Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- References

- Copyright

Android Based Vehicle with Robotic Arm

Authors: Dnyaneshwar Patkulkar, Shrikant Barawkar, Ruturaj Ajagekar, Shobha Nikam

DOI Link: https://doi.org/10.22214/ijraset.2023.52618

Certificate: View Certificate

Abstract

We have seen that workers are facing various problems when working in mass production factories, most famously in the manufacturing of cars and many more applications. So that we came up with the solution to tackled these problems. Witha robotic arm and a gripper technology is used to pick and place things. It can be used for the selection and placement of objects according on the situation. Wireless operation of this arm is mounted on the top of the vehicle using with an Android smartphone. The android phone acts as the controller and is used to transfer Bluetooth signals. The vehicle can be moved forward, backward, left, and right using these commands. Two motors are employed at the receiver, which are used to move the vehicle and the Servo motors are used to handle the arm and gripper movements. The android phone acts as a remote to control the vehicle. With the help of Bluetooth technology communications can be established with the vehicle & a robotic arm via Arduino. T the driver IC are used to control the required motors after receiving the commands from Android application. Any Android device will be able to control the vehicle remotely. This device with robotic device may help industries and can used in domestic application such that it will reduce human effort

Introduction

I. INTRODUCTION

The advancement in robotics technology has opened up new possibilities in many fields, including disaster relief, industrial automation, and exploration. With the increasing demand formore efficient and safe ways of performing tasks in these challenging environments, there is a need for robots that can operate autonomously or be controlled remotely. The development of Android-based vehicles equipped with robotic arms is one such solution that is gaining traction in recent years.

The Android-based vehicle with a robotic arm combines the mobility of a vehicle with the dexterity of a robotic arm, making it an ideal platform for tasks that require both mobility and manipulation. With the integration of sensors and Android-based control systems, the vehicle can be remotely operated, allowing the operator to access and perform tasks in hazardous or inaccessible locations. The modular design of the robotic arm also allows for the attachment of different tools and payloads, making it versatile and adaptable for a wide range of tasks.

This project aims to develop an Android-based vehicle with a robotic arm that can be remotely operated using an Android application. The vehicle is equipped with various sensors, including a camera, temperature sensor, and obstacle detection sensors, to aid in navigation and the execution of tasks. The robotic arm is designed to be modular, allowing for the attachment of different tools and payloads to suit various tasks. With this system, we hope to provide a costeffective and efficient solution for remote operation and execution of tasks in challenging environments.

A. Objective of the System

- To design & build vehicle using Android: A robust vehicle which will be used to move forward, reverse and left-side, right-side such that it will able to lift objects via a robotic arm.

- To Lift the Object: The vehicle will move towards object and easily pick-up the desired object and will drop to desired location.

- To drop the object at desired location: As the object is picked up, the vehicle will move further to desired location and dropped or place object over there.

- To Develop Android application as a user Interface: An interactive user Interface developed via Android such that it will transmit signal to Arduino via Bluetooth

II. PROPOSED METHODOLOGY

With a robotic arm and a gripper technology is used to pick and place things. It can be used for the selection and placement of objects according on the situation. Wireless operation of this arm is mounted on the top of the vehicle using with an Android smartphone. The android phone acts as the controller and is used to transfer Bluetooth signals. The vehicle can be moved forward, backward, left, and right using these commands. Two motors are employed at the receiver, which are used to move the vehicle and the Servo motors are used to handle the arm and gripper movements.

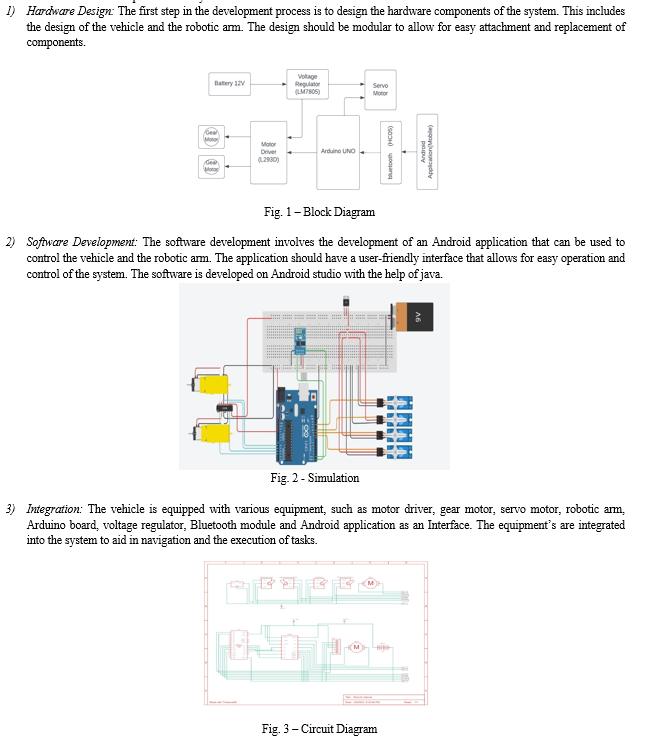

The development of an Android-based vehicle with a robotic arm involves several steps and methodologies. The following are the methods used in the development of the system:

4) Testing and Validation: The system is tested to ensure that it meets the design requirements and performs the intended functions. The testing involves both hardware and software testing to ensure that the system is reliable and efficient.

5) Deployment: The final step in the development process is the deployment of the system. The system is deployed in the target environment, and the operator can remotely control the vehicle and the robotic arm using the Android application.

Overall, the development of an Android-based vehicle with a robotic arm involves a combination of mechanical, electrical, and software engineering methodologies. The integration of these methodologies ensures the development of a robust and efficient system that can perform tasks in challenging environments.

III. SYSTEM DESIGN

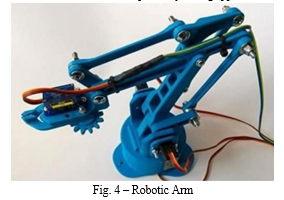

A. Robotic Arm

Robotic arms are used in various applications such as manufacturing, assembly lines, and scientific research.

- Degrees of Freedom (DOF): Degrees of freedom refer to the number of individual parameters that describe the position and orientation of an object. A robotic arm's DOF determines its flexibility and its ability to reach specific points in space. The four degrees of freedom in this robotic arm allow it to move in four independent directions.

- Base Angle: The base angle of the robotic arm refers to the angle at which the arm is mounted to its base. A 360-degree base angle means that the arm can rotate fully around its base, allowing it to reach any point within its reach. This provides the arm with more flexibility in its movements and makes it easier to access various points in space.

- Shoulder Angle: The shoulder angle of the robotic arm refers to the angle between the base and the first joint of the arm. A 120degree shoulder angle means that the arm can reach up and out, making it suitable for reaching objects that are higher up or farther away.

- Elbow Angle: The elbow angle of the robotic arm refers to the angle between the first and second joints of the arm. A -120degree elbow angle means that the arm can reach down and out, making it suitable for reaching objects that are lower down or closer to the ground.

- Gripper Angle: The gripper angle of the robotic arm refers to the angle at which the end effector (the gripper) is positioned. The gripper can be positioned at either a 30-degree or 45degree angle, depending on the application. A 30-degree angle is suitable for objects that are small or require a delicate touch, while a 45-degree angle is suitable for larger or heavier objects.

The robotic arm is created keeping in mind that it has to place on the top of the vehicle and can also be controlled remotely. The diameter of the base id 31mm. Length of the arm from base to shoulder is 80mm. The arm from shoulder to elbow is 80mm. The arms of upper elbow and lower elbow are 46.3mm and 35mm respectively. The gripper can wide open up to 50mm.

B. Vehicle

Vehicle design is the process of designing and developing a vehicle that meets the specific needs and requirements of the intended use. The design process involves several steps and considerations, including:

- Define the Vehicle's Purpose: The first step in the design process is to define the vehicle's purpose. This involves identifying the intended use of the vehicle, such as transportation, off-roading, or racing.

- Determine the Vehicle's Specifications: Once the vehicle's purpose has been defined, the next step is to determine the vehicle's specifications. This includes the size, weight, power, and performance requirements.

- Develop the Vehicle's Concept: The next step is to develop the vehicle's concept. This involves creating sketches and 3D models of the vehicle's design to ensure that it meets the requirements and specifications.

- Prototype Development: After the vehicle's concept has been developed, the next step is to create a prototype. This involves building a working model of the vehicle to test its functionality and performance.

Another main component of the project is the remote-controlled vehicle which can be controlled using an android application which is interfaced with the hardware of the vehicle controller. The GUI in the application gives an idea about the vehicle controls and is much easier to use. The command given by the application is processed on the controller and controls the gear motors giving user full control of the vehicle.

The movement of the vehicle is controlled by the gear motors. The motion of the motors decides the orientation and the moments of the vehicle.

- Forward - forward rotation of both gear motor

- Backward - backward rotation of both gear motor

- Right - forward/backward movement via right motor rotation

- Left - forward/backward movement via left motor rotation

IV. APPLICATION

The four-degree-of-freedom robotic arm with the specified joint angles can be used in various applications. For example, it can be used in manufacturing to assemble small components or in the healthcare industry for surgical procedures. The arm's ability to reach high and low positions makes it suitable for use in assembly lines, where it can pick up and move objects at different heights. The gripper's adjustable angle makes it suitable for various applications. A 30-degree angle is ideal for picking up delicate objects, such as medical equipment, while a 45-degree angle is suitable for picking up larger objects, such as automotive components.

V. RESULT AND DISCUSSION

The android application working as an interface, will transmit signals to Arduino via Bluetooth module. Transmitted signals will include instruction i.e., to move left, right, forward and backward. Also, it includes rotation of servo motors. Further, these received signals at Arduino via Bluetooth module leads to control of the vehicles and Robotic Arm. Hence, the Robotic Arm will able to lift different object and it will drop at desired location.

VI. ACKNOWLEDGMENT

I am delighted to express my sincere and profound gratitude to my supervisor, Dr. Shobha Nikam, Assistant Professor in the Department of Electronics & Telecommunication Engineering, for her invaluable guidance, unwavering support, and assistance in pursuing further studies in adaptive signal processing. Her expertise and encouragement have been pivotal in shaping my understanding of the subject matter and in the successful completion of this work. I would also like to extend my appreciation to the Head of the Department, Dr. M. P. Sardey, and the Project Coordinator, Dr. Shobha Nikam, along with all the members of the Department of Electronics & Telecommunication Engineering at AISSMS IOIT, Pune, for their cooperation in various capacities.

The motivation for this work stems from the inspiring leadership of our esteemed Principal, Dr. P. B. Mane, whose vision and dedication have been a constant source of inspiration to me.

References

[1] R. Siegwart and I. Nourbakhsh, Introduction to Autonomous Mobile Robots, Cambridge, MA:MIT Press, 2004. [2] Anuj Kakran et al., \"Smart Border Surveillance System using Wireless Sensor Network and Computer Vision\", International Conference on Automation Computational and Technology Management (ICACTM), 24–26 April 2019, ISBN 978-1-5386-8011-7. [3] N. K James, M Liu and Meng Wang, \"iBotGuard: An Internet-Based Intelligent Robot Security System Using Invariant Face Recognition Against Intruder\", IEEE Transactions on Systems Man & Cybernetics Part C: Applications and Reviews, vol. 35, no. 1, February 2005.M. Wegmuller, J. P. von der Weid, P. Oberson, and N. Gisin, “High resolution fiber distributed measurements with coherent OFDR,” in Proc. ECOC’00, 2000, paper 11.3.4, p. 109. [4] Palagati Harish, R. Subhashini and K Priya, \"Intruder detection by extracting semantic content from surveillance videos\", Green Computing Communication and Electrical Engineering (ICGCCEE) 2014 International Conference on, pp. 1-5, 2014. (2002) The IEEE website. [Online]. Available: http://www.ieee.org/ [5] Harish Bhaskar, \"Integrated human target detection identification and tracking for surveillance applications\", 6th IEEE International Conference Intelligent Systems, pp. 467-475, 2012. [6] Xin Jin, Soumalya Sarkar, Asok Ray, Shalabh Gupta and Thyagaraju Damarla, \"Target detection and classification using seismic and PIR sensors\" in IEEE Sensors Journal, IEEE, vol. 12, no. 6, pp. 1709-1718, 2012. [7] S. Nishanthini, M. Abinaya and S. Malathi, \"Smart Video Surveillance system and alert with image capturing using android smart phones\", International Conference on Circuit Power and Computing Technologies, pp. 1714-1722, 2015. [8] X. L. Zhu, L. S. Guang, K. Zhang, Y. Y. Chen and Q. Q. Meng, \"Synchronous line-tracking robots based on STM32\", Journal of Measurement Science and Instrumentation, vol. 4, no. 1, pp. 58-62, Oct. 2013. [9] C. E. Palazzi, M. Brunati and M. Roccetti, \"An OpenWRT solution for future wireless homes\", International Conference on Multimedia and Expo, pp. 1701-1706, 2010. [10] F. Lohier and J. Nuesch, Wireless multimedia device with real time adjustment of packet retry function and bit rate modulation, 1910. [11] B. D. Veerasamy, \"Creating a model http server program using java\", International Journal of Computer Science & Information Security, vol. 7, no. 2, pp. 248-255, Jul. 2010. [12] J. Kabachinski, \"Surfing the Web: http URLs and HTML\", Biomedical Instrumentation & Technology, vol. 36, no. 1, pp. 49-52, Aug. 2002.

Copyright

Copyright © 2023 Dnyaneshwar Patkulkar, Shrikant Barawkar, Ruturaj Ajagekar, Shobha Nikam. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET52618

Publish Date : 2023-05-20

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online