Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Review Paper on Bacterial Self-Healing Concrete

Authors: Vaidik Sharma, Prof. Mayur Singi

DOI Link: https://doi.org/10.22214/ijraset.2023.54586

Certificate: View Certificate

Abstract

Bacterial self-healing concrete (BSHC) has emerged as a promising technology in the field of construction materials due to its ability to autonomously repair cracks and enhance the durability and service life of concrete structures. This paper presents a comprehensive review of the existing literature on the strength properties of bacterial self-healing concrete. The objective of this review is to provide an overview of the research conducted in this area, assess the effectiveness of bacterial self-healing in improving the mechanical properties of concrete, and identify potential areas for future research.

Introduction

I. INTRODUCTION

Self-healing Concrete is known for having self-healing properties. The capacity of concrete to self-heal or self-repair allows for crack rectification and repair utilizing either autonomous or autogenous procedures. All of these processes are characterized by the durability of concrete, which is one of its qualities. Concrete's materialistic durability helps it resist itself against chemical or physical threats. When durability deteriorates, the likelihood of fracture formation increases.

There are numerous remedies for this common structural cracking problem, both before and after the fracture. One of the remedial methods is self-healing or bacterial concrete. Self-Healing Concrete is a form of concrete that, due to a bacterial reaction, may repair or fill gaps on its own after hardening. Small fractures with a width of 0.05 to 0.1mm that occur in a structure can be observed to be completely sealed by repeating dry and wet cycles. Water particles infiltrate the fissures and act as capillaries, which is how this self-healing process occurs. These water droplets hydrate the partially or entirely unreacted cement, causing it to expand and fill the fissure. When the cracks are larger, more repair work is required. Acid-producing bacteria are used to aid in the natural healing of fractures. In dry settings, these bacteria may persist in latent cells for more than 200 years. These microorganisms hasten the healing of fractures.

Concrete constructions have a life expectancy of 50-100 years. However, decay of the structure begins within 10 years, even in some cases within a year of completion. After a given number of years, little fractures form in the framework, which might be structural or superficial. "Bacteria-based Self-Healing Concrete" is a revolutionary way for dealing with fractures in concrete. The self-healing concrete uses a specific form of bacteria from genus Bacillus, as well as a calcium-based nutrient, to cure fractures. Bacteria may remain latent in concrete for up to 200 years. When a fracture forms and water seeps into the crack, the bacteria in the dormant stage get active and convert calcium lactate into limestone.

Self-healing concrete is produced by a biological reaction between unreacted limestone and a calcium-based nutrition with the assistance of bacteria to repair construction defects. Along with the calcium supplement calcium lactate, certain microorganisms known as Bacillus are utilised. When mixing is complete during the production of concrete, these materials are added to the wet concrete. The latent stage of this bacterium can last for almost 200 years. Water pours into the concrete cracks as soon as they develop. The bacteria's spores start to grow and begin to feed on the calcium lactate, which consumes oxygen. Limestone is created from the soluble calcium lactate. The insoluble limestone starts to become more solid. Consequently, the crack is spontaneously filled without outside assistance. Another benefit of this process is that by consuming oxygen while converting calcium into limestone, the bacteria prevent steel from corroding because of cracks. This increases the steel-reinforced concrete construction's durability.

II. LITERATURE REVIEW

Various studies and research have been conducted on bacterial self-healing concrete, as well as workability and strength of the concrete. The following research are available to assess the qualities of concrete based on Bacteria, or self-healing concrete, to determine the behaviour and properties of self-healing concrete.

(Abishek Kumar A. A 2020), In the study, self-healing concrete was made and bacteria were introduced in quantities of 5ml, 10ml, and 15ml. The data reveal that adding 10ml of bacteria produces the greatest outcomes. A 10ml rise in bacteria strength is noticed. When compared to ordinary concrete, there is a 4.8% increase in 7-day strength, a 12.21% rise in 14-day strength, and a 1.33% increase in 28-day strength.

Similarly, split tensile strength was tested, and the results reveal a rise in split tensile strength of 7%, 4.21%, and 10% after 7 days, 14 days, and 28 days, respectively. Water absorption was also seen in these samples. Water absorption decreased by 9.72% in a 10ml bacterial sample.

(Aditya Tadimeti 2020), diverse polymers were utilized with bacillus subtilis in diverse aquatic settings in this study. The results reveal that bacillus subtilis can digest polythene in fresh water, but the amount of degradation reduces as the water becomes saline or in saline water. ABS and HIPS plastics, on the other hand, showed no deterioration. As a result, they are acceptable for usage with Bacillus subtilis. The use of Bacillus subtilis reduces polythene waste. Bacillus can be utilized to reduce polythene trash, however more literature and study is needed to learn about the aquatic environment. So that garbage in the water can be degraded as well.

(C. Manvith Kumar Reddy 2020), Bacteria at a concentration of 107 cells/ml are employed in this study, coupled with a calcium supply. Calcium lactate was employed as the calcium source. The concrete was tested for flexural strength. Adding bacteria and calcium lactate resulted in an increase in flexural strength. A maximum rise of 4% is expected. The period of healing and the length of the fracture were also measured in the study. This demonstrates that bacterial concrete heals faster than ordinary concrete and can cure cracks up to 100µm in length.

(Mors and Jonker 2019), the study was written as part of the Material for Life (M4L) research initiative. Four alternative self-healing concrete methods were examined in this research programme. Microcapsules containing sodium silicate, porous aggregates containing microorganisms, shape memory polymers, and mineral healing agents are examples. The results reveal that fracture width and permeability diminish over time. The variation in crack width is assessed using an ultrasonic pulse velocity meter as well as an optical camera and microscope. The results demonstrate that sodium silicate-based capsules outperform others in terms of healing cracks greater than 100µm in length.

(S.Dinesh 2017), When compared to conventional concrete, introducing bacteria to concrete increased its compressive and tensile strengths while decreasing its permeability, water absorption, and reinforcement corrosion. By healing structural fractures, bacterial concrete significantly improves the structure's durability. Because of its inherent ability to precipitate calcite continually, the phrase "Smart Bio material" also applies to bacterial concrete. This material has been shown to be better to regular concrete since it is ecologically friendly and self-healing. Bacterial concrete will be produced in the near future for the building of long-lasting, inexpensive, and ecologically friendly high-quality structures. It is feasible to utilise since it will be more successful economically and practically because it requires specialist effort.

(Kunamineni Vijay 2017), Understanding how urease-producing bacteria isolates like Bacillus subtilis and Bacillus pasteuri species may be used to heal concrete cracks is critical to this work. The study looked at numerous bacterial species that may be used to mend fractures. Furthermore, this study found that bacteria increase the compressive strength of concrete and Portland cement mortar cubes. The use of bacteria has the benefit of lowering water penetration and chloride ion permeability. The present study's findings propose using "microbial concrete" as an alternative and superior concrete sealer that is cost-effective, ecologically friendly, and ultimately enhances the lifetime of building components.

(N. Ganesh Babu 2016), Bacterial concrete was made here, coupled with calcium lactate as a calcium the source. The compressive strength of 5% bacterial concrete rises by 2.63% as compared to normal concrete in the study programme. Bacteria were introduced in various quantities of 3.5% and 5%. The greatest results were obtained by combining 10% calcium lactate and 5% bacteria; the compressive strength increased by 4.35% above standard concrete.

(E. Tziviloglou 2016), The lightweight mortar with the built-in bacteria-based healing agent performs superior crack sealing in this research, especially when subjected to more realistic healing cycles such as wet/dry cycles rather than continual immersion in water. Oxygen consumption measurements and ESEM observations show that bacterial activity is the source of this enhanced behavior. When heavy sand is replaced with light aggregates, the compressive strength of the bacteria-based mortar is diminished. This material, on the other hand, might be used as an outer layer on a heavier building or whenever a lightweight structure is required. Overall, utilizing this material will be helpful for structures since its better crack sealing behavior will assist to minimize durability difficulties caused by micro cracking.

(Renée M. Mors 2012), The report gives a brief overview of the self-healing concrete being developed in Tudelft's Microlab. This is the fundamental step taken by "Mr. H. Jonker," the developer of self-healing concrete, towards bacterial concrete. This study discusses numerous bacteria that can be employed as self-healing agents in concrete. According to this, a calcium carbonate layer is created on the fracture surface by utilizing bacteria with a calcium source, sealing and inhibiting the access to stagnant materials.

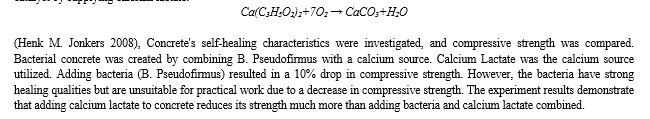

For a better understanding, the layer development was given by the following equations, where bacteria would only operate as a catalyst by supplying calcium lactate.

Conclusion

Following are the conclusions of the study: 1) The incorporation of bacteria in concrete has demonstrated the ability to enhance the healing capacity of concrete structures. The bacteria, typically of the genus Bacillus, have been found to produce calcium carbonate when activated in the presence of moisture and nutrients. This process helps to repair microcracks and restore the structural integrity of the concrete. 2) The healing process facilitated by the bacteria has shown promising results in terms of strength recovery. The production of calcium carbonate effectively fills the cracks, leading to improved load-bearing capacity and increased tensile strength of the concrete. This self-healing mechanism has the potential to extend the service life of concrete structures. 3) The utilization of bacterial self-healing concrete aligns with sustainable construction practices. The self-healing mechanism reduces the need for frequent repairs and maintenance, resulting in cost savings and reduced environmental impact. Additionally, the production of calcium carbonate by bacteria is a natural and environmentally friendly process. 4) The study has evaluated the performance of bacterial self-healing concrete under various conditions, including temperature variations, freeze-thaw cycles, and chemical exposure. The results indicate that the healing process remains effective and can withstand these challenging conditions, further highlighting the durability and resilience of this innovative concrete technology. 5) The study on strength properties of bacterial self-healing concrete has demonstrated its potential as a sustainable solution for enhancing the strength, durability, and longevity of concrete structures. The incorporation of bacteria in concrete has proven effective in healing microcracks, improving strength recovery, reducing permeability, and providing resilience under different environmental conditions. Further research and development in this field can lead to widespread adoption of bacterial self-healing concrete in the construction industry, promoting sustainable infrastructure and reducing maintenance costs.

References

[1] 10262 (2019). Concrete Mix Proportioning-Guidelines. New Delhi: Bureau of Indian Standards. Https://civiconcepts.com/wp-content/uploads/2020/11/4.IS-10262-2019-New-Mix-design.pdf [2] IS:1199 (1959). Methods of Sampling and Analysis of Concrete. New Delhi: Bureau of Indian Standards. [3] IS:2386 (1963). Methods of Test For Aggregate For Concrete. New Delhi: Indian Standards Institution. Https://law.resource.org/pub/in /bis/S03/is.2386.5.1 963.pdf. [4] IS:383 (2016). Coarse and Fine Aggregates for Concrete - Specification. BUREAU OF INDIAN STANDARDS. Http://skgcgroup.com/wp-content/uploads/2020/02/IS%20383-2016.pdf. [5] IS:516 (1959) Methods of Tests For Strength of Concrete. New Delhi: Bureau of Indian Standards. [6] IS:5816 (1999) Splitting Tensile Strength Of Concrete-Method of Test. New Delhi: Bureau Of Indian Standards. Https://www.iitk.ac.in/ce/test/IS-codes/is.5816.1999.pdf. [7] IS:8112 (2013) Ordinary Portland Cement, 43 Grade — Specification Bureau Of Indian Standards. Https://www.iitk.ac.in/ce/test/IS-codes/is.8112.2013.pdf. [8] Abishek Kumar A. A, Eveena Stephen, Merin George, Ansaf muhammad, Naveen Charles. 2020. Evaluation of Strength and Durability Properties for Various Amount of Bacillus Subtilis Bacteria in Concrete. International Journal of Engineering Research & Technology (IJERT) 548-551. Http://www.ijert.org. [9] Aditya Tadimeti, Jeff Sutton. 2020. The Effects of Different Aquatic Environments on the Rate of Polyethylene Biodegradation by Bacillus subtilis. Journal of Emerging Investigators ll: 1-7. Www.emerginginvestigators.org. [10] Bennett, Natalie. 2021. Twitter. June 29. Https://twitter.com/natalieben/status/1409902839434973184. [11] C. Manvith Kumar Reddy, B. Ramesh, Macrin D, Kanth reddy. 2020. \"Influence of bacteria Bacillus subtilis and its effects on flexural strength of concrete.\" Materials Today: Proceedings 1-6. Doi:https://doi.org/10.1016/j.matpr.2020.07.225. [12] 2019-20. Central Pollution Control Board Annual Report. Delhi, India: Ministry of Environment, Forest & Climate Change. Https://cpcb.nic.in/openpdffile.php?Id=umvwb3j0rmlszxmvmti0m18xnje2ntyxotaxx21lzglhcghvdg8xmtgzni5wzgy=. [13] 2021. Central Public Works Department. Delhi: Government of India. Https://cpwd.gov.in/Publication/DSR_2021_VOL_I_ENGLISH_Dir.pdf. [14] Henk M. Jonkers, Erik Schlangen. 2008. \"Development of a bacteria-based self healing concrete.\" Tailor Made Concrete Structures – Walraven & Stoelhorst 425-430. Https://www.researchgate.net/publication/267716612. [15] Jogi, Pavan Kumar, and T.V.S Vara Laxmi. 2021. \"Self healing concrete based on different bacteria: A review.\" materialstoday Proceedings 1246-1252. Doi:https://doi.org/10.1016/j.matpr.2020.08.765. [16] N. Ganesh Babu, Dr. S. Siddiraju. 2016. \"An Experimental Study on Strength and Fracture Properties of Self Healing Concrete.\" International Journal of Civil Engineering and Technology (IJCIET) 7 (3): 398-406. Http://www.iaeme.com. [17] Paul, sulav indra. 2021. \"Identification of marine sponge-associated bacteria of the Saint Martin’s island of the Bay of Bengal emphasizing on the prevention of motile Aeromonas septicemia in Labeo rohita.\" Aquaculture 1-13. Doi:doi:10.1016/j.aquaculture.2021.737156. [18] Renée M. Mors, Henk M. Jonkers. 2019. \"Bacteria?based self?healing concrete: evaluation of full scale demonstrator projects.\" RILEM Technical Letters 138-144. Doi:http://dx.doi.org/10.21809/rilemtechlett.2019.93. [19] Renée M. Mors, Henk M. Jonkers. 2012. \"Bacteria-based self-healing concrete-an itroduction.\" 32-39.

Copyright

Copyright © 2023 Vaidik Sharma, Prof. Mayur Singi. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET54586

Publish Date : 2023-07-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online