Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- References

- Copyright

An Overview on 3D Printing

Authors: Ashish Jha, Tanmay Sharma, Suyash Jain, Rahul Poddar , Navjot Kaur Bhatiya

DOI Link: https://doi.org/10.22214/ijraset.2024.62845

Certificate: View Certificate

Abstract

As technology advances, innovations are beginning to appear in the building industry. Among these are the advances made in 3-D printing technology. The materials and methods available at the period are used by civil engineers to construct buildings. Because 3D printing technology is currently faster, less expensive, requires less work, and has a lower error margin than traditional construction methods, it is gaining interest. This technique allows for the production of small-scale, diverse products as well as intricately designed buildings. Creating structures using 3D printing printers requires, first and foremost, 3D model design. A recipe for building materials should be created by determining the proper mixing ratios in order to be able to stack layers on top of one another without collapsing and to carry out 3D printing without shrinkage cracks. The printing layer\'s breadth and thickness are continuously regulated during the building material placement process, which creates layered production without the need for a Mold. In buildings constructed with this technique, consideration is given to the use of sustainable building materials. Studies are also conducted on the usage of materials with zero waste. This study aims to analyse the literature and provide a quick introduction to this new generation of methods.

Introduction

I. INTRODUCTION

3D PRINTING is the new technology in the construction sector; there are strong arguments on the benefits offered and challenges to overcome by this technology. Industries have begun to re-establish their production systems with the developing technology. 3D printing technology has also been improving of late years, along with additive manufacturing. 3D printing technologies enable design optimization and have advantages over traditional manufacturing methods. It is necessary to keep up with the new age in order to survive in the variable sector with the increase in the competitive environment. The construction industry is also under the pressure of change due to technological developments. Therefore, it is attracting great attention in the construction industry as a new strategic challenge. Among the numerous prospects of 3D Concrete Printing as found in the literature, cheaper construction, reduced material use, improved safety, less reliance on human resources, better branding and market share, durable and sustainable construction, etc., are widely discussed. One of the main advantages of 3D Concrete Printing is found to be savings in labour requirements. Even though construction works are historically very labour intensive, the impact of the labour market due to the use of 3D Printing in construction has not been extensively investigated. Labour plays an important role in the construction industry. As mentioned earlier, according to the International Labor Organization, the construction industry produces about 8.4% employment in the world. In the contrary, the industry is struggling to improve the productivity for decades since construction works are highly dependent on human workforces with little use of technology and industrialization. These workforces account at least 25% of the total project cost. Often unskilled labour and/or shortage of labour also hamper the construction progress. Surely, increasing use of technologies including the 3D Concrete Printing would minimize the reliance on human resources with the potential to increase productivity and improve occupational safety and health of the workers by reducing risky works are to be done with innovative technologies. Therefore, a large-scale adoption of 3D Printing in construction could be beneficial for the construction industry with a possibility of significant job cuts for many people around the world. This is an ambivalent situation that should be explored in more detail. Accordingly, this study investigates the impact of labour market due to the use of 3D Printing in construction. Through a wider search of the literature and case study analyses, the study aims to understand how 3D Concrete Printing would replace conventional construction activities in terms of labour requirements, labour cost, productivity improvement, occupational safety and health, and effects on job market. The study would be particularly important for the countries where construction is one of the major workforces, as well as for the places where there is a shortage of skilled construction labourers and workers and are highly dependent on migrated workers. The application of 3D printers has taken its place in the field of engineering, especially in the field of medicine and automotive. There have been developments in additive production technology in layers with cement and various materials.

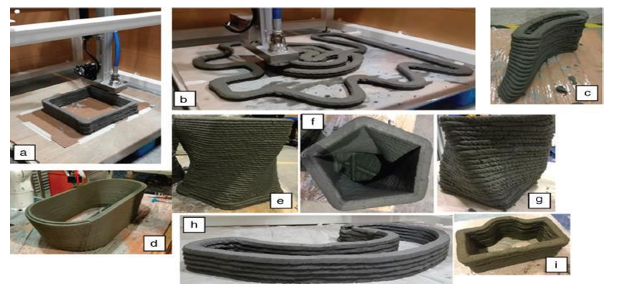

This technology has emerged as a joint product of materials science, robotic coding and architectural design studies, using the advantages of shotcrete and self-compacting concrete. In this type of printing, the ability to pump, workability and construct of fresh concrete and the strength of hardened concrete are of great importance.

Rheological properties such as viscosity and yield stress are also considered critical properties to control the printable property of printer concrete. The lack of a certain standard in the mixture design and the insufficient number of studies affect these properties negatively. The main purpose of this paper is to briefly review 3D printing technology applications in the construction industry. The studies discuss the future of 3D printing technology in the field of construction and suggestions are made for possible uses in the construction industry. Traditional manufacturing methods are based on the principle of subtracting material from the raw material during the manufacture of parts. In additive manufacturing, which is one of the new production techniques that has become widespread today, unlike traditional manufacturing methods based on material reduction techniques from the part, the part is produced directly from the material. The device used in manufacturing manufactures the part layer by layer by following a tool path derived from the geometry of the part to be produced. It is possible to produce parts with complex geometries and the loss of material during manufacturing is at a minimum level due to this unique feature of additive manufacturing. The foundations of the additive manufacturing method date back to the 1980s. It is known that the SLA-1 device produced by the 3D System company is the first 3D printer system. Additive manufacturing is one of the modern manufacturing methods that has gained importance in recent years. It is a form of manufacturing in which the 3D model is obtained by adding layer by layer the powders to be built using geometric data. With additive manufacturing methods, parts with complex geometry can be obtained quickly. The 3D manufacturing process is divided into subclasses such as SLA (Stereolithography), SLS (Selective Laser Sintering), FDM (Fused Deposition Modelling), DLP (Digital Light Processing), EBM (Electron Beam Melting) and LOM (Laminated Object Manufacturing) according to the materials used and the principle of combining materials. 3D printing technology, which has caused changes by breaking new ground in diverse sectors, has moreover affected the construction sector. Building production in construction contains of significant stages like design, projecting and implementation. With the improvement of innovation, digital manufacturing has been used for a long time in the design and projecting phase of buildings. The design and projection of the building is supported two-dimensional (2D) drawings and scale models. Today, 2D drawings and prototypes are replaced by three-dimensional (3D) modelling techniques. Designers, architects and engineers have had the advantage of making the necessary changes in their projects easily, seeing the problems that may arise before the implementation and making the changes that occur in unforeseen situations during the implementation phase with digital modelling methods. The implementation phase of building production, on the other hand, did not change as fast as the design process and remained dependent on the traditional method of building production. ?n the last years, the interest in 3D printing technology has increased because of the fact that it provides design freedom, less error margin, less material wastage, less waste material, and reduced cost compared to the traditional method in the construction industry.

II. 3D PRINTING TECHNOLOGY

3D printing can create physical objects from a geometrical representation by successive addition of material. This 3D process has experienced a phenomenal expansion in recent years. First commercialized of the 3D printing processes in year 1980 by Charles Hull. Currently, 3D printing is primarily used for producing artificial heart pumps, jewelry collections, 3D printed cornea, PGA rocket engine, steel bridge in Amsterdam and other products related to the aviation industry as well as the food industry.

3D printing technology has originated from the layer-by-layer fabrication technology of three-dimensional (3D) structures directly from computer-aided design (CAD) drawing. 3D printing technology is truly innovative and has emerged as a versatile technology stage. It opens new opportunities and gives hope to many possibilities for companies looking to improve manufacturing efficiency. Conventional thermoplastics, ceramics, graphene-based materials, and metal are the materials that can be printed now by using 3D printing technology. 3D printing technology has the potential to revolutionize industries and change the production line.

The adoption of 3D printing technology will increase the production speed while reducing costs. At the same time, the demand of the consumer will have more influence over production. Consumers have greater input in the final product and can request to have it produced to fit their specifications at the mean time the facilities of 3Dprinting technology will be located closer to the consumer, allowing for a more flexible and responsive manufacturing process, as well as greater quality control.

Furthermore, when using 3D printing technology, the need for global transportation is significantly decreased. This is because, when manufacturing sites are located nearer to the end destination, all distribution could be done with fleet tracking technology that saves energy and time. Lastly, the adoption of 3D printing technology can change the logistics of the company. The logistics of the companies can manage the entire process, offer more comprehensive and start-to-finish services. Nowadays, 3D printing is widely used in the world. 3D printing technology is increasingly used for the mass customization, production of any types of open- source designs in the field of agriculture, in healthcare, automotive industry, and aerospace industries. At the same time, there are several disadvantages to the adoption of 3D printing technology in the manufacturing industry. For instance, the effect of the use of 3D printing technology is that it will reduce the use of manufacturing labor so automatically will greatly affect the economy of countries that rely on a large number of low skill jobs.Furthermore, by using 3D printing technology, users can print many different types of objects such as knives, guns and dangerous items. Therefore, the use of 3D printing should be limited to only certain people to prevent terrorists and criminals bring guns without detected. At the same time, the people who get a hold of a blueprint will be able to counterfeit products easily. This is because the use of 3D printing technology is simple, just sketching, and setting the data in the machine-printed so 3D objects can generate. To sum up, 3D printing technology has emerged during recent years as a flexible and powerful technique in advanced manufacturing industry. This technology has been widespread in many countries, especially in the manufacturing industry. Therefore, this paper presents an overview of the types of 3-D printing technologies, the application of 3D printing technology and lastly, the materials used for 3D printing technology in the manufacturing industry.

III. 3D PRINTING IN CONSTRUCTION

In the construction industry, 3D printing can be used to create construction components or to 'print' entire buildings. Construction is well-suited to 3D printing as much of the information necessary to create an item will exist as a result of the design process, and the industry is already experienced in computer aided manufacturing. The recent emergence of building information modelling (BIM) in particular may facilitate greater use of 3D printing. Construction 3D printing may allow, faster and more accurate construction of complex or bespoke items as well as lowering labour costs and producing less waste. It might also enable construction to be undertaken in harsh or dangerous environments not suitable for a human workforce such as in space. The 3D printing systems created specifically for construction are commonly known as "construction 3D printers." A 3D sprinting project typically starts with a 3D digital model of the structure that needs to be constructed. The model is virtually sliced into layers. The printing robot or gantry system then follows a pre-programmed path to deposit each layer of material, tracing the layer outlines and extruding material until it has completed the whole slice. Once one layer is complete, it begins the next on top of the first, and construction continues like this until the full structure is built. It may use materials such as concrete, metal, or polymers to form this 3D structure.

The most common 3D printing technology for construction involves a robotic arm that extrudes concrete while moving back and forth. Powder binding and additive welding are other methods used for 3D printing in construction. Powder binding involves the solidification of powder layers to create the desired object. Additive welding was demonstrated in Amsterdam with the printing of a functional, full-scale metal bridge. To date, 3D printing has been used to print houses, offices, and other structures. It is computer-controlled technology that is helping us to build a three-dimensional object by the process of additive manufacturing, which creates objects by adding layers to them. Additive manufacturing allows us to create complex designs and the best part is that it takes very little time to build, and it builds houses with very few labours, and the cost estimation for construction is very low. 3D printing in the construction industry is revolutionary and enormously getting attention from every part of the construction industry of the world. In this research paper, we had worked on three major areas of 3d printers considering their work in the construction industry. It was developed in the early 80s but at that time, it was of no use because it was very costly and expensive to use. In 2000, it became relatively friendly to use, as it allows to create the design on the computer and the cost comparison was very less as it uses plastics and waste materials to form the concrete of 3D houses. And suddenly it became affordable and became viable for a wide range of design, models, etc. The construction industry is slow to embrace new technologies. In recent years, though, 3D printing has emerged as a promising solution to many of the industry’s challenges. 3D printing, also known as additive manufacturing, is a process of laying down cross-sectional layers of material one after another until the complete object is built. This technique has been used for decades in the automotive and aerospace industries, among others. Its potential for construction, however, has only recently been explored. Technology has the potential to revolutionize the way we design and build structures, making construction faster, more efficient, and more sustainable.

IV. CASE STUDY

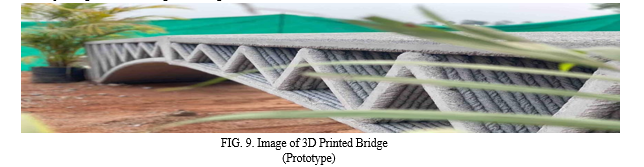

1. Prototype 3D Printed Bridge

Developed as a collaboration between IIT Hyderabad and Simpliforge Creations in India. IIT Hyderabad’s Department of Civil Engineering, led by Prof. KVL Subramaniam, designed and evaluated a prototype 3D printed bridge. Although not a building, this project showcases the application of 3D printing technology in civil engineering infrastructure. The bridge represents a step forward in exploring innovative construction methods. The bridge stands at Charvitha Meadows, Siddipet, India. The bridge was designed at IIT Hyderabad using form optimization techniques to reduce the use of concrete and reinforcement. The concept followed the “Material Follows Force” principle, resulting in an efficient structural form. Simpliforge Creations, a startup specializing in 3D concrete printing solutions, brought the design to life.

They created a custom extrusion and software system specifically for this project, fully demonstrating the benefits of their 3D printing system. The bridge was printed off-site in less than 2 hours at Simpliforge’s printing facility using an industrial robotic arm 3D printer. Significance: 3D concrete printing has the potential to transform the construction industry by offering rapid, efficient, and free-form construction. This project showcases the capabilities of 3D construction printing technology and its applications in infrastructure, defence, and disaster scenarios.

2. India’s First 3D Printed Two-Storey Building

It is located in Kanchipuram facility near Chennai, India. India’s largest construction company, Larsen & Toubro Construction (L&T), completed the country’s first 3D printed two-Storey building. The structure has a modest floor space of 65m² and was fabricated using a large-format concrete 3D printer supplied by OEM COBOD. L&T’s in-house team developed a locally sourced 3D printable concrete mix for the project. Notably, the building adheres to all of India’s building codes and features integrated reinforcement bars. The entire construction process took 106 hours. It is a two-Storey structure. The building boasts a modest floor space of 65 square meters (approximately 700 square feet). The entire building, including roofs and foundations, is 3D printed using an in-house developed concrete mix. L&T Construction, India’s largest construction company, spearheaded this project. They used a large-format concrete 3D printer supplied by OEM COBOD. The building even features integrated reinforcement bars and is fully compliant with all of India’s building codes.

By demonstrating expertise in 3D printing, L&T Construction pushes the boundaries of automated robotic construction. The project aligns with India’s goal of providing real housing for its citizens as part of the ‘Housing for All by 2022’ program.

3. Post Office

India’s first 3D printed post office was inaugurated in Bengaluru, and it’s quite a remarkable feat in construction technology. The post office is located at Cambridge Layout in east Bengaluru. It was built using 3D Concrete Printing Technology by Larsen & Toubro Construction, with structural design assistance from the Indian Institute of Technology (IIT) Madras. The construction was originally scheduled to be completed in 45 days, but it was finished in just 43 days. The adoption of 3D printing technology resulted in a cost saving of 30-40% compared to conventional construction methods. It also allowed for more flexibility in the shape of the building. The post office has a built-up area of 1,000 square feet. The post office was inaugurated on August 18, 2023, by Ashwini Vaishnav, Union Minister for Railways, Communications, and Electronics & Information Technology. This project represents a major milestone in architectural innovation and is a testament to India’s progress in adopting new technologies.

References

[1] Dickens PM. (1995) Research development in rapid prototyping. Proceedings of the Institution of Mechanical Engineers, 209(4): 261-266. [2] Dong Jie, Zhao Shengxiang, Tie Mei. (2013 )3D printing technology -- A New Revolution in Manufacturing Technology. Science Think Tank, 05: 80-86. [3] Li ran, Qi Xiangdong. (2015) Application and Research of 3D Printing Technology in Construction Industry. Electronic Technology and Software Engineering, 05:102 [4] Luo Yi. (2020) Application and Development Prospect of 3d Printing Architecture. Journal of Shenzhen Vocational and Technical College, 01:34-39. [5] Chen Jing. (2015) Current situation and Prospect of 3D printing construction Technology. Sichuan Cement, 10:37+27. [6] Lei Sheng, Lei Wu. (2021) Review of 3D Printed Concrete Technology Research. China Concrete and Cement Products, 10:7-11. [7] Ding Liyun, Xu Jie, Qin Yawei. (2015) A Review of the Research and Application of 3d Printing in Building Digital Construction Technology. Journal of civil engineering and management, 03:1-10. [8] https://manufactur3dmag.com/iith-simpliforge-india-first-3d-printed-bridge. [9] https://economictimes.indiatimes.com/industry/indl-goods/svs/engineering/lt-first-to-3d-print-ground-plus-one-building-in-india/articleshow/79938589.cms. [10] https://www.livemint.com/news/india/l-t-prints-3d-ground-plus-one-building-in-india-11608802479662.html. [11] https://3dprintingindustry.com/news/lt-construction-completes-indias-first-3d-printed-two-storey-building-in-106-hours-182514/ [12] https://www.arch2o.com/3d-printed-house-apis-cor/ [13] https://www.arch2o.com/3d-printed-house-apis-cor/arch2o-3d-printed-house-by-apis-cor-entirely-created-in-one-day-4/ [14] https://www.arch2o.com/wp-content/uploads/2017/11/Arch2O-3d-printed-house-by-apis-cor-entirely-created-in-one-day-2.jpg [15] https://materialdistrict.com/article/amsterdams-3d-printed-cabin/ [16] https://materialdistrict.com/wp-content/uploads/2016/08/amsterdam-s-3d-printed-cabin-04.jpg [17] https://www.bing.com/search?q=urban+cabin+amsterdam+%2c+netherlands+3d+printing&is=NW_XFC&pq=urban+cabin+amsterdam+%2c+netherlands+3d+pr&sk=NW_XFC1&sc=10-41&cvid=95B4A48C4F7943D5AE2D2B48F1554E3C&FORM=QBRE&sp=2&ghc=1&lq= [18] https://3dprinting.com/construction/dubai-unveils-worlds-largest-on-site-3d-printed-building/ [19] https://www.bing.com/search?q=milestone+project+dubai%2c+uae+3d+printing&qs=NW_XFC&pq=milestone+project+dubai%2c+uae+3d+pr&sc=1034&cvid=4A98217921EC4E68BD4C2D1DCBDE4CC0&FORM=QBRE&sp=1&ghc=1&lq=0 [20] https://3dprintingindustry.com/news/a-french-family-is-the-first-to-move-into-a-3d-printed-house-135881 [21] https://www.iconbuild.com/projects/house-zero [22] https://www.archdaily.com/960714/tecla-technology-and-clay-3d-printed-house-mario-cucinella-architects/6087223bf91c81a7b80001c9-tecla-technology-and-clay-3d-printed-house-mario-cucinella-architects-sketch [23] https://www.archdaily.com/960714/tecla-technology-and-clay-3d-printed-house-mario-cucinella-architects [24] https://www.archdaily.com/960714/tecla-technology-and-clay-3d-printed-house-mariocucinella-architects/6087215df91c81a7b80001bc-tecla-technology-and-clay-3d-printedhouse-mario-cucinella-architects-photo [25] https://www.bing.com/search?q=Tecla%20House%20Italy&qs=ds&form=ATCVAJ

Copyright

Copyright © 2024 Ashish Jha, Tanmay Sharma, Suyash Jain, Rahul Poddar , Navjot Kaur Bhatiya. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62845

Publish Date : 2024-05-28

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online