Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Bio Fiber Odyssey

Authors: Hemlata U. Karne, Krutika P. Dhole, Abhishek S. Guhagarkar, Manthan Alanadakar, Shruti Dabhade, Harshal Gawande

DOI Link: https://doi.org/10.22214/ijraset.2024.64539

Certificate: View Certificate

Abstract

Solid waste management presents a significant challenge for modern society. This research project aims to address this issue by utilizing agricultural waste—specifically, sugarcane bagasse, banana fibers, and dry leaves—to manufacture handmade paper. The fibers are collected, sun-dried, and cleaned in a water vat to remove dust and impurities. They are then cooked with a 10% caustic solution in a pressure cooker and subsequently blended for different time intervals. To achieve discoloration and further purification, a diluted Clorox solution is employed. Three types of paper are produced: one using only the raw fibers, another with the addition of 2% calcium carbonate and 2% starch, and a third with 5% of these additives. The papers are then dried and ironed to enhance smoothness. Various properties, including GSM, pH, thickness, bulk, and moisture content, are measured. Papers made from bagasse fibers are heavier and more suitable for rough use, while those made from banana fibers are softer and ideal for applications such as tissues and wipes. This eco-friendly process not only utilizes agricultural waste but also consumes minimal electricity.

Introduction

I. INTRODUCTION

Paper has been used for writing and packaging for centuries. Around 105 CE , Cai Lun of China is credited with the invention of paper.Paper originated in China and travelled to the Middle East before reaching Europe in the 13th century. Paper is made by pressing together moist fibers and drying them to create flexible sheets. Its applications range from writing and printing to packaging, cleaning products, industrial processes, construction, and even as a food ingredient. Paper production involves both wood and non-wood materials, such as bagasse and banana fibers. Eco-friendly paper production methods, which avoid alkali and pollution, offer significant benefits over conventional methods, including reducing global warming. Handmade paper industries are gaining popularity due to their eco-friendly nature, which supports forest growth and environmental preservation. This project focuses on producing handmade paper from bagasse and banana fibers.

A. Handmade Paper from Bagasse

The first step in producing paper from bagasse, begin by gathering bagasse from a nearby sugar mill or reusing sugarcane stalks after juice extraction. Spread the bagasse thinly and let it air dry in the sun until it has a low moisture content, which usually takes a few days. Once dried, use garden shears or a small grinder to cut the bagasse into smaller pieces about 1-2 inches long. To soften the fibers before pulping, immerse the chopped bagasse in water in a big container for 24 hours. After soaking, transfer small portions of the mixture to a blender and process until the fibers have broken down into a pulp, adding extra water as needed for a smooth consistency. To bleach the pulp, make a moderate solution by combining hydrogen peroxide (3-5% concentration) with water at a 1:10 ratio. Pour the pulp into the bleaching solution, stir thoroughly, and leave for a few hours, stirring occasionally. Rinse the bleached pulp well in clean water to eliminate any remaining bleaching chemical. To refine, return the bleached pulp to the blender or use a hand-held mixer to further refine the fibers, improving bonding and paper strength. To make a slurry, dilute the refined pulp with water in a large basin. Pour the slurry onto a fine mesh screen or a wooden frame with a screen to properly distribute the pulp. Lift the screen, allowing excess water to drain, then press the wet sheet against absorbent materials like felt or cloth to remove additional water. Finally, completely dry the pressed sheet with a heat source or by air drying. After drying, smooth the paper with a rolling pin or equivalent instrument and cut it to the desired size.

B. Handmade Paper from Banana Fibers

Banana fibers are ideal for papermaking due to their high alpha-cellulose and low lignin content. Today, banana fibers are used as a raw material for paper pulp to produce various types of paper, including tissue, blotting, tracing, and writing paper. Bananas are a key fruit crop globally and especially in Oman, which is the largest banana producer in the Gulf region, specifically in Dhofar and the Batinah region.

Research indicates that sugarcane bagasse has the lowest silica content (9.78%) and the highest carbon content (90.22%) compared to rice straw and rice husk. Approximately 10% of the world's chemical pulp is produced using non-wood materials such as bagasse and wheat straw. The soda process is preferred for chemical pulping of non-wood materials due to its economic viability on a small scale and compatibility with sugarcane processing.

A preliminary economic analysis of the soda process for producing commodity silica, lignin, and pulp for papermaking is presented. However, a major challenge in using bagasse for papermaking is its high pith content (35-40%). Conventional depithing methods, including dry depithing followed by wet cleaning, remove only about 50% of the pith, resulting in around 15% pith in the depithed bagasse.

Nakagolo investigates the use of sugarcane bagasse and mixed waste paper for handmade paper production, aiming to offer a sustainable alternative to traditional methods. The study finds that this combination can produce acceptable quality paper, enhancing environmental sustainability by reducing waste[1].This study evaluates the feasibility of using sugarcane bagasse and banana fibers in Oman to produce handmade paper. It highlights the environmental and economic benefits of using local agricultural residues and finds that the combination yields a viable and durable paper product [2]. Sanganeri handmade paper industry as an eco-friendly, employment-generating sector in India.

Despite its benefits, it faces challenges like high costs and outdated technology. The study calls for greater government support and investment to enhance its growth potential and environmental impact [3]. The research paper investigates the production of handmade paper using sugarcane bagasse and other natural fibers. It found that a blend of bagasse, sisal fiber, and cotton pulp (40:30:30) produced the highest quality paper in terms of strength and durability. Sensory evaluations were positive, and the blended paper was more cost-effective than cotton-only paper. The study concludes that this approach offers a sustainable and environmentally friendly method for producing handmade paper [4]. The study highlights banana fiber as a promising, sustainable alternative for the Indian handmade paper industry, offering a cost-effective and eco-friendly solution. By using an alkaline pulping process and enzymatic refining, banana fiber can produce high-quality paper while reducing energy use and utilizing agricultural waste [5]. The paper "Production of Handmade Paper from Sugar Cane Bagasse," published in BJEDIS, details UFRJ and IFRJ's method for converting sugarcane bagasse into high-quality Kraft paper. Using bagasse from Duque de Caxias, RJ, and a homemade pulping process, the study produced paper suitable for crafts and small-scale use, showcasing the potential of agricultural residues for sustainable production [6].

The study examines using waste and extracted banana fibers from Bangladesh to produce eco-friendly paper. While extracted fibers yield better pulp, waste fibers still meet handmade paper standards, offering a sustainable, low-cost alternative that benefits rural and small-scale production.[7]. The article reviews various aspects of handmade paper (HMP) production, including its history, innovative materials used, the process of making HMP, and the role of HMP in conservation and sustainability[8]. The study on "Handmade paper from waste banana fiber" shows that while extracted banana fiber (EBF) yields higher quality paper, waste banana fiber (WBF) can still produce satisfactory handmade paper under the right conditions. This approach offers a sustainable, eco-friendly solution for waste management and supports local economies in banana-growing regions [9]. The research highlights banana stem as a cost-effective, sustainable raw material for paper pulp, using the kraft process to extract cellulose. The resulting paper shows good strength, brightness, and smoothness, making banana stem a viable, eco-friendly alternative to traditional wood-based materials for producing various types of paper [10]. This paper explores the use of banana stem fibers for Kraft paper, highlighting their potential as a sustainable alternative to wood due to their low lignin and high cellulose content, which reduces chemical and energy needs.

It outlines the chemical retting process and the benefits of using agricultural residues in paper production [11]. This paper reviews the potential of non-wood fibers like banana stems for sustainable paper production, noting their high cellulose and low lignin content ideal for Kraft paper. It also discusses the Kraft process's development and highlights the economic and environmental advantages of using agricultural residues, such as reduced wood use and lower processing costs [12]. This research investigates producing eco-friendly paper from bagasse using natural binders like aloe vera and corn starch. It demonstrates the successful creation of durable, biodegradable paper with potential applications in daily life, highlighting the environmental benefits of recycling agricultural waste [13]. The article "Handmade Paper from MUSA Acuminata (Banana) Stem" in *IJARSCT* explores banana stems as a sustainable, cost-effective source for handmade paper. It describes the pulping process, which extracts cellulose, and highlights the benefits of banana fibers, including economic gains for farmers and environmental advantages like waste reduction [14].

II. MATERIALS AND METHOD

Fig : Graphical Presentation of each step

A. Sample Collection

Bagasse was obtained from a local sugar mill.

Banana fibers were collected from an agricultural farm.

B. Sample Preparation

Both samples were thoroughly washed. They were then soaked in a 10% caustic soda solution (100 grams caustic soda per 1000 milliliters of water) for at least one day. The soaked samples were subsequently dried in the sun.

C. Pulping Process

The samples were cooked for 30 minutes. They were then washed with hot water, followed by tap water.

D. Mixing

The pulped material was mixed in a blender for 5 minutes with a small amount of water.

E. Bleaching Process

To remove the brown colour and achieve a whiter pulp, a bleaching agent (Clorox) was used.

F. Paper Making

A paper sheet was formed using an inlet frame. Additives (calcium carbonate and starch) were added to the pulp in varying percentages: 0% for the first paper, 2% for both additives in the second paper, and 5% for both additives in the third paper. These additives were intended to enhance the paper's properties.

G. Ironing

As the final step, the paper was ironed to achieve smoothness and straightness.

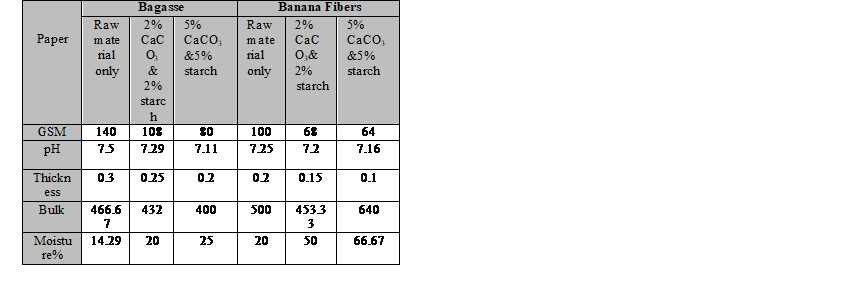

III. RESULT AND DISCUSSIONS

- GSM Test: The GSM (grams per square meter) values were calculated for three types of bagasse paper and three types of banana fiber paper. For both types of paper, the GSM ratio increased with the addition of CaCO3 and starch. Initially, the GSM ratio for bagasse paper was higher than for banana fiber paper. This trend continued with the addition of 2% CaCO3 and 2% starch, as well as with 5% CaCO3 and 5% starch. Overall, the highest GSM ratio was observed in bagasse paper with 5% CaCO3 and 5% starch.

- pH Test: The pH values increased with the addition of CaCO3 and starch in both bagasse and banana fiber papers. Bagasse papers consistently had higher pH values compared to banana fiber papers across all tested conditions.

- Thickness Test: Bagasse papers exhibited greater thickness, indicating their suitability for rough uses, while banana fiber papers were more suitable for sophisticated applications. The highest thickness was found in bagasse paper with 5% CaCO3 and 5% starch, measuring 0.3 mm. In both types of paper, thickness increased with the addition of CaCO3 and starch.

- Bulk Test: A high bulk value indicates good paper quality. The bulk value increased with the addition of CaCO3 and starch in bagasse paper. However, for banana fiber papers, the paper with 2% CaCO3 and 2% starch had the lowest bulk value, while the paper made from raw banana fibers alone had the highest bulk value. The average bulk value for all paper types ranged between 400 and 500.

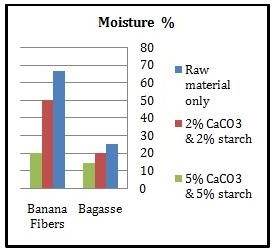

- Moisture Test: Banana fiber papers had a higher moisture content compared to bagasse papers, making them suitable for uses such as facial tissue, tracing paper, and transparent paper. The addition of CaCO3 and starch decreased the moisture content in both bagasse and banana fiber papers. Overall, banana fiber papers retained more moisture than bagasse papers.

Table: Comparison of paper quality from Banana and Bagasse fibers

Fig. Graphical presentation of paper quality comparison

Fig. Graphical presentation of paper quality comparison

Fig : Sample of handmade Papers

Conclusion

This study demonstrates the potential of using agricultural waste—banana fiber, bagasse, and dry leaves—as raw materials for high-quality handmade paper. Banana fiber excels in tensile strength and absorbency, ideal for tissues and wipes; bagasse is denser, making it suitable for durable packaging; and dry leaves offer versatility for various applications. Utilizing these materials not only reduces landfill waste but also lowers energy use and chemical inputs, presenting a sustainable alternative to traditional wood-based paper production. The findings support the feasibility and environmental benefits of this approach.

References

[1] Nakagolo , Maria Gorret (2019 -06) Production of handmade paper from sugarcane bagasse anda mixed grade of waste paper. [2] Khalsa Al-Sulaimani ,Priy Brat Dwiwedi (December 2017) Production of handmade papers from sugarcane bagasse and banana fiber in Oman , International Journal of Students Research in Technology & Management 5(3):16. [3] Ruby Jain , Madhu Kulhar , Shepali Chakravarty , A study of Sanganeri Handmade Paper Industries , Internaltional Journal of Interdisciplinary and Multidisiciplinary Studies (IJIMS) , 2017, Vol 4 , No.2,79-85.ISSN-(Print ): 2519-7908 ; ISSN- (Electronic);2328-0343. [4] K.J . Sannapapamma , Deepa .S. Bhairappanavar , Sanjay B. Patil . “Subjective evaluation of baggase composite handmade papers for variegated applications “. J. Farm Sci.35(1):(146-150) March 2022, University of Agricultural Sciences , Dharwad -580 005 , Karnataka , India . [5] Atul Kumar , B. P . Singh , R.K. Jain, A.K Sharma , Banana Fiber (Musa saptieum):” A Suitable Raw Material for Handmade Paper Industry via Enzymatic Refining “( 10 October 2013). International Journal of Research &Technology (IJERT) ISSN:2278-0181 , Vol 2 Issue 10. [6] Fabiola da Silveira Maranhao , Daniela Batista O Gaspar , Cintia Patricia Santos da Paxiao ,Thuanny Moraes de Almeida , Emnaulele Nunes de Lima Figueiredo Jorge :” Production of Handmade Paper from the Sugar Cane Bagasse Pulping “ (2021) ,Brazilian Journal of Experimental Design Data Analysis and Inferential Statistics , ISSN-:2763-6925. [7] Kazi Md Yasin Arafat , Md.Sarwar Jahan , Jannatum Nayeem . “Handmade paper from waste banana fiber” (2018). Article in Bangladesh Journal of Scientific and Industrial Research , May (2018). [8] Alka Madhukar Thakker , Danmei Sun , “ Handmade Papers :Innovation , Technology , and Design , Journal of Natural Fibers , 2023 , VOL 20.NO 1, 2187505. [9] K.M.Y.Arafat, J.Nayeem, A.H.Quadery , M. A .Quaiyyum , M. Sarwar Jahan (2018) ,Handmade paper from waste banana fiber , Bangladesh Journal of Scientific And Industrial Research . [10] Lakhan Singh , Dr. Tarun Katri Bandyopadhyay , International Journal of Scientific & Engineering , Volume 4 , Issue 7 , July-2013, ISSN:2229-5518. [11] Prashant A Giri , Ramprasad Nigudkar, Shubham D Kalan , Experimental Investigation of Kraft Paper Making from Banana (Musa Sapientum) Stem Fibers and Study of Advancements in Fiber Extraction Process (April ,2018) JETIR , Volume 5 Issue 4, (ISSN:2349-5162). [12] Saurabh S. Mahatme , Yogesh A . Landge , Hitesh A .Tawade , Yamaji B. Najan , Experimental Investigation On Producing Paper Using Non-Wood Fiber (May 2019), JETIR , Volume 6, Issue 5, (ISSN-2349-5162). [13] Nguyen Thi Xuan Hanth , Nguyen Thi Bich Ngoc, Vo Thi Hai Yen, Research on the process of making paper from bagasse at laboratory scale (2022).T he Dau Mot University Journal of Science (ISSN- 2615-9635). [14] Ms. Akanksha Mote , MR. Aniket Gavade , Mr. Santosh Bandgar , Mr.Avinash Narute , Handmade Paper from MUSA Accuminta (Banana ) Stem, (2023) International Journal of Advanced Research in Science , Communication and Technology (IJARSCT) Volume 3, Issue 1 , ISSN :(2581-9429).

Copyright

Copyright © 2024 Hemlata U. Karne, Krutika P. Dhole, Abhishek S. Guhagarkar, Manthan Alanadakar, Shruti Dabhade, Harshal Gawande. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64539

Publish Date : 2024-10-10

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online