Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Analysis of Deflection Characteristics in Externally Reinforced PCC Beams: An Ansys-Based Study Comparing Bonded Steel Plate Applications and Thickness Change Criteria

Authors: Shruti Vaidya, Dr. Umesh Pendharkar

DOI Link: https://doi.org/10.22214/ijraset.2024.64034

Certificate: View Certificate

Abstract

The study of deflection characteristics of externally reinforced plain cement concrete (PCC) beams using ANSYS represents a crucial exploration in civil engineering. This research examines the ultimate behaviour of PCC beams improved with external reinforcement, focusing on their deflection properties under different loading conditions. After identifying the gaps of the literature review, the different objectives have decided such as study of PCC beam, selecting the deflection parameter, using FEM modelling to check the behaviour, application of steel plate type retrofitting method over different faces of member, under different thickness of retrofitted steel plates with different grades of concrete. This study has distributed under two findings. In former one, the application of with and without usage of bonding steel plate and in latter, the comparison in terms of thickness change criteria is selected. After simulation the results have drawn and the conclusions have compared. After comparing different cases with each other, the study shows that the PCC beam will perform better using different thickness of external reinforcement of steel plates type retrofitting in combination with different grades, simultaneously deflection reduced accordingly under the application of load.

Introduction

I. INTRODUCTION

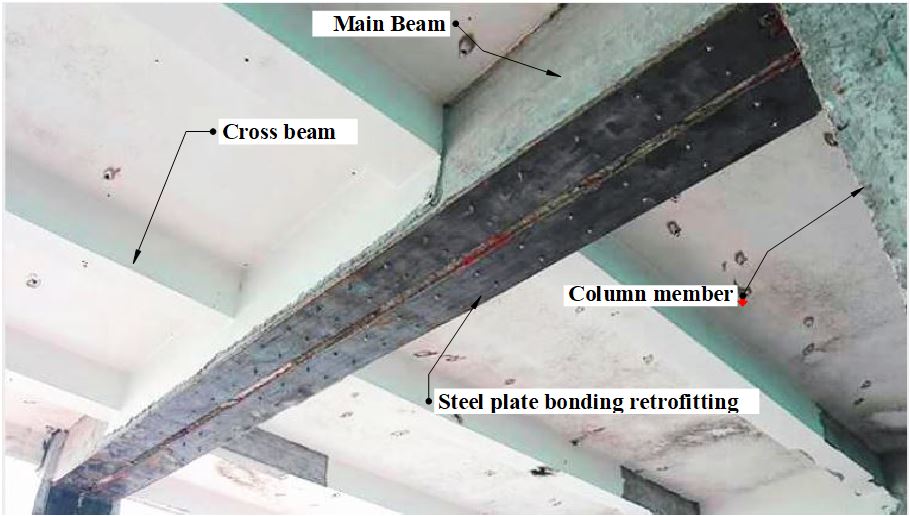

In the field of civil engineering, the retrofitting of existing structures is considered a crucial practice aimed at enhancing the load-carrying capacity, durability, and overall performance of buildings and infrastructure. Among the various retrofitting techniques available, the steel plate bonding method is recognized as a highly effective and versatile approach.

This method involves the application of steel plates to the surface of structural elements, such as beams, columns, and slabs, to improve their mechanical properties and extend their service life. Increased durability is achieved through the application of external reinforcement, especially in cases where PCC beams are utilized.

II. APPLICATION OF EXTERNAL REINFORCEMENT

The use of steel plates as external reinforcement enhances structural capacity and extends the life of buildings by bonding or bolting them to beams, columns, and slabs. This method increases load-bearing capacity, flexural, and shear strength, providing a quick and effective solution with minimal disruption. Properly coated steel plates offer excellent corrosion resistance and are cost-effective compared to structural replacement.

They can be custom-fabricated for various shapes and sizes, improving performance, especially in seismic regions. Additionally, steel plates preserve the aesthetics of historical buildings while significantly enhancing their structural integrity. The fig. 1 below shows the application of steel plate as retrofitting to beam member.

Fig: 1: Application of steel plate as external reinforcement to PCC beam member

III. RESEARCH OBJECTIVES

Taking into account the outlined problem statement to propose a new research work that provides the solution to the selected problem statement, the need and identification of the research gap has achieved. Following are the selected objectives:

- To study a Precast Cement Concrete beam member and its behavior by selecting the deflection parameter.

- To check the internal and external behavior of flexural member, the member selected with a fixed dimension in analysis software ANSYS, using a Finite Analysis Modeling with selected boundary conditions.

- To study the same beam member by using the application of steel plate type retrofitting method over different faces of member so that comparative analysis conducted.

- Retrofitting of a beam in service aims to achieve better flexure capacity. This study extended to determine the response of behaviour of flexure member under different thickness of retrofitted steel plates.

- The stiffness of the member plays an important role in analyzing the behavior under loading. This study can be extended for the determination of behaviour of flexure member made up of different concrete grades.

This study has distributed into three findings under head Study I and Study II

1) Study I: Application of with and without usage of bonding steel plate

In this part, the comparison of the deflection behavior under different loads on PCC member with and without using bonding steel plate application over different faces has selected.

2) Study II: Comparison in terms of thickness change criteria

In this part, the thickness of steel bonding plate is also in varying form, hence in this part the thickness change criteria has selected and determination of deflection behavior by variation of changing the thickness.

IV. PROCEDURE AND 3D MODELLING OF THE STRUCTURE

Comprehensive input data and its descriptions about the model given below. The input data used for creation of PCC beam and external reinforcement made up of steel are shown below:-

Table 1: General data used

|

Constraint |

Data used for all model cases |

|

Cross section of beam |

200mm x 300mm |

|

Span of beam |

3000mm |

|

Modulus of elasticity |

E = 5000 x (Fck)^0.5 For M20 = 22360.679 N/sq. mm For M25 = 25000 N/sq. mm For M30 = 27386.127 N/sq. mm For M35 = 29580.398 N/sq. mm |

|

Poisson’s ratio |

M20 – 0.15-0.20 M25 – 0.18-0.22 M30 – 0.20-0.25 M35 – 0.22-0.28 |

|

FEM mesh size |

20mm x 20mm |

|

Bonding steel plate thickness |

3mm, 6mm and 9mm |

|

Bonding steel plate grade |

Fe 250 grade |

|

Modulus of elasticity |

E = 200,000 MPa |

Table 2: Loading data used

|

Constraint |

Data used for all model cases |

|

Dead load |

Self-weight |

|

Point load of 100KN |

|

|

Point load of 200KN |

|

|

Point load of 300KN |

|

|

Point load of 400KN |

|

|

Point load of 500KN |

Table 3: Various cases used for comparative analysis

|

Models framed for analysis |

Abbreviation |

|

Simply supported PCC beam without using bonding steel plate |

SB |

|

Simply supported PCC beam using bonding steel plate of 3mm thickness at base |

SB-3B |

|

Simply supported PCC beam using bonding steel plate of 6mm thickness at base |

SB-6B |

|

Simply supported PCC beam using bonding steel plate of 9mm thickness at base |

SB-9B |

|

Simply supported PCC beam using bonding steel plate of 3mm thickness at two side faces |

SB-3S |

|

Simply supported PCC beam using bonding steel plate of 6mm thickness at two side faces |

SB-6S |

|

Simply supported PCC beam using bonding steel plate of 9mm thickness at two side faces |

SB-9S |

|

Simply supported PCC beam using bonding steel plate of 3mm thickness at base and two side faces |

SB-3BS |

|

Simply supported PCC beam using bonding steel plate of 6mm thickness at base and two side faces |

SB-6BS |

|

Simply supported PCC beam using bonding steel plate of 9mm thickness at base and two side faces |

SB-9BS |

|

Simply supported PCC beam using bonding steel plate of 3mm thickness at base, two side faces and top face |

SB-3BST |

|

Simply supported PCC beam using bonding steel plate of 6mm thickness at base, two side faces and top face |

SB-6BST |

|

Simply supported PCC beam using bonding steel plate of 9mm thickness at base, two side faces and top face |

SB-9BST |

Note: here,

SB = Simply supported PCC beam

3B/6B/9B = provided Bonding Steel Plate of 3mm/6mm/9mm thickness at base

3S/6S/9S = provided Bonding Steel Plate of 3mm/6mm/9mm thickness at two side faces

3BS/6BS/9BS = provided Bonding Steel Plate of 3mm/6mm/9mm thickness at both base and at two side faces

3BST/6BST/9BST = provided Bonding Steel Plate of 3mm/6mm/9mm thickness at base, at two side faces and top face

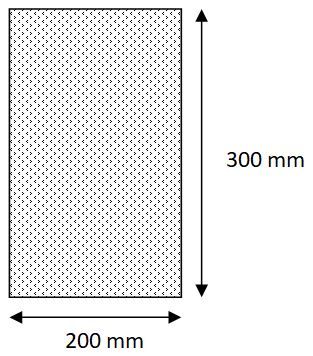

Fig. 2: Cross section of simply supported PCC beam without using bonding steel plate (SB)

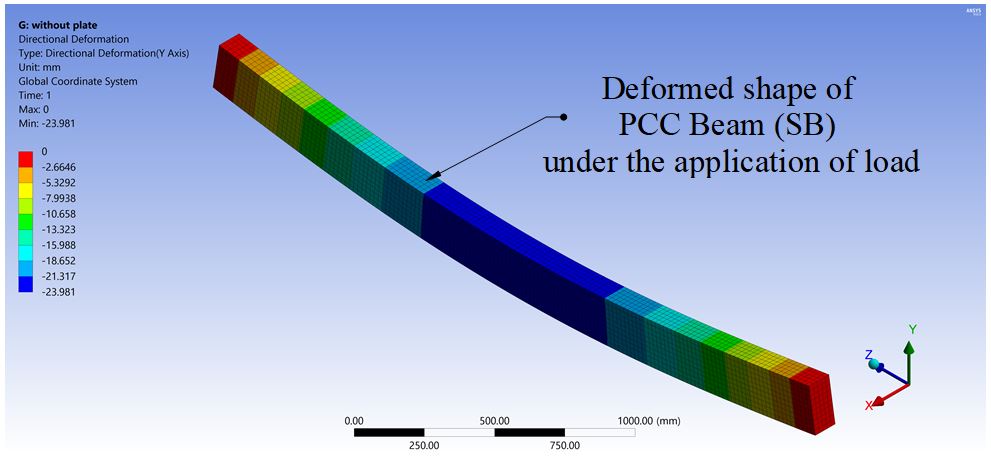

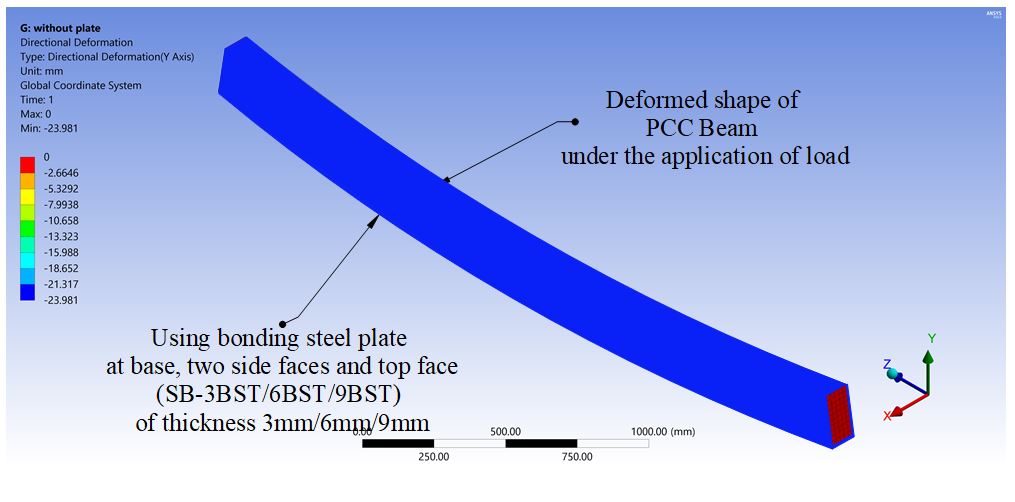

Fig. 3: Deformed view of simply supported PCC beam without using bonding steel plate (SB)

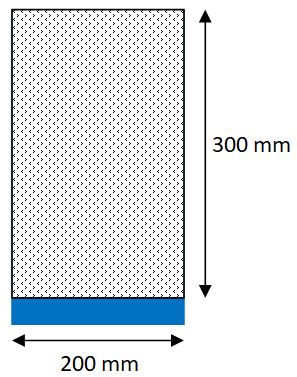

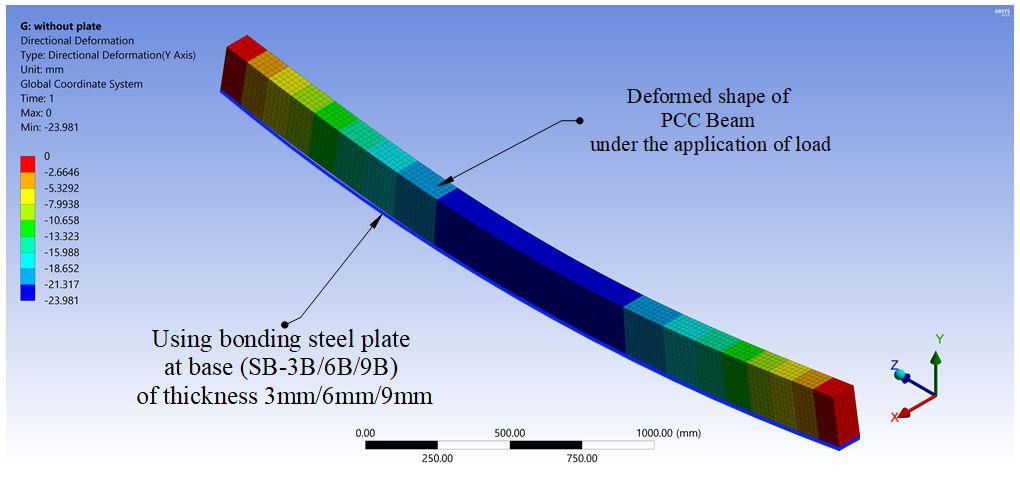

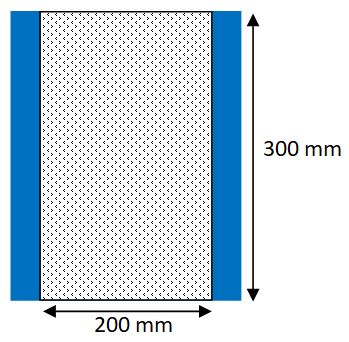

Fig. 4: Cross section of simply supported PCC beam using bonding steel plate of 3mm/6mm/9mm thickness at base (SB-3B/6B/9B)

Fig. 5: Deformed view of simply supported PCC beam using bonding steel plate of 3mm/6mm/9mm thickness at base (SB-3B/6B/9B)

Fig. 7: Deformed view of simply supported PCC beam using bonding steel plate of 3mm/6mm/9mm thickness at two side faces (SB-3S/6S/9S)

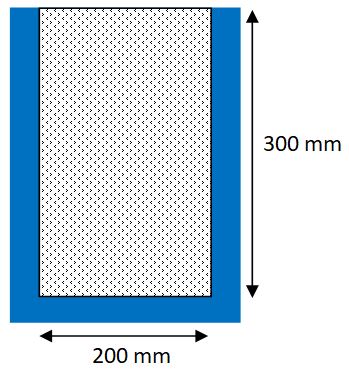

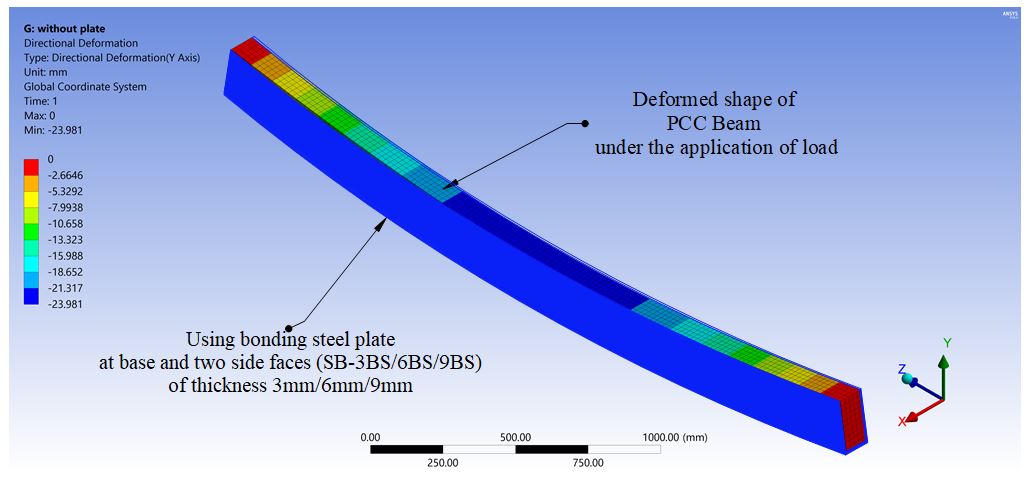

Fig. 8: Cross section of simply supported PCC beam using bonding steel plate of 3mm/6mm/9mm thickness at base and two side faces (SB-3BS/6BS/9BS)

Fig. 9: Deformed view of simply supported PCC beam using bonding steel plate of 3mm/6mm/9mm thickness at base and two side faces (SB-3BS/6BS/9BS)

Fig.10: Cross section of simply supported PCC beam using bonding steel plate of 3mm/6mm/9mm thickness at base, two side faces and top face (SB-3BST/6BST/9BST)

Fig. 11: Deformed view of simply supported PCC beam using bonding steel plate of 3mm/6mm/9mm thickness at base, two side faces and top face (SB-3BST/6BST/9BST)

Fig. 11: Deformed view of simply supported PCC beam using bonding steel plate of 3mm/6mm/9mm thickness at base, two side faces and top face (SB-3BST/6BST/9BST)

V. RESULTS ANALYSIS

Comparative results as per different objectives decided are shown in the form of figures 12 to 16 below:-

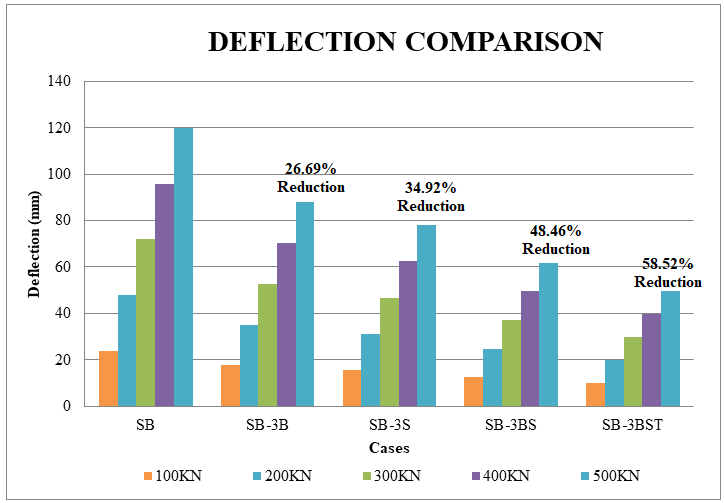

1) Study I: Application of with and without usage of bonding steel plate

Fig. 12: Deflection comparison for Study I

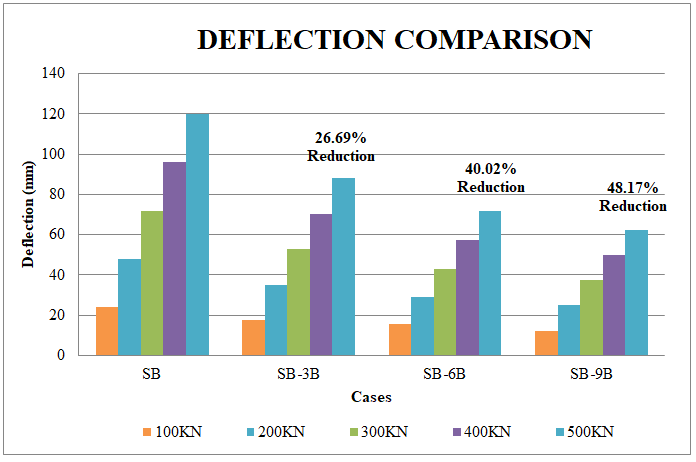

2) Study II: Comparison in terms of thickness change criteria

Fig. 13: Deflection comparison using bonding steel plate of 3mm, 6mm, 9mm thickness at base

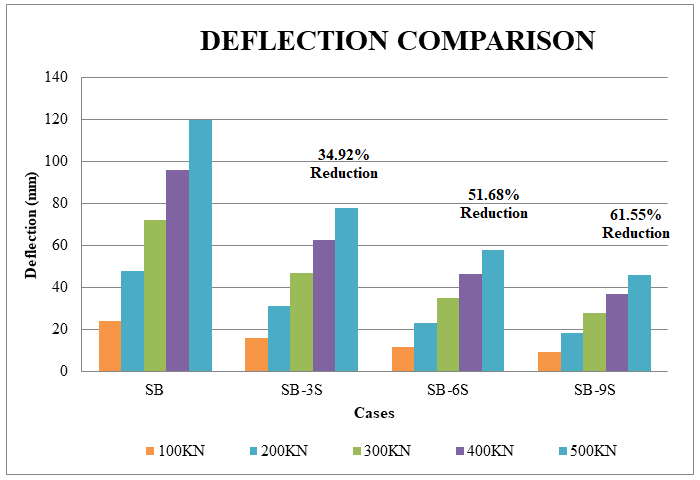

Fig. 14: Deflection comparison using bonding steel plate of 3mm, 6mm, 9mm thickness at two side faces

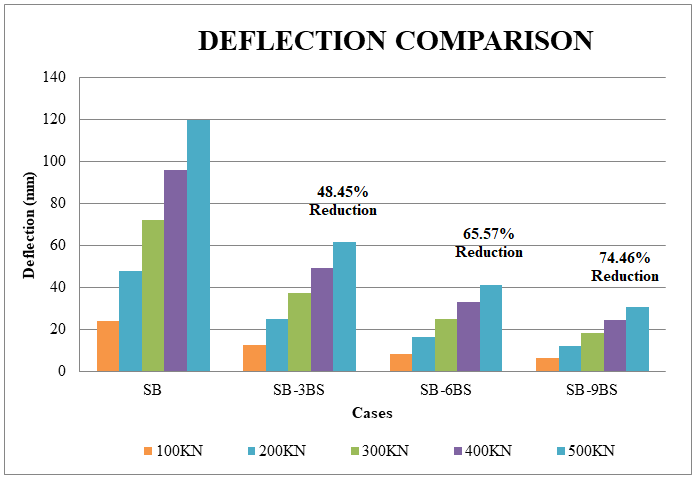

Fig. 15: Deflection comparison using bonding steel plate of 3mm, 6mm, 9mm thickness at base and two side faces

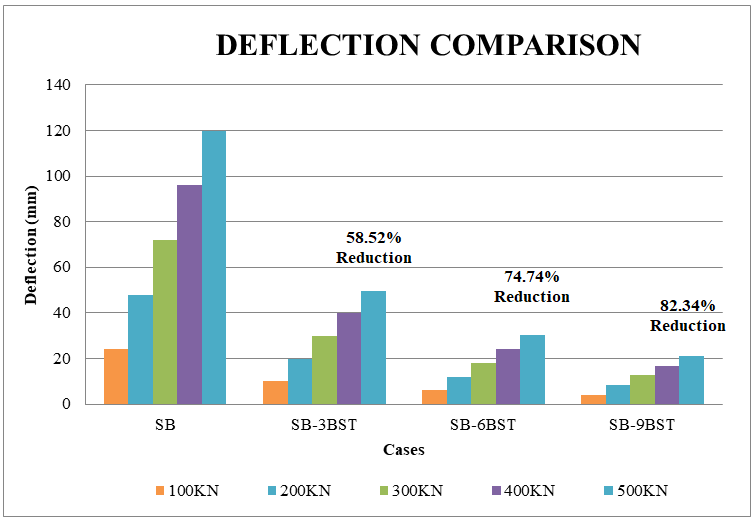

Fig. 16: Deflection comparison using bonding steel plate of 3mm, 6mm, 9mm thickness at base, two side faces and top face

Conclusion

A conclusion for comparison of distinct cases involves different models simulation and comparative results have drawn that has provided below with recommendations separately:- 1) Conclusions for comparison based on application of with and without usage of bonding steel plate-Study I • On comparing maximum deflection values, fixing the loading values from 100 KN to 500 KN, concrete grade M20 and 3mm bonding steel plate as constants, for different cases, the deflection values reduced by 26.69 % when using bonding steel plate at base. • 34.92 % reduction has observed when using bonding steel plate at two side faces. • The maximum deflection values reduced by 48.46 % when using bonding steel plate at base and two side faces. • By using the bonding steel plates at base, two side faces and top face, the maximum deflection reduced by 58.52 % which is more reduction as compared to all the cases. This part of the project concluded that the usage of bonding steel plate type retrofitting is more effective for reducing the deflection values. The reduction of deflection is more when covering maximum faces of the beam. 2) Conclusions for comparison based on thickness change criteria-Study II • On comparing maximum deflection values, fixing the loading values from 100 KN to 500 KN, concrete grade M20 and using 3mm, 6mm and 9mm bonding steel plate as constants, for different cases, the deflection values reduced by 26.69 % for 3mm, 40.02 % for 6mm and 48.17 % for 9mm when using bonding steel plate at base. • 34.92 % reduction has observed for 3mm, 51.68 % for 6mm and 61.55 % for 9mm when using bonding steel plate at two side faces. • The maximum deflection values reduced by 48.45 % for 3mm, 65.57 % for 6mm and 74.46 % for 9mm when using bonding steel plate at base and two side faces. • By using the bonding steel plates at base, two side faces and top face, the maximum deflection reduced by 58.52 % for 3mm, 74.74 % for 6mm and 82.34 % for 9mm which is more reduction as compared to all the cases. This part of the project concluded that the usage of bonding steel plate type retrofitting is more effective for reducing the deflection values. The reduction of deflection is more when covering maximum faces of the beam with increase of thickness of steel plate. Application of the complete conclusion is that when designing a beam with reinforcement and section dimension is less, to bear that part of the structure, then we use bonding steel type retrofitting. Also, if the section has passed the strength criteria but the serviceability criterion fails, the member locally can be retrofitted with bonding steel plate type so that the serviceability issues can be fulfilled.

References

[1] Eray Ozbek. (2016). Strengthening of RC Beams with Solid Steel Plates. In Athens Journal of Technology & Engineering (Vol. 3, Issue 4, pp. 291–293). [2] Majid Abdul Ameer, I., Hatif Naji, A., & Ibrahim, A. M. (2020). Finite Element Analysis Of Reinforced Concrete Wide Beams Using Internal Steel Plates As Shear Reinforcement. In Journal of Engineering Science and Technology (Vols. 15–15, Issue 6, pp. 4134–4156). [3] Tjitradi, D., Eliatun, Taufik, S., & Mariamah. (2022). Ansys Modelling Behaviour of The Reinforced Concrete Beam with The Effect of Various Reinforcement Type and Concrete Strength. International Journal of Civil Engineering and Technology (IJCIET), 9–9, 1–13. [4] Havale, S., Desai, Y. N., Desai, H. R., Khade, S. B., Patil, R. N., & Barage, U. D. (2023). FEM Analysis On Stiffened Plates Using Ansys. In International Research Journal of Modernization in Engineering Technology and Science (Vols. 05–05). [5] Tarigan, J., Patra, F. M., & Sitorus, T. (2018). Flexural strength using Steel Plate, Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP) on reinforced concrete beam in building technology. IOP Conference Series. Earth and Environmental Science, 126, 012025. [6] Kisa?a, D., & Furtak, K. (2023). Deflections of Steel Plate-Concrete Composite Beams in the Light of Experimental Studies. Archives of Civil Engineering. [7] Wang, Y. C. (1998). Deflection of Steel-Concrete Composite Beams with Partial Shear Interaction. Journal of Structural Engineering. [8] Bharti, R. D., & Khuswaha, P. N. (2019). Review Paper on RCC Beam with & without Fibre Reinforced Polymer. In International Journal of Trend in Scientific Research and Development (Vols. 4–4, pp. 474–477) [9] Nasr, E. (2019). Strengthening of R.C. Beams Using Different Techniques. In IOSR Journal of Mechanical and Civil Engineering (Vol. 16, Issue 1, pp. 72–82). [10] K S, S., & James, R. M. (2018). Strengthening of RC Beam with Web Bonded Steel Plates. International Journal of Engineering and Techniques, 71. [11] Ozbek, E., Bocek, M., & Aykac, S. (2016). Strengthening of RC Beams with Solid Steel Plates. In Athens Journal of Technology & Engineering (Vol. 3, pp. 291–293). [12] Alfeehan, A. (2014). Strengthening Of R.C. Beams By External Steel Plate Using Mechanical Connection Technique. Journal of Engineering and Sustainable Development, 2, 202–204. [13] Kuddus, M. A., & Azad, I. H. (2017). Laboratory Investigation on Performance of Strengthening Techniques of RCC Beam. American Journal of Civil Engineering and Architecture, 5(1), 25–28. [14] Dawood, M. B., & Al-Saffar, D. H. (n.d.). Flexural behavior of steel concrete composite beam with web openings and strengthened by CFRP laminates. In XIII International Conference on Computational Plasticity. Fundamentals and Applications. [15] Abed, M. J., Nasharuddin, K., Alam, M. A., Zakaria, C., & Fayyadh, M. M. (2012). Damaged Rc Beams With Circular Web Opening Repaired Using Different Configurations Of Bonding Steel Plate. International Journal of Civil Engineering and Technology (IJCIET), 3, 70–83. [16] Nie, J., Fan, J., & Cai, C. S. (2004). Stiffness and Deflection of Steel–Concrete Composite Beams under Negative Bending. In Journal of Structural Engineering (Vols. 130–130, Issue 11, pp. 1842–1851). [17] Rendy Thamrin, (2018). Effect Of Strengthening Method And Development Length On Flexural Strength Of RC Beams With Steel Plates. Journal of Engineering Science and Technology (Vols. 13–13, pp. 3781–3794). [18] Warke, K. S., & Bogar, V. (2023). Experimental And Finite Element Analysis Of Steel-Concrete Composite Beams. In International Research Journal of Modernization in Engineering Technology and Science (Vols. 05–05). [19] Hu, D., Wang, Y., & Ding, F. (2020). Deflection Calculation of Steel-Concrete Composite Beams Considering Effects of Shear Lag and Slip. IOP Conference Series. Materials Science and Engineering, 772(1), 012063. [20] Reyaz, A., Mohsin Thakur, M., & Ahmad, I. (2014). Deflection Control In Rcc Beams By Using Mild Steel Strips (An Experimental Investigation). In IJRET: International Journal of Research in Engineering and Technology (pp. 20–21). [21] Hussein, M., Afefy, H. M. E. D., & Khalil, A. H. a. K. (2013). Innovative Repair Technique for RC Beams Predamaged in Shear. Journal of Composites for Construction, 17(6). [22] E I, E. J., & K, M. (2021). Experimental investigation on Flexural Strength of Steel-Concrete composite beam using Steel plate. In International Research Journal of Engineering and Technology (IRJET) (pp. 4248–4250). [23] Bagherinejad, K., Hosseinpour, E., & Hosseini, S. H. (2015). Evaluation of Rectangular Concrete-Filled Steel-Hollow Section Beam-Columns. Journal of Asian Scientific Research, 5(1), 46–59.

Copyright

Copyright © 2024 Shruti Vaidya, Dr. Umesh Pendharkar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64034

Publish Date : 2024-08-21

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online