Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Review: Soil Stabilisation Using Agricultural Waste and Cementitious Material

Authors: Koushlandra Yadav, Preeti Tiwari, Pooja Singh

DOI Link: https://doi.org/10.22214/ijraset.2024.58303

Certificate: View Certificate

Abstract

Stabilization is a broad term that refers to the various methods used to improve the engineering performance of a soil and its application in a variety of engineering works. Soil stabilisation is a major concern for civil engineers today, both for road construction and for increasing soil strength or stability, which reduces construction costs. Soil stabilisation is the chemical or physical modification of soil properties to improve the soil\'s engineering quality. The primary goal of soil stabilisation is to increase the soil\'s bearing capacity, resistance to weathering processes, and permeability. Due to the rapid growth of urbanization and industrialization, minimizing industrial waste. Because of the rapid growth of urbanization and industrialization, reducing industrial waste has become a major issue in recent years. To encounter this innovative and nontraditional research on waste utilization is becoming increasingly important. Soil improvement using waste materials such as slags, rice husk ash, and silica fume has been recommended from an environmental standpoint in geotechnical engineering. This paper examines the effects of blast furnace slag, fly ash, and micro silica added to black cotton soil to improve soil properties. In addition, this paper provides a review of the use of various solid waste materials for soft soil stabilisation. However, there are numerous methods and techniques available for stabilising these soils. This study describes how waste materials can be used to stabilise soft soil.

Introduction

I. INTRODUCTION

Soft soils have low shear strength, low CBR, and alternate wetting and drying cycles. Soil strengthening increases bearing capacity, decreases settlement, and helps to reduce soil liquefaction. Since then, significant progress has been made in the construction and design of geotechnical structures such as foundations, embankments, pavements, and retaining walls. The need for soil stabilisation arises from a variety of challenges such as poor bearing capacity, a high rate of settlement after construction, excavation instability, and high construction costs; improve sub-grade strength on clayey soil. Soil stabilisation is the process of improving soil engineering properties by combining stabilizers to increase load bearing capacity and resistance to weathering. Various stabilising agents are used to improve the engineering properties of soft soils. These are primary (hydraulic) and secondary (non-hydraulic) additives that react with pozzolanic minerals and water to form a cementitious composite. The study's goal is to determine how soil can be stabilised using waste from various sources, including agriculture and industry. The various materials include bagasse ash, rice husk ash, fly ash, coir fiber, human hair fiber, banana fiber, and so on.

Soil improvement can be classified into several categories, including modification, stabilisation, or both. The modification can be accomplished by compacting, replacing the original soil, or combining soils. While stabilisation is the process of improving soil strength and durability to the point where they are completely suitable for construction. Many waste materials are used to change the properties of soft soil. Lime, cement, fly ash, and other materials help to stabilise the soil. The engineering properties of soft soil subgrade layer may need to be improved in order to make such soil suitable for construction using the stabilisation method. Pavement subgrade stabilisation used blast furnace slag, cement, fly ash, and micro silica fume.

II. REVIEW BASED ON STABILISATION WITH CEMENTITIOUS MATERIAL

The review is based on Stabilisation of material having cementitious properties such as fly ash, silica fume, GGBS are as follows-

J Bala Krishna (2017) presents the efficacy of sodium based alkaline activators and class F fly ash as an additive in improving the engineering characteristics of expansive Black cotton soils. Sodium hydroxide concentrations of 10, 12.5 and 15 molal along with 1 Molar solution of sodium silicate were used as activators. The activator to ash ratios was kept between 1 and 2.5 and ash percentages of 20, 30 and 40 %, relatively to the total solids. The effectiveness of this binder is tested by conducting the Unconfined compressive strength (UCS) at curing periods of 3,7 and 28 days and is compared with that of a common fly ash-based binder, also the most effective mixtures were analysed for mineralogy with XRD.

Suitability of alkaline activated fly ash mix as a grouting material is also ascertained by studying the rheological properties of the grout such as, setting time, density and viscosity and is compared with that of common cement grouts. Results shows that the fluidity of the grouts correlate very well with UCS, with an increase in the former resulting in a decrease in the latter. In this work a new idea of stabilizing the expansive soil using alkali activated fly ash was discussed. The chemical sodium hydroxide and sodium silicate were used as a chemical activator for the fly ash. The method of sample preparation, proportion of chemical additive, curing of sample and changes in basic geotechnical properties of expansive soil.

Er. Rehana Rasool (2017) studied to improve various engineering properties of the soil by using waste material Ground Granulated Blast Furnace Slag (GGBS) as an alternative to lime or cement, so as to make it capable of taking more loads from the foundation structures. This paper includes the evaluation of soil properties like unconfined compressive strength test and California bearing ratio test. The soil sample was collected from Lalru and addition to that, different percentages of GGBS (0%, 6%, 12 %, 18 % and 24%). was added to find the variation in its original strength. Based on these results CBR test was performed with the GGBS percentages (0%, 6%, 12 %, 18 % and 24%). From these results, it was found that optimum GGBS (18%) gives the maximum increment in the CBR value compared with all the other combinations.

S.W.Thakare, Priti Chauhan (2016) presents the results of stabilization of local black cotton soil with lime, fly ash and micro silica. Series of laboratory tests have been conducted with varying percentage of these stabilizers, added individually and in combinations, to determine their optimum percentages. From the results, it is observed that CBR value, for both soaked and unsoaked conditions, increases substantially by addition of 5% micro silica along with 3% fly ash and 3% lime. The pavement designed with these improved values of CBR indicated a marked reduction in its thickness leading to economy in the construction of road pavements on or using soft clayey soils.

Dayalan J (2016) has studied about the different amount of fly ash and GGBS are added separately i.e. 5, 10, 15 and 20% by dry weight of soil are used to study the stabilization of soil. The performance of stabilized soil are evaluated using physical and strength performance tests like specific gravity, atterberg limits, standard proctor test and California Bearing Ratio (CBR) test at optimum moisture content. From the results, it was found that optimum value of fly ash is 15% and GGBS is 20% for stabilisation of given soil based on CBR value determined.

Abdelzaher E. A. Mostafa et.al (2016) investigations have been carried out on clay subgrade soil; using several types of stabilizers. Due to the increase in traffic loads and the importance of subgrade layer in strengthen the pavement section to prevent the earlier damage. In this study the first step (based on the designed experimental program) samples were prepared with and without any additives; the used additives were lime (L), silica fume (SF), and nanosilica (NS). The tried percentages of lime were 2, 4, 6 and 8% and 5, 10 and 15% for SF, while 1, 2 and 3% used for NS. The second step was to examine the physical and mechanical properties of the prepared mixes using modified proctor test, Atterberg limits test, free swelling (FS%) test, unconfined compressive strength (UCS) and California Bearing Ratio (CBR) tests. Finally, direct shear (DS) test was carried out on the optimum mixes from the second step. All mixes were tested after two curing periods 7 and 28 days using UCS and FS%. The results indicated that the optimum moisture content (OMC) increased, while the maximum dry density (MDD) dramatically decreased for all used additives and plasticity index (P.I) decreased. The FS% decreased, and the maximum reduction in FS% was occurred at the two combinations (8% L + 15% SF) and (8%L+3%NS). The UCS increased by adding both SF and NS activated by lime to the test soil, and the optimum percentages of the two combinations were occurred at 6%L+10%SF and 6%L+3%NS for traditional and nanomaterials additives respectively. So, control samples and the two optimum combinations have been prepared for CBR and DS tests. The DS test was carried out at dry and submerged conditions, while CBR test was carried out at soaked condition. The results indicated that the maximum value of CBR occurred at 8% L + 10% SF, while DS results indicated that adding 6L+10SF and 6L+3NS, the soil parameters (cohesion and internal friction angle) have been improved.

Chhaya Negi, R.K.Yadav , A.K. Singhai (2013) studied that due to rapid growth of urbanization and industrialization, minimization of industrial waste is serious problem in present days. To encounter this innovative and nontraditional research on waste utilization is gaining importances now a days. Soil improvement using the waste material like Slags, Rice husk ash, Silica fume etc., in geotechnical engineering has been recommended from environmental point of view. The main objective of this study is to evaluate the feasibility of using Silica fume as soil stabilization material. In this paper the effect of Silica fume on engineering characteristics of expansive clay like Black Cotton Soil has been presented. A series of laboratory experiment has been conducted on black cotton soil blended with Silica fume content from 5% to 20% by weight of dry soil. The experimental results showed a significant increase in California bearing ratio and Unconfined compressive strength. The Differential free swell of the clay is reduced from 50% to 7% with increase in Silica fume content from 0% to 20% respectively.

The Proctor compaction results showed a small decrease in Maximum dry density and increase in Optimum moisture content. From this investigation it can be concluded that the Silica fume as a potential to improve the characteristics of black cotton soil.

III. REVIEW BASED ON STABILISATION WITH WASTE MATERIAL

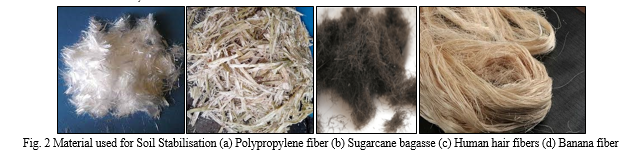

The review is based on Stabilisation of waste material such as polypropylene fiber, sugarcane bagasse , bagasse ash , human hair fibers, banana fiber, are as follows-

Ayyappan et. al (2010) analyzed polypropylene fiber with fiber lengths of sizes 6mm, 12mm and 24 mm for reinforcing the soil. Samples of soil-fly ash mix were made for MDD with variations from 0 to 1.5% by weight of fiber. For all soil-fly ash mix samples optimum percentage of reinforcement was adopted as 1% by weight of soil-fly ash mix. Maximum value was attained at 12mm length of fiber for reinforcement of soil-fly ash mix. For all mixes CBR value due to fibers length 12mm at 1% by dry weight was increased. The results showed that reinforced soil- fly ash mix with 12 mm fibers at 1% gave better performance.

Kawade1 et al. [2013] examined utilization of industrial and agricultural waste, sugarcane bagasse ash. Sugarcane ash had been physically and chemically differentiated and partly replaced in proportion of 10%, 15%, 20%, 25% and 30% of cement by weight. Fresh concrete properties such as slump and hardened concrete properties at the age of 7, 28, 56 and 90 days were tested. The outcomes indicated that characteristics of concrete increased with replacement of 15% SCBA in cement. The results showed that sugarcane ash mix concrete had considerably high strength in comparison to concrete without sugarcane ash. Hence, it could be concluded that cement can be replace by sugarcane ash up to a limit of 15%.

Wubshet [2013] evaluated the suitability of bagasse ash for stabilization of weak soil. They studied index properties of soil. The preliminary investigations of the soil showed that it belong to A-7-5 class in the soil classification system of AASHTO. Atterberg’s limits, free swell, free swell index, free swell ratio, compaction and subgrade strength tests were used to assess characteristics of stabilized soil. The soil was stabilized with bagasse ash in proportion of 5%, 10%, 15%, 20%, 25% and 30% by dry weight of the soil. Bagasse ash reduced plasticity index, swelling and MDD with an increase in OMC and CBR with all higher bagasse ash contents. It was found out that bagasse ash stabilized soil do not meet the minimum requirement of ERA (Ethiopian Roads Authority) pavement manual specification so that it could be used as a sub-grade material for pavement construction. Additional study is also incorporated as a supplementary work to investigate the effect of applying 3% lime as an activator in combination with 15% bagasse on the geotechnical properties of the soil for uncured and cured soil samples. The results indicated that lime in combination with bagasse ash is suitable for improving the plasticity index, swelling and CBR. The CBR value increased by curing showed that the mix had ability for time-dependent increase in strength that would decrease the amount of stabilizer required for the construction of roads on the soft soil. It showed that lime in combination with bagasse ash can be effectively used to improve expansive soils with low soaked CBR value and high plasticity.

Kharade et al. (2014) studied bagasse ash with partial replacement in black cotton soil in various proportions like 3%, 6%, 9%, 12%. They establish that optimum proportion of bagasse ash was 6%. The results at this proportion were like MDD increased by 5.8%, CBR increased by 41.52% and UCS increased by 43.58% which showed that, by adding bagasse ash CBR and compressive strength increased about 40%, whereas density showed considerable change only.

Butt et al. (2015) studied high compressibility clayey with human hair fibers as stabilizer in proportions of 0.5%, 1%, 1.5%, 2% and 2.5 % by weight to analyses human hair fibers outcomes on the performance of clay. HHF are non- biodegradable waste, which increase environmental and health problems. It is available in abundance and at low cost too, which could not be used as a reinforcement only to develop underprivileged locations for sustainable erection but also to reduce its disposal problems.

The HHF haphazardly distributed in soil specimens were tested for its various engineering properties by performing tri-axial test and CBR on different samples of reinforced soil and then these results were compared with virgin soil. At fiber length 25mm showed various advantages like superior strength characteristics, high toughness and low cost. Therefore, with increased quantity of human hair fibers, dry density first reduced slightly by incrementing the fiber and after that remained constant practically. Due to moisture absorption from hair fibers OMC increased slightly. It is found that 2% fiber enhance the un-drained shear strength and CBR of expansive soil greatly.

Teresa and Joy (2016) investigated banana fiber as soil stabilizer which is a waste material. Different tests like UCS, CBR, consistency limits, and compaction were conducted and outcomes were analyzed. The proportion of banana fiber varies from 0.25%, 0.75%, 1%and 2%. The banana fiber enhances the characteristics of soil. The optimal dosage of banana fiber was obtained at 0.75%for marine clay. It was found that dry density decreased and OMC increased with banana fiber. The shear strength changed from 8.5kN/m2 to 32.91kN/m2 with 0.75% of banana fiber and CBR changed from 2.79 to 13.2 which make it good for sub-grade.

Rathan et al. (2016) analyzed expansive soil using rice husk ash known as RHA by using different percentages 5%, 10%, 20%, 30%, 40%, 50% of it. Different test such as, liquid limit and plastic limit, free swell index, specific gravity, MDD and OMC, CBR and direct shear test were carried out. Values of LL and FSI were decreased abruptly by increasing the percentage in RHA. The OMC decreased gently from 17.89% to 13.25% and MDD increased from 16.39kN/m3 to 19.5kN/m3 for 80% rice husk ash for clay. For soil-RHA mix the undrained consistency was decreased from 60 KN/m2 to 30 KN/m2 and value of angle of friction (Φ) increased from 17°5' to 38°. The values of soaked CBR and the unsoaked CBR were increased from 2.4% to 4.4% and 3.2% to 9.3% respectively.

Subramani and Udayakumar (2016) analyzed soil stability by reinforcing it with waste coir fiber. Coir is a type of geo-textile which is cost effective. Lab tests such as stress state during a tri-axial test, UCS, direct shear test and CBR had been performed on virgin soil and reinforced soil with different percentages of coir like 0.25%, 0.50%, 0.75%, and 1%. The results for strength, CBR and UCS of reinforced soil were increased by increase in the proportion of coir fiber. Maximum enhancement in CBR and UCS were occurred with 0.5% of coir waste fiber. Results showed that 0.5% coir in the soil was optimum proportion having maximum value for soaked CBR. Therefore, this value could be used as economic stabilization.

Conclusion

It has been observed that as the percentage of fly ash and GGBS increases, the optimum moisture content decreases while the maximum dry density increases, resulting in an increase in soil compatibility and hardness. The soft soil has poor bearing capacity, making it unsuitable for construction. This study proposed low-cost and effective materials for soil stabilisation. This study found that using waste as a stabiliser helped to resolve the waste disposal crisis while also improving the engineering properties of soft soil and lowering construction costs when compared to other types of stabilising agents.

References

[1] J Bala Krishna, “Soil Stabilization with Flyash”, International Journal of Research Sciences and Advanced Engineering, Volume 2, Issue 19, PP: 196 - 208, Jul – Sep: 2017. 3) [2] Er. Rehana Rasool, Er. Kshipra Kapoor, “Comparative Study on Stabilization of Soil with Ground Granulated Blast Furnace Slag (GGBS)”, International Journal of Latest Research in Science and Technology, ISSN (Online):2278-5299, Volume 6, Issue 3, May-June 2017 4) [3] S.W. Thakare, Priti Chauhan, “Stabilization of Expansive Soil with Micro Silica, Lime and Fly Ash for Pavement”, International Journal of Engineering Research, ISSN:2319-6890(online), 2347- 5013(print), Volume No.5, Issue Special 1 pp: 09- 13, 8 & 9 Jan 2016 5) [4] Dayalan J, “Comparative Study on Stabilization of Soil with Ground Granulated Blast Furnace Slag (GGBS) and Fly Ash”, International Research Journal of Engineering and Technology, e-ISSN: 2395 -0056, p-ISSN: 2395-0072, Volume: 03 Issue: 05 6) [5] Abdelzaher E. A. Mostafa, Mohamed. S. Ouf and Mokhtar F. Elgendy “Stabilization of Subgrade Pavement Layer Using Silica Fume and Nano Silica” International Journal of Scientific & Engineering Research, Volume 7, Issue 3, March-2016 7) [6] Chhaya Negi, R.K.Yadav , A.K. Singhai, “Effect of Silica Fume on Engineering Properties of Black Cotton Soil”, International Journal of Computational Engineering Research, Vol, 03, Issue, 7. [7] Ayyappan S., Hemalatha, M.K. and Sundaram M., “Investigation of Engineering Behavior of Soil, Polypropylene Fiber and Fly Ash-Mixtures for Road Construction”, International Journal of Environmental Science and Development, vol.1, no.2, pp.171, 2010. [8] Kawade U. R., V. R. Rathi, andVaishali D. Girge. \"Effect of Use of Bagasse Ash on Strength of Concrete.\" International Journal of Innovative Research in Science, Engineering and Technology vol.2, no. 7, pp. 2997-3000, 2013. [9] Wubshet M. “Bagasse Ash as a Sub-grade Soil Stabilizing Material” Doctoral dissertation, Dept. Geotech. Engineering, Addis Ababa University, Ethiopia, 2013. [ [10] Kharade A.S., Suryavanshi V.V., Gujar B.S. and Deshmukh R.R., “Waste Product Bagasse Ash from Sugar Industry can be Used as Stabilizing Material for Expansive Soils”. International Journal of Research in Engineering and Technology, vol.3, no.3, pp.506-512, 2014. [11] Butt Wajid Ali, B. A. Mir, and J. N. Jha. \"Strength Behavior of Clayey Soil Reinforced with Human Hair as a Natural Fiber\", Geotechnical and Geological Engineering, vol. 34, no.1, pp.411-417, 2016. [12] Teresa Sunny and Annie Joy “Study on the Effects of Clay Stabilized with Banana Fiber’’, International Journal of Scientific Engineering and Research (IJSER), vol.4, pp.96-98,2016. [13] Ramesh S.T. and Naik U.P., “Stabilization of Expansive Soil”, International Journal of Engineering and Innovative Technology, vol. 5 no. 12, pp.71-77, 2016. [14] Sodhi Navdeep Singh, Shish Pal, and Sonthwal Vinod K. \"Soil Strengthening Using Waste Materials\" International Research Journal of Engineering and Technology (IRJET), vol. 4, no. 12, pp. 1731-174, 2017.

Copyright

Copyright © 2024 Koushlandra Yadav, Preeti Tiwari, Pooja Singh. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET58303

Publish Date : 2024-02-05

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online