Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Battery Management System Using IoT

Authors: Charandeep Kumar Rajana, Yegiti Ravindra, Simhadri Nithin Reddy

DOI Link: https://doi.org/10.22214/ijraset.2024.61134

Certificate: View Certificate

Abstract

This study presents an Arduino-based system for advising users of nearby EV stations and tracking the status of their automobile batteries. The MQ-2 gas sensor, DHT11 temperature sensor, and DC voltage sensor are the three main sensors that the system interfaces with through the use of an Arduino Uno microcontroller as the central controller. When the battery temperature rises over safe limits, the DHT11 sensor monitors it and sends out alarms. By detecting gases being released into the atmosphere, the MQ-2 gas sensor warns customers of possible battery problems. Through the use of a Java web application, the DC voltage sensor suggests local EV stations and notifies users when levels are low. The sensor measures voltage and percentage. By delivering timely alerts and making charging facilities easier to use, this integrated solution raises user awareness of battery health and promotes safer driving. By fusing Arduino technology with sensor data and web application capability, it illustrates how IoT can be used practically in the automotive industry.

Introduction

I. INTRODUCTION

The primary objective of this project is to develop an integrated system that effectively monitors the health of car batteries and offers insights into nearby Electric Vehicle (EV) stations. The system utilizes an Arduino Uno microcontroller along with sensors for temperature, gas detection, and voltage measurement. Specifically, the DHT11 temperature sensor is employed to notify users if the battery temperature surpasses safe thresholds, while the MQ-2 gas sensor detects emissions from the battery, triggering alerts if necessary. Additionally, a DC voltage sensor is utilized to monitor battery levels and relay data to a Java web application in case of low battery levels. This web application utilizes the received data to recommend nearby EV stations, thereby advocating sustainable driving habits and ensuring a seamless driving experience. Ultimately, this project serves as a tangible demonstration of IoT technology's practical application in enhancing automotive safety and convenience.

Ensuring the veracity of sensor data poses a difficulty for battery monitoring systems that leverage IoT technology. The accuracy of measurements of gas, voltage, and temperature can be impacted by sensor reading variations, calibration drift, and external variables. To keep these problems at bay and data accuracy within reasonable bounds, frequent calibration and maintenance procedures are required. When it comes to automotive applications, where energy resources are limited, power consumption is a major concern for IoT-based battery monitoring systems. If we want our devices to last longer on a single charge and work without interruptions, we need to find a way to balance the need for real-time monitoring with power efficiency. To overcome this obstacle, optimization methods including low-power standby modes, duty cycling, and energy-efficient hardware design are crucial.

A flexible microcontroller board ideal for both professionals and enthusiasts is the Arduino Uno. With six analog and fourteen digital connections, it has plenty of connectivity thanks to the ATmega328P microprocessor. Programming and power supply are made simpler by its USB interface. Its inclusion of a voltage regulator, reset button, and clock circuit guarantees dependable operation. Visual feedback for debugging is provided by onboard LEDs. Widely utilized in a range of projects, from wearable technology to home automation, it is well-liked for its affordability, robust community, and ease of use. The Arduino Uno fosters creativity in electronics for both novices and experts.

An electrochemical device called a battery is used to store chemical energy and transform it into electrical energy when needed. Batteries are the main energy storage component of electric vehicles (EVs), supplying power to the electric motor that moves the vehicle forward. The driving range, acceleration, and general efficiency of the EV are all dependent on these rechargeable batteries. When designing batteries for electric vehicles, factors like energy density, power output, charging speed, and cycle life are vital to take into account. Improved EV performance, lower costs, and a quicker shift to electric vehicles are all made possible by advancements in battery technology, which also helps to lessen dependency on fossil fuels.

The project's scope encompasses the creation of a fully functional prototype that integrates Arduino Uno with sensors to monitor car battery health and provide information about nearby EV stations. The system is designed to detect battery temperature and gas emissions, alerting users to potential issues. Moreover, it monitors battery voltage, sending alerts to a Java web application upon detecting low battery levels.

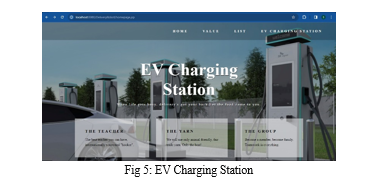

This web application then suggests nearby EV stations based on the battery's condition. By showcasing the feasibility and efficacy of employing IoT technology in enhancing car battery monitoring and promoting the adoption of electric vehicles, this project aims to contribute to the advancement of automotive technology.

Currently, car owners rely on manual methods to assess battery health, such as voltage checks or visual inspections for damage or corrosion. However, these manual approaches are prone to limitations, including the lack of continuous, real-time monitoring and the inconvenience of physical access to the battery. Consequently, car owners may remain unaware of potential safety hazards until they manifest as breakdowns or damage, emphasizing the necessity for a more proactive monitoring system. Additionally, existing systems typically lack integration with external databases containing EV station information, limiting their ability to provide comprehensive guidance on nearby charging facilities.

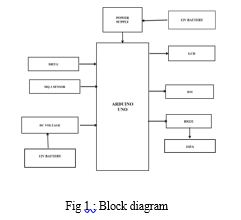

The proposed system is designed to enhance automotive safety and convenience through the integration of various components, including sensors, microcontrollers, and web applications. At its core is the Arduino Uno microcontroller, which interfaces with sensors like the DHT11 temperature sensor, MQ-2 gas sensor, and DC voltage sensor to gather real-time data on battery health parameters. A robust data processing module within the Arduino Uno analyzes this data, triggering alerts in case of anomalies and relaying low battery levels to the Java web application. Complementing this setup is a dynamic Java web application that processes received data to suggest nearby EV stations based on the battery's condition. This system offers continuous, remote monitoring of battery health, promoting early detection of safety hazards and sustainable driving practices. It eliminates the inconvenience of manual methods and provides tailored guidance on EV stations, showcasing the practical application of IoT technology in enhancing automotive functionality and user experience.

The success of systems for monitoring and managing batteries depends on the reliability of data transfer and communication. The prompt transmission of sensor data to the monitoring platform might be jeopardized by problems with signal interference, inconsistent network coverage, and delay. To reduce the effect of connectivity issues and guarantee data integrity, it is important to implement strong communication protocols, error correction methods, and redundancy measures. Internet of Things (IoT) battery monitoring systems must prioritize security in order to shield private information from prying eyes and foil attempts at manipulation. The system is vulnerable to cyber attacks and privacy breaches due to weak vulnerabilities in communication routes. Standard security procedures in the business, like end-to-end encryption, access control, and frequent security audits, make the system more esistant to harmful attacks.

As they must accommodate a wide variety of car models and battery types, battery monitoring systems face substantial problems in terms of scalability and compatibility. Deliberate design and standardization are necessary to guarantee compatibility with current vehicle systems and to accommodate forthcoming technology developments. The monitoring system may be easily integrated and scaled across several platforms because to its flexible structures, modular components, and open communication protocols. The success of battery monitoring systems that are based on the Internet of Things depend on how well users embrace and use them. Engagement of users and promotion of active engagement in battery management activities necessitates user-friendly interfaces, intuitive dashboards, and instructive notifications. If consumers are informed about the advantages of proactive battery monitoring, such as increased safety, efficiency, and savings on costs, they are more likely to embrace and incorporate the system into their everyday lives.

Electric vehicles (EVs) and their batteries have greatly improved the environment by lowering air pollution and greenhouse gas emissions and fostering energy independence from renewable sources. Once emblematic of mobility, fossil fuel cars now confront issues such as volatile fuel prices, unstable oil reserves, and global unrest. Battery-powered electric vehicles (EVs) are starting to take the lead in transportation as concerns over climate change rise.

This trend is being aided by advancements in battery technology, government incentives, and customer desire for greener mobility options. This change represents a revolution in the automotive sector, as EVs are expected to replace fossil fuel cars as the main method of mobility in the near future.

EV battery faults can result from a variety of causes, including internal short circuits, thermal runaway caused by overheating, electrode degradation, and manufacturing flaws. Inconsistencies in cell production caused by manufacturing flaws may cause uneven performance or early failure.

Excessive heat buildup can induce thermal runaway, which can harm batteries and be dangerous. Internal short circuits can result in electrical problems or even fires, while electrode degradation over time lowers battery capacity and lifespan. To reduce these hazards and improve battery reliability in EVs, it is essential to ensure strict quality control methods are followed throughout production and to put in place efficient heat management systems.

II. METHODOLOGY

A. Hardware Setup

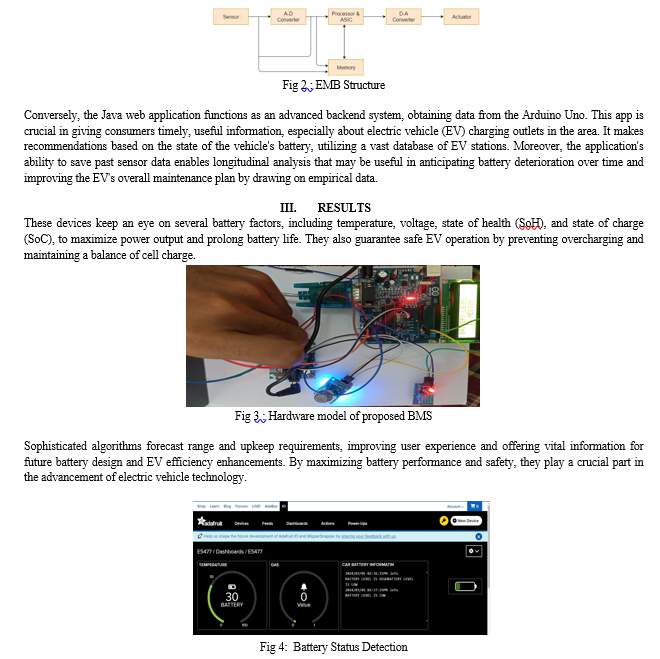

The Arduino Uno microcontroller, which controls data gathering and communication, is the central component of the hardware configuration for battery monitoring via the Internet of Things. Comprehensive health tracking of the automobile battery is ensured by its connectivity with sensors such as the DHT11 and MQ-2. The DHT11 sensor is essential for temperature monitoring since high temperatures drastically shorten battery life and performance. However, the MQ-2 sensor is skilled at spotting gasses that could point to damage or leaks in the battery, acting as an early warning system against future malfunctions. Real-time data from these sensors is sent to the Arduino, which processes it and can then transfer it to a networked system or user interface for additional processing. Since promptness and accuracy are essential in these configurations, every sensor is calibrated in accordance with the standards necessary for automotive use. In particular, the DC voltage sensor, which gauges the battery's voltage and charge state, is essential. It needs to be accurate since even minute variations in voltage readings can result in inaccurate evaluations of the state of the battery. To guarantee steady operations and accurate data, the voltage and current requirements of these sensors must be carefully considered during integration with the Arduino Uno. Maintaining accuracy over time also requires regular calibration and maintenance of these sensors, which is made easier by the IoT framework's ability to provide remote updates

and diagnostics. The development of the Java web application and the Arduino sketch are both included in the software design. A number of tasks were programmed to be performed in the Arduino sketch. Interfacing with sensors like the MQ-2 gas sensor, DC voltage sensor, and DHT11 temperature sensor is one of these responsibilities. These sensors provide data, which the sketch is made to read and process properly. For example, it assesses the battery's health by comparing temperature and gas levels to preset standards. Furthermore, the sketch is configured to sound an alert to tell the user if any parameter crosses safe bounds.

B. Software Design

Interface with the sensors: The software is engineered to establish connections with various sensors, including the DHT11 temperature sensor, MQ-2 gas sensor, and DC voltage sensor. Through these connections, it gathers relevant data from each sensor. For example, it retrieves temperature readings from the DHT11 sensor, gas concentration data from the MQ-2 sensor, and voltage measurements from the DC voltage sensor. This enables the software to access a comprehensive range of environmental and system parameters essential for its functions.

Process sensor data: The software processes sensor data by analyzing temperature and gas levels against predefined thresholds. This analysis helps determine the battery's health status by identifying deviations from expected nor Trigger alerts: The software is configured to sound an alarm if any parameter crosses pre-established safe boundaries. The user receives these warnings immediately, informing them of the exceeded threshold and guaranteeing early awareness of any potential problems.

Communicate with Java web application:

Transmit battery health data to java web application for further analysis and EV station suggestions. The Java web application was developed to receive data from the Arduino Uno and provide real-time suggestions on nearby EV stations. It utilizes a database of EV stations to make recommendations based on the battery's condition and stores historical data for future reference.

C. Testing Procedures

A DC voltage sensor, a MQ-2 gas sensor, and a DHT11 temperature sensor are among the sensors with which the Arduino sketch is specifically designed to connect well. Monitoring the operational and environmental factors that impact battery health is a critical function of these sensors. The sketch assesses whether the temperature and gas levels are within safe operating limits. The user will always be informed when any of the readings go above these pre-established safe limits thanks to critical warnings that are designed to sound. Furthermore, all of the battery health data that has been gathered is sent for additional analysis because this configuration is made to function seamlessly with a similar Java web application.

IV. FUTURE SCOPE

The idea may be improved in the future by incorporating cutting-edge machine learning algorithms to evaluate sensor data and produce more precise battery health forecasts. To prevent unplanned breakdowns and enable proactive maintenance, this may entail creating predictive maintenance models that identify battery issues before they happen. Furthermore, the system might be improved to offer more individualized suggestions for EV station sites based on user preferences, including availability, cost, and charging speed. To customize recommendations to each user's requirements and interests, this may entail incorporating user profiles into the Java web application. Additionally, the system might be modified to incorporate additional sensor types, including proximity sensors for collision avoidance or ultrasonic sensors for parking assistance. This would improve the system's overall performance and give consumers access to a wider range of tools for controlling and keeping an eye on their cars. All in all, these upcoming improvements would increase the system's intelligence, usability, and effectiveness in encouraging environmentally friendly driving habits and improving the entire driving experience.

Conclusion

In conclusion, the project has successfully demonstrated the feasibility and effectiveness of using Arduino-based systems for monitoring car battery health and suggesting nearby EV stations. By integrating sensors for temperature, gas, and voltage monitoring with a Java web application, the system provides valuable information to users, enhancing their awareness of their vehicle\'s battery health and promoting sustainable driving practices. Future enhancements, such as integrating machine learning algorithms and expanding sensor support, could further improve the system\'s functionality and user-friendliness. Overall, the project showcases the potential of IoT technology in the automotive industry and highlights the importance of proactive battery monitoring for ensuring safety and efficiency on the road.

References

[1] Y. Khawaja, N. Shankar, I. Qiqieh, J. Alzubi, O. Alzubi, M. K. Nallakaruppan, and S. Padmanaban, ‘‘Battery management solutions for Li-ion batteries based on artificial intelligence,’’ Ain Shams Eng. J., Mar. 2023, Art. no. 102213. [2] S. S. Ravi and M. Aziz, ‘‘Utilization of electric vehicles for vehicle-to-grid services: Progress and perspectives,’’ Energies, vol. 15, no. 2, p. 589, Jan. 2022. [3] M. Uzair, G. Abbas, and S. Hosain, ‘‘Characteristics of battery management systems of electric vehicles with consideration of the active and passive cell balancing process,’’ World Electr. Vehicle J., vol. 12, no. 3, p. 120, Aug. 2021. [4] D.Selavabharathi and N.Muruganatham Experimental analysis on battery based health monitoring system for electric vehicle\", Mater. Today Proc., vol. 45, pp. 1552-1558, 2021. [5] H.-Y. Pai, K.-C. Ho, G.-J. Chen, P.-H. Liao, S.-C. Wang and Y.-H. Liu, \"An SOC-based Active Equalizer for Fast Charge Balance of Series-Connected Battery Pack\", 2020 IEEE 29th International Symposium on Industrial Electronics (ISIE), pp. 655-659, 2020. [6] R. Xiong, S. Ma, H. Li, F. Sun and J. Li, \"Toward a Safer Battery Management System: A Critical Review on Diagnosis and Prognosis of Battery Short Circuit\", iScience, vol. 23, no. 4, pp. 101010, 2020. [7] B. Balasingam, M. Ahmed and K. Pattipati, \"Battery Management Systems-Challenges and Some Solutions\", Energies, vol. 13, no. 11, 2020. [8] P. Sivaraman and C. Sharmeela, \"IoT-Based Battery Management System for Hybrid Electric Vehicle\" in Artificial Intelligent Techniques for Electric and Hybrid Electric Vehicles, John Wiley & Sons, Ltd, pp. 1-16, 2020. [9] S. Haldar, S. Mondal, A. Mondal and R. Banerjee, \"Battery Management System Using State of Charge Estimation: An IOT Based Approach\", 2020 National Conference on Emerging Trends on Sustainable Technology and Engineering Applications (NCETSTEA), pp. 1-5, 2020. [10] K. Liu, K. Li, Q. Peng, and C. Zhang, ‘‘A brief review on key technologies in the battery management system of electric vehicles,’’ Frontiers Mech. Eng., vol. 14, no. 1, pp. 47–64, Mar. 2019. [11] M. A. Hannan, M. M. Hoque, A. Hussain, Y. Yusof, and P. J. Ker, ‘‘State-of-the-art and energy management system of lithium-ion batteries in electric vehicle applications: Issues and recommendations,’’ IEEE Access, vol. 6, pp. 19362–19378, 2018. [12] L. Ianniciello, P. H. Biwolé and P. Achard, \"Electric vehicles batteries thermal management systems employing phase change materials\", Journal of Power Sources, vol. 378, pp. 383-403, 2018. [13] R. Xiong, J. Cao, Q. Yu, H. He, and F. Sun, ‘‘Critical review on the battery state of charge estimation methods for electric vehicles,’’ IEEE Access, vol. 6, pp. 1832–1843, 2018. [14] X. Liu, T. Zhao, S. Yao, C. B. Soh and P. Wang, \"Distributed Operation Management of Battery Swapping-Charging Systems\", IEEE Trans. Smart Grid, vol. 10, no. 5, pp. 5320-5333, 2018. [15] M. Lelie, T. Braun, M. Knips, H. Nordmann, F. Ringbeck, H. Zappen, and D. Sauer, ‘‘Battery management system hardware concepts: An overview,’’ Appl. Sci., vol. 8, no. 4, p. 534, Mar. 2018. [16] Manish Mawatwal, Aayush Mohanty, Anitha G. S. State of Charge Estimation for Rechargeable Lithium-ion Battery using ANFIS MATLAB. International Journal of Engineering Research And 2020; V9. https://doi.org/10.17577/ IJERTV9IS030565.

Copyright

Copyright © 2024 Charandeep Kumar Rajana, Yegiti Ravindra, Simhadri Nithin Reddy. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET61134

Publish Date : 2024-04-27

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online