. Investigation on Mechanical and Water Absorption Properties of Natural/Synthetic Hybrid Fiber Composites:

F.S.M Radzi et al. [77] investigated the mechanical and water absorption properties of natural/synthetic hybrid fiber-reinforced composites using sugar palm, kenaf, and bamboo along with fibreglass and Kevlar. They found that different weight contents of natural fibers influenced mechanical strength, with sugar palm fibers demonstrating excellent water resistance.

o. Optimization of Stacking Sequence and Fiber Content in Hybrid Laminated Composites:

M.N.M.Azlin et al. [79] emphasized the importance of optimizing stacking sequence and fiber content for woven kenaf/polyester fiber reinforced PLA hybrid laminated composites to tailor mechanical and morphological properties based on specific application requirements.

p. Mechanical Properties of Various Natural Fiber Reinforced Laminates:

S.Satbrief et al. [80] tested the mechanical properties of ukam, banana, sisal, coconut, hemp, and E-glass fiber reinforced laminates. They found that natural fibers are of interest for low-cost engineering applications and can compete with artificial glass fibers when high stiffness per unit weight is desirable.

q. Sustainable Utilization of Covid-19 Waste Face Masks:

Mashrafi Bin Mobarak et al. [82] investigated the sustainable utilization of Covid-19 waste face masks by fabricating composite materials incorporating shredded masks into the UPR matrix using the hand lay-up technique. The study aimed to evaluate the mechanical properties of these composites.

r. Analysis of Wood Charcoal Filler in Natural Fiber Reinforced Polymer Composites:

Subrata Chandra Das et al. [84] analyzed the incorporation of wood charcoal as a filler in natural fiber reinforced polymer composites. They tested the developed composite formulations for mechanical and physicochemical properties, revealing improved tensile properties with a 4?wt% charcoal filler modification compared to the reference composite. However, further increase in filler content led to lower mechanical properties. Thermogravimetric analysis showed increased thermal stability of the 4?wt% charcoal filler modified composite.

s. Impact of Fillers on Microhardness and Characterizations of Composites:

Jaideep Adhikari et al. [86] observed an increase in microhardness with filler incorporation in composites, reaching its maximum at 20 wt% filler content. Various characterizations were performed on composites fabricated with 20 wt% filler content, including Vicker’s microhardness testing, SEM, EDS, XRD, FTIR spectroscopy, TG analysis, DSC, LOI testing, and water absorption test.

Fillers in Composites: Jaideep Adhikari et al. [86] investigated filler effects on composites, showing increased microhardness with filler incorporation, peaking at 20 wt%.

Conclusion

The integration of natural fibers with polymer matrices through hand layup offers a sustainable approach to composite material production with significant potential for growth in various sectors. This review aims to highlight key advancements, identify areas for improvement, and stimulate further research in optimizing the properties and applications of natural fiber reinforced polymer matrix composites. By incorporating renewable and environmentally friendly fibers like jute into polymer matrices, composite materials become more eco-friendly while retaining desirable properties. Industries, from automotive to construction, stand to benefit from these lightweight, strong, and potentially cost-effective materials. The review underscores the importance of ongoing research efforts to enhance mechanical properties, optimize manufacturing processes, and explore new applications. By recognizing both strengths and areas needing improvement, researchers can guide future studies towards maximizing the benefits of natural fiber reinforced polymer composites, thus contributing to a more sustainable future in materials science and engineering.

References

[1] Md. Farhad Ali, Md. Asib Ahmed, Md. Sahadat Hossain, Samina Ahmed, A.M. Sarwaruddin Chowdhury, Effects of inorganic materials on the waste chicken feather fiber reinforced unsaturatedpolyesterresin-basedcomposite:Anapproachtoenvironmentalsustainability, Composites Part C: Open Access, Volume 9,2022, 100320, ISSN 2666-6820, https://doi.org/10.1016/j.jcomc.2022.100320. [2] AlessandroJ.G.dosSantos,MauricioM.Ribeiro,AlessandrodeC.Corrêa,JeandaS.Rodrigues, Douglas S. Silva, Raí F.P. Junio, Sergio N. Monteiro,, Morphological, chemical and mechanical properties of hybrid polyester composites reinforced with bamboo fibers and kaolin waste, Journal of Materials Research and Technology, Volume 30, 2024, Pages 1-15, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2024.03.003. [3] Md. Tarik Hossain, Md. Sahadat Hossain, Mohammad Shahriar Kabir, Samina Ahmed, Ruhul A. Khan, A. M. Sarwaruddin Chowdhury, Improvement of mechanical properties of jute-nano cellulose-reinforcedunsaturatedpolyesterresin-basedcomposite:Effectsofgammaradiation, Hybrid Advances, Volume 3, 2023, 100068, ISSN 2773-207X,https://doi.org/10.1016/j.hybadv.2023.100068. [4] Berihun AbebawMebratie,Bekalu SintayehuAyele,AddisuAlamirew Meku, Investigating the tensile and flexural strength of sunflower oil treated Ethiopian Highland bamboo fibre reinforcedpolyestercomposites,AdvancesinBambooScience,Volume3,2023,100021,ISSN 2773-1391, https://do i.org/10.1 016/j.bamboo.2023.100021. [5] Bnar Ibrahim Omer, Yassin Mustafa Ahmed, Rzgar Mhammed Abdalrahman, Impact of textile types and their hybrids on the mechanical properties and thermal insulation of mohair- reinforcedpolyesterCompositelaminates,ResultsinMaterials,Volume21,2024,100502,ISSN 2590-048X,https://d oi.org/10.10 16/j.rinma.2023.100502. [6] AliShahmirzaloo,MarcoManconi,BartvandenHurk,BowenXu,RijkBlok,PatrickTeuffel, Numerical and experimental validation of the static performance of a full-scale flax fiber- polyester composite bridge model to support the design of an innovative footbridge, Engineering Structures, Volume 291, 2023, 116461, ISSN 0141-0296,https://doi.org/10.1016/j.engstruct.2023.116461. [7] Mateus Hofmann, Abu T. Shahid, Marina Machado, Mário Garrido, João C. Bordado, João R. Correia,GFRPbiocompositesproducedwithanovelhigh-performancebio-basedunsaturated polyester resin, Composites Part A: Applied Science and Manufacturing, Volume 161, 2022, 107098, ISSN 1359-835X,https://doi.org/10.1016/j.compositesa.2022.107098. [8] JonathanB.Dawit,HirpaG.Lemu,Yohannes Regassa, Adugna D.Akessa, Investigation of the mechanical properties of Acacia tortilis fiber reinforced natural composite, Materials Today: Proceedings, Volume 38, Part 5, 2021, Pages 2953-2958, ISSN 2214-7853, https://doi.org/10.1016/j.matpr.2020.09.308. [9] TaufiqSaidi,MuttaqinHasan,ZahraAmalia,ShafiraSalsabila,Theanalysisofthebondstrength between natural fiber reinforced polymer (NFRP) sheets and concrete, Results in Engineering, Volume 18, 2023, 101124, ISSN 2590-1230, https://doi.org/10.1016/j.rineng.2023.101124. [10] N.V.Rachchh,P.S.Ujeniya,R.K.Misra,MechanicalCharacterisationofRattanFibrePolyester Composite, Procedia Materials Science, Volume 6, 2014, Pages 1396-1404, ISSN 2211-8128, https://doi.org/10.1016/j.mspro.2014.07.119. [11] M.N.M. Azlin, S.M. Sapuan, M.Y.M. Zuhri, E.S. Zainudin, Effect of stacking sequence and fiber contentonmechanicalandmorphologicalpropertiesofwovenkenaf/polyesterfiberreinforced polylactic acid (PLA) hybrid laminated composites, Journal of Materials Research and Technology, Volume 16, 2022, Pages 1190-1201, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2021.12.046. [12] MansourRokbi,HocineOsmani,AbdellatifImad,NoureddineBenseddiq, Effect of Chemical treatment on Flexure Properties of Natural Fiber-reinforced Polyester Composite, Procedia Engineering, Volume 10, 2011, Pages 2092-2097, ISSN 1877-7058, https://doi.org/10.1016/j.proeng.2011.04.346. [13] A. Atiqah, M.N.M Ansari, M.S.S. Kamal, A. Jalar, N.N. Afeefah, N. Ismail, Effect of alumina trihydrate as additive on the mechanical properties of kenaf/polyester composite for plastic encapsulatedelectronicpackagingapplication,JournalofMaterialsResearchandTechnology, Volume 9, Issue 6, 2020, Pages 12899-12906, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2020.08.116. [14] Nadendla Srinivasababu, J. Suresh Kumar, K. Vijaya Kumar Reddy, Manufacturing and CharacterizationofLongPalmyraPalm/Bo rassusFlabelliferPetioleFibreReinforcedPolyester Composites, Procedia Technology, Volume 14, 2014, Pages 252-259, ISSN 2212-0173, https://doi.org/10.1016/j.protcy.2014.08.033. [15] Pardi, Sri Aprilia, Yanna Syamsuddin,Zuhra, Amri Amin, Ika Zuwanna, Physical, morphological, mechanical and thermal properties of polyester composites reinforced with orientation of purun fiber (Eleocharisdulcis) composition, South African Journal of Chemical Engineering, Volume 47, 2024, Pages 338-344, ISSN 1026-9185, https://doi.org/10.1016/j.sajce.2023.11.014. [16] Mohammed Y. Abdellah, Mustafa Gamal Sadek, Hamzah Alharthi, G.T. Abdel-Jaber, Ahmed H. Backar, Characteristic properties of date-palm fibre/sheep wool reinforced polyester composites,JournalofBioresourcesandBioproducts,Volume8,Issue4,2023,Pages430-443, ISSN2369-9698, https://doi.org/10.1016/j.j obab.2023.09.003. [17] Christopher O. Ndukwe, Benjamin O. Ezurike, Paul C. Okpala, Comparative studies of experimentalandnumericaleva luationoftensilepropertiesofGlassFibreReinforcedPolyester (GFRP) matrix, Heliyon, Volume 7, Issue 5, 2021, e06887, ISSN 2405-8440, https://doi.org/10.1016/j.heliyon.2021.e06887. [18] Mateus Hofmann, Marina Machado, Abu Shahid, Filipe Dourado, Mário Garrido, João C. Bordado,JoãoR.Correia, Pultruded carbon fibre reinforced polymer strips produced with a novel bio-based thermoset polyester for structural strengthening, Composites Science and Technology, Volume 234, 2023, 109936, ISSN 0266-3538, https://doi.org/10.1016/j.compscitech.2023.109936. [19] M.A. de Farias, M.Z. Farina, A.P.T. Pezzin, D.A.K. Silva, Unsaturated polyester composites reinforced with fiber and powder of peach palm: Mechanical characterization and water absorption profile, Materials Science and Engineering:C, Volume29,Issue2,2009,Pages510- 513, ISSN 0928-4931, https://doi.org/10.1016/j.msec.2008.09.020. [20] Saad R. Ahmed, Sanjeev Khanna, Investigation into features of fracture toughness of a transparentE-glassfiberreinforcedpolyestercompositesatextre metemperatures, Heliyon, Volume 6, Issue 5, 2020, e03986, ISSN 2405-8440, https://doi.org/10.1016/j.heliyon.2020.e03986. [21] Mohammed Mohammed, Jawad K. Oleiwi, Anwar Ja\'afar Mohamad Jawad, Aeshah M. Mohammed, Azlin F. Osman, Rozyanty Rahman, Tijjani Adam, Bashir O. Betar, Subash C.B. Gopinath,OmarS.Dahham,Effectofzincoxidesurfacetreatmentconcentrationandnanofiller loading on the flexural properties of unsaturated polyester/kenaf nanocomposites, Heliyon, Volume 9, Issue 9, 2023, e20051, ISSN 2405-8440, https://doi.org/10.1016/j.heliyon.2023.e20051. [22] Mohammed Mohammed, Jawad K. Oleiwi, Anwar Ja\'afar Mohamad Jawad, Aeshah M. Mohammed, Azlin F. Osman, Rozyanty Rahman, Tijjani Adam, Bashir O. Betar, Subash C.B. Gopinath,OmarS.Dahham,Effectofzincoxidesurfacetreatmentconcentrationandnanofiller loading on the flexural properties of unsaturated polyester/kenaf nanocomposites, Heliyon, Volume 9, Issue 9, 2023, e20051, ISSN 2405-8440, https://doi.org/10.1016/j.heliyon.2023.e20051. [23] N. Abilash, M. Sivapragash, Optimizing the delamination failure in bamboo fiber reinforced polyestercomposite, JournalofKingSaudUniversity-EngineeringSciences,Volume28,Issue1, 2016, Pages 92-102, ISSN 1018-3639, https://doi.org/10.1016/j.jksues.2013.09.004. [24] Hamdy M. Naguib, Usama F. Kandil, Ahmed I. Hashem, Yasser M. Boghdadi, Effect of fiber loading on the mechanicaland physical properties of“green” bagasse–polyester composite, Journal of Radiation Research and Applied Sciences, Volume8,Issue4,2015,Pages544-548, ISSN 1687-8507, https://doi.org/10.1016/j.jrras.2015.06.004. [25] Caroline G. de Oliveira, Frederico M. Margem, Sergio N. Monteiro, Felipe Perissé Duarte Lopes, Comparison between tensile behavior of epoxy and polyester matrix composites reinforced with eucalyptus fibers, Journal of Materials Research and Technology, Volume6, Issue4, 2017,Pages 406-410, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2017.08.002. [26] Niccolò Aravecchia, Jorge Bañuls-Ciscar, Alessio Caverzan, Giacomo Ceccone, Estefania Cuenca, LiberatoFerrara,KonstantinosGrigoriad is,PaoloNegro,MattiaRodriquens,On the feasibility of using Polyester(PE)waste particles from metal coating industry as a secondary raw materials in concrete, Cleaner Materials, Volume 9, 2023, 100193, ISSN 2772-3976, https://doi.org/10.1016/j.clema.2023.100193. [27] E.O. Achukwu, J.O. Odey, M.M. Owen, N. Lawal, G.A. Oyilagu, A.I. Adamu, Physical and mechanical properties of flamboyant(DelonixRegia)pod filled polyester composites, Heliyon, Volume 8, Issue 1, 2022, e08724, ISSN 2405-8440, https://doi.org/10.1016/j.heliyon.2022.e08724. [28] Rulin Yang, Guangqiang Xu, Wenjie Tao, Qinggang Wang, Yong Tang, Recycled polymer: Green roads for polyester plastics, GreenCarbon,Volume2,Issue1,2024,Pages1-11,ISSN2950-1555, https://doi.org/10.1016/j.greenca.2024.01.004. [29] G.L.EaswaraPrasad,B.S.KeerthiGowda,R.Velmurugan, ComparativeStudyofImpactStrength Characteristics of Treated and Untreated Sisal Polyester Composites, Procedia Engineering, Volume 173, 2017, Pages 778-785, ISSN 1877-7058, https://doi.org/10.1016/j.proeng.2016.12.096. [30] Hao Tang, Xiao-bai Zhou, Xiao-lu Liu, Effect of Magnesium Hydroxide on the Flame Retardant Properties of Unsaturated PolyesterResin,ProcediaEngineering, Volume52,2013,Pages336- 341, ISSN 1877-7058,https://doi.org/10.1016/j.proeng.2013.02.150. [31] Sanjeev Kumar, Lalta Prasad, Sandeep Kumar, Vinay Kumar Patel, Physico-mechanical and Taguch designed sliding wear properties of Himalayan agave fiber reinforced polyester composite, Journal of Materials Research and Technology, Volume 8, Issue 4, 2019, Pages 3662-3671,https://doi.org/10.1016/j.jmrt.2019.06.004 [32] Aidy Ali, Rabiatun Adawiyah, Kannan Rassiah, Wei Kuan Ng, Faiz Arifin, Faiz Othman, Muhammad Shauqi Hazin, M.K. Faidzi, M.F. Abdullah, M.M.H. Megat Ahmad, Ballistic impact properties of woven bamboo- woven E-glass- unsaturated polyester hybrid composites, Defence Technology, Volume 15, Issue 3, 2019, Pages 282-294, ISSN 2214- 9147,https://doi.org/10.1016/j.dt.2018.09.001 [33] E.O. Achukwu, J.O. Odey, M.M. Owen, N. Lawal, G.A. Oyilagu, A.I. Adamu, Physical and mechanical properties of flamboyant (Delonix Regia) pod filled polyester composites, Heliyon, Volume 8, Issue 1, 2022, e08724, ISSN 2405-8440 https://doi.org/10.1016/j.heliyon.2022.e08724 [34] Mateus Hofmann, Abu T. Shahid, Marina Machado, Mário Garrido, João C. Bordado, João R. Correia, GFRP biocomposites produced with a novel high-performance bio-based unsaturated polyester resin, Composites Part A: Applied Science and Manufacturing, Volume 161, 2022, 107098, ISSN 1359-835X, https://doi.org/10.1016/j.compositesa.2022.107098 [35] Femiana Gapsari, Anindito Purnowidodo, Putu Hadi Setyarini, Suteja Suteja, Zainul Abidin, Sanjay Mavinkere Rangappa, Suchart Siengchin, Flammability and mechanical properties of Timoho fiber- reinforced polyester composite combined with iron powder filler, Journal of Materials Research and Technology, Volume 21, 2022, Pages 212-219, ISSN 2238-7854 https://doi.org/10.1016/j.jmrt.2022.09.02 [36] Khalil Ahmed, Muhammad Nasir, Nasreen Fatima, Khalid M. Khan, Durey N. Zahra, Structural mass irregularities and fiber volume influence on morphology and mechanical properties of unsaturated polyester resin in matrix composites, Journal of Advanced Research, Volume 6, Issue 6, 2015, Pages 833-838, ISSN 2090-1232 https://doi.org/10.1016/j.jare.2014.06.007 [37] Farhan Ansari, Mikael Skrifvars, Lars Berglund, Nanostructured biocomposites based on unsaturated polyester resin and a cellulose nanofiber network, Composites Science and Technology, Volume 117, 2015, Pages 298-306, ISSN 0266-3538 https://doi.org/10.1016/j.compscitech.2015.07.004 [38] N. Abilash, M. Sivapragash, Optimizing the delamination failure in bamboo fiber reinforced polyester composite, Journal of King Saud University - Engineering Sciences, Volume 28, Issue 1, 2016, Pages 92-102, ISSN 1018-3639 https://doi.org/10.1016/j.jksues.2013.09.004 [39] P.P. Binu, K.E. George, M.N. Vinodkumar, Effect of Nanoclay, Cloisite15A on the Mechanical Properties and Thermal Behavior of Glass Fiber Reinforced Polyester, Procedia Technology, Volume 25, 2016, Pages 846-853, ISSN 2212-0173 https://doi.org/10.1016/j.protcy.2016.08.191 [40] Fábio de Oliveira Braga, Lucas Tedesco Bolzan, Édio Pereira Lima Jr., Sergio Neves Monteiro, Performance of natural curaua fiber-reinforced polyester composites under 7.62mm bullet impact as a stand-alone ballistic armor, Journal of Materials Research and Technology, Volume 6, Issue 4, 2017, Pages 323-328, ISSN 2238-7854 https://doi.org/10.1016/j.jmrt.2017.08.003 [41] Marcos Vinícius Fonseca Ferreira, Anna Carolina Cerqueira Neves, Caroline Gomes de Oliveira, Felipe Perissé Duarte Lopes, Frederico Muylaert Margem, Carlos Maurício Fontes Vieira, Sergio Neves Monteiro, Thermogravimetric characterization of polyester matrix composites reinforced with eucalyptus fibers, Journal of Materials Research and Technology, Volume 6, Issue 4, 2017, Pages 396-400, ISSN 2238-7854 https://doi.org/10.1016/j.jmrt.2017.09.002 [42] hinnappa Arumugam, Senthilkumar Arumugam, Sarojadevi Muthusamy, Mechanical, thermal and morphological properties of unsaturated polyester/chemically treated woven kenaf fiber/AgNPs@PVA hybrid nanobiocomposites for automotive applications, Journal of Materials Research and Technology, Volume 9, Issue 6, 2020, Pages 15298-15312, ISSN 2238- 7854 https://doi.org/10.1016/j.jmrt.2020.10.084 [43] Caroline G. de Oliveira, Frederico M. Margem, Sergio N. Monteiro, Felipe Perissé Duarte Lopes, Comparison between tensile behavior of epoxy and polyester matrix composites reinforced with eucalyptus fibers, Journal of Materials Research and Technology, Volume 6, Issue 4, 2017, Pages 406-410, ISSN 2238-7854 https://doi.org/10.1016/j.jmrt.2017.08.002 [44] N. Mohd Nurazzi, A. Khalina, S.M. Sapuan, R.A. Ilyas, S. Ayu Rafiqah, Z.M. Hanafee, Thermal properties of treated sugar palm yarn/glass fiber reinforced unsaturated polyester hybrid composites, Journal of Materials Research and Technology, Volume 9, Issue 2, 2020, Pages 1606-1618, ISSN 2238-7854 https://doi.org/10.1016/j.jmrt.2019.11.086 [45] Verônica Scarpini Candido, Alisson Clay Rios da Silva, Noan Tonini Simonassi, Fernanda Santos da Luz, Sergio Neves Monteiro, Toughness of polyester matrix composites reinforced with sugarcane bagasse fibers evaluated by Charpy impact tests, Journal of Materials Research and Technology, Volume 6, Issue 4, 2017, Pages 334-338, ISSN 2238-7854 https://doi.org/10.1016/j.jmrt.2017.06.001 [46] Gabriel Oliveira Glória, Maria Carolina Andrade Teles, Felipe Perissé Duarte Lopes, Carlos Maurício Fontes Vieira, Frederico Muylaert Margem, Maycon de Almeida Gomes, Sergio Neves Monteiro, Tensile strength of polyester composites reinforced with PALF, Journal of Materials Research and Technology, Volume 6, Issue 4, 2017, Pages 401-405, ISSN 2238-7854 https://doi.org/10.1016/j.jmrt.2017.08.006 [47] Anderson Oliveira da Silva, Karollyne Gomes de Castro Monsores, Suzane de Sant’ Ana Oliveira, Ricardo Pondé Weber, Sergio Neves Monteiro, Hélio de Carvalho Vital, Influence of gamma and ultraviolet radiation on the mechanical behavior of a hybrid polyester composite reinforced with curaua mat and aramid fabric, Journal of Materials Research and Technology, Volume 9, Issue 1, 2020, Pages 394-403, ISSN 2238-785 https://doi.org/10.1016/j.jmrt.2019.10.068 [48] Kusmono, H. Hestiawan, Jamasri, The water absorption, mechanical and thermal properties of chemically treated woven fan palm reinforced polyester composites, Journal of Materials Research and Technology, Volume 9, Issue 3, 2020, Pages 4410-4420, ISSN 2238-7854 https://doi.org/10.1016/j.j mrt.2020.02.065 [49] V. Vignesh, A.N. Balaji, N. Nagaprasad, Mavinkere Rangappa Sanjay, Anish Khan, Abdullah M. Asiri, Ghulam M. Ashraf, Suchart Siengchin, Indian mallow fiber reinforced polyester composites: mechanical and thermal properties, Journal of Materials Research and Technology, Volume 11, 2021, Pages 274-284, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2021.01.023 [50] Mashrafi Bin Mobarak, Md. Sahadat Hossain, Fariha Chowdhury, Samina Ahmed, Covid-19 waste facemask conundrum: A facile way of utilization through fabricating composite material with unsaturated polyester resin and evaluation of its mechanical properties, Heliyon, Volume 8, Issue 12, 2022, e12197, ISSN 2405-8440, https://doi.org/10.1016/j.heliyon.2022.e12197 [51] M.N.M. Azlin, S.M. Sapuan, M.Y.M. Zuhri, E.S. Zainudin, Effect of stacking sequence and fiber content on mechanical and morphological properties of woven kenaf/polyester fiber reinforced polylactic acid (PLA) hybrid laminated composites, Journal of Materials Research and Technology, Volume 16, 2022, Pages 1190-1201, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2021.12.046 [52] Femiana Gapsari, Anindito Purnowidodo, Putu Hadi Setyarini, Suteja Suteja, Zainul Abidin, Sanjay Mavinkere Rangappa, Suchart Siengchin, Flammability and mechanical properties of Timoho fiber-reinforced polyester composite combined with iron powder filler, Journal of Materials Research and Technology, Volume 21, 2022,Pages 212-219, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2022.09.025 [53] Md. Farhad Ali, Md. Asib Ahmed, Md. Sahadat Hossain, Samina Ahmed, A.M. Sarwaruddin Chowdhury, Effects of inorganic materials on the waste chicken feather fiber reinforced unsaturated polyester resin-based composite: An approach to environmental sustainability, Composites Part C: Open Access, Volume 9, 2022, 100320, ISSN 2666-6820, https://doi.org/10.1016/j.jcomc.2022.100320 [54] Mohammed Y. Abdellah, Mustafa Gamal Sadek, Hamzah Alharthi, G.T. Abdel-Jaber, Ahmed H. Backar, Characteristic properties of date-palm fibre/sheep wool reinforced polyester composites, Journal of Bioresources and Bioproducts, Volume 8, Issue 4, 2023, Pages 430- 443, ISSN 2369-9698 https://doi.org/10.1016/j.jobab.2023.09.003 [55] Berihun Abebaw Mebratie, Bekalu Sintayehu Ayele, Addisu Alamirew Meku, Investigating the tensile and flexural strength of sunflower oil treated Ethiopian Highland bamboo fibre reinforced polyester composites, Advances in Bamboo Science, Volume 3, 2023, 100021, ISSN 2773-1391 https://doi.org/10.1016/j.bamboo.2023.100021 [56] Md. Tarik Hossain, Md. Sahadat Hossain, Mohammad Shahriar Kabir, Samina Ahmed, Ruhul [57] Khan, A. M. Sarwaruddin Chowdhury, Improvement of mechanical properties of jute-nano cellulose-reinforced unsaturated polyester resinbased composite: Effects of gamma radiation, Hybrid Advances, Volume 3, 2023, 100068, ISSN 2773- 207X,https://doi.org/10.1016/j.hybadv.2023.100068 [58] H. Mohit, Sanjay Mavinkere Rangappa, Krittirash Yorseng, Suchart Siengchin, Hadi M. Marwani, Anish Khan, Abdullah M. Asiri, Discarded water hyacinth/pineapple fibers and carbon/innegra fabrics and TiC nanoparticles reinforced UV resistant polyester composites, Journal of Materials Research and Technology, Volume 24, 2023, Pages 5059-5081, ISSN 2238-7854,https://doi.org/10.1016/j.jmrt.2023.04.061 [59] Mateus Hofmann, Marina Machado, Abu Shahid, Filipe Dourado, Mário Garrido, João C. Bordado, João R. Correia, Pultruded carbon fibre reinforced polymer strips produced with a novel bio-based thermoset polyester for structural strengthening, Composites Science and Technology, Volume 234, 2023,109936, ISSN 0266-3538,https://doi.org/10.1016/j.compscitech.2023.109936 [60] Mohammed Y. Abdellah, Mustafa Gamal Sadek, Hamzah Alharthi, G.T. Abdel-Jaber, Ahmed H. Backar, Characteristic properties of date-palm fibre/sheep wool reinforced polyester composites, Journal of Bioresources and Bioproducts, Volume 8, Issue 4, 2023, Pages 430- 443, ISSN 2369-9698, https://doi.org/10.1016/j.jobab.2023.09.003 [61] G. Dilli Babu, K. Sivaji Babu, P. Nanda Kishore, Tensile and Wear Behavior of Calotropis Gigentea Fruit Fiber Reinforced Polyester Composites, Procedia Engineering, Volume 97, 2014, Pages 531-535, ISSN 1877-7058 https://doi.org/10.1016/j.proeng.2014.12.279 [62] G.SureshKumar,AthotaRathan,DinBandhu,B.MadhusudhanReddy,H.RaghavendraRao, Sujeeth Swami, Kuldeep K. Saxena, Sayed M. Eldin, Nittala Noel Anurag Prashanth, Mechanical and thermal characterization of coir/hemp/polyester hybrid composite for lightweight applications,JournalofMaterialsResearchandTechnology,Volume26,2023, Pages 8242-8253, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2023.09.144 [63] Md. Farhad Ali, Md. Asib Ahmed, Md. Sahadat Hossain, Samina Ahmed, A.M. Sarwaruddin Chowdhury, Effects of inorganic materials on the waste chicken feather fiber reinforced unsaturatedpolyesterresin-basedcomposite:Anapproachtoenvironmentalsustainability, Composites Part C: Open Access, Volume 9, 2022, 100320, ISSN 2666-6820, https://doi.org/10.1016/j.jcomc.2022.100320 [64] AbiolaJohnAdeyi,OladayoAdeyi,EmmanuelOlusolaOke,OlusegunAbayomiOlalere,Seun Oyelami, Akinola David Ogunsola, Effect of varied fiber alkali treatments on the tensile strength of Ampelocissuscavicaulis reinforced polyester composites:Prediction, optimization,uncertaintyandsens itivityanalysis,Advanced Industrial and Engineering Polymer Research, Volume 4, Issue 1, 2021, Pages 29-40, ISSN 2542-5048, https://doi.org/1 0.1016/j.aiepr.2020.12.002 [65] BnarIbrahimOmer,YassinMustafaAhmed,RzgarMhammedAbdalrahman,Impactoftextile types and their hybrids on the mechanical properties and thermal insulation of mohair- reinforced polyester Composite laminates, Results in Materials, Volume 21, 2024, 100502, ISSN 2590-048X, https://doi.org/10.1016/j.rinma.2023.100502 [66] Altairley M. Freires, Alessandro de C. Corrêa, Mauricio M. Ribeiro, Silmara M. Cardoso, Jean da S. Rodrigues, Douglas S. Silva, Raí Felipe P. Junio, Sergio N. Monteiro, Mechanical propertiesandstatisticalanalysisofpolyestercompositereinforcedwithmiritifibersbraided using crochet technique, Journal of Materials Research and Technology, Volume 28, 2024, Pages4392-4400,ISSN2238-7854,https://doi.org/10.1016/j.jmrt.2023.12.153 [67] A.Serras-Malillos,B.B.Perez-Martinez,A.Lopez-Urionabarrenechea,E.Acha,B.M.Caballero,Integralrecyclingofpolyesterbasedend-of-lifefibrereinforced plasticwasteto wardssyngas generation, Sustainable Materials and Technologies, Volume 38, 2023, e00773, ISSN 2214- 9937, https://doi.or g/10.1016/j.susmat.2023.e00773 [68] .SivasubramanianPalanisamy,KavimaniVijayananth,ThulasiManiMurugesan,Murugesan Palaniappan, Carlo Santulli, The prospects of natural fiber composites: A brief review, International Journal of Lightweight Materials and Manufacture, Volume 7, Issue 4, 2024, Pages 496-506, ISSN 2588-8404, https://doi.org/10.1016/j.ijlmm.2024.01.003 [69] MohammedY.Abdellah,MustafaGamalSadek,Hamzah Alharthi,G.T.Abdel-Jaber,AhmedH. Backar, Characteristic properties of date-palm fibre/sheep wool reinforced polyester composites,JournalofBioresourcesandBioproducts,Volume8,Issue4,2023,Pages430- 443,ISSN2369-9698,https://doi.org/1 0.1016/j.joba b.2023.09.003 [70] KhalilAhmed,MuhammadNasir,NasreenFatima,KhalidM.Khan,DureyN.Zahra,Structural mass irregularities and fiber volume influence on morphology and mechanical properties of unsaturated polyester resinin matrix composites, Journal of Advanced Research, Volume 6, Issue 6, 2015, Pages 833-838, ISSN 2090-1232, https://doi.org/10.1016/j.jare.2014.06.007 [71] VinayakS.Hiremath,D.MallikarjunaReddy,RajasekharaReddyMutra,AdityaSanjeev, Thulasidhas Dhilip kumar,NaveenJ, Thermal degradation and fire retardant behavior of Naturalfibre reinforced polymeric composites-A comprehensive review, Journal of Materials Research and Technology, Volume 30, 2024, Pages 4053-4063, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2024.04.085 [72] S. Sathees Kumar, Dataset on mechanical properties of natural fiber reinforced polyestercomposites forengineeringapplications,DatainBrief,Volume28,2020,105054,ISSN2352-3409,https://doi.org/10.1016/j.dib.2019.105054 [73] S.H. Mahmud, S.C. Das, M.Z.I. Mollah, M.M. Ul-Hoque, K.S. Al-Mugren, M.R.I. Faruque, R. A. Khan,Thermoset-polymermatrixcompositematerialsofjuteandglassfibrereinforcements: Radiation effects determination, Journal of Materials Research and Technology, Volume 26, 2023, Pages 6623-6635, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2023.08.298 [74] Akhyar,AsriGani,MasriIbrahim,FatlulUlmi,AhmadFarhan,Theinfluenceofdifferentfiber sizes on the flexural strength of natural fiber-reinforced polymer composites, Results in Materials, Volume 21, 2024, 100534, ISSN 2590-048X, https://doi.org/10.1016/j.rinma.2024.100534 [75] Ajith Gopinath, M. Senthil Kumar, A. Elayaperumal, Experimental Investigations on MechanicalPropertiesOfJuteFiberReinforcedCompositeswithPolyesterandEpoxyResin Matrices, Procedia Engineering, Volume 97, 2014, Pages 2052-2063, ISSN 1877-7058, https://doi.org/10.1016/j.proeng.2014.12.448 [76] MohammadSalmanHaque,M.A.Islam,Wastenaturalfibersforpolymertougheningand biodegradability of epoxy-based polymer composite through toughness and thermal analysis,Heliyon,Volume10,Issue6,2024,e28110,ISSN2405-8440, https://doi.org/10.1016/j.heliyon.2024.e28110 [77] AliShahmirzaloo,MarcoManconi,BartvandenHurk,BowenXu,RijkBlok,PatrickTeuffel, Numerical and experimental validation ofthe static performance ofa full-scaleflax fiber- polyester composite bridge model to support the design of an innovative footbridge, EngineeringStructures,Volume291,2023,116461,ISSN0141-0296, https://doi.org/10.1016/j.engstruct.2023.116461 [78] Edwin Raja Dhas J, Anton Savio Lewise K, Naveen Kumar Kulandaiyappan, Vijayanandh Raja, AhamedSaleel,MamdoohAlwetaishi,BeenaStanislausArputharaj,AhmedM.HassanDeif, Hussein A.Z. AL-bonsrulah, Manufacturing and experimental characterization of new- developed natural fiber reinforced polymer nanocomposite, Journal of Materials Research and Technology, Volume 26, 2023, Pages 6084-6095, ISSN 2238-7854,https://doi.org/10.1016/j.jmrt.2023.08.187 [79] F.S.M.Radzi,M.J.Suriani,A.AbuBakar,A.Khalina,C.M.Ruzaidi,WBWanNik,M.Awang, F.Zulkifli,S.Abdullah,R.A.Ilyas,SayedM.Eldin,EffectofreinforcementofAlkaline-treated sugar palm/bamboo/kenaf and fibreglass/ Kevlar with polyester hybrid biocomposites: mechanical,morphological,andwaterabsorptionproperties,JournalofMaterialsResearch and Technology, Volume 24, 2023, Pages 4190-4202, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2023.04.055 [80] Pardi,SriAprilia,YannaSyamsuddin,Zuhra,AmriAmin,IkaZuwanna,Physical, morphological, mechanical and thermal properties ofpolyester composites reinforced with orientationofpurunfiber(Eleocharisdulcis)composition,SouthAfricanJournalofChemical Engineering, Volume 47, 2024, Pages 338-344, ISSN 1026-9185, https://doi.org/10.1016/j.sajce.2023.11.014 [81] M.N.M.Azlin,S.M.Sapuan,M.Y.M.Zuhri,E.S.Zainudin,Effectofstackingsequenceandfiber content on mechanical and morphological properties of woven kenaf/polyester fiber reinforced polylactic acid (PLA) hybrid laminated composites, Journal of Materials Research and Technology, Volume 16, 2022, Pages 1190-1201, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2021.12.046 [82] S. SatBrief, Volume 28,hees Kumar, Dataset on mechanical properties of natural fiber reinforcedpolyestercompositesforengineeringapplications,Datain2020,105054,ISSN 2352-3409, https://doi.org/10.1016/j.dib.2019.105054 [83] MashrafiBinMobarak,Md.SahadatHossain,FarihaChowdhury,SaminaAhmed,Covid-19 waste facemask conundrum: A facile way of utilization through fabricating composite material with unsaturated polyester resin and evaluation of its mechanical properties, Heliyon,Volume8,Issue12,2022,e12197,ISSN2405-8440 https://doi.org/10.1016/j.heliyon.2022.e12197 [84] .MohammedMohammed,RozyantyRahman,AeshahM.Mohammed,BashirO.Betar,AzlinF.Osman,TijjaniAdam,OmarS.Dahham,SubashC.B.Gopinath,Improvinghydrophobicity and compatibility between kenaf fiber and polymer composite by surface treatment with inorganic nano particles, ArabianJournalofChemistry,Volume15,Issue11,2022,104233, ISSN1878-5352,https://doi.org/10.1016/j.arabjc.2022.104233 [85] Subrata Chandra Das, Sheikh Ashek-E-Khoda, Md. Abu Sayeed, Suruzzaman, Debasree Paul, SajibAnindaDhar,SotiriosA.Grammatikos,Ontheuseofwoodcharcoalfillertoimprovethe properties of natural fiber reinforced polymer composites, Materials Today: Proceedings, Volume 44, Part 1, 2021, Pages 926-929, ISSN 2214-7853, https://doi.org/10.1016/j.matpr.2020.10.808 [86] M.A. de Farias,M.Z.Farina,A.P.T.Pezzin, D.A.K.Silva, Unsaturated polyester composites reinforced withfiber and powder of peach palm: Mechanical characterization and water absorptionprofile,MaterialsScienceandEngineering:C,Volume29,Issue2,2009,Pages 510-513, ISSN 0928-4931, https://doi.org/10.1016/j.msec.2008.09.020 [87] .JaideepAdhikari,BhabatoshBiswas,SumitChabri,NilRatanBandyapadhyay,PravinSawai, Bhairab Chandra Mitra, Arijit Sinha, Effect of functionalized metal oxides addition on the mechanical, thermal and swelling behaviour of polyester/jute composites, Engineering ScienceandTechnology,anInternationalJournal,Volume20,Issue2,2017,Pages760-774, ISSN2215-0986,https://doi.org/10.1016/j.jestch.2016.10.016 [88] NadendlaSrinivasababu,J.SureshKumar,K.VijayaKumarReddy,MechanicalandDielectric Properties of Thysanolaena Maxima (Broom Grass) Long Fibre Reinforced Polyester Composites, Procedia Materials Science, Volume 6, 2014, Pages 1006-1016, ISSN 2211- 812,https://doi.org/10.1016/j.mspro.2014.07.171 [89] NadendlaSrinivasabab,J.SureshKumar,K.VijayaKumarReddy,Manufacturingand CharacterizationofLongPalmyraPalm/BorassusFlabelliferPetioleFibreReinforcedPolyester Composites, Procedia Technology, Volume 14, 2014, Pages 252-259, ISSN 2212-0173, https://doi.org/10.1016/j.protcy.2014.08.033 [90] M.A.A. Ghani, Z. Salleh, Koay Mei Hyie, M.N. Berhan, Y.M.D. Taib, M.A.I. Bakri, Mechanical Properties of Kenaf/Fiberglass Polyester Hybrid Composite, Procedia Engineering, Volume 41,2012,Pages1654-1659,ISSN1877-7058,https://doi.org/10.1016/j.proeng.2012.07.364 [91] Altairley M. Freires, Alessandro de C. Corrêa, Mauricio M. Ribeiro, Silmara M. Cardoso, Jean da S. Rodrigues, Douglas S. Silva, Raí Felipe P. Junio, Sergio N. Monteiro, Mechanical propertiesandstatisticalanalysisofpolyestercompositereinforcedwithmiritifibersbraided using crochet technique, Journal of Materials Research and Technology, Volume 28, 2024, Pages4392-4400,ISSN2238-7854,https://doi.org/10.1016/j.jmrt.2023.12.153 [92] Y. Yasin, H. Khalid, M. U. Farooq, M. U. Shahid, M. U. Mushtaq, and U. Munir, \"Experimental evaluation of mechanical characteristics of concrete composites reinforced with jute fibers using bricks waste as alternate material for aggregates,\" Next Materials, Volume 5, 2024. https://doi.org/10.1016/j.nxmate.2024.100232 [93] S. Gowtham, T. Jeevanantham, J. Emelda, and J. Edric, \"Investigation on effect of fibre orientation on mechanical behaviour of polymer matrix natural fibre reinforced composite material,\" 2024, pp. 1-7. Materials Today: Proceedings, 10, 1-7. https://doi.org/10.1016/j.matpr.2024.04.022 [94] A. Sharma, H. Singh, S. Sharma, N. Dhall, B. Singh, R. Kumar, S. K. Chaurasiya, and K. Kashyap, \"Finite element modelling and analysis of jute fibre reinforced PLA matrix composite,\" Materials Today: Proceedings, 2024. https://doi.org/10.1016/j.matpr.2024.04.056 [95] D. O. Agumba, G. Park, J. W. Kim, and J. Kim, \"Biobased natural fiber-reinforced composites derived from lignin-based resin and mercerized jute fibers,\" Materials Letters, vol. 360, pp. 136055, 1 April 2024. https://doi.org/10.1016/j.matlet.2024.136055 [96] A. Kareem, P. V. Reddy, V. S. Kumar, and T. Buddi, \"Influence of the stacking on mechanical and physical properties of jute/banana natural fiber reinforced polymer matrix composite,\" Materials Today: Proceedings, 2023. https://doi.org/10.1016/j.matpr.2023.11.017 [97] A. K. Saravanan, A. R. Prasad, D. Muruganandam, G. Saravanan, S. Vivekanandan, and M. Sudhakar, \"Study on natural fiber composites of jute, pineapple, and banana compositions percentage of weight basis for thermal resistance and thermal conductivity,\" Materials Today: Proceedings, vol. 37, no. 2, pp. 147-151, 2021. https://doi.org/10.1016/j.matpr.2020.04.662 [98] M. K. Anirudh, A. M. Nandhu Lal, M. P. Harikrishnan, J. Jose, J. Thasim, A. S. Warrier, R. Venkatesh, U. B. Vaddevolu, and A. Kothakota, \"Sustainable seedling pots: Development and characterisation of banana waste and natural fibre-reinforced composites for horticultural applications,\" Int. J. Biol. Macromol. vol. 270, pt. 1, pp. 132070, Jun. 2024. https://doi.org/10.1016/j.ijbiomac.2024.132070. [99] K. Kishore, N. K. Wagri, and S. Kumar, \"A Review on Natural Fibers and Mechanical Properties Materials Today: Proceedings Name, vol. 5, no. 1, pp. 1785-1790, 2018. [100] K. M. M. Rao, K. M. Rao, and A. V. R. Prasad, \"Fabrication and testing of natural fibre composites: Vakka, sisal, bamboo and banana,\" Materials & Design, vol. 31, no. 1, pp. 508-513, January 2010. [Online]. Available: https://doi.org/10.1016/j.matdes.2009.06.023. [101] M. M. H. Kanok, S. S. Shifa, M. S. Haque, and A. Akter, \"Comparative study on mechanical properties of banana-glass fiber reinforced epoxy hybrid composites,\" Materials Today: Proceedings, September 1, 2023. [Online]. Available: https://doi.org/10.1016/j.matpr.2023.08.356. [102] T. N. Babu, A. Mandliya, A. K. Singh, A. Singh, and D. R. Prabha, \"Evaluation of tensile properties of epoxy resin based composites reinforced with jute/banana/flax and uni-axial glass fibers,\" International Journal of Civil Engineering and Technology (IJCIET), vol. 8, no. 2, pp. 347–357, February 2017. Article ID: IJCIET_08_02_037. ISSN Print: 0976-6308, ISSN Online: 0976-6316. http://www.iaeme.com/IJCIET/issue s.asp?JType=IJCIE T&VType=8&IType=2. © IAEME Publication Scopus Indexed. [103] M. K. Manik and P. Shukla, \"Mechanical properties of epoxy resin matrix composites made of jute fiber, bagasse, and glass fiber,\" International Journal of Creative Research Thoughts (IJCRT), vol. 10, no. 1, pp. 49-56, January 2022. ISSN: 2320-2882. [104] S. Suresh and D. Mangal, \"Mechanical properties of hybrid glass/jute reinforced epoxy composites,\" International Journal of Engineering Sciences and Research Technology, vol. 7, no. 5, pp. 233-240, May 2018.

Copyright

Copyright © 2024 Sravanthee S, A. Prabhu Kumar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63448

Publish Date : 2024-06-24

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online