Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Automated Waste Sorting System

Authors: Prof. Sneha R. Sontakke, Kshitija S. Tayade, Sanika D. Kale, Payal P. Ingle, Grishma A. Ingle

DOI Link: https://doi.org/10.22214/ijraset.2024.58256

Certificate: View Certificate

Abstract

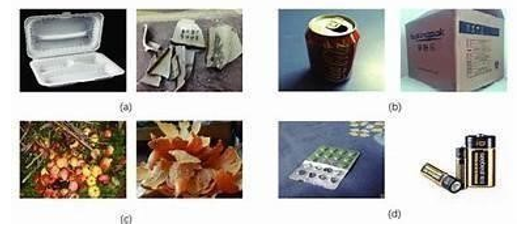

Managing solid waste through recycling is a crucial measure to mitigate adverse effects like sanitation and health issues arising from excessive landfill usage. However, the intricacies and costs associated with sorting solid waste pose challenges to recycling efforts. To streamline this process, our study proposes a Deep Learning approach employing computer vision to automatically recognize and categorize waste into five primary types: plastic, metal, paper, cardboard, and glass. Our conceptual system entails an automated recycling bin that opens its lid corresponding to the identified waste type. The primary focus of our work lies in the development and optimization of Machine Learning algorithms for efficient waste identification. We utilized pre-existing images to train a minimum of 12 variants of the Convolutional Neural Network (CNN) algorithm across three classifiers: Support Vector Machine (SVM), Sigmoid, and SoftMax. Our findings reveal that the VGG19 model with a SoftMax classifier achieves an accuracy of approximately 88%.

Introduction

I. INTRODUCTION

The world generates nearly 4 billion tons of waste annually, with urban areas contributing significantly. Waste is expected to increase by 70% in 2025, particularly in less developed countries. Urban industrial growth exacerbates solid waste disposal challenges, mainly managed through inefficient and expensive landfilling, causing pollution and health issues. Burning waste is another method but leads to air pollution and health risks. Recycling is crucial for environmental protection and health. Motivated by the health risks associated with manual waste separation, an automated system combining Convolutional Neural Network (CNN) and Support Vector Machine (SVM) is developed to enhance accuracy and efficiency in waste sorting. The system uses a pre-trained ResNet-50 model to address issues like vanishing gradient in CNNs. ResNet-50 employs residual models to overcome the vanishing gradient problem, offering a more effective approach to waste separation and recycling.

II. BIAS IN AI-DRIVEN CHATBOTS

|

Authors |

Techniques Used Classes Accuracy |

Additional Information |

||

|

Yang et al. |

SVM, CNN (AlexNet) |

Glass, Paper, Metal, Plastic, Cardboard |

SVM: 63%, CNN: 22% |

Future work includes attempts to classify multiple objects in a single input. |

|

Adedeji et al.

|

CNN (ResNet50) + SVM |

Glass, Paper, Plastic, Metal |

87% |

Small dataset size, faster than manual sorting. |

|

Aral et al.

|

CNN (Xception, MobileNet, DenseNet, InceptionResNetV2) |

Not specified |

DenseNet121: 95%, DenseNet169: 95%, InceptionResNetV2: 94% |

Increased dataset size using various techniques. |

|

Desai et al. |

CNN |

Degradable, Nondegradable |

Not specified |

Proposed a robotic arm for waste sorting. |

|

Ziouzios et al. |

CNN (ResNet34) |

Cardboard, Glass, Metal, Paper, Plastic, Trash |

92% |

Used Raspberry Pi and LoRaWan connectivity for bin automation. |

|

Özkaya et al |

CNN (AlexNet, InceptionV3, ResNet, VGG-16, SquezeeNet) |

Glass, Paper, Cardboard, Plastic, Metal, Trash |

InceptionV3 + SVM: 97.86%, VGG-16 + SVM: 97.46%, AlexNet + SVM: 97.23% |

Various CNN models compared with SoftMax and SVM as classifiers. |

|

Bircanoglu et al. |

RecycleNet, CNN (ResNet, MobileNet, InceptionResNet, DenseNet, Xception) |

Not specified |

DenseNet121 (Adam): 95%, DenseNet121 (SGD): 95%, RecycleNet: 81% |

Comparison of CNN models with different optimizers |

|

Bernado et al. |

CNN (VGG16, AlexNet), SVM, KNN, RF |

Glass, Metal, Paper, Plastic |

VGG16: 93% |

Plan to apply data augmentation and fine-tuned models in the future |

III. METHODOLOGY

A. Requirements and Objectives

The smart recycling bin system is designed with specific requirements and objectives to enhance waste management processes. These objectives encompass the determination of desired features, including waste classification accuracy, real time processing capabilities, and an intuitive user interface. The system aims to seamlessly integrate sensors that serve various purposes, such as cameras for image capture, weight sensors to quantify waste, and proximity sensors for detection. A critical aspect involves the selection of a suitable microcontroller or processor capable of handling sensor data, executing data processing tasks, managing system operations, and facilitating communication with external devices or networks. The next step involves the development of algorithms and software for efficient data acquisition and preprocessing from the integrated sensors.

The heart of the system lies in the creation and training of a deep learning model, such as a Convolutional Neural Network (CNN), to classify waste items based on the sensor data. This entails the generation of a labeled dataset comprising images of different waste items, which serves as the foundation for training and validating the model. The system's real-time waste classification functionality is implemented through the utilization of the trained deep learning model. As waste items are deposited into the bin, the system processes data from the sensors, ensuring accurate and timely classification. The user interface is a crucial component, and efforts are directed towards developing a user friendly interface that facilitates seamless interaction with the smart recycling bin.

IV. GENERAL ARCHITECTURE OF CONVOLUTIONAL NEURAL NETWORK

CNN is a type of deep feed-forward neural network that has proven to be effective for various applications, including image classification, object detection, segmentation, and many others. One of the earliest and most influential CNN models was LeNet-5, developed by Yann LeCun. It was originally designed for handwritten and machine-printed character recognition, but its success led to its use in many other areas, including facial recognition and self-driving cars. The architecture of a CNN is unique compared to other types of neural networks, such as multi-layer perceptron. CNN layers are arranged in three dimensions, including width, height, and depth. Neurons in one layer only connect to some of the neurons in the following layer, rather than all of them. A simple CNN architecture consists of several layers with each layer transforming one activation volume into another through a differentiable function.

The four main types of layers used to build CNN architectures include the convolutional layer, the ReLU layer, the pooling layer, and the fully connected. The figure illustrates the general architecture of a CNN.

It consists of multiple layers, each with a specific function in transforming the input image to a set of class probabilities. The input image is firs processed by a set of convolutional layers, followed by ReLU layers for nonlinearity and pooling layers to downsample the feature maps. Finally, the fully-connected layers are used to obtain the class probabilities.

V. LIMITATION

- Initial Investment: High upfront costs for implementing robotic waste management systems may pose a barrier, particularly for smaller municipalities or developing regions.

- Technological Complexity: Robotics systems may face challenges in handling diverse and constantly changing waste streams, requiring advanced sensors and adaptive algorithms.

- Maintenance Challenges: Regular maintenance and potential breakdowns of robotic components could lead to operational disruptions and increased maintenance costs.

- Limited Adaptability: Current systems might struggle with unanticipated waste items, complex sorting requirements, or irregular waste shapes, limiting their adaptability to evolving waste streams.

VI. FUTURE SCOPE

The future prospects of managing recyclable waste using robotics include improvements in efficiency through AIpowered sorting, autonomous robots for collection, and intelligent recycling facilities. The incorporation of IoT for live monitoring, predictive maintenance, and data analytics aims to enhance resource utilization, contributing to a more sustainable and environmentally friendly process. The development of sophisticated robotic systems could address intricate sorting tasks, leading to increased recovery of recyclable materials and decreased contamination. Moreover, successful implementation will require collaborative initiatives among industries, governments, and technology developers to fully unlock the capabilities of robotic waste management systems.

Conclusion

In our pursuit of identifying the most effective Machine Learning algorithm for recyclable trash detection, we conducted experiments involving 12 variations of Convolutional Neural Networks (CNNs) across three distinct classifiers. This model successfully categorized waste into five distinct classes, namely glass, paper, plastic, metal, and cardboard. Despite our initial aim of encompassing six waste classes, including food waste, we fell short due to limitations in the dataset. Exclusion of food waste was a direct consequence of the dataset constraints, impacting the comprehensiveness of our classification system. However, it is important to note that further refinement and optimization are imperative before considering the implementation of this solution in an automated recycling bin system.

References

[1] Nadish Ramsurrun1, Geerish Suddul2, Sandhya Armoogum, Ravi Foogooa “Recyclable Waste Classification Using Computer Vision And Deep Learning” Conference Paper · August 2021 doi: 10.1109/ZINC52049.2021.9499291 [2] Kaza, Silpa; Yao, Lisa C.; Bhada-Tata, Perinaz; Van Woerden, Frank. 2018. What a Waste 2.0 : A Global Snapshot of SolidWaste Management to 2050. Urban Development;. Washington, DC. https://openknowledge.worldbank.org/handle/10986/30317 [3] G. Suddul and N. Nedoomaren, “An Energy Efficient and Low-Cost Smart Recycling Bin,” International Journal of Computer Applications, vol. 180, no. 29, pp. 18–22, 2018. doi: 10.5120/ijca2018916698. [4] O. Adedeji and Z. Wang, “Intelligent Waste Classification System Using Deep Learning Convolutional Neural Network,” Procedia Manufacturing, vol. 35, pp. 607–612, 2019. doi: 10.1016/j.promfg.2019.05.086. [5] D. Ziouzios and M. Dasygenis, “A Smart Recycling Bin for Waste Classification,” 2019 Panhellenic Conference on Electronics & Telecommunications(PACET),2019. doi:10.1109/pacet48583.2019.8956270. [6] Gu, Shanqing; Pednekar, Manisha; and Slater, Robert (2019) \"Improve Image Classification Using Data Augmentation and Neural Networks,\" SMU Data Science Review: Vol. 2 : No. 2 , Article Available at: https://scholar.smu.edu/datasciencereview/vol2/iss2/ [7] Saar, S., Stutz, M. & Thomas, V. M. (2004) Towards intelligent recycling: a proposal to link bar codes to recycling information. Resources, Conservation & Recycling. 41 (1), 15-22. [8] S. Costa, A. C. S. Bernardes, J. V. A. Pereira, V. H. Zampa, V. A. Pereira, G. F. Matos, E. A. Soares, C. L. Soares, and A. F. Silva, “Artificial Intelligence in Automated Sorting in Trash Recycling,” Anais do XV Encontro Nacional de Inteligência Artificiale Computacional (ENIAC 2018), 2018. doi:10.5753/eniac.2018.4416. [9] Abdoli, S. (2009) RFID application in municipal solid waste management system. International Journal of Environmental Research. 3 (3), 447-454. [10] J. Donovan, “No Title,” Auto-trash sorts garbage automatically at the techcrunch disrupt hackathon,2016.[Online]. Available:https://techcrunch.com/2016/09/13/auto-trashsortsgarbage%0Aautomaticallyat-the-techcrunch-disrupthackathon/. [11] Y. Tang, “Deep Learning using Linear Support Vector Machines,” International Conference on Machine Learning 2013: Chal- lenges in Representation Learning Workshop. Atlanta, Georgia, USA., (2013) pp. 1-6. [12] Bircanoglu, M. Atay, F. Beser, O. Genc, and M. A. Kizrak, “RecycleNet: Intelligent Waste Sorting Using Deep Neural Networks,” 2018 Innovations in Intelligent Systems and Applications (INISTA), 2018. doi:10.1109/inista.2018.8466276. [13] Gu, Shanqing; Pednekar, Manisha; and Slater, Robert (2019) \"Improve Image Classification Using Data Augmentation and Neural Networks,\" SMU Data Science Review: Vol. 2 : No. 2 , Article Available at: https://scholar.smu.edu/datasciencereview/vol2/iss2/

Copyright

Copyright © 2024 Prof. Sneha R. Sontakke, Kshitija S. Tayade, Sanika D. Kale, Payal P. Ingle, Grishma A. Ingle. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET58256

Publish Date : 2024-01-31

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online