Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Advanced Fault Detection Techniques in Electric Vehicle Electrical Systems Using MATLAB: A Comprehensive Review

Authors: Suprotip Ghosh Hazra, Prof. Rekha A. Chaudhari, Abhishek M. Pandey, Omkar R. Kale, Niteen J. Kharade

DOI Link: https://doi.org/10.22214/ijraset.2024.63253

Certificate: View Certificate

Abstract

Electric vehicles (EVs) are pivotal in transitioning to sustainable transportation, offering significant environmental benefits over traditional internal combustion engine vehicles. However, EVs\' reliability and safety hinge critically on their electrical systems\' robustness. Faults within these systems, particularly in the motor drives, battery packs, and power electronics, can lead to catastrophic failures, compromising vehicle performance and passenger safety. Therefore, advanced fault detection techniques are essential for ensuring the dependable operation of EVs, minimizing risks, and reducing maintenance costs. This comprehensive review paper delves into the state-of-the-art fault detection methodologies applied to EV electrical systems, focusing on using MATLAB for simulation and analysis. This review\'s scope encompasses various fault detection techniques, including model-based approaches, signal processing methods, data-driven algorithms, and hybrid techniques. These methodologies are critically analysed for their effectiveness in identifying and diagnosing faults in key EV components such as motors, batteries, and power electronics. Key findings from the reviewed literature indicate that model-based techniques, which rely on mathematical models to predict normal system behaviour, are highly effective in scenarios where the system dynamics are well-understood. Signal processing techniques, utilizing tools like Fourier and wavelet transforms, are adept at detecting faults characterized by specific signal patterns. Data-driven approaches, leveraging machine learning and statistical methods, excel in complex systems where fault characteristics are not easily modelled. Hybrid techniques that integrate multiple approaches offer enhanced fault detection capabilities, combining the strengths of each method. This paper highlights the significant role of MATLAB in developing and implementing these fault detection techniques. MATLAB\'s extensive toolboxes, such as the Control System Toolbox, Signal Processing Toolbox, and Neural Network Toolbox, provide powerful computational and visualization capabilities, facilitating the development of robust fault detection algorithms. With its graphical modelling environment, Simulink is particularly noted for its utility in simulating EV systems and fault scenarios, enabling comprehensive analysis and validation of fault detection strategies.

Introduction

I. INTRODUCTION

The global transportation sector is transforming towards electric vehicles (EVs) to reduce the environmental impact of conventional internal combustion engines (ICEs) and address the pressing challenges of climate change and energy security. EVs, which encompass battery electric vehicles (BEVs), hybrid electric vehicles (HEVs), and fuel cell electric vehicles (FCEVs), offer significant advantages in terms of reduced greenhouse gas emissions, improved energy efficiency, and lower operational costs. However, the widespread adoption of EVs is contingent upon addressing critical concerns related to their reliability, safety, and overall performance. Electric vehicles are complex systems that rely heavily on their electrical components, particularly the motor drive and battery systems, which are subject to various faults and degradation mechanisms. Faults in these critical subsystems can lead to unexpected failures, compromising the vehicle's performance, efficiency, and, more importantly, the safety of passengers and other road users. Consequently, developing advanced fault detection techniques tailored specifically for EV electrical systems has emerged as a crucial area of research and development. Effective fault detection and diagnosis strategies are essential for ensuring the reliable operation of EVs and enabling proactive maintenance, thereby minimizing the risk of catastrophic failures and associated costs. Early detection of faults can facilitate timely corrective actions, extend the lifespan of critical components, and ultimately enhance the overall user experience and acceptance of EVs. Furthermore, robust fault detection techniques can contribute to developing fault tolerant control strategies, enabling continued operation under certain fault conditions, thereby improving EV systems' overall resilience and safety.

The increasing complexity and integration of these systems further underscores the importance of fault detection in EV electrical systems. As EVs continue to evolve, incorporating advanced technologies such as distributed motor drives, highly integrated power electronics, and sophisticated battery management systems, the potential for faults and the need for reliable fault detection mechanisms become even more critical. Additionally, the safety-critical nature of transportation systems demands stringent fault detection and diagnosis capabilities to ensure the continuity and reliability of EV operation. The primary objective of this comprehensive review paper is to provide a thorough examination of advanced fault detection techniques specifically tailored for electric vehicle electrical systems, with a particular emphasis on the application of MATLAB-based computational tools and simulations. The review aims to synthesize and critically analyse the state-of-the-art methods, algorithms, and approaches employed in the fault detection and diagnosis of EV motor drives, battery systems, and other electrical components. The scope of this review encompasses a wide range of fault detection techniques, including model-based approaches, signal-based methods, data-driven algorithms, and hybrid techniques that combine multiple strategies. The review will explore the application of various computational tools, such as MATLAB/Simulink, for modelling, simulation, and analysis of EV electrical systems under both healthy and faulty conditions. Additionally, the review will examine the integration of advanced signal processing techniques, machine learning algorithms, and deep learning architectures for enhancing fault detection accuracy, robustness, and real-time performance. Furthermore, the review will delve into the specific challenges and considerations associated with fault detection in different components of EV electrical systems. For instance, in the context of motor drives, the review will explore techniques for detecting faults such as demagnetization, eccentricity, inter-turn short circuits, and winding failures in permanent magnet synchronous motors (PMSMs), which are widely used in EVs. Additionally, the review will investigate fault detection methods for battery systems, addressing issues such as cell inconsistency, thermal faults, and capacity degradation, which are crucial for ensuring the safety and longevity of EV battery packs. The review will also examine the application of advanced computational tools, such as finite element analysis (FEA) and numerical simulations, for modelling and analysing fault scenarios in EV electrical systems. These techniques can provide valuable insights into the behaviour of faults and their impact on system performance, enabling the development and validation of effective fault detection strategies. The review will address the challenges and limitations associated with existing fault detection techniques, highlighting the research gaps and opportunities for further advancements. Particular attention will be given to the unique requirements and constraints of EV electrical systems, such as the need for real-time fault detection, cost-effectiveness, and the ability to operate under varying operating conditions and fault scenarios. Additionally, the review will explore emerging trends and future directions in fault detection for EV electrical systems, including the integration of advanced technologies such as blockchain, Internet of Things (IoT), and edge computing for secure and distributed fault monitoring and diagnosis. By providing a comprehensive overview of advanced fault detection techniques and their application in EV electrical systems, this review paper aims to serve as a valuable resource for researchers, engineers, and practitioners involved in the development, testing, and deployment of reliable and safe electric vehicles. It will contribute to the ongoing efforts in advancing the state-of-the-art in fault detection and diagnosis, ultimately enhancing the overall reliability, safety, and performance of electric vehicles, and accelerating their widespread adoption in the transportation sector.

II. ELECTRIC VEHICLE ELECTRICAL SYSTEM OVERVIEW

As an environmentally friendly and sustainable alternative to conventional internal combustion engines, electric vehicles (EVs) are rapidly gaining traction. At the heart of an EV lies its electrical system, which is responsible for powering the vehicle's propulsion and auxiliary systems. This electrical system is a complex and integrated network of various components, each playing a critical role in ensuring the vehicle's overall performance, efficiency, and safety. In this section, we will provide an overview of the main components that constitute the EV electrical system and discuss the common faults that can occur within these components.

A. Main Components

The battery pack is the primary energy source in an EV, storing and supplying the electrical energy required for propulsion and auxiliary systems. Lithium-ion batteries are the most used technology in modern EVs due to their high energy density, relatively long lifespan, and reasonable cost. The battery pack typically consists of multiple battery modules, each containing numerous individual battery cells connected in series or parallel configurations to achieve the desired voltage and capacity requirements. Electric motors convert electrical energy from the battery pack into mechanical energy to rotate the wheels, with permanent magnet synchronous motors (PMSMs) and induction motors being widely used due to their high efficiency, compact size, and excellent power density, particularly PMSMs for their high torque density and reliability.

Power electronics components, such as inverters and converters, play a crucial role in managing and controlling the flow of electrical energy within the EV system; inverters convert direct current (DC) from the battery pack into alternating current (AC) to drive the electric motors, while converters regulate and condition the voltage levels for various electrical loads and subsystems. Control systems, consisting of a central electronic control unit (ECU) and various embedded controllers and sensors, are responsible for coordinating and managing the operation of the various components within the EV electrical system, with the ECU acting as the brain of the EV by processing sensor data, executing control algorithms, and providing commands to actuators and other components to ensure optimal performance, efficiency, and safety.

???????B. Common Faults in EV Electrical Systems

Despite the inherent advantages of EVs, their electrical systems are susceptible to various faults and failures that can compromise the vehicle's performance, reliability, and safety. Detecting and diagnosing these faults in a timely and accurate manner is crucial for ensuring the proper functioning of the EV and preventing potential hazards or costly repairs. Some common faults that can occur in EV electrical systems like battery faults which include issues such as overcharging or over discharging of battery cells, leading to degradation or thermal runaway, cell inconsistency or imbalance within the battery pack causing uneven aging and reduced capacity, internal short circuits or open circuits within battery cells or modules, and thermal faults due to excessive heating or cooling issues. Motor faults encompass winding short circuits, including inter-turn, turn-to-ground, and phase-to-phase faults, demagnetization, or eccentricity faults in permanent magnet motors, bearing faults or rotor faults leading to vibrations and mechanical degradation, and stator or rotor insulation failures. Power electronics faults involve insulated gate bipolar transistor (IGBT) failures in inverters or converters, gate driver circuit faults or control signal issues, capacitor aging or failures in DC-link or snubber circuits, and electromagnetic interference (EMI) or electromagnetic compatibility (EMC) issues. Lastly, sensor and actuator faults consist of sensor failures or drifts affecting accurate measurement of parameters like voltage, current, temperature, or position, actuator faults such as stuck or sluggish response in contactors, relays, or solenoids, and communication faults or data corruption in sensor or actuator networks. Detecting and diagnosing these faults is crucial for maintaining the reliability, safety, and efficient operation of EVs. Advanced fault detection techniques, leveraging computational tools like MATLAB, signal processing, machine learning, and data-driven approaches, can play a vital role in addressing these challenges. By accurately identifying and characterizing faults in the EV electrical system, appropriate corrective actions can be taken, enabling proactive maintenance, fault mitigation strategies, and potentially extending the lifespan of critical components. Furthermore, the integration of fault detection systems with other vehicle subsystems, such as battery management systems (BMS) and vehicle control systems, can facilitate coordinated fault handling and enable fault-tolerant operation modes. This can ensure the continued operation of the vehicle, albeit with potentially reduced performance, until a safe stop or maintenance intervention can be achieved.

III. FAULT DETECTION TECHNIQUES

A. Overview of Fault Detection

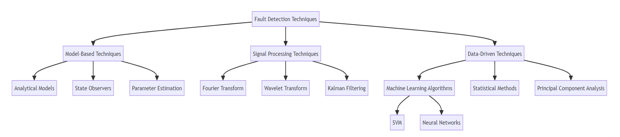

Fault detection is the process of identifying and recognizing deviations from normal operating conditions or expected behaviour in a system or component. In the context of electric vehicle (EV) electrical systems, fault detection plays a crucial role in ensuring reliable and safe operation by identifying potential faults or failures before they escalate into catastrophic events. Effective fault detection techniques can enable timely corrective actions, proactive maintenance, and fault mitigation strategies, ultimately enhancing the overall performance, efficiency, and lifespan of the EV electrical components. Fault detection techniques can be broadly classified into three main categories: model-based techniques, signal processing techniques, and data-driven techniques. These techniques leverage various computational tools, mathematical models, signal analysis methods, and machine learning algorithms to analyse the system's behaviour and detect anomalies or deviations from expected patterns.

???????B. Model-Based Techniques

Model-based fault detection techniques rely on mathematical models that describe the expected behaviour of the system or component under consideration. These models can be analytical, based on first principles and fundamental laws of physics, or empirical, derived from experimental data or system identification processes. Model-based techniques are particularly useful when the system dynamics and fault characteristics are well understood and can be accurately described by mathematical equations. Some techniques like Analytical models that are derived from the fundamental principles of physics, including electromagnetic theory, circuit theory, and mechanical dynamics. These models are extensively used to simulate the behaviour of electric vehicle (EV) electrical components such as electric motors, power electronics, and battery systems.

By comparing the simulated behaviour of these components with actual system measurements, deviations can be detected and analysed to identify potential faults. This method provides a comprehensive understanding of how different components should function under normal conditions, making it easier to spot anomalies that indicate faults. State observers also play a crucial role in model-based fault detection techniques. These observers estimate the internal states of a system based on the measured inputs and outputs, using a precise mathematical model of the system dynamics. By comparing the estimated states with the actual measured states, discrepancies can be identified. These discrepancies often point to potential faults or errors in the modelling process, thus serving as an early warning system for maintenance needs and system reliability. Parameter estimation techniques are another essential tool in the fault detection arsenal. These techniques involve estimating the values of specific system parameters, such as resistance, inductance, or friction coefficients, by analysing the measured system inputs and outputs. Any significant changes in these parameter values can indicate the presence of faults. For instance, an unexpected increase in resistance could suggest a deteriorating connection or material degradation, while changes in inductance might signal issues with the magnetic properties of motor components. By continuously monitoring and updating these parameters, faults can be detected and identified promptly, enabling timely interventions to prevent more serious system failures.

???????C. Signal Processing Techniques

Signal processing techniques analyse the measured signals from various sensors and components within the EV electrical system to detect and characterize faults. These techniques are particularly useful when the fault signatures are present in the signal characteristics, such as amplitudes, frequencies, or time-domain patterns. Some techniques like Fourier transform which is a powerful signal processing tool that decomposes a time-domain signal into its constituent frequency components. In electric vehicle (EV) electrical systems, various faults can introduce specific frequency components or harmonics into the measured signals, such as motor currents or vibration signals. By analysing the frequency spectrum, these fault signatures can be detected and characterized, allowing for early diagnosis and intervention. For example, certain mechanical faults in motors might produce distinct harmonic frequencies that can be identified through a Fourier analysis, making it possible to pinpoint issues before they escalate into more serious problems. Wavelet transforms that offers a complementary approach to Fourier transforms, particularly useful for analysing non-stationary signals where the frequency content varies over time. EV electrical systems often encounter transient events or operate under time-varying conditions, leading to non-stationary signals. Wavelet transforms decompose a signal into different time-frequency scales, which allows for the identification of fault signatures localized in specific time or frequency regions. This capability is crucial for detecting and analysing transient faults or anomalies that might not be apparent in a traditional frequency analysis. For instance, wavelet analysis can effectively capture the sudden spikes or dips in the signal associated with intermittent faults or abrupt changes in operating conditions. Kalman filtering is another advanced signal processing technique used for state estimation and filtering in dynamic systems. In the context of fault detection, Kalman filters can estimate the system states based on noisy or incomplete measurements. By comparing these estimated states with actual measurements, residuals can be generated and analysed for fault detection purposes. The Kalman filter’s ability to provide real-time estimates of system states makes it particularly valuable in dynamic environments, where it can quickly identify deviations from expected behaviour. This method is especially effective in EV systems, where maintaining accurate state information is critical for ensuring reliable and safe operation. By continuously monitoring the residuals, potential faults can be detected early, allowing for timely maintenance, and reducing the risk of unexpected failures.

???????D. Data-Driven Techniques

Data-driven fault detection techniques rely on historical data and machine learning algorithms to learn patterns and models directly from the available data. These techniques are particularly useful when the system dynamics or fault characteristics are complex or not well understood, making it difficult to develop accurate analytical models. Some techniques like Machine learning algorithms, such as support vector machines (SVMs), neural networks, and decision trees, are powerful tools for fault detection and diagnosis in various systems. These algorithms are trained on labelled data sets that include examples of both healthy and faulty conditions. Through this training process, the algorithms learn to recognize patterns and classify new data points or patterns as either healthy or faulty. This capability is invaluable in enabling real-time fault detection and diagnosis, which can improve system reliability and prevent potential failures. Statistical methods which offer another approach for fault detection. Techniques like hypothesis testing, control charts, and regression analysis can identify deviations from normal operating conditions or expected patterns in measured data. These methods are particularly useful in scenarios where the system's behaviour follows statistical properties or when the data is noisy or uncertain, providing robust detection capabilities under various conditions.

Principal component analysis (PCA) is a dimensionality reduction technique that can also be used for fault detection. PCA transforms high-dimensional data into a lower-dimensional space while retaining the maximum variance in the data. By analysing the principal components and their contributions, it is possible to detect deviations from normal operating conditions, indicating potential faults. This method is effective in identifying underlying patterns and anomalies in complex data sets, making it a valuable tool for maintaining system health and performance.

These fault detection techniques can be used individually or in combination, depending on the specific requirements and characteristics of the EV electrical system under consideration. Additionally, hybrid approaches that combine multiple techniques, such as model-based techniques with signal processing or data-driven methods, can leverage the strengths of each approach and provide more robust and accurate fault detection capabilities. In the context of this review, we will explore the application of these fault detection techniques in various components of the EV electrical system, including battery packs, electric motors, power electronics, and control systems. Emphasis will be placed on the use of MATLAB-based computational tools and simulations, which offer a powerful and versatile environment for modelling, simulation, signal processing, and data analysis tasks related to fault detection in EV electrical systems.

IV. MATLAB IN FAULT DETECTION

A. Introduction to MATLAB

MATLAB offers a comprehensive set of tools and features that facilitate the development, implementation, and analysis of complex engineering systems. Its high-level programming language, combined with a vast collection of built-in functions and toolboxes, enables researchers and engineers to rapidly prototype, simulate, and analyze intricate systems with ease. One of the key strengths of MATLAB lies in its matrix-based computation capabilities, which are particularly useful for solving linear algebra problems, implementing control algorithms, and processing signal and image data. Additionally, MATLAB's intuitive visualization tools allow for effective data representation and interpretation, aiding in the understanding and communication of complex results. MATLAB offers several advantages that make it an attractive choice for fault detection applications in EV electrical systems like MATLAB provides a wide range of specialized toolboxes tailored for various engineering domains, including control systems, signal processing, machine learning, and fault diagnosis.

These comprehensive toolboxes encapsulate advanced algorithms, functions, and tools, enabling researchers and engineers to rapidly develop and deploy fault detection techniques without the need for extensive low-level programming. Seamlessly integrating with Simulink, a graphical environment for modelling, simulating, and analysing dynamic systems, MATLAB allows for the visual representation and simulation of complex systems, making it invaluable for modelling EV electrical components and evaluating fault detection techniques under various operating conditions. Additionally, MATLAB offers tools for code generation and deployment, facilitating the integration of developed algorithms and models into embedded systems, real-time platforms, and production environments, which is particularly useful for implementing fault detection techniques in actual EV electrical systems. With an open interface, MATLAB enables integration with other programming languages and software environments, allowing for the incorporation of existing libraries, algorithms, and tools into the MATLAB ecosystem. Supported by comprehensive documentation, tutorials, and a vast user community, MATLAB makes it easier to learn, troubleshoot, and share knowledge and best practices, ensuring robust support for users at all levels.

???????B. MATLAB Toolboxes and Simulink

MATLAB offers a wide range of toolboxes and add-ons that are particularly relevant to fault detection applications in EV electrical systems. Some of the most used toolboxes in are Control System Toolbox in MATLAB provides a comprehensive set of tools for designing, analysing, and simulating control systems, including functions for Modelling, analysis, and control system design, as well as tools for state-space and transfer function representations, which are essential for model-based fault detection techniques. The Signal Processing Toolbox offers a vast collection of algorithms and functions for signal processing, analysis, and visualization, with tools for filtering, spectral analysis (e.g., Fourier and wavelet transforms), parametric Modelling, and time-frequency analysis, which are crucial for signal-based fault detection techniques. The Neural Network Toolbox provides tools for designing, training, and simulating neural networks, including functions for data preprocessing, network architecture selection, training algorithms, and performance evaluation, enabling the development of data-driven fault detection techniques based on machine learning algorithms. Simulink, a graphical environment for Modelling, simulating, and analysing dynamic systems, allows for the visual representation and integration of various components, including mechanical, electrical, and control elements, and is particularly useful for Modelling EV electrical systems, simulating fault scenarios, and evaluating the performance of fault detection techniques under different operating conditions.

Additionally, MATLAB offers a wide range of additional toolboxes and extensions that can be integrated with Simulink, such as the Simscape Electrical toolbox for Modelling electrical systems, the Simscape Driveline toolbox for Modelling driveline components, and the Simscape Battery toolbox for Modelling battery systems, allowing for accurate and detailed simulations of EV electrical systems and enabling comprehensive fault detection and diagnosis studies.

???????C. Case Studies Using MATLAB

MATLAB and its associated toolboxes have been extensively used in various research studies and industrial applications for fault detection in EV electrical systems. Here are some illustrative case studies demonstrating the application of MATLAB-based fault detection techniques:

- Battery Fault Detection: Researchers have utilized MATLAB's Signal Processing Toolbox and Machine Learning Toolbox to develop data-driven fault detection techniques for lithium-ion battery packs in EVs. These techniques involve extracting features from battery voltage, current, and temperature signals, and applying machine learning algorithms, such as support vector machines (SVMs) or neural networks, to classify the battery's operating condition as healthy or faulty. MATLAB's visualization tools are used to analyse and interpret the results, facilitating the identification of potential battery faults or degradation mechanisms.

- Motor Fault Detection: MATLAB's Control System Toolbox and Simulink have been employed to model and simulate permanent magnet synchronous motors (PMSMs) used in EV propulsion systems. Researchers have used these tools to investigate various motor faults, such as demagnetization, eccentricity, and winding faults. By simulating the motor's behaviour under different fault conditions and analysing the resulting signals (e.g., currents, voltages, and vibrations), researchers can develop and validate fault detection algorithms and techniques.

- Power Electronics Fault Detection: Researchers have leveraged MATLAB's Simscape Electrical toolbox and Simulink to model and simulate power electronics components, such as inverters and converters, used in EV electrical systems. These simulations can incorporate various fault scenarios, including IGBT failures, gate driver faults, and capacitor degradation. By analysing the simulated signals and system behaviour, researchers can develop and test fault detection algorithms based on signal processing techniques or data-driven methods.

- Real-Time Implementation: MATLAB's code generation and deployment capabilities have been utilized to implement fault detection algorithms and techniques in real-time systems. For example, researchers have developed fault detection algorithms in MATLAB and then generated embedded code for deployment on microcontrollers or field-programmable gate arrays (FPGAs) used in EV electrical systems. This allows for real-time monitoring and fault detection in actual EV applications.

These case studies demonstrate the versatility and power of MATLAB in supporting fault detection research and development for EV electrical systems. The combination of MATLAB's computational capabilities, specialized toolboxes, and integration with Simulink provides a comprehensive environment for modelling, simulating, analysing, and implementing advanced fault detection techniques, ultimately contributing to the development of more reliable and safer electric vehicles.

V. IMPLEMENTATION OF FAULT DETECTION ALGORITHMS IN MATLAB

MATLAB offers a comprehensive and versatile environment for implementing advanced fault detection algorithms for electric vehicle (EV) electrical systems. Its powerful computational capabilities, extensive toolboxes, and seamless integration with Simulink provide researchers and engineers with a wide range of tools and functionalities to develop, validate, and deploy fault detection techniques. This section explores the implementation of various fault detection algorithms in MATLAB, focusing on model-based, signal processing-based, and data-driven approaches.

???????A. Model-Based Fault Detection

Model-based fault detection techniques rely on mathematical models that describe the expected behaviour of the system or component under consideration. MATLAB offers a rich set of tools and functions for developing analytical models, implementing state observers, and performing parameter estimation, which are essential components of model-based fault detection algorithms.

Developing Analytical Models in MATLAB - MATLAB's symbolic computation capabilities and toolboxes, such as the Symbolic Math Toolbox and the Control System Toolbox, facilitate the development of analytical models for EV electrical components. These models can be derived from fundamental principles, such as electromagnetic theory, circuit theory, and mechanical dynamics, and can be used to simulate and analyse the system's behaviour under various operating conditions and fault scenarios. For example, researchers can develop analytical models for permanent magnet synchronous motors (PMSMs) used in EV propulsion systems, incorporating factors such as winding configurations, magnetic circuit characteristics, and mechanical dynamics. These models can then be used to simulate and analyse the motor's behaviour under different fault conditions, such as demagnetization, eccentricity, or winding faults. Implementation of State Observers and Parameter Estimation Techniques - State observers and parameter estimation techniques are vital components of model-based fault detection algorithms. MATLAB's Control System Toolbox provides a range of functions and tools for designing and implementing state observers, such as Kalman filters and Luenberger observers, as well as parameter estimation algorithms like recursive least squares and extended Kalman filters. For example, researchers can implement state observers to estimate the internal states of a battery management system (BMS) based on measured inputs and outputs, such as voltage, current, and temperature. By comparing the estimated states with the measured states, any discrepancies can be attributed to potential faults or modelling errors, enabling fault detection and diagnosis. Similarly, parameter estimation techniques can be used to estimate critical parameters of EV electrical components, such as battery internal resistance, motor winding resistance, or inverter switching characteristics. Changes in these parameter values can indicate the presence of faults, facilitating fault detection and identification.

???????B. Signal Processing-Based Fault Detection

Signal processing techniques play a crucial role in fault detection algorithms by analysing measured signals from various sensors and components within the EV electrical system. MATLAB's Signal Processing Toolbox and related toolboxes provide a wide range of functions and tools for implementing signal processing algorithms, including Fourier transforms, wavelet transforms, and Kalman filters.

Implementation of Fourier and Wavelet Transforms - The Fourier transform is a powerful signal processing tool for decomposing time-domain signals into their constituent frequency components. MATLAB's Signal Processing Toolbox offers a comprehensive set of functions for performing Fourier analysis, including the Fast Fourier Transform (FFT) and related algorithms. In the context of fault detection in EV electrical systems, researchers can use Fourier analysis to detect fault signatures present in the frequency spectrum of measured signals, such as motor currents or vibration signals. For example, certain fault conditions in PMSMs may introduce specific harmonics or sidebands in the stator current spectrum, which can be detected and analysed using Fourier techniques implemented in MATLAB. Wavelet transforms are particularly useful for analysing non-stationary signals, where the frequency content varies over time. MATLAB's Wavelet Toolbox provides a wide range of functions for wavelet analysis, including continuous and discrete wavelet transforms, as well as wavelet packet decomposition and reconstruction. Wavelet analysis can be applied to EV electrical system signals to detect and characterize transient fault signatures or localized time-frequency patterns. For instance, in the case of battery fault detection, wavelet analysis can be used to identify and isolate cell inconsistencies or thermal events by analysing the time-varying characteristics of voltage or temperature signals.

Use of Kalman Filters for Fault Detection - Kalman filters are widely used in signal processing and fault detection applications for state estimation and filtering in dynamic systems. MATLAB's Control System Toolbox and related toolboxes offer a range of functions and tools for implementing various types of Kalman filters, such as linear Kalman filters, extended Kalman filters, and unscented Kalman filters.

In the context of fault detection in EV electrical systems, Kalman filters can be used to estimate the system states based on noisy or incomplete measurements. By comparing the estimated states with the actual measurements, residuals can be generated and analysed for fault detection purposes. For example, researchers can implement Kalman filters to estimate the state of charge (SOC) and internal states of a lithium-ion battery pack based on voltage, current, and temperature measurements. Any deviations between the estimated and measured states can indicate potential faults, such as cell inconsistencies or internal short circuits, enabling fault detection and diagnosis.

???????C. Data-Driven Fault Detection

Data-driven fault detection techniques rely on historical data and machine learning algorithms to learn patterns and models directly from the available data. MATLAB provides a comprehensive set of toolboxes and functions for implementing data-driven fault detection algorithms, including machine learning models, statistical methods, and principal component analysis (PCA).

Training and Deploying Machine Learning Models in MATLAB - MATLAB's Machine Learning Toolbox and related toolboxes, such as the Neural Network Toolbox and the Statistics and Machine Learning Toolbox, offer a wide range of functions and tools for training and deploying machine learning models for fault detection applications. Researchers can use these toolboxes to train supervised learning models, such as support vector machines (SVMs), neural networks, or decision trees, on labelled data sets containing examples of both healthy and faulty conditions. These trained models can then be used to classify new data points or patterns as either healthy or faulty, enabling fault detection and diagnosis. For example, researchers can train machine learning models on data collected from EV battery packs, including voltage, current, and temperature measurements, along with labels indicating whether the battery pack is healthy or exhibiting specific fault conditions. The trained models can then be deployed to monitor real-time battery data and detect potential faults or degradation mechanisms.

Integration of Statistical Methods and PCA - MATLAB's Statistics and Machine Learning Toolbox provides a comprehensive set of functions and tools for implementing statistical methods and principal component analysis (PCA) for fault detection applications. Statistical methods, such as hypothesis testing, control charts, and regression analysis, can be used to detect deviations from normal operating conditions or expected patterns in the measured data. These methods are particularly useful when the system's behaviour exhibits statistical properties or when dealing with noisy or uncertain data. PCA is a dimensionality reduction technique that can be used for fault detection by transforming high-dimensional data into a lower-dimensional space while retaining the maximum variance in the data. By analysing the principal components and their contributions, deviations from normal operating conditions can be detected, indicating potential faults. For example, researchers can use PCA to analyse high-dimensional data sets collected from EV electrical systems, such as motor currents, voltages, and vibration signals. Deviations in the principal components or their contributions can indicate the presence of faults or abnormal operating conditions, enabling fault detection and diagnosis. MATLAB's comprehensive toolboxes, extensive documentation, and active user community provide valuable resources and support for implementing these fault detection algorithms effectively. Additionally, MATLAB's code generation and deployment capabilities allow researchers and engineers to seamlessly transition from algorithm development to real-time implementation on embedded systems or test platforms, enabling practical applications of fault detection techniques in EV electrical systems.

VI. CHALLENGES AND FUTURE DIRECTIONS

A. Technical Challenges

Electric vehicles (EVs) are inherently complex systems, incorporating numerous interdependent components such as the battery, inverter, motor, and various control systems. This complexity poses significant challenges for fault detection, as each component may exhibit unique fault characteristics. The integration of multiple systems necessitates sophisticated fault detection algorithms that can accurately isolate and diagnose faults amidst the normal operational noise. For example, demagnetization faults in Permanent Magnet Synchronous Motors (PMSMs) require precise monitoring and can be challenging to detect due to their subtle initial symptoms and the influence of other operational factors??. Effective fault detection in EV systems must often occur in real-time to prevent catastrophic failures and ensure passenger safety. This requirement places a high demand on the processing power and speed of diagnostic algorithms. Real-time processing must be capable of quickly analysing data from multiple sensors, detecting anomalies, and initiating corrective actions without significant delay. Techniques like model-based approaches and advanced signal processing can be computationally intensive, posing a challenge for implementation in real-world scenarios where hardware limitations exist??. The efficacy of fault detection algorithms heavily depends on the availability and quality of data. Inconsistent or incomplete data can lead to false positives or missed detections. EV systems generate vast amounts of data from various sensors, but this data must be accurately labelled and free from noise to train effective machine learning models.

Furthermore, the diversity in EV designs and operating conditions can result in significant variability in the data, complicating the development of universally applicable fault detection methods??.

???????B. Research Gaps

Artificial Neural Networks (ANNs) have shown promise in detecting complex patterns and anomalies in EV systems. However, there is a critical need for more robust algorithms specifically tailored for detecting demagnetization faults in PMSMs. Existing methods often fail to distinguish these faults under varying operational conditions, leading to unreliable fault detection. Future research should focus on developing ANN-based algorithms that can learn from a wide range of fault scenarios and accurately identify demagnetization faults even in the presence of noise and other system anomalies??. Fault detection systems must seamlessly integrate with other vehicle systems, such as the Battery Management System (BMS) and Advanced Driver Assistance Systems (ADAS). This integration can enhance the overall safety and reliability of the vehicle but also introduces additional complexity. Effective integration requires standardized communication protocols and interoperability between different system components, which is currently an area lacking comprehensive research. Addressing this gap could lead to more cohesive and efficient fault detection systems??.

???????C. Future Trends

Machine learning and artificial intelligence (AI) are poised to revolutionize fault detection in EV systems. Future trends indicate a shift towards more sophisticated AI models capable of predictive maintenance. These models can analyse historical and real-time data to predict potential failures before they occur, thus enabling proactive maintenance strategies. Techniques such as deep learning and reinforcement learning are expected to play a significant role in developing these predictive models, offering improved accuracy and reliability over traditional methods??. The integration of IoT with EVs allows for continuous monitoring and real-time data collection, which can be analysed in the cloud to detect faults. This approach enables the deployment of more computationally intensive algorithms that would be impractical to run on-board the vehicle. IoT and cloud-based systems also facilitate remote diagnostics and over-the-air updates, enhancing the vehicle's ability to manage and mitigate faults. The future will likely see an increased adoption of these technologies, providing a more comprehensive and efficient fault detection framework??. ensure the reliability and effectiveness of fault detection algorithms, standardized testing and validation methods are essential. Currently, there is a lack of universally accepted benchmarks and testing protocols for evaluating fault detection systems in EVs. Developing these standards would enable more consistent and reliable assessments of new algorithms, fostering greater trust and adoption of advanced fault detection technologies. This standardization would also facilitate the regulatory approval process, making it easier to implement new systems in commercial EVs??. In conclusion, addressing the technical challenges and research gaps in fault detection for EV electrical systems requires a multi-faceted approach, leveraging advances in AI, IoT, and standardized testing methodologies. Future research and development in these areas will be crucial for enhancing the safety, reliability, and efficiency of electric vehicles, thereby supporting their widespread adoption in modern transportation.

Conclusion

In this comprehensive review, we explored the advanced fault detection techniques applied to the electrical systems of electric vehicles (EVs) using MATLAB. The significance of reliable fault detection methods in EVs cannot be overstated, given their crucial role in ensuring the safety, reliability, and efficiency of these vehicles. The review highlighted several key aspects: various fault detection methods, including model-based approaches, signal-based techniques, and data-driven methodologies. Model-based methods, such as state observers and parameter estimation, provide accurate fault detection but often require detailed system models. Signal-based techniques utilize time-domain, frequency-domain, and time-frequency domain analyses to identify faults through deviations in signal patterns. Data-driven methods leverage machine learning algorithms to predict and classify faults based on historical data, offering a promising avenue for robust and scalable fault detection. MATLAB\'s role as a powerful tool for simulating and implementing fault detection algorithms was underscored, with its extensive libraries, toolboxes, and simulation capabilities making it an ideal platform for developing and testing fault detection techniques in EV systems. Examples included using MATLAB for finite element analysis (FEA), system simulations, and implementing machine learning models. The complexity of EV systems poses significant challenges for fault detection. Real-time processing requirements, data availability, and quality are critical issues that need to be addressed. The need for robust algorithms capable of detecting various types of faults, including demagnetization faults in motors, was emphasized. The integration of fault detection systems with other vehicle systems, such as the Internet of Things (IoT) and cloud-based monitoring, represents a significant advancement. Future trends point towards the adoption of advanced machine learning and artificial intelligence (AI) techniques to enhance fault detection capabilities. Standardized testing and validation methods are also essential for ensuring the reliability of these systems. The implications of advanced fault detection techniques for the industry and research are profound. As EV adoption continues to grow, the need for reliable and efficient fault detection systems becomes increasingly critical. Implementing advanced fault detection techniques significantly enhances the reliability and safety of EVs. Early detection of faults can prevent catastrophic failures, reduce maintenance costs, and extend the lifespan of vehicle components. This leads to increased consumer confidence and broader adoption of EV technology. For the automotive industry, the integration of sophisticated fault detection systems into EVs can provide a competitive edge. Manufacturers can offer vehicles with improved safety features, reduced downtime, and lower total cost of ownership. Additionally, the use of IoT and cloud-based monitoring allows for continuous vehicle health monitoring and predictive maintenance, further enhancing the reliability of EVs. The review identifies several research gaps and future directions: the need for the development of robust algorithms, particularly for detecting demagnetization faults using artificial neural networks (ANN). These algorithms should be capable of operating in various conditions and handling different types of faults. Future research should focus on the seamless integration of fault detection systems with other vehicle subsystems. This includes the use of IoT for real-time data collection and cloud-based platforms for data analysis and storage. Machine learning and AI hold great potential for advancing fault detection techniques. Research should explore new models and algorithms that can enhance fault detection accuracy and reduce false positives. The development of standardized testing and validation methods is essential for ensuring the reliability and effectiveness of fault detection systems. This includes creating benchmarks and test protocols that can be universally applied. In conclusion, the advancements in fault detection techniques for EV electrical systems using MATLAB offer significant benefits for both the industry and research communities. By addressing the current challenges and leveraging emerging technologies, we can develop more reliable, efficient, and safe EVs, paving the way for a sustainable transportation future.

References

[1] Zhu S, Li H, Wang G, Kuang C, Chen H, Gao J, Xie W. Research on Fault-Tolerant Control of Distributed-Drive Electric Vehicles Based on Fuzzy Fault Diagnosis. Actuators. 2023; 12(6):246. [2] Alzuabidi, Ola & Hussein Alameen, Mohammed. (2021). Fault Detection of Electric Vehicle Motor Based on Flux Performance Using FEM. Periodicals of Engineering and Natural Sciences. 9. 5-11. 10.21533/pen.v9i3.2077. [3] Trivedi M, Kakkar R, Gupta R, Agrawal S, Tanwar S, Niculescu V-C, Raboaca MS, Alqahtani F, Saad A, Tolba A. Blockchain and Deep Learning-Based Fault Detection Framework for Electric Vehicles. Mathematics. 2022; 10(19):3626. [4] Rana, Deepika & Arora, Mamta. (2016). Energy Efficient Cluster-Based Routing Protocol in Wireless Sensor Network using Flower Pollination Algorithm. International Journal of Electrical and Electronics Research. 4. 102-109. 10.37391/IJEER.090308. [5] Cong X, Zhang C, Jiang J, Zhang W, Jiang Y, Zhang L. A Comprehensive Signal-Based Fault Diagnosis Method for Lithium-Ion Batteries in Electric Vehicles. Energies. 2021; 14(5):1221. [6] A. Srujana, A. Srilatha, and S. Suresh, “Electric Vehicle Battery Modelling and Simulation Using MATLAB-Simulink,” Turkish Journal of Computer and Mathematics Education, vol. 12, no. 3, pp. 4604–4609, 2021, Accessed: Jun. 11, 2024. [7] Khaneghah MZ, Alzayed M, Chaoui H. Fault Detection and Diagnosis of the Electric Motor Drive and Battery System of Electric Vehicles. Machines. 2023 [8] J. Faiz and E. Mazaheri-Tehrani, \"Demagnetization Modeling and Fault Diagnosing Techniques in Permanent Magnet Machines Under Stationary and Nonstationary Conditions: An Overview,\" in IEEE Transactions on Industry Applications, vol. 53, no. 3, pp. 2772-2785, May-June 2017 [9] M. shahab and M. Moavenian, “Fault Detection and Isolation of Vehicle Driveline System,” Apr. 2012. [10] Ben Salem, Fatma. (2020). Stator Winding Fault Diagnosis of Permanent Magnet Synchronous Motor-Based DTC-SVM Dedicated to Electric Vehicle. 10.5772/intechopen.88784. [11] M. Zafarani, E. Bostanci, Y. Qi, T. Goktas and B. Akin, \"Interturn Short-Circuit Faults in Permanent Magnet Synchronous Machines: An Extended Review and Comprehensive Analysis,\" in IEEE Journal of Emerging and Selected Topics in Power Electronics, vol. 6, no. 4, pp. 2173-2191, Dec. 2018 [12] N. S. Hegde, S. Pasumarthy, and S. S. Kupnoor, “Predictive Analysis Of Faults In Electric Vehicles,” EPRA International Journal of Multidisciplinary Research (IJMR), vol. 9, no. 5, pp. 1–1, Jun. 2023, Accessed: Jun. 11, 2024. [13] K. L. Butler, M. Ehsani and P. Kamath, \"A Matlab-based modeling and simulation package for electric and hybrid electric vehicle design,\" in IEEE Transactions on Vehicular Technology, vol. 48, no. 6, pp. 1770-1778, Nov. 1999 [14] J. Hong et al., \"Detection and Classification of Rotor Demagnetization and Eccentricity Faults for PM Synchronous Motors,\" in IEEE Transactions on Industry Applications, vol. 48, no. 3, pp. 923-932, May-June 2012

Copyright

Copyright © 2024 Suprotip Ghosh Hazra, Prof. Rekha A. Chaudhari, Abhishek M. Pandey, Omkar R. Kale, Niteen J. Kharade. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63253

Publish Date : 2024-06-11

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online