Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- References

- Copyright

Adding Fibers for Improving the Properties of Concrete and its Impact Resistance

Authors: Mohammed Ali Younus Alqasi, Masoud Ehmed Suliman Ehmed, Farhat Eljelane Abubaker

DOI Link: https://doi.org/10.22214/ijraset.2024.65165

Certificate: View Certificate

Abstract

This study is summarized in the search for the possibility of using fiberglass to improve the bending resistance of beams, and to obtain results that can be analyzed and some recommendations can be drawn, 18 concrete beams with a length of 70 cm and a cross-sectional area of 10x20 cm were cast and tested, five of them contain main reinforcement in the tension area and fiber-reinforced concrete that was placed in the casting mold at different depths from the lower surface level of the beams from the depth of the beam, and a beam without fibers was cast as a model for comparison, and the fifth reinforced with beams only in the shear areas was also used as a model for comparison, and 4 other beams not reinforced with main steel in the tension area and reinforced concrete for the depth of the beam and another containing normal concrete. Through this study, it became clear that the presence of fiber concrete in the compression zone for structural elements that are subject to bending clearly affects the structural behavior, as the amount of sagging increases, especially under the influence of weak loads, compared to the value of the total collapse load obtained from one of the beams that were tested.

Introduction

I. INTRODUCTION

Different types of fibers are used to improve the specifications of normal concrete and its impact resistance, and not all of these types can be used in high-strength concrete, as the physical properties of some commercial types of fibers do not allow their use in high-strength concrete. Among these types, plastic fibres are rarely used to improve the mechanical properties of high-strength concrete, except to enhance its fire resistance and in some cases its impact resistance. These plastic fibers have a very weak modulus of plasticity that cannot significantly improve the hardness of concrete, which is usually required when adding fibers to concrete at the present time. Steel fibers or carbon fibers can also be added to high-strength concrete. For example, steel fibers are used in seismically active areas, and they can also be used when the cost of bars becomes high so that using fibers is more economical. However, in general, adding steel fibers does not improve the compressive strength of high-strength concrete as we want, as is the case with other types of concrete, in addition to the fact that fibers reduce the workability of concrete. Concrete beams are considered important elements in construction works, and are always designed to resist shear forces, bending moments and torsional moments, and their importance increases the better and less costly their resistance to these forces. Based on the above, in this research we try to study the shear and bending resistance of beams reinforced with fiberglass concrete and the possibility of benefiting from fiberglass material to resist shear forces.

Resistance is generally considered one of the most important properties of concrete, as it expresses several properties such as durability and impermeability, and because it gives a comprehensive picture of the quality of concrete, due to its direct relationship with the structure of the hardened cement paste. Sometimes durability is more important than resistance when concrete is exposed to physical and chemical effects, and concrete with high resistance is usually less permeable and more solid. Resistance results from the resistance of the cement mortar, the strength of the adhesion between the cement mortar and the coarse aggregate particles, and the resistance of the coarse aggregate to the stresses imposed on it [1, 2].

Concrete in general has many types, each of which has a specific property or characteristic that distinguishes it from others and gives the purpose of its use. For example, foundation concrete resists heavy loads and resists corrosion resulting from chemical reactions from salts present in the soil, and concrete used in road construction resists weathering factors... etc. Each type of concrete has a distinctive characteristic that makes it more suitable for a specific construction work than others - but there is an important common characteristic, which is the resistance of concrete to pressure [3, 4]. The purpose for which any concrete structure is built can be summarized in a basic function, which is to resist the forces acting on it, whatever their nature.

II. PREVIUS STUDY

The mechanical properties of reinforced concrete can be improved early by using ultra-high performance fibers (UHPFRC). On the other hand, the use of steel fibers and polypropylene as additives to high strength concrete (HSC) improved the mechanical properties at each volume fraction. Moreover, it was observed that the tensile strength at splitting and flexural strength of concrete were significantly enhanced [8]. The introduction of fibers into concrete resulted in a decrease in water absorption, and a significant or slight decrease in the electrical resistance of concrete when compared to normal concrete [9]. The recycled high density plastic fibers when added to concrete slightly increased the tensile strength and flexural modulus (fracture), while the compressive strength and modulus of elasticity of concrete were not affected. The fibers mainly contributed to providing flexural ductility after cracking and by improving the service properties of concrete such as reducing plastic shrinkage, cracking, and shrinkage during drying and water permeability [10].

Engineers at the Technical University of Dresden have succeeded in manufacturing a woven concrete bridge that can withstand a weight of more than 30 tons, i.e. 265 normal people standing on it at once without being affected. The bridge remained stable despite the weight of 30 tons being placed on it and began to collapse after the weight was raised to 38 tons. This bridge weighs 5 tons, while a similar bridge made of concrete and traditional materials usually weighs 25 tons. Experiments have confirmed that the lifespan of the innovative bridge material is no less than its durability, and laboratory estimates indicate that the bridge will remain standing and sturdy for at least 50 years, which is the same estimated age of an iron and concrete bridge of the same standards. The bridge was also subjected to numerous tests, especially in the areas of vibration and sound, and it has proven to be highly durable [5].

According to the engineers, the era of heavy steel-reinforced concrete is over and has been replaced by the era of lightweight, yet durable, fabric concrete. The new material is lightweight and durable thanks to a network of glass and carbon fibers that permeate the concrete and replace the steel reinforcement. Laboratory experiments have shown that fabric concrete is more durable than reinforced concrete [6, 7].

III. THE PRACTICAL SIDE

A. Concrete Mix Proportions

TABLE I

Weights in concrete mix

|

Material kg/m3 |

Cement |

Coarse Aggregate |

Fine Aggregate |

Water |

Fibers |

|

350 |

1090 |

750 |

175 |

0.6 |

B. Materials used and their Properties

TABLE ii

Chemical composition of used cement

|

Contents |

Ratio |

|

Sio2 |

22.2 % |

|

Al2o3 |

% 4.76 |

|

Fc2o3 |

%4.88 |

|

Cao |

%63.93 |

|

Mgo |

%1.98 |

|

So3 |

%2.25 |

TABLE III

Physical properties of used cement

|

Test |

Results |

Libyan Standard Specifications Limits No.(12/2000) |

|

Initial doubt time (hour) |

2:38 |

Not less than 45 minutes |

|

Final doubt time (hour) |

5:25 |

Not more than 10 hours |

|

Volume constant Ma (mm) |

5 |

Not more than 10 mm |

|

Specific gravity |

3.15 |

Compatible |

TABLE IV

Physical properties of fine aggregate

|

Test |

Test Results |

British Specification |

|

Specific gravity |

2.62 |

2.6 –2.7 |

|

Unit weight (Kg/m3) |

1610 |

1400-1800 |

TABLE V

Sieve Analysis of Fine Aggregate

|

Sieve mm |

Remaining on each sieve |

Cumulative weight gm |

Reserved percentage % |

Passing percentage % |

|

2.38 |

0 |

0 |

0 |

100 |

|

1.18 |

0 |

0 |

0 |

100 |

|

0.6 |

7.9 |

7.9 |

1.58 |

98.42 |

|

0.3 |

220.4 |

228.3 |

45.66 |

54.34 |

|

0.15 |

268.6 |

496.9 |

99.3 |

0.7 |

|

Pan |

6.9 |

503 |

100.6 |

0 |

TABLE VI

Physical properties of coarse aggregate

|

Test |

Test Results |

Libyan Standard |

|

Specific gravity |

2.63 |

2.6 –2.7 |

|

Unit weight (Kg/m3) |

1707 |

1400-1800 |

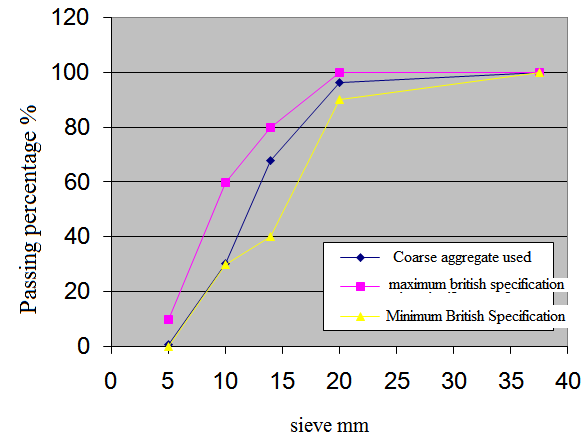

Fig 1: Sieve analysis of coarse aggregate

C. Treatment

The appropriate treatment method was chosen based on the capabilities and conditions available in the laboratory. The water immersion method was used, which is considered the most efficient method, but it is not practical because it requires a large amount of water. Therefore, its use is limited to small laboratory samples, cubes in water for 7 and 28 days. The wet covers method is considered the economical method, as wet burlap was used to retain water and ensure that it remains wet for a long time without interruption on the cameras.

D. Tests and results

1) The relationship between defliction and the load for beams

a) Defliction and the load for beams without reinforcement in the tension zone

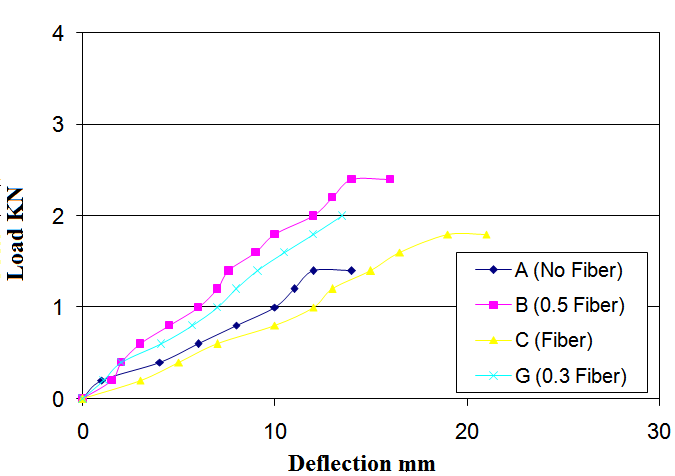

Figure 2 shows the results for the beams tested under the influence of bending load, where the maximum value of the total load achieved was 2.37 KN for the beam containing fibers at 50% of the cross-sectional area. As for the beam containing glass fibers in the entire section, the softening value was high, reaching 21.8 mm at the maximum breaking load of approximately 2.0 kN. Therefore, noted that the presence of glass fibers in the compression zone weakened the resistance of beam C to bending compared to beam A, which did not contain fibers. The clear improvement in the structural behavior of beam C due to the presence of glass fibers in the entire section had a positive effect in increasing the resistance of the beam, in addition to the improvement in the softening value, which achieved the best results for beams that did not contain reinforcing steel in the tension zone. As for the rest of the beams, their results were average.

In general, although the collapse of the beams was in the shear zone, the achieved softening values show us that there is a safety factor for these beams that should be utilized in design, especially from an economic perspective.

Fig 2: load and deflection for beams without reinforcement in the tension zone

b) The relationship between the relaxation and the load for beams reinforcement in the tension zone

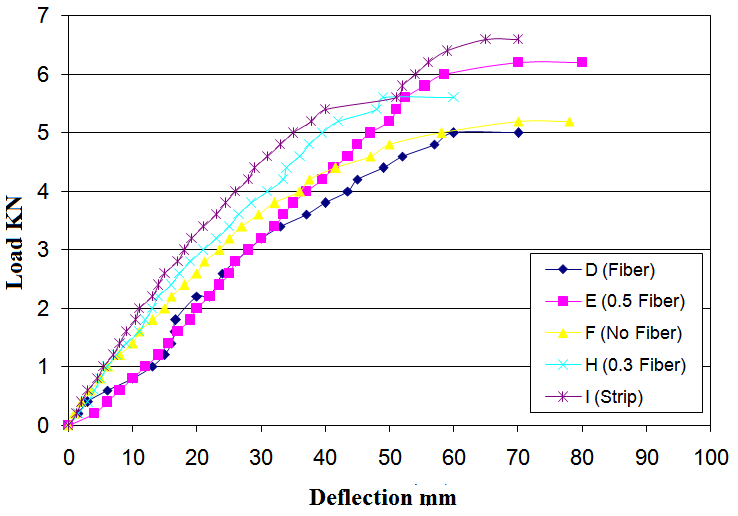

Figure 3 shows that the use of glass fibers gives the possibility of flexibility to the reinforced beams in the tension zone, and considering that beam D contains glass fibers in the entire section, it recorded a good value for sagging of 70 mm at a fracture load of 5.0 kN, while the beams that do not contain fibers recorded a sagging value of 78 mm at a fracture load of 5.2 kN. Therefore, from the figure, we notice that the presence of glass fibers in the entire section gave the concrete more flexibility without improving the load value, in addition to the fact that the change from the stage of flexibility to plasticity was clear in the beam that contains fibers in the entire section. Beam I, reinforced with trusses in the shear zone, showed better results for the modulus of elasticity compared to beam D, which contains fibers to resist shear. However, for beam H, which only contains fibers at a distance of one-third of the section depth in the tension zone, we note that the fibers contributed to improving the bending resistance and obtaining the elongational collapse. This is in contrast to the structural behavior of beam F, which does not contain reinforcement in the shear zone, which collapsed suddenly in the bending zone, which is unexpected. Perhaps the reason is due to the high percentage of the main reinforcing steel in the tension zone.

Fig 3: load and deflection for reinforced beams in the tension zone

2) Strain and load

a)For Beams Without Reinforcement

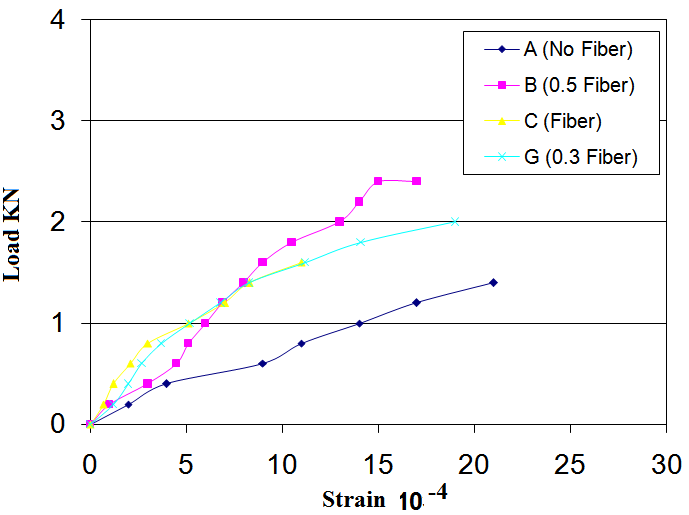

Figure 4 shows the relationship between strain and load on beams without reinforcement in the tension zone. It was noted that the maximum strain value for beam A was 0.0022 achieved at a load of 1.38 kN, and compared to the beam containing glass fibers in the entire section, the maximum strain value was 0.0014 at a load of 2.1 kN. Therefore, the presence of glass fibers improved the resistance of the section, especially in the shear zone where collapse is expected. As for the compression zone, it was noted that the resistance of the concrete was weak, which indicates that the presence of fiber concrete in half the section in the tension zone achieved a better improvement in the structural behavior of the beam.

The results were better when fiber concrete was used only in one-third of the section depth in the tension zone. Indeed, the effect of fibers in the compression zone weakens the resistance of concrete to pressure. Consequently, the strain value is affected, especially since the strain values in this test were measured in the compression zone. Beam B containing fiber concrete in half the section depth in the tension zone recorded good results compared to the beams without main reinforcement in the tension zone where the maximum load value was 2.4 kN at which the strain value was 0.0016.

Fig 4: load and strain in concrete for beams without reinforcement in the tension zone

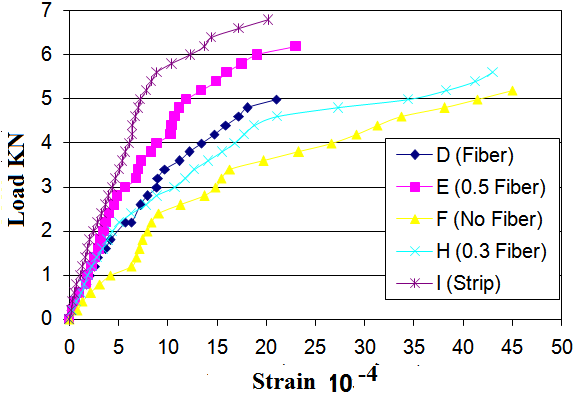

b) Reinforced beams in the tension zone

Figure 5 shows the relationship between load and strain for beams reinforced with 2Φ10mm main steel in the tension section. Compared to beam I reinforced with trusses in the shear zones, all strain results for the beams shown in the figure recorded higher values for the same loads. The presence of fiber concrete in the compression zone for the beams tested was the main reason for the decrease in the strain value for the concrete elements exposed to bending. While the presence of fiber concrete in half the total depth of the beam in terms of tension achieved good strain results and improved the total load value and a clear increase when calculating the elasticity modulus value.

Beam F achieved the highest strain value of 0.0052 at a total load of 5.18 kN. The absence of reinforcement in the shear zone contributed to obtaining a very high strain that achieved good structural behavior for concrete compression under the influence of bending. In addition, the collapse that occurred for beam F was unexpected as it collapsed suddenly in the tension zone, and the reason, as previously stated, may be due to the high percentage of reinforcement in the tension zone.

Beam E reinforced with 2Φ10mm main reinforcement in addition to the presence of glass fibers in the tension zone at a depth of 50% of the total depth of the section showed results that were approximately average between the values obtained from beam I and beam D. This shows that the possible limit for using fiber concrete to reinforce concrete sections that are subject to bending in the tension zone is 50% of the total depth of the section, as the presence of fiber concrete in the compression zone of concrete elements subject to bending had a negative effect on most of the values obtained when measuring the strain of concrete in the compression zone.

Fig 5: load and strain in concrete for reinforced beams in the tension zone

IV. RESULTS

- The presence of fiber concrete in the compression zone for structural elements subject to bending clearly affects the structural behavior as the amount of sagging increases under the influence of weak loads compared to the total collapse load value.

- The use of fiber concrete in the tension zone for concrete elements subject to bending improves the value of the first load for cracking, as the cracks are well distributed on the surface of the concrete, which makes it possible to reduce their expansion, in addition to the fact that the presence of fibers in the tension zone increases the resistance of these elements to bending.

- The behavior of the equilibrium axis plane in concrete sections containing fibers is completely different from those that do not contain fibers, as shown by this study in all sections that partially contain fiber concrete, so it is necessary to conduct extensive studies and tests when using fiber concrete partially to correct the design equations.

- Most of the beams in which fiber concrete was used showed the first cracking at a load of approximately 90% of the total load value for the beam collapse. Therefore, it is difficult to predict the safety factor according to the design equations used, and it is necessary to verify this and make the required corrections to the equations.

References

[1] BAECHLE, Thomas R.; EARLE, Roger W. (ed.). Essentials of strength training and conditioning. Human kinetics, 2008.? [2] GROUDEN, Melissa E.; JOSE, Paul E. Do sources of meaning differentially predict search for meaning, presence of meaning, and wellbeing. International journal of wellbeing, 2015, 5.1.? [3] SETAREH, Mehdi; DARVAS, Robert. Concrete structures. Pearson/Prentice Hall, 2007.? [4] MEDDAH, Mohammed Seddik; BENCHEIKH, Mohamed. Properties of concrete reinforced with different kinds of industrial waste fibre materials. Construction and building materials, 2009, 23.10: 3196-3205.? [5] UNTERMARZONER, Franz, et al. Deck Slab Elements for the Accelerated Construction of Steel–Concrete Composite Bridges. Applied Sciences, 2023, 13.13: 7825.? [6] WU, Taige. Research on the application of high performance concrete and steel structure combination in civil engineering. Applied Mathematics and Nonlinear Sciences, 2024, 9.1.? [7] SMITH, D. G. E.; POMONIS, A. Steel reinforced concrete: The Japanese perspective on earthquake resistant composite construction. In: Seismic Design and Practice into the Next Century. Routledge, 2022. p. 341-351.? [8] YOO, Doo-Yeol; BANTHIA, Nemkumar. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cement and Concrete Composites, 2016, 73: 267-280.? [9] AFROUGHSABET, Vahid; OZBAKKALOGLU, Togay. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Construction and building materials, 2015, 94: 73-82.? [10] PEŠI?, Ninoslav, et al. Mechanical properties of concrete reinforced with recycled HDPE plastic fibres. Construction and building materials, 2016, 115: 362-370.?

Copyright

Copyright © 2024 Mohammed Ali Younus Alqasi, Masoud Ehmed Suliman Ehmed, Farhat Eljelane Abubaker. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65165

Publish Date : 2024-11-11

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online