Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Automatic E-Bike Stand for Two Wheeler

Authors: Prof. Akshay D. Rajput, Omkar K. Kale, Suraj M. Rajguru, Aditi R. Saraf

DOI Link: https://doi.org/10.22214/ijraset.2024.59318

Certificate: View Certificate

Abstract

This paper aims to enhance the efficiency of manual actuation and automation for sliding of side-stand to increase the safety of the rider. In the modern developing world, automobile plays an important role especially two-wheeler i.e. (motorcycles& bikes) plays a major role. Even though they are helpful there are some accidents due to the carelessness of the rider. To rectify this problem many advanced measures have been taken, but they are least helpful. To overcome the limitations of the existing methods a new model of \"Automated E- side stand retrieving device\", an electromechanical system, is introduced by using electric circuits and gear mechanism. The automatic side stand retrieval system is powered by the same source as every other electrical component on the vehicle, namely the battery. Due to the gear mechanism, increased torque will help the motor to lift the side stand easily.

Introduction

I. INTRODUCTION

Two wheelers are most prone to accidents due to their fragile nature. One of the issues of motorbike accidents is that people forget to slide their side stands back in place on starting the bike. So here we propose an automated side stand slider system that will automatically slide the side stand back in position when user starts his/her bike. In this system e make a demonstration model with a demo starter for bike and a frame used to hold starter, demo bike and sidestand in position. The frame is used to mount bile upright using frame. The starter consists of a microcontroller circuit used to monitor the starter and then operate the stand sliding mechanism. The stand consists of a motorized system used to operate the stand. The circuit monitors the starter, on starting the bike the sidestand is operated by the motor using a shaft to slide from a vertical position to a horizontal position. On turning off the key in other direction to lock bike the system moves the motorized stand shaft in opposite direction so as to move the stand in a direction perpendicular to the bottom frame rod which rests the motor bike on side stand. Thus we have a fully automated sidestand system.

When it comes to two-wheelers, crashes happen when people ride at high speeds, don't wear helmets, don't stick to the speed limit, and fail to remove the side stand while riding. What are the most common causes of the collision? Forgetting to lift the side stand causes massive injuries in rural and urban areas alike since all other causes of accidents to have safety measures in place, but accidents caused by side stands do not. Here at the crash statistics [3], this condition is responsible for 36% of all deaths.

Table 1: Cause of Accidents During The Year 2012-2015

|

Serial No |

The Accident's Cause |

Accidents as a percentage |

|

01 |

Forgetting to raise the side-stand |

36% |

|

02 |

Does not maintain speed limit |

38% |

|

03 |

Does not obey traffic rules |

22% |

|

04 |

Other Problems |

04% |

A lot of researchers have dedicated their time to this field. We gather some information about the work of the researchers and giving them in the sequence below. Diagaraja [4] developed and filed a patent for a two- wheel side stand warning device that alerts the rider to the retrieval of the side stand. The warning is used in two- wheelers to warn or guide the rider to the unreleased position of the side stand while driving. It consists of the tension spring, the touch switches, and the electrical wiring circuit. There is a tension spring in the side stand, which closes the electrical circuit for the horn supplied in the vehicle or the alarm to beep through the touch switch. It's getting its power from the battery in the vehicle. It indicates to the rider the horn or warning about the unreleased location of the side stand or side stand in use. A patent is developed and filed by Parvez [5] for a two- wheel automatic stand, using a DC motor and a hydraulic pump, together with a distribution manifold and with a power pack reserve oil tank (Other choices are: a) 12 V DC actuator type or b) pneumatically motorized cylinder type or c) a hydraulically charged cylinder type. This mechanism allows the two-wheeler legs to be unfolded from their horizontal position to the vertical position and to force the mounting of the legs to a preset height that raises the two wheels and parks them up to their pre-set height, using the use of hydraulic cylinders or other methods such as Pneumatic Cylinders or Motorized Actuators. On the return path, the motor is reversed and, in the case of a hydraulically charged cylinder, the multiply inverses flow of the fluid, so the reversal of the operation sinks the stand to the previous position again and then unfolds it back to the horizontal position, which positions the two wheels ready to travel. The stand will quickly lift and unload a two-wheel when positioning it on the stand and back 7 in the riding position. It's simple to use and enables a person to park the two-wheel-drive in narrow lanes when the manual stand has no room. In this way, it can be possible to rotate horizontally across vertical positions, such as a combination of racks and pinion gears or liver systems or a hydraulic multi- cylinder system. Joy [6] developed a battery-connected anti-accident ignition device that is connected to the battery, plunger. The switch system is connected on one side of the battery to the other end with the ignition body as well as with the plunger by means of the node.. With the help of a frame, the plunger is earthed. The battery used is a regular 12V battery. The plunger device is attached to the side by the coiled spring. All the appliances used are common systems used in two- wheelers. The interface between a switch system and the plunger is through cables. The main feature is that the circuit will not be braked while the stand is in the OFF position so that the current from the battery passes through it directly. The earth given for it won't work in this case. All the current flows only from the created main circuit, hence the current fluctuates from the battery to the ignition coil. This current flow allows the vehicle to get started. When the stand is in the ON position, the circuit breaks and the current flows from the battery not through the ignition coil, but rather through the earthling, supplied by the plungers with the help of the chassis. The voltage-current is transferred into the rubber portion of the vehicle in which the current is absorbed and the current flow into the Earth's surface using the side stand current. Kumar [7] developed a new mechanism that is based on the simplicity and success of the trigger mechanism. The operation consists of three principal components: clutch, stand, and trigger. The pitch causes the button and the clutch triggers to raise the pitch. The stand retrieves itself as it is applied to the clutch to move the machinery. He assessed and optimized the spring to its final design that is the most productive process.

Sanjeev [8], developed a Two-wheeler Side Stand Unfolded Side Lock Link mechanism In this system the side stand lock link makes the contact with the gear lever thereby indicating the person handling the vehicle about the unreleased side stand when the rider tries to apply the gear in an unreleased state of stand and prevent him from being endangered or to have an unsafe ride of the motorcycle.

The two-wheeler side stand unfolded side lock link for the vehicle is one of the lifesaving mechanism which prevents the rider from riding the vehicle in the unreleased position of the ride stand. Gulhane [9] fabricated a side stand lifting mechanism based on a simple mechanism and it is operated manually by the means on the feet power of the rider. The working consists of three mechanisms. The main mechanism is the spring mechanism by which the stand lifts up automatically without any manual effort. The second one is the locking mechanism which is used for locking and de-locking the stand. The last one is the lever mechanism which can operate the spring. As pressing the gear lever which is attached to the hook catch-lock get stretched to pull the lock by which lock gets de-locked. With this hook, it escapes from the lock and the stand gets lifted automatically by spring action manually. As pressing the lever the wire which is attached to the hook catch-lock gets stretched and pulls the lock by which lock gets de- locked. With this hook, it escapes from the lock and the stand gets lifted automatically by spring action. Gawande

[10] developed a side stand lifting mechanism on which Electrically operated servo motor driven mechanisms are used to do the end job of lifting and unlocking the side stand and the footrest respectively. The mechanism works on the signals sent to it by a microcontroller circuit, which generates these signals based on the user code feed to it. By integrating this mechanism to the vehicle, the side stand will automatically leave off when the ignition is turned on and the footrest will automatically unlock when an adult passenger is seated on the vehicle's pillion seat Nayan[11] developed a Mechanism that retrieves side stand by Clutch. As the starter button is pushed, the electric circuit begins to operate, and when the clutch is pressed, the electric circuit receives electricity. The electric motor then rotates and applies driving power to the stand, lifting it. When the maximum of the stand is touched or pressed, the power supply for the motor's forward path is removed. Power will be sent directly to the spark plug at the same time, and the two-wheeler will run. In line with cycling operational theory, Jichkar [12] has created a new side stand slider. With the aid of electronic components such as servo motor, engine driver, Arduino, the system operates on electronic circuits on the bike. A demonstration model with a bike demo starter and a frame is created in this procedure to preserve the starter, the demo bike, and the side stand. The frame is 9 used to mount the bike with a frame upright. The starter consists of a circuit for controlling the starter and then using the mechanism for the sliding stand. The stand consists of a motorized device used to power the stand's microcontroller. The circuit tracks the starting pad, the motor pushes the side stand from a slider to a horizontal position at the start of the bike. When the key turns off to lock the bike, the mechanism pushes the motorized stand shaft in the opposite direction to drive the stand perpendicular to the underframe rod, which lies on the motorcycle side. We, therefore, have a fully automated motorcycle side-stand system.

The limitations of the existing methods, to say, when the rider is not paying attention, the side-stand sensor just sends a blip to the speedometer interface and is ineffectual. In mechanical projects, various difficulties such as gear wear and limb injuries are seen while actuating gears. The main disadvantage is that it cannot be used on all sorts of two-wheelers. So, in order to address this issue, this "Automated side stand retrieving device" is fabricated which can be mounted to any type of two-wheeler (mopeds, geared, non-geared, hand geared bikes). Because the assembly uses electronic components, there is no wear in the gears and no injury to the legs when actuating the gears.

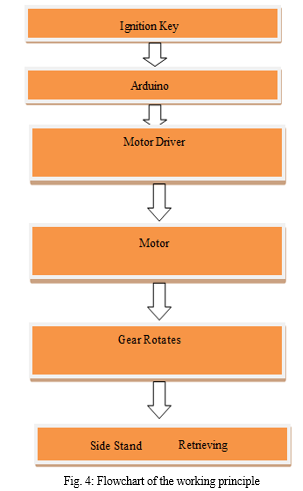

The Automatic Side-Stand Retrieving system is designed to reduce the number of accidents caused by riders forgetting to recover their side-stand before starting their two-wheeler. It operates in such a way that when the vehicle rider turns on the ignition key of the two-wheeler, the side-stand of the two-wheeler is retrieved, and when the ignition key is switched off, the side-stand automatically returns to the upright position. The details are briefly explained in the Methodology sections of this paper.

II. METHODOLOGY

Modern two-wheelers do not require a kick-start to start their engines; instead, they are equipped with auto- start or auto-ignition systems that accomplish this function as soon as the key is switched on. This installation relies on a battery to function. A 3D model is designed at first in commercial CAD software, shown in figure 2.

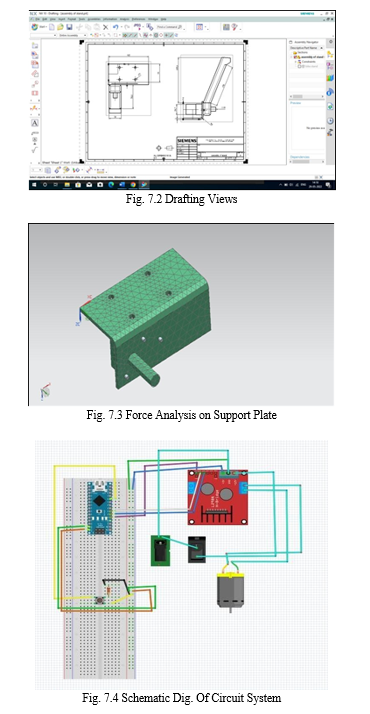

This automation is related to the limit switch. The system uses the two-limit switch which is placed two places of stand. When the limit switch is actuated, the stand will automatically place. If another limit switch is actuated the side stand will automatically returns to the initial position.

When limit switch is actuated, the signal is passed to the micro controller from the limit switch. The micro controller saves the data and actuates the relay. This relay is used to actuate the motor.

Thus, by the stand is placed. If another limit switch is operated this sends the signal to the micro controller. So, this actuates the relay thus the motor is operated and the stand is return to the initial position. In this project, a novel method of automatic bike stand is been designed and developed for motorcycle bike drivers.

As everyone in today’s world is riding bike it is essential to take care of unwanted troubles. Each and every bike should have automatic bike stand. (Shubham Bagul1), 2017.

A. Assembly Procedure

- First, she took the angle plate and attached it to the bottom of the chassis pipe of the bike.

- Taking the second rubber packing, they stuck the packing to the chassis pipe.

- He took the Clamp and applied the rubber packing to the chassis pipe of bike.

- Now take the bolt and put the washer in it and take the bolt and put it in the angle and clam holes. Tighten the bolts with nuts & stand assembly done.

- The rest of the microcontroller circuit we didn't

- Have space in the bike so we fitted it to the bike bumper.

B. Following Electronic Components We Used In Project

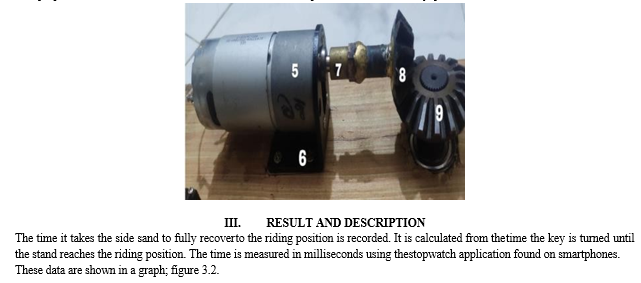

Servo Motor, Motor Gearbox, Arduino ATMEGA328p,Two- Wheeler Battery, Ignition key. A DC gear motor is used here for lifting the bike stand

Instead of starting up their engines with auto-start or auto-ignition to execute this operation, the current two- wheel drives require a kick start. The key is activated. It is powered by a battery for this system to operate. It is seen and examined the battery-powered operation of the key ignition is discovered and examined for automating the actuation side-standing.

The rpm of the motor is being fixed by Arduino coding. High torque DC gear motor is used instead of a Servo motor just because the servo motor couldn't give such torque and power. The motor is connected to the side-stand with the help of coupling, for the operation of the side-stand in the desired manner. The motor is attached to the side-stand through a coupling and two bevel gear, allowing the side-stand to operate as intended. The motor operates in such a way that it may rotate the stand to the proper 90-degree angle as required by the user. The motor is linked to the motor driver, which controls and begins its movement. The motor driver is also linked to the controlling unit, which is Arduino nano. The Arduino receives the input from the bike's ignition key as a push button and sends the output to the motor driver as the input to actuate.

.The Arduino will get input from the ignition key, therefore it is hooked to the ignition key (i.e. starter). The ignition input is obtained from the starter when it switches on or off, and the Arduino will then supply input to the motor driver for side-stand movement.

Here, one 10 teeth bevel gear is mounted with the motor. This gear is working as the pinion. It meshes with another 18 teeth bevel gear. This gear is mounted with a shaft that is connected with the side stand at the other end. This gear mechanism will increase the torque which will help the motor to lift the side stand easily. For reducing the friction between the gear shaft and support plane a bearing is used. A DC gear motor and bevel gears are used in the assembly, which is controlled by a motor driver. The microcontroller is linked to the motor driver. The ignition system sends a signal to the microcontroller. A signal is provided to the microcontroller when the rider enters the key and turns the ignition on or off. The microcontroller accepts the signal as an input and determines whether the ignition is on or off. Accordingly, the output signal is provided to the motor driver.

So, the total working procedure is as follows:

The microcontroller sends an input signal to the motor driver, which controls the DC motor. The motor driver turns low current signal to high signal for driving the motor.. The DC motor receives a signal from the motor driver. After receiving the signal from the motor driver, the motor is turned on. The side stand is attached to the DC motor with the help of coupling and gears.

The motor rotates in response to the signal from the motor driver. The servo motor is actuated as follows in response to the signal received: -

- Ignition ON – Rotates 90 degrees counterclockwise. Side-stand in rest position

- Ignition OFF – 90° clockwise rotation. Side-stand in an upright position.

C. Fabrication

The proposed model is fabricated in the mechanical workshop and then the circuitry parts.

IV. OBJECTIVES

The project of automatic bike stand is carried to achieve some of the objectives like:

- To develop actual implementation setup of automatic bike stand.

- To avoid accidents in daily life.

- It decreases human efforts

V. PROBLEM STATEMENT

- Accident occurs due to stand at down position.

- Load test carried out on stand

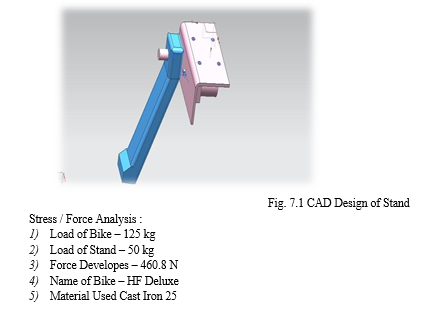

VI. DESIGN OF STAND

The starter consists of a microcontroller circuit used to monitor the starter and then operate the stand sliding mechanism. The stand consists of a motorized system used to operate the stand. The circuit monitors the starter, on starting the bike the side stand is operated by the motor using a shaft to slide from a vertical position to a horizontal position. On turning off the key in other direction to lock bike the system moves the motorized stand shaft in opposite direction so as to move the stand in a direction perpendicular to the bottom frame rod which rests the motor bike on side stand. Thus, we have a fully automated side stand system for motor bikes.

Conclusion

The main purpose of this study is to offer a sturdy and safe mechanism without compromising with the design of the bike to decrease accidents involving not lifting the side stands. Specifications of Bevel gears used, are provided. The fabrication including circuit diagram is also shown. By this mechanism the time of side stand retrieving is only 928 milliseconds which is convenient enough. By the mechanism minimize manual actuation and maximize automation for sliding of side-stand to increase the safety of the rider. It consumes only 24W and 53.93 kg-cm torque is developed by which any kind of two wheeler side stand can easily be lifted. Also, while making anything more convenient has been a primary goal behind all inventions throughout history, the mechanism of the project does not interfere with the operating mechanism of the engine, and so the engine\'s efficiency is not impaired. The concluding remarks are: 1) Average stand retrieval time 928 milliseconds 2) Generated average torque 53.93 kg-cm

References

[1] “Bangladesh Two-Wheeler Market, by Vehicle Type (Motorcycle, Scooter/Moped), by Engine Capacity (Up to 125cc, 126-250cc, 250-500cc and Above 500cc), by Company and by Geography, Forecast & Opportunities, 2025.” https://www.researchandmarkets.com/reports/51 05836/bangladesh-two-wheeler-market-by- vehicle-type (accessed Jul. 30, 2021). [2] “Road Accident in Bangladesh: 21 died on roads every day| DailyStar.” https://www.thedailystar.net/backpage/road- accident-in-bangladeh-21-died-every-day- 1852867 (accessed Jul. 30, 2021). [3] H. J. Hurt, J. Ouellet, and D. Thom, “Motorcycle Accident Cause Factors and Identification of Countermeasures: Volume 1 Technical Report,” vol. January, no. Contract No. DOT HS-5-01160, p. 425 pgs, 1981, Accessed: Jul. 30, 2021. [Online]. Available: https://rosap.ntl.bts.gov/view/dot/5652. [4] D. R, “Indian Patents. 220469:MOTOR CYCLE SIDE STAND ALARM FOR TWO WHEELERS,” 220469, 2008. [5] P. Bharucha, “Automatic two wheeler stand,” Jan. 16, 2008. [6] C. Joy, K. Mahorey, A. Sharma, and A. Sahu, “Anti-Accident Ignition System,” Int. J. Eng. Res. Technol., vol. 3, no. 5, May 2014, Accessed: Jul. 30, 2021. [Online]. Available: www.ijert.org. [7] N. Kumar and S. Reddy, “Side Stand Retrieval System Using Trigger Mechanism,” Int. J. Emerg. Technol. Eng. Res., vol. 4, no. 4, Apr. 2016, Accessed: Jul. 30, 2021. [Online]. Available: www.ijeter.everscience.org. [8] S. N. K, “Bike Side Stand Unfolded Ride Lock Link,” Intenational J. Eng. Sci. Res. Technol., vol. 2, no. 9, pp. 2551–2552, Sep. 2013, Accessed: Jul. 30, 2021. [Online]. Available: http://www.premjis.com/lml/freedom_prima_1.

Copyright

Copyright © 2024 Prof. Akshay D. Rajput, Omkar K. Kale, Suraj M. Rajguru, Aditi R. Saraf. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59318

Publish Date : 2024-03-22

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online