Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Bamboo as a Building Material

Authors: Dipjyoti Dey, Himakshi Das

DOI Link: https://doi.org/10.22214/ijraset.2024.63516

Certificate: View Certificate

Abstract

Bamboo is a versatile and remarkable plant; it is famous for its rapid growth, strength and sustainability, making it one of the most valuable and widely used natural resources. Bamboo has been utilized by humans for thousands of years. Its application ranges from construction to furniture and textile industries. In many Asian countries, bamboo is used as a primary building material for houses, bridges and scaffoldings. In recent years, bamboo has gained global recognition as a sustainable alternative to traditional materials. Its versatility, strength and eco-friendliness make it an ideal choice for a wide range of products. As the world becomes increasingly aware of the need for sustainable practices, bamboo stands out as a plant that can contribute to a more environmentally conscious future. The aim of the following study undertaken is to determine the physical and mechanical properties of bamboo for its use in construction industries. For this study, the bamboo samples were collected. Compression test, Water absorption test and Compressive Strength Test on Concrete Cube using stone aggregate and bamboo aggregate were performed. The material (Bamboo) used for these tests are neat, clean and free from any defects.

Introduction

I. INTRODUCTION

Bamboo is an adaptable and sustainable building material that has become a popular substitute in the construction sector because of its many advantages in the structural, economic, and environmental domains. Bamboo is a material that grows quickly, it grows approximately 7.5 to 40 cm a day and has exceptional strength, durability, and flexibility. It can be harvested without depleting natural resources. These qualities make it a great choice for a variety of architectural applications. This quick-growing grass has been used for centuries in many different civilizations worldwide, but because of its remarkable mechanical qualities and eco-friendliness, its use as a green building material has grown significantly in the last few years.

Bamboo has distinct qualities that make it an environmentally friendly material of choice for building projects. These qualities include its high tensile strength, low weight, and quick growth rate. Bamboo is a sustainable alternative that reduces deforestation and increases biodiversity because it may mature quickly compared to traditional hardwoods. Bamboo is further distinguished as a carbon-neutral building material by its capacity to store carbon dioxide during growth, which is consistent with international efforts to mitigate climate change.

A. Common Uses

- Bamboo is a strong and durable material that is often used for construction purposes.

- Bamboo shoots are a popular food in many cultures. They can be eaten fresh, cooked or pickled.

- Bamboo is a popular material for furniture because it is strong, lightweight and sustainable.

- Bamboo fibers can be used to make a variety of textiles, including cloth, paper and rope.

- Bamboo is a popular material for making musical instruments, such as flutes and drums.

- Bamboo can be used to make a variety of decorations, such as wind chimes and sculptures. Bamboo decorations are often beautiful and elegant.

B. Various Treatment Methods for Preservation of Bamboo

- Water Leaching: This is one of the earliest methods for preserving bamboo. The idea is based on immersing the bamboo for a certain period (4-8 months) in clean, flowing water. Starch and sugars that are present in the bamboo will slowly be rinsed away. Due to this, insects will find the pole less appealing as food. It’s crucial to remember, that even after this process, the bamboo is not entirely resistant to insect attacks.

- Fermentation: In this method, the bamboo is supposed to decompose for three to four months in mud and tree leaves. The starches and sugars in the compost are converted into acid by the microbes and bacteria, which reduces the risk of insect predation.

- Smoking: Freshly picked bamboo is less moist after being smoked and the sugars inside the bamboo pole are extruded. Additionally, the bamboo tissues absorb the chemical elements in smoke, which aids in shielding it from insects. In order to treat each pole consistently, it is important to maintain uniformity in the heat and smoke quality throughout the bamboo preservation process.

- Salt Water Immersion: This method involves submerging the bamboo in sea water for 30 days – 3 months, which allows the bamboo’s parenchyma to release its sweet sap and absorb the salt solution through the fibres. To allow for maximum salt penetration into the bamboo, holes are bored through the pole’s core to release the internodes of the bamboo.

C. Advantages of Using Bamboo as a Building Material:

- Strength and Durability: Bamboo is incredibly strong and durable. It has a tensile strength that is comparable to steel. It is also very flexible making it resistant to earthquakes.

- Lightweight: Bamboo is much lighter than concrete or steel, making it easier to transport and work with. This can also reduce the construction cost.

- Sustainability: Bamboo is a renewable resource that grows quickly. It can be harvested in 3-5 years compared to 20-30 years for other trees. It also sequester carbon dioxide, making it a carbon negative material.

- Cost – effective: Bamboo is a relatively inexpensive building material. This is because it is a renewable resource that can be harvested quickly and easily.

- Versatility: Bamboo can be used for a variety of different building applications, including flooring, roofing, furniture and structural components.

D. Disadvantages of Using Bamboo as a Building Material

- Fire Resistance: Bamboo is not as fire resistant as some other building materials, such as concrete and steel.

- Susceptibility to Pests and Diseases: Bamboo is susceptible to attack by insects, fungi and bacteria which can reduce its strength and durability.

- Lack of Standardization: There is no single international standard for bamboo construction, which can make it difficult to find qualified contractors and ensure the quality of the materials.

- Dimensional Instability: Bamboo can shrink and swell with changes in moisture content, which can lead to problems with joints and connections.

E. Objectives

The main objectives of the study are:-

- To determine compressive strength and water absorption by taking bamboo as building material.

- To determine the compressive strength of concrete cube made up of stone aggregate and bamboo aggregate using M25 grade of concrete.

II. LITERATURE REVIEW

Aashish Jodhani et al. 2016 It has been discovered that bamboo is more durable when it is vertical than when it is horizontal. Bamboo can be bent primarily if heat or pressure is applied. The seasoning ingredient used will determine the type of coating. Bamboo can be treated with an emulsion brush coat or dip coat. The design of bamboo reinforced concrete beams is comparable to that of steel reinforcing design.

Dr. Rajiv Ganguly et al. 2015 the density of bamboo is very low which makes it very light material. Water absorption capacity increases as increase in node. Tensile stress increases as increase in number of nodes.

I.K. Khan et al. 2014 examined bamboo reinforced concrete beams through an experimental study. They compared circular, square and triangular cross-section bamboo beams strengthened with steel and bamboo sticks. The load carrying capacity, deflection, flexural strength and shear strength of bamboo reinforced beams with square cross sections are higher than those with triangular and rectangular cross sections, according to experimental results. Therefore, bamboo has a tensile strength and elastic modulus that are respectively equal to 50% and 30% of steel.

H. M. A Mahzuz et al. 2013 studied stress-strain curve of different samples of bamboo to find out Modulus of Elasticity and Yield Strength. Attempts were also made to understand the bond strength of bamboo with concrete by the experimental setup of Pull out test. Pull out test of steel were also performed to report a relative comparison. They concluded that bamboo offers much less strength than that of steel.

Anurag Nayak et al. 2013 bamboo can be used in building in place of wood and other materials. Bamboo that has been utilised as reinforcement material should be waterproofed to prevent swelling when it comes into contact with concrete. The bamboo reinforcement method is less expensive than the steel reinforcement.

Ajinkya Kaware et al. 2013 tested compressive and tensile strength on bamboo. After conducting an experimental investigation, they came to the conclusion that bamboo has a high water absorption rate and good tensile strength, making it suitable for use as reinforcement in R.C.C structures. Round bamboo has a compressive strength of 47.9 MPa to 69.9 MPa.

C.S. Verma et al. 2012 studied the inner to outer region of any cross section, the tensile qualities of bamboo laminate, made from bamboo slivers picked from various parts of bamboo culms (Dendrocalamus strictus), increase from the inner to the outer region and the same is true from bottom to top. While from the bottom to the top of bamboo culms, the matrix modulus rises and the fibre modulus falls. They concluded that the experimental studies demonstrate that bamboo’s tensile strength and Young’s modulus increase from inner to outer area in cross section and from the bottom to the top of bamboo culms as a result of an increase in the volume fraction of fibers. The strength of culms rises as they get taller to make up for the loss of stiffness as a result of the geometry of the culms.

Atul Agarwal et al. 2011 performed axial compression and bending tests on plain, steel and bamboo reinforced members. For instance, a total of 12 columns, each measuring (150x150x1000) mm were casted using design mix (M20) as per IS code. These columns contained 3 steel reinforcement columns, 3 plain concrete columns, 3 untreated bamboo reinforcement columns and 3 treated bamboo reinforcement columns (with varied reinforcement percentages i.e. 3,5 and 8%). The load deformation curves showed notable nonlinearity, demonstrating the bamboo’s ability to absorb energy. Inability of most columns developed in shear under compressive pressure. Untreated bamboo and plain concrete both displayed brittle behaviour in which, around 80% of maximum axial force, little cracks appeared at the surface of the column. The load capacity dropped after reaching the maximum load.

Amada and Untao 2001 examined bamboo’s fracture characteristics. Unlike other research, this one claims that bamboo fibers almost match steel in terms of tensile strength. The primary finding is that the bamboo’s ability to fracture depends on where it comes from. The average fracture is discovered to occur in the nodes.

III. METHODOLOGY

The samples of bamboo species which is available in Assam, India were collected to find out different properties of bamboo. Compression test, water absorption test and compressive strength test using concrete mix design using the collected bamboo samples were conducted. Concrete cubes were made using stone as coarse aggregate and bamboo as coarse aggregate, then compressive strength test was performed using Universal Testing Machine.

A. Compression Test on Bamboo

Bamboo sample is cut into a certain size. The specimen were placed on the bearing plate of the Universal Testing Machine and aligned properly with the centre of thrust in the testing machine plates. The loading was applied axially on specimen. Due to constant application of load, the specimen started cracking at a point and final breakdown of the specimen were noted.

Conclusion

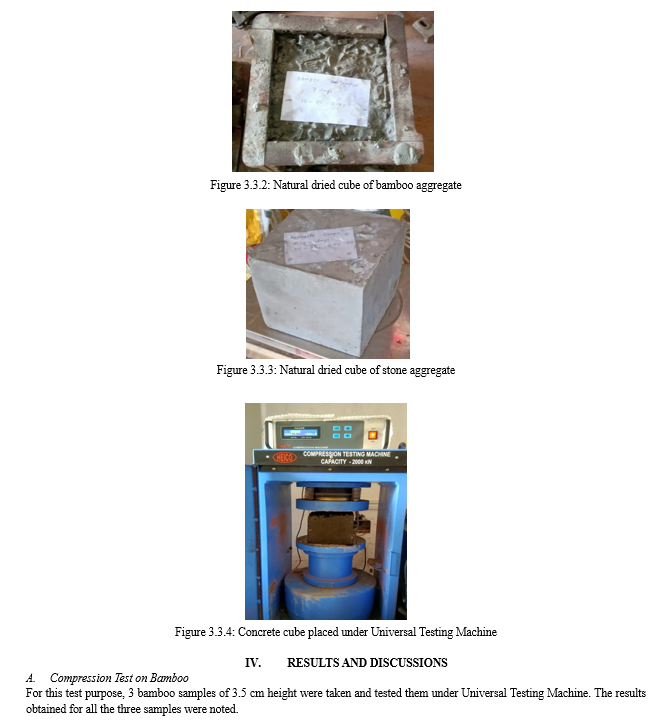

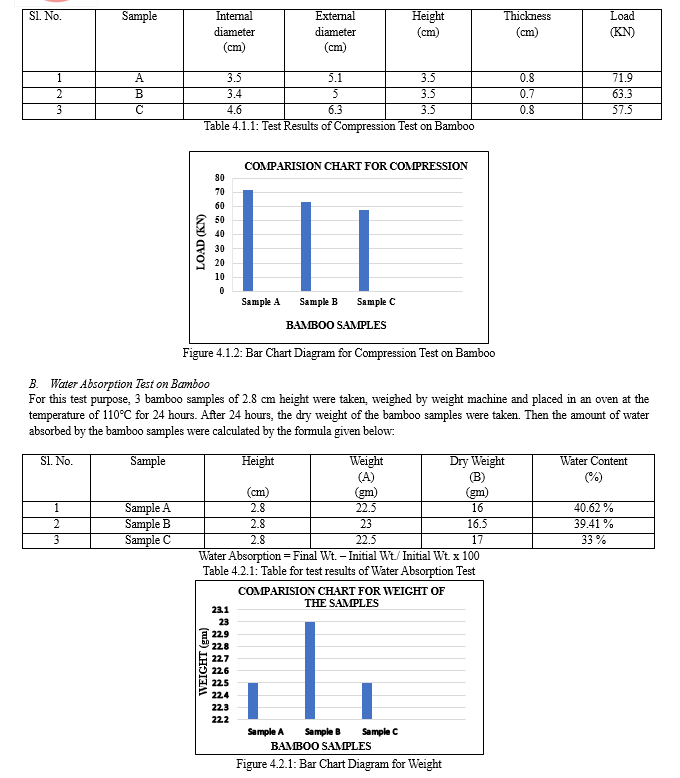

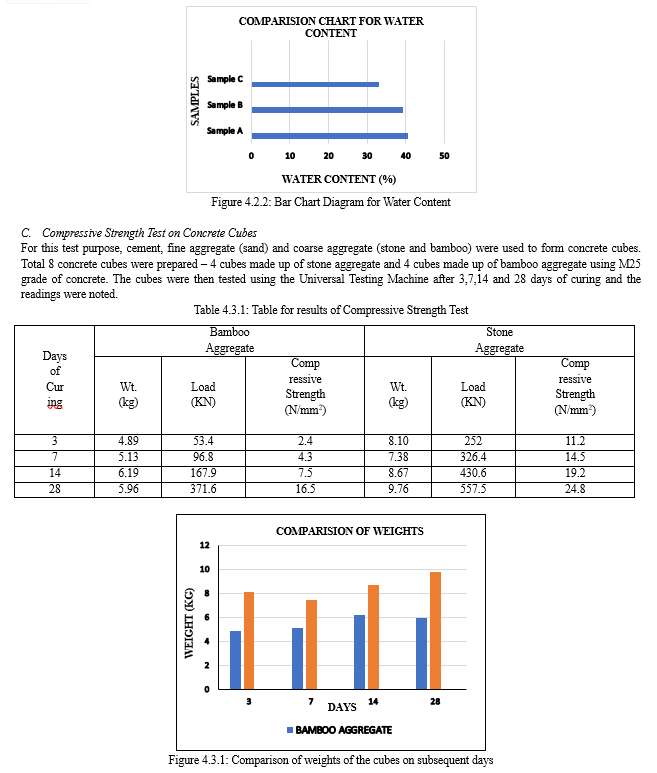

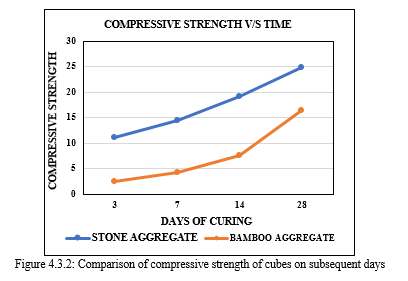

The tests were conducted using stone aggregate and bamboo aggregate to ascertain the compressive strength of bamboo, its ability to absorb water, and the compressive strength of bamboo cubes. Many samples that have been gathered and tested on are used to support the testing. Tables and graphs have been used to display the findings of the various tests.

References

[1] Ashish Jodhani and Abhay Singh (2016). Bamboo as Construction Material and Bamboo Reinforcement. International Journal of Civil and Structural Engineering, Vol. 4, 312-323 [2] Dr. Rajiv Ganguly (2015). Bamboo as green alternative to steel for reinforced concrete elements of a low cost residential building. Electronic Journal of Geotechnical Engineering, Vol. 20, 1523-1545 [3] I. K. Khan (2014). Performance of bamboo reinforced concrete beam. International Journal of Science, Engineering and Technology, Vol. 2, 1253-1264 [4] H. M. A Mahzuz (2013). Determination of Several Properties of a Bamboo. Journal of Civil Engineering Research, Vol. 3, 16-21 [5] Anurag Nayak (2013). Replacement of Steel by Bamboo Reinforcement. IOSR Journal of Mechanical and Civil Engineering, Vol. 8, 50-61 [6] Ajinkya Kaware (2013). Review of Bamboo as Reinforcement Material in Concrete Structure. International Journal of Innovative Research in Science, Engineering and Technology, Vol. 2, 2461-2464 [7] C.S. Verma (2012). Tensile Strength Analysis of Bamboo and Layered Laminate Bamboo Composite. International Journal of Engineering research and applications, Vol. 2, 1253-1264 [8] Atul Agarwal (2011). Experimental Investigation on Behaviour of Bamboo Reinforced Concrete Members. 16th International Conference on Composite Structures, Voil. 71, 610-617 [9] Amada and Untao (2001). Fracture Properties of Bamboo. Composites Part B: Engineering, Vol. 32, 451-459 [10] IS 456 (2000)

Copyright

Copyright © 2024 Dipjyoti Dey, Himakshi Das. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63516

Publish Date : 2024-06-30

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online