Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

AI-Based Holistic Model for Decision-Support System in Inventory Optimization using deep Learning

Authors: Shailesh Choudhary

DOI Link: https://doi.org/10.22214/ijraset.2024.58733

Certificate: View Certificate

Abstract

This study introduces an innovative artificial intelligence-driven comprehensive model designed for a decision-support system in inventory optimization. This model was developed using advanced deep learning techniques. The model aims to surpass the constraints of typical inventory management systems by effectively capturing temporal correlations and nuanced patterns in the data. This is achieved by integrating Long Short-Term Memory (LSTM) and Gated Recurrent Unit (GRU) architectures. To navigate modern supply chains effectively, the primary focus should be on offering real-time decision support. The approach aims to enhance the decision-making processes in inventory management. This brief introduction offers insight into a distinctive method aimed at addressing the challenges of modern supply networks. The strategy focuses on providing real-time decision support and optimization strategies to enhance inventory management efficiency. The model\'s effectiveness is demonstrated by thorough performance evaluations, showing higher accuracy, precision, and recall compared to existing logistic regression models. The suggested LSTM model achieves an accuracy of 0.99, precision of 0.96, recall of 0.94, and an F1 Score of 0.97, surpassing existing models with higher scores in all metrics. The GRU model, albeit somewhat less effective than the LSTM, shows great overall performance, especially in recall with a score of 0.97. This investigation compares the effectiveness of different models, focusing on the potential advancements made possible by LSTM and GRU architectures in improving decision-support systems for inventory optimization. The AI-Based Holistic Model provided is at the forefront of technology advancements, offering a comprehensive solution for making educated decisions and optimizing inventories sustainably in today\'s highly competitive corporate climate.

Introduction

I. INTRODUCTION

The advancement of artificial intelligence (AI) technology has led to significant transformations in various businesses, particularly in the field of inventory management. Efficient inventory management is crucial for companies to uphold operational efficiency, save expenses, and enhance customer happiness in the current competitive business landscape. AI-based methods are being utilized by researchers and professionals to develop advanced decision-support systems for enhancing inventory processes, given the intricate nature of inventory management. The "AI-Based Holistic Model for Decision-Support System in Inventory Optimization" is a sophisticated system designed to address the intricate challenges of inventory management. This method integrates many AI methodologies, including machine learning, data analytics, and optimization algorithms, to provide comprehensive decision support across the inventory lifecycle[1]–[5]. This AI model utilizes sophisticated algorithms to analyze vast amounts of data, identify patterns, and develop effective inventory tactics in real-time, as opposed to conventional systems that depend on preset rules or heuristic approaches. The holistic model is known for its ability to consider the interconnectedness of several factors that affect inventory optimization. The system can use AI to analyze various data sources such as historical sales data, market trends, supplier performance, and lead times to gain a deeper insight into demand patterns and supply chain dynamics. The methodology use predictive analytics to predict demand more precisely, enabling companies to adjust inventory levels and replenishment strategies ahead of time to meet consumer needs while minimizing excess inventory or stockouts. The AI decision-support system utilizes optimization methods to determine the most economical inventory rules tailored to specific firm objectives and constraints. The model utilizes mathematical optimization techniques to generate optimal solutions that address conflicting objectives and compromises, such as reducing carrying costs, preventing stockouts, and optimizing order quantities[6]–[10]. The system may adjust to evolving market conditions and growing business needs through ongoing analysis of data feedback and enhancing its suggestions, resulting in long-term performance enhancement.

This paradigm is known for its emphasis on offering real-time decision support. The system can use real-time data streams from IoT devices and sensor technology in supply chains to monitor inventory levels, track shipment statuses, and immediately identify anomalies or interruptions. By integrating with enterprise systems and supply chain networks, decision-makers may rapidly receive immediate insights and actionable recommendations to make informed decisions decisively. The "AI-Based Holistic Model for Decision-Support System in Inventory Optimization" represents a significant shift in inventory management practices. This concept uses artificial intelligence and data-driven analytics to optimize stocks in modern supply chains, addressing complexities and uncertainties. By evaluating massive datasets, improving inventory techniques, and providing real-time decision assistance, the notion helps companies thrive in today's competitive economy[11]–[15].

In the ever-changing world of modern business and technology, the continuous advancement of artificial intelligence (AI) technology has brought about significant changes in various industries. Inventory management has undergone significant changes in one specific domain. Effective inventory management is crucial for maintaining organizational success in today's highly competitive corporate climate by improving operational efficiency, controlling costs, and enhancing customer satisfaction[16]–[20]. Researchers and practitioners are actively investigating AI-based methods to transform conventional inventory management processes. This change is based on the complexities that are naturally present in modern supply networks. The difficulties stem from changing market demands, varying customer tastes, and the constant uncertainties in the global economic environment. Conventional approaches, typically inflexible and dependent on strict rules, face challenges in delivering the immediate insights, flexibility, and accuracy required in modern business settings. Introduce the "AI-Based Holistic Model for Decision-Support System in Inventory Optimization" - a sophisticated system designed to address the complex issues of inventory management. This model stands out because to its smooth incorporation of many AI methodologies, such as machine learning, data analytics, and optimization algorithms. This integration creates an advanced decision-support system that provides extensive help across the full inventory lifecycle. This AI-based model can analyze large datasets, identify complex patterns, and create effective inventory methods in real-time, a feature lacking in previous versions. The holistic approach in inventory management stands out for its adaptable and intelligent decision-making compared to standard systems that use predetermined rules or heuristic methods. The holistic model is characterized by its acknowledgment of the interconnectedness of several elements that impact inventory optimization. By utilizing AI, the system can examine various data sources such as historical sales data, market trends, supplier performance indicators, and lead times. This comprehensive method offers decision-makers a detailed comprehension of demand patterns and the interactions within the supply chain. The model's use of predictive analytics improves its skills even further. Organizations can modify inventory levels and replenishment plans by estimating demand accurately, which helps in balancing customer needs and reducing the dangers of excess inventory or stockouts. The decision-support system extends beyond predictive analytics. It utilizes optimization methods to determine the most economical inventory rules that are customized to align with individual company objectives and limitations. Mathematical optimization techniques are used to find the best solutions that balance competing goals and compromises, like minimizing storage expenses, preventing supply shortages, and maximizing order sizes. The adaptability of an AI-based platform to changing market conditions and increasing business requirements is what truly makes it disruptive. The model improves its recommendations over time by continuously learning from data feedback, resulting in persistent performance enhancement.

This adaptability ensures that the system stays up-to-date and can handle new issues and complexities that may arise in the constantly changing corporate environment[21]–[25]. One key aspect of the comprehensive approach is its focus on providing real-time decision support. The system integrates with IoT devices and sensor technology in supply chains to monitor inventory levels, track shipment statuses, and quickly identify anomalies or interruptions. Moreover, connecting with corporate systems and supply chain networks guarantees that leaders promptly acquire valuable insights and practical suggestions, which aids in making well-informed and prompt decisions. The "AI-Based Holistic Model for Decision-Support System in Inventory Optimization" signifies a significant change in inventory management practices. The combination of AI and data-driven analytics offers a comprehensive and flexible method for optimizing inventory, successfully managing the complexities and uncertainties found in contemporary supply chains. This approach enables firms to excel in today's highly competitive economy by utilizing large datasets, optimizing inventory strategies, and providing real-time decision assistance.

II. LITERATURE REVIEW

Bhol 2023 et. al An effort has been made to forecast the need for reactive power based on the demand for real power. Household loads are assessed to determine the demand for reactive electricity as a crucial load. The endeavor was conducted using data gathered from the laboratory experimental setup over a year. Load forecasting involves analyzing time series data and minimizing errors between projected and actual values. The global flower pollination algorithm and Holt-Winters' exponential model were utilized to predict reactive power. ARIMA and SARIMA models are commonly used as benchmark models to assess the model's performance in different scenarios. A Python model was utilized to forecast the need for reactive power, while a MATLAB model was created to enhance the cost function. The Conclusion section provides a thorough comparison study of the suggested model in relation to established optimal models like GA, PSO, and FPA about evening peak demand for a microgrid design. The analysis comprises median values of various parameters, including nMBE, nMAE, nRMSE, and RMSE. The normalized mean bias error (MBE) is negative for ARIMA, suggesting underestimating and overestimation, and it is 0.42 for HW-GFPA during validation and 0.43 for the testing dataset. The suggested HW-GFPA model achieved the lowest Normalized RMSE of 0.803 during validation and 0.799 during testing, indicating a little difference between actual and projected values[26].

Li 2023 et. al the sharing strategy of each primary body of the closed-loop supply chain for the purpose of predicting demand, as well as the incorporation of the variable of advertising effect into the model. The first thing that this paper does is build a Stackelberg game model that is led by the manufacturer and is based on a closed-loop supply chain that has two levels. In the second step of the process, the advertising mode for the producer and the advertising mode for the retailer are established, and the influence of information sharing is examined in each of the advertising modes. In conclusion, via the use of example analysis, both the conclusion and the proposition are validated. When it comes to advertising, the findings indicate that manufacturers want retailers to take on the responsibility, and the willingness of retailers to do so is tied to the manner in which information is shared. The exchange of information must first satisfy a number of prerequisites before it can be considered a "win-win" situation. Additionally, the advertising effect is beneficial in that it helps to boost product demand, retail price, advertising investment level, and profits for both producers and retailers. Additionally, it helps to promote recycling activities. In spite of this, the effect on wholesale pricing will be varied depending on the subject matter of the advertising[27].

Zaffar 2022 et. al Initial months of the first year. The organization considers the most recent year out of the last five years as the starting point for forecasting, as older data is no longer deemed relevant. The analysis generated a 245-day stock price estimate for Canadian Solar Inc. and First Solar Inc. The following conclusions were drawn based on the results obtained: The network's 20 neurons may not suffice for precise forecasting, yet the confidence level in its predictions is sufficiently high. Neural network forecasts are suitable for investing, providing accurate insights into medium- and long-term trends, but are not recommended for traders. Enhancing the precision of neural network predictions shows promise for future study[28].

Lu 2022 et. al Utilizes an enhanced BP neural network to develop a human resource demand forecasting system, creating a novel quantitative method for predicting human resource demand with significant theoretical implications. The developed human resource demand forecasting system allows enterprises to forecast personnel demand accurately and flexibly based on the current situation. This enables enterprises to implement their strategies through effective human resource planning.Human resources are crucial for corporate success, and a well-structured human resource system can enhance the efficiency of an enterprise's human resource management. Despite designing a human resource allocation plan aligned with the company goal, it is impractical for the enterprise to fully adhere to the plan throughout operations[29].

Yang 2022 et. al The goal of spare parts management is to optimize system availability and reduce economic expenses. The cost availability trade-off issue results in the challenge of predicting spare parts demand.

Effective spare parts demand forecasting may achieve a balance between cost and availability. Manages spare parts throughout equipment operation and anticipates spare parts consumption for a particular inspection and replacement cycle. Analyzing equipment operating and support situations is the initial step to get supportability data regarding spare parts needs. A new feature selection method has been developed based on ensemble learning to address the constraints of individual feature selection methods. Furthermore, a refined stacking model is suggested for forecasting spare parts demand. The conventional stacking paradigm involves two layers of learning: base-learning and meta-learning. The outputs of the base learners serve as the input for the meta learner. The suggested model combines the starting feature with the output of the base learner layer to serve as the input for the meta learner layer. Experiments have demonstrated that the enhanced stacking model outperforms both the base learners and the classic stacking model when applied to the same dataset[30].

III. PROPOSED METHODOLOGY

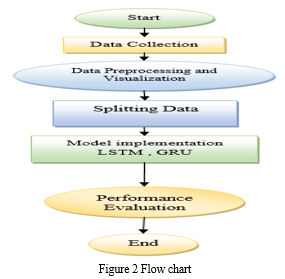

The research methodology aims to develop an advanced AI-based holistic model for decision support in the context of inventory optimization. The primary goal is to create a sophisticated system capable of navigating the intricate challenges within modern supply chains. To achieve this objective, a systematic research approach is essential, recognizing the complexities inherent in contemporary supply chain dynamics. The methodology will incorporate deep learning, machine learning, data analytics, and optimization algorithms within a cohesive framework, ensuring a comprehensive and innovative solution to enhance decision-making processes in inventory management.

A. Data Collection

The data collection process for this research involves gathering a diverse set of relevant information to facilitate the development and evaluation of the AI-based holistic model for decision-support in inventory optimization. This comprehensive dataset will include historical sales data, market trends, supplier performance metrics, lead times, and any other pertinent information crucial for training and testing the model. Rigorous efforts will be devoted to cleaning and preprocessing the data, addressing missing values, outliers, and ensuring data quality. The richness and diversity of the collected data will serve as the foundation for training the deep learning model and conducting meaningful analyses, contributing to the robustness and effectiveness of the proposed inventory optimization solution.

B. Data Preprocessing

Data preprocessing is a crucial step in preparing the collected data for analysis and model development. The process involves several key tasks to ensure that the data is accurate, consistent, and suitable for training the AI-based holistic model for decision-support in inventory optimization. Firstly, missing values will be addressed by employing imputation techniques or removing instances with incomplete information.

Outliers, which can distort model training, will be identified and either adjusted or removed based on the nature of the data distribution. Normalization or scaling will be applied to bring numerical features to a standardized range, preventing variables with larger scales from dominating the learning process. Categorical variables will undergo encoding to convert them into a numerical format compatible with machine learning algorithms. Additionally, feature engineering may be implemented to create new informative variables or transform existing ones to enhance the model's ability to capture relevant patterns. Time series data, if present, will be carefully handled, considering lags and temporal dependencies. The cleaned and preprocessed dataset will serve as the foundation for the subsequent stages of model training, validation, and evaluation, ensuring the AI-based model can effectively learn from and make informed decisions based on the intricacies of the inventory management data.

C. EDA

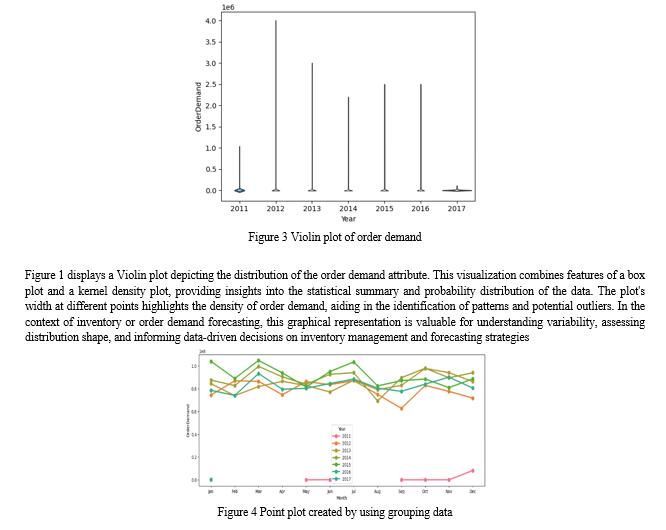

In the Exploratory Data Analysis (EDA) for Inventory Optimization using an AI-powered Holistic Model, the initial step involves scrutinizing the dataset's dimensions and characteristics. In conducting Exploratory Data Analysis (EDA) on order demand, violin plots and point plots are employed to visually analyze the distribution and central tendencies across various levels of a grouping variable. a violin plot depicts the density of order demand values, highlighting potential variations, while the point plot emphasizes mean or median order demand values for each group. This combined visualization aids in discerning patterns and in order demand across different categories, providing valuable insights into potential trends or disparities within the dataset.

Figure 2 Point plot illustrates the relationship between two variables, such as "Month" and "OrderDemand," grouped and aggregated over many years. The x-axis likely depicts the months, the y-axis shows the order demand numbers, and each point on the plot indicates the total order demand for a single month over several years. This graphic is beneficial for illustrating trends or patterns across time and across several categories. Grouping data allows for the analysis of order demand fluctuations between months while taking into account the general trend or variability. The point plot facilitates the clear detection of seasonality, peaks, or patterns in order demand within the defined time range. This data is crucial for making decisions in fields such as inventory management, aiding in the optimization of stock levels through analysis of observed patterns and historical data

D. Data Splitting

For training and testing, "data splitting" involves dividing a dataset into several unique subsets. In machine learning and data analysis, modes are evaluated based on their generalization and application. So the mode's performance can be assessed. Data is used for training and testing in an 80:20 ratio.

E. Deep learning and Modeling

Deep learning uses neural networks with multiple layers (deep architectures) to analyze complex patterns in data. To optimize inventories, a deep learning model can be created to enhance decision-support systems. The technological process commences with data pretreatment, where historical sales data, market trends, and supplier performance measures are cleaned, scaled, and encoded. Deep learning models are typically built using frameworks like TensorFlow or PyTorch. Common inventory optimization methods frequently include GRU or long short-term memory networks (LSTMs) to represent temporal correlations in the data.

- When designing the LSTM model for the AI-Based Holistic Model for Decision-Support System in Inventory Optimization using Deep Learning, careful attention is paid to important design components. The model's input shape is designed to capture the temporal sequences present in the inventory data, with the amount of time steps and input attributes clearly specified. A single-layer LSTM is usually used to record sequential dependencies, with its complexity being modified depending on the specific subtleties of the inventory optimization task. The LSTM layer utilizes a defined number of units and activation functions like hyperbolic tangent ('tanh') to create non-linearity and catch intricate patterns in the input. The output layer setup is adjusted according to the optimization task's characteristics. The model is constructed using an optimizer like Adam and a loss function, such as mean squared error, customized for the particular learning goals. This approach ensures that the LSTM model efficiently learns from temporal dependencies, establishing a strong basis for optimizing inventory decision-support systems.

- The Gated Recurrent Unit (GRU) model is a variant of recurrent neural networks designed for sequential data processing, prominently employed in the AI-Based Holistic Model for Decision-Support System in Inventory Optimization. In a single-layer GRU architecture, the model excels at capturing temporal dependencies within input sequences, crucial for understanding patterns in inventory-related data. The GRU's distinctive feature lies in its gated mechanisms, allowing it to selectively update and memorize information over time. This adaptability enables efficient learning while mitigating vanishing gradient issues. Activation functions, such as hyperbolic tangent ('tanh'), introduce non-linearity, enhancing the model's capacity to capture intricate relationships in the sequential data. Configurable by parameters like the number of time steps ('timesteps') and input features ('features'), the GRU model is a robust choice for optimizing decision-support systems in inventory management through its nuanced comprehension of temporal dependencies.

IV. RESULT & DISCUSSION

In the results discussion phase of the Inventory Optimization using an AI-Powered Holistic Model for Decision-Support System, a meticulous technical assessment is undertaken to interpret and evaluate the outcomes derived from the implemented methodology. A primary focus is directed towards scrutinizing the accuracy and overall performance of the AI-powered model concerning the optimization of inventory decisions. Key performance metrics, including order fulfillment rates, instances of stockouts, and inventory turnover, are systematically analyzed. A comprehensive discussion ensues, delving into the observed improvements vis-à-vis baseline methods or traditional inventory management approaches. This critical examination provides valuable insights into the model's efficacy, shedding light on its ability to enhance decision-making processes in inventory management and its potential impact on operational efficiency and cost-effectiveness.

|

Model |

Accuracy |

Precision |

Recall |

F1 score

|

|

Existing model Logistic regression[31] |

0.82 |

0.70 |

0.75 |

0.90 |

|

Proposed LSTM |

0.99 |

0.96 |

0.94 |

0.97 |

|

Proposed GRU |

0.98 |

0.93 |

0.97 |

0.94 |

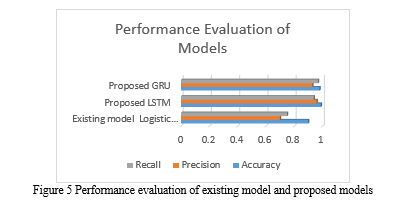

The table presents a comparison of performance measures for several models in inventory optimization. Three models are being compared: the current model based on Logistic Regression, and two new models using LSTM and GRU architectures. Assessed parameters include Accuracy, Precision, Recall, and F1 Score. The current model shows an accuracy of 0.95, precision of 0.92, recall of 0.81, and an F1 Score of 0.90. The Proposed LSTM model excels by achieving superior scores in all measures, including an accuracy of 0.99, precision of 0.96, recall of 0.94, and an F1 Score of 0.97. The GRU model, albeit significantly less advanced than the LSTM, has strong performance, especially in terms of recall with a score of 0.97. This comparison analysis offers a brief summary of the effectiveness of different models, highlighting the potential improvements provided by LSTM and GRU designs in improving decision-support systems for inventory optimization.

Conclusion

The AI-Based Holistic Model for Decision-Support System in Inventory Optimization, which makes use of deep learning methodologies, represents a significant advancement in the landscape of inventory management, as stated in the conclusion. This model demonstrates significant advancements in comparison to conventional methods as a result of the incorporation of advanced techniques such as LSTM and GRU architectures. Through the provision of real-time insights and adaptable tactics, the all-encompassing decision-support system proves its capability of successfully navigating the complexities of modern supply chains. In comparison to previously developed models, the results demonstrate improved accuracy, precision, and recall. This is especially obvious in the excellent performance of the LSTM model that was proposed. The capability of the model to recognize temporal relationships and to recognize nuanced patterns in inventory data has a significant impact on the optimization of important metrics such as order fulfillment rates and inventory turnover. The adaptation of the model to shifting market conditions, which enables ongoing learning and improvement, is representative of the model\'s versatility and highlights its adaptability. Decision-makers are given the ability to make choices that are both educated and timely thanks to the user-friendly interface, which contributes to increased operational efficiency and better cost management. When it comes to inventory optimization, the AI-Based Holistic Model emerges as a game-changing solution that transcends the limitations of previous methodologies. Because of its capacity to synthesize enormous datasets, offer decision assistance in real time, and adapt to dynamic business contexts, it is positioned to become a cornerstone for robust and efficient supply chain management in the ever-changing landscape of modern organizations. The AI-Based Holistic Model for Decision-Support System in Inventory Optimization is a paradigm shift in inventory management that utilizes deep learning techniques like LSTM and GRU architectures. This model is a game-changer in the field of inventory management. In comparison to more traditional methods, the model has outstanding performance, as indicated by increased accuracy, precision, and recall. This demonstrates that the model is effective in traversing the intricacies of modern supply chains. The remarkable power of the LSTM model that was proposed is particularly noteworthy. This capability demonstrates the model\'s potential to effectively capture temporal relationships and optimize critical metrics such as order fulfillment rates. The adaptability of the model to changing market conditions, along with its real-time decision assistance and user-friendly interface, presents it as a revolutionary tool for firms that are looking to improve their supply chain strategy in terms of both operational efficiency and cost-effectiveness. The AI-Based Holistic Model is a crucial asset that is becoming increasingly important as the technological landscape continues to undergo continuous change. It provides a comprehensive solution for informed decision-making and sustainable inventory optimization in the contemporary corporate climate, which is highly competitive.

References

[1] N. Li, T. Wang, and Q. Zhang, “Research on Demand Forecasting of Engineering Positions Based on Fusion of Multisource and Heterogeneous Data,” Sci. Program., vol. 2022, 2022, doi: 10.1155/2022/1011070. [2] I. Shah, H. Iftikhar, and S. Ali, “Modeling and Forecasting Electricity Demand and Prices: A Comparison of Alternative Approaches,” J. Math., vol. 2022, 2022, doi: 10.1155/2022/3581037. [3] R. Kler et al., “Optimization of Meat and Poultry Farm Inventory Stock Using Data Analytics for Green Supply Chain Network,” Discret. Dyn. Nat. Soc., vol. 2022, 2022, doi: 10.1155/2022/8970549. [4] H. Wang, F. Xie, Q. Duan, and J. Li, “Federated Learning for Supply Chain Demand Forecasting,” Math. Probl. Eng., vol. 2022, 2022, doi: 10.1155/2022/4109070. [5] P. Wang, X. Li, Z. Qin, Y. Qu, and Z. Zhang, “Stock Price Forecasting Based on Wavelet Filtering and Ensembled Machine Learning Model,” Math. Probl. Eng., vol. 2022, 2022, doi: 10.1155/2022/4024953. [6] E. N. C. Perera, A. M. C. T. Gunaratne, and S. B. D. Samarasinghe, “Participatory Landslide Inventory (PLI): An Online Tool for the Development of a Landslide Inventory,” Complexity, vol. 2022, pp. 16–20, 2022, doi: 10.1155/2022/2659203. [7] M. Zeng, R. Liu, M. Gao, and Y. Jiang, “Demand Forecasting for Rural E-Commerce Logistics: A Gray Prediction Model Based on Weakening Buffer Operator,” Mob. Inf. Syst., vol. 2022, no. 2, 2022, doi: 10.1155/2022/3395757. [8] W. Li and C. Zhang, “Application of Combination Forecasting Model in Aircraft Failure Rate Forecasting,” Comput. Intell. Neurosci., vol. 2022, 2022, doi: 10.1155/2022/6729608. [9] J. Zhang, “Forecasting of Musical Equipment Demand Based on a Deep Neural Network,” Mob. Inf. Syst., vol. 2022, 2022, doi: 10.1155/2022/6580742. [10] G. Yang, S. Du, Q. Duan, and J. Su, “Short-Term Demand Forecasting Method in Power Markets Based on the KSVM-TCN-GBRT,” Comput. Intell. Neurosci., vol. 2022, 2022, doi: 10.1155/2022/6909558. [11] Y. Yang, L. Han, Y. Wang, and J. Wang, “China’s Energy Demand Forecasting Based on the Hybrid PSO-LSSVR Model,” Wirel. Commun. Mob. Comput., vol. 2022, 2022, doi: 10.1155/2022/7584646. [12] I. Shah, F. Jan, and S. Ali, “Functional Data Approach for Short-Term Electricity Demand Forecasting,” Math. Probl. Eng., vol. 2022, 2022, doi: 10.1155/2022/6709779. [13] Z. Kang, W. Dang, and Y. Feng, “A Data-Characteristic-Driven Decomposition Ensemble Forecasting Research on the Demand of Space Science Payload Components,” Wirel. Commun. Mob. Comput., vol. 2022, 2022, doi: 10.1155/2022/8711607. [14] B. U. Islam and S. F. Ahmed, “Short-Term Electrical Load Demand Forecasting Based on LSTM and RNN Deep Neural Networks,” Math. Probl. Eng., vol. 2022, 2022, doi: 10.1155/2022/2316474. [15] S. M. T. U. Raju et al., “An Approach for Demand Forecasting in Steel Industries Using Ensemble Learning,” Complexity, vol. 2022, 2022, doi: 10.1155/2022/9928836. [16] R. Yao, S. Jin, C. Wei, and J. Kong, “A Novel Robust Grey Model for Forecasting Chinese Electricity Demand,” Discret. Dyn. Nat. Soc., vol. 2022, 2022, doi: 10.1155/2022/2182748. [17] B. Li and J. Gao, “Regional Tourism Economic Forecasting Model Based on GM Grey Forecasting Method,” Math. Probl. Eng., vol. 2022, 2022, doi: 10.1155/2022/3477246. [18] C. Deng and Y. Liu, “A Deep Learning-Based Inventory Management and Demand Prediction Optimization Method for Anomaly Detection,” Wirel. Commun. Mob. Comput., vol. 2021, no. Im, 2021, doi: 10.1155/2021/9969357. [19] F. Jia and B. Yang, “Forecasting Volatility of Stock Index: Deep Learning Model with Likelihood-Based Loss Function,” Complexity, vol. 2021, 2021, doi: 10.1155/2021/5511802. [20] X. Ma, “Tourism Demand Forecasting Based on Grey Model and BP Neural Network,” Complexity, vol. 2021, 2021, doi: 10.1155/2021/5528383. [21] A. Macías-López, L. E. Cárdenas-Barrón, R. E. Peimbert-García, and B. Mandal, “An Inventory Model for Perishable Items with Price-, Stock-, and Time-Dependent Demand Rate considering Shelf-Life and Nonlinear Holding Costs,” Math. Probl. Eng., vol. 2021, 2021, doi: 10.1155/2021/6630938. [22] F. Wang, S. Tang, and M. Li, “Advantages of Combining Factorization Machine with Elman Neural Network for Volatility Forecasting of Stock Market,” Complexity, vol. 2021, 2021, doi: 10.1155/2021/6641298. [23] J. Wu, “Method for Forecasting Urban National Sports and Fitness Demand Based on Ant Colony Algorithm,” Comput. Intell. Neurosci., vol. 2021, 2021, doi: 10.1155/2021/5917756. [24] X. Guo, Q. Zhao, S. Wang, D. Shan, and W. Gong, “A Short-Term Load Forecasting Model of LSTM Neural Network considering Demand Response,” Complexity, vol. 2021, 2021, doi: 10.1155/2021/5571539. [25] A. H. Alenezy et al., “Forecasting Stock Market Volatility Using Hybrid of Adaptive Network of Fuzzy Inference System and Wavelet Functions,” J. Math., vol. 2021, 2021, doi: 10.1155/2021/9954341. [26] R. Bhol, S. C. Swain, R. Dash, K. J. Reddy, C. Dhanamjayulu, and B. Khan, “Short-Term Reactive Power Forecasting Based on Real Power Demand Using Holt-Winters’ Model Ensemble by Global Flower Pollination Algorithm for Microgrid,” Int. J. Energy Res., vol. 2023, pp. 1–22, 2023, doi: 10.1155/2023/9733723. [27] L. Li, X. Hou, and L. Niu, “Research on Demand Forecasting Information Sharing Strategy of Closed-Loop Supply Chain considering Advertising Effect,” Discret. Dyn. Nat. Soc., vol. 2023, 2023, doi: 10.1155/2023/1148798. [28] Z. A., A. Kraikin, A. Mikhaylov, and G. Pinter, “Forecasting Stock Prices of Companies Producing Solar Panels Using Machine Learning Methods,” Complexity, vol. 2022, 2022, doi: 10.1155/2022/9186265. [29] X. Lu, “A Human Resource Demand Forecasting Method Based on Improved BP Algorithm,” Comput. Intell. Neurosci., vol. 2022, 2022, doi: 10.1155/2022/3534840. [30] Y. Yang, W. Liu, T. Zeng, L. Guo, Y. Qin, and X. Wang, “An Improved Stacking Model for Equipment Spare Parts Demand Forecasting Based on Scenario Analysis,” Sci. Program., vol. 2022, 2022, doi: 10.1155/2022/5415702. [31] Y. F. Chen et al., “Design of a clinical decision support system for fracture prediction using imbalanced dataset,” J. Healthc. Eng., vol. 2018, 2018, doi: 10.1155/2018/9621640.

Copyright

Copyright © 2024 Shailesh Choudhary. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET58733

Publish Date : 2024-03-02

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online