Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

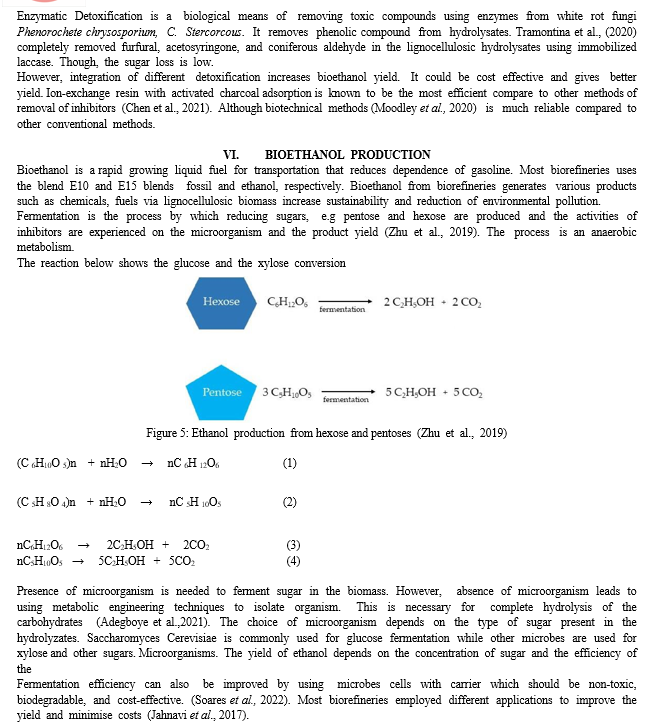

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Bioethanol: A Sustainable Liquid Fuel as Substitute to Gasoline

Authors: Abdulsalam A. A., Aliyu S., Bashar B. L., Danillela U. Y., Ahmad Z. U., Aminu M. B., Gbadamosi L. A.

DOI Link: https://doi.org/10.22214/ijraset.2024.63555

Certificate: View Certificate

Abstract

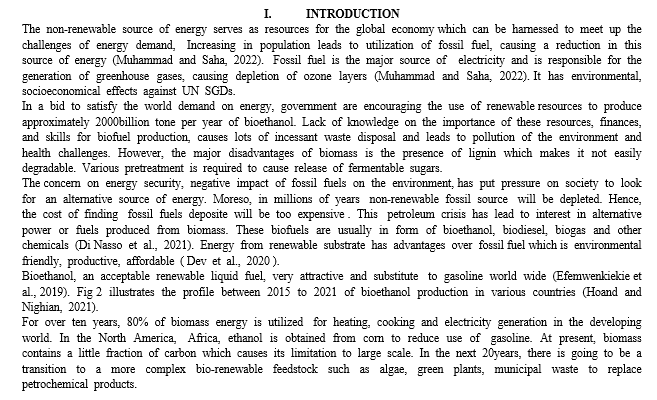

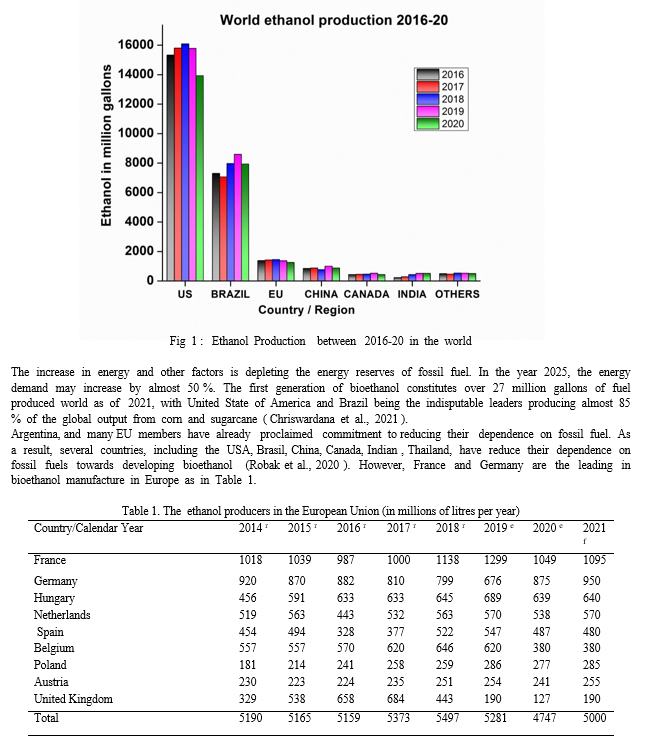

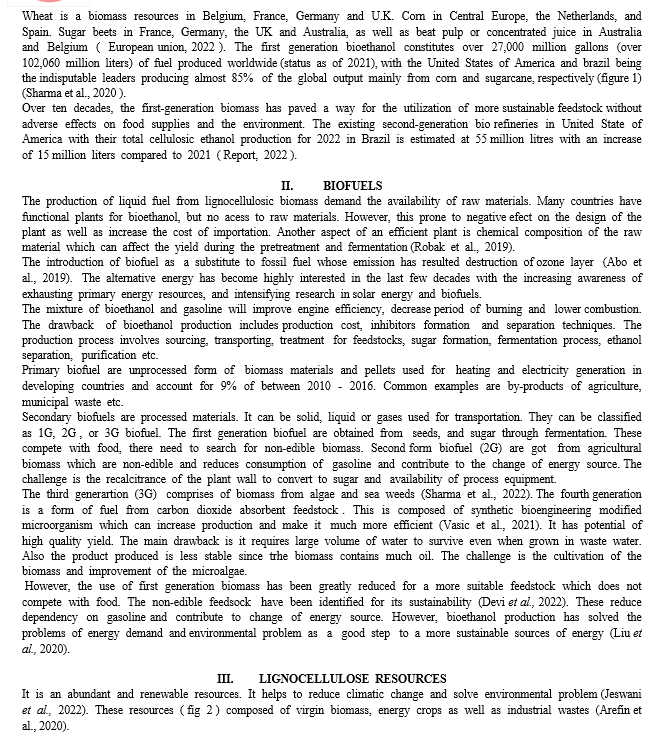

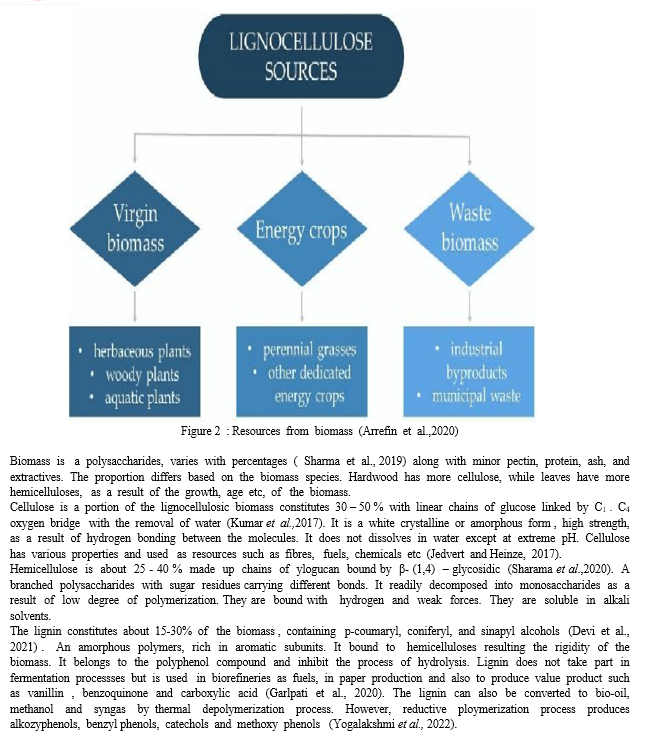

Fossil fuel dependence is a growing concern due to its contribution to greenhouse gas emission, climatic change and environmental pollution. This highlights the urgency for alternative source of energy that is renewable, environmental friendly, stability in price, and attractive for sustainable development. Bioethanol, a biofuel has emerged as the most acceptable liquid fuel and as a promising alternative to gasoline. Bioethanol, derived from sugars and starch, has raised sustainability concern as it can lead to competition for land use and potentially driven-up food prices especially in developing countries. Meanwhile, Lignocellulosic biomass, a non-food resources, abundant in cellulose and hemicellulose, present a more sustainable feedstock for bioethanol production. This approach could offer advantages like affordability, environmental friendliness, reduce reliance on traditional fuels and compensate for fuel scarcity. Furthermore, bioconversion technology of lignocellulosic biomass to bioethanol is required to improve its efficiency and cost effectiveness, making it a highly attractive option for a greener energy in the future.

Introduction

Conclusion

The global energy crisis and environmental challengs pose a major problems facing the society and a concern to the researchers. Biofuel produced from renewable and sustainable feedstocks contributes to national development and economic growth. Bioethanol production from lignocellulosic biomass makes the production cost insignificant due to the abundant of the lignocellulosic biomass. The main challenge in bioethanol production include lignocellulosic recalcitrance, high enzyme cost, the inhibition of enzymes and microorganism, low bioethanol yields and high energy demand for bioethanol recovery and dehydration. The pretreatment method is one of the expensive and most intensive step in second generation biorefineries. The physico-chemical is regarded as the most cost effective method of pretreatment but the major disadvantages is that it generates inhibitors that decreases the enzymes activities and microorganism growth rate. The establishment of improved design and sustainable pretreatment methods will lower energy and chemical consumption, and minimize inhibitors generation and improved the carbohydrate recovery. However, the design of new genetically modified microorganism, enzymes activity, simultaneous assimilation of hexose and pentose sugars and high resistance to inhibitors would promote high yield of bioethanol production and production cost. Distillation method is still in used in recovery of bioethanol from fermentation broth. The application of hybrid processes of azeotrope distillation and dehydration will decrease the energy and operation cost of large scale bioethanol separation.

References

[1] Abo, B.O.; Gao, M.; Wang, Y.; Wu, C.; Ma, H.; Wang, Q. (2019). Lignocellulosic Biomass for Bioethanol: An Overview on Pretreatment, Hydrolysis and Fermentation Processes. Rev. Environ. Health 34, 57–68. [2] Arefin, M.A.; Rashid, F.; Islam, A. A (2021). Review of Biofuel Production from Floating Aquatic Plants: An Emerging Source of Bio-Renewable Energy. Biofuels Bioprod. Biorefin. 15, 574–591. [3] ASTM, (2011). Standard Specification for Denatured Fuel Ethanol for Blending with Gasolines for use of Automobile Spark-lgnition Fuel. Annual book of ASTM Standard, ASTM Standard D4806-11. [4] Awowoxale and Lokhat, (2019) Harnessing the potential of bioethanol paltry from lyra business in Nig. Biofuel, bioprod, Biorefining, 13 (1). 192-207. [5] Chen, J.; Zhang, B.; Luo, L.; Zhang, F.; Yi, Y.; Shan, Y.; Liu, B.; Zhou, Y.; Wang, X.; Lü, X. (2021). A Review on Recycling Techniques for Bioethanol Production from Lignocellulosic Biomass. Renew. Sustain. Energy Rev. 149, 111370. [6] Chaudhary, R.; Kaushal, J.; Singh, G.; Kaur, A.; Arya, S.K. (2022). Melioration of Enzymatic Ethanol Production from Alkali Pre-Treated Paddy Straw Promoted by Addition of Surfactant. Biocatal. Biotransform. [7] Chan , K, Adijalle, T.T, Lai, S, Barnase , M, perrier, J (2020) effect of mechanical pretreatment For enzymatic hydrolysis of woody rariduous, Corn stover of alfalfa. Waste Biomass Valorization, 11, 5847-5856. [8] Chundawat, S.P.; Pal, R.K.; Zhao, C.; Campbell, T.; Teymouri, F.; Videto, J.; Nielson, C.; Wieferich, B.; Sousa, L.; Dale, B.E. (2020). Ammonia Fiber Expansion (AFEX) Pretreatment of Lignocellulosic Biomass. J. Vis. Exp. 158, e57488. [9] Chriswardana T.H., Mulyaningsih Y., Mulyaningsih Y., Bahar A.H. and Riayatsyah T.M.I. (2021). Optimization of sugar production from Durian seeds via alkaline hydrolysis for second-generation bioethanol production, Clean Energy, 5(2), 375-86. [10] Cruz ML, de Resende MM, Ribeiro EJ (2021) Improvement of ethanol production in fed-batch fermentation using a mixture of sugarcane juice and molasse under very high-gravity conditions. Bioprocess Biosyst Eng 44:617–625. [11] Das, N.; Jena, P.K.; Padhi, D.; Kumar Mohanty, M.; Sahoo, G. A (2021). Comprehensive Review of Characterization, Pretreatment and Its Applications on Different Lignocellulosic Biomass for Bioethanol Production. Biomass Conv. Bioref. 82, 1–25. [12] Den, W.; Sharma, V.K.; Lee, M.; Nadadur, G.; Varma, R.S. (2018). Lignocellulosic Biomass Transformations via Greener Oxidative Pretreatment Processes: Access to Energy and Value-Added Chemicals. Front. Chem. 6, 141. [13] Devi, A.; Singh, A.; Bajar, S.; Pant, D.; Din, Z.U. (2021). Ethanol from Lignocellulosic Biomass: An in-Depth Analysis of Pre-Treatment Methods, Fermentation Approaches and Detoxification Processes. J. Environ. Chem. Eng. 9, 105798. [14] Dey, P.; Pal, P.; Kevin, J.D.; Das, D.B. (2020). Lignocellulosic Bioethanol Production: Prospects of Emerging Membrane Technologies to Improve the Process—A Critical Review. Rev. Chem. Eng. 36, 333–367. [15] Elumalai, S., Agarwal, B., Runge, T, M., and Sangwan, R, S. (2018). Advances in transformation of Lignocellulosic Biomass to carbohydrate-derived Fuel Precursors, in Biorefinery of Biomass to Biofuels, 87-116. [16] European Union: Biofuels annual. For bioethano production (2022): A Circular Bioeconomy Approach. Bioenerg. Res.Fuel, and future. In Bioethanol production from Food Crops; Ray, R.C, Ramachandran [17] Garlapati V.K., Chandel, A.K., Kumari, S.J., Sharma, S., Sevda, S., Ingle, A.P., Pant, D. (2020). Circular economy aspect of lignin towards a lignocelluloses biorefinery. Renew Sust. Energy. Rev 130:109977. [18] Ghanbari, S., Niu, C.H. (2018). Characterization of a high-performance biosorbent for natural gas dehydration. Energy Fuels. 32, 11979-11990. [19] Ge, S; wu y, pery w, Yia, C, Mai, C Cai, L (2021) High pressure Co2 hydrillerimal pretreatment of peanut shell for enzymatic hydrolysis conversion into glucose. Chem.. Eng. J. 385:123949. [20] Ha S, Kannah RY, Kasthuri S, Gunasekaran M, Pugazhendi A, Rene ER, Pant D, Kumar G, Banu JR (2020) Profitable biomethane production from delignified rice straw biomass: the effect of lignin, energy and economic analysis. Green Chem 22:8024–8035. [21] Hoang T., Nghiem N.P (2021). Recent Developments and Current Status of Commercial Production of Fuel Ethanol, Fermentation, 7(4), 314 [22] Jahnavi, G.; Prashanthi, G.S.; Sravanthi, K.; Rao, L.V (2017). Status of Availability of Lignocellulosic Feed Stocks in India: Biotechnological Strategies Involved in the Production of Bioethanol. Renew. Sustain. Energy Rev. 73, 798–820. [23] Joshi A., Kanthaliya B., Meena S., Khan F. and Arora J. (2021) - Process consolidation approaches for cellulosic ethanol production, In: Ray R.C., Sustainable Biofuels, Academic Press, 43-72 [24] Jeswani, H.K.; Chilvers, A.; Azapagic, A. (2020). Environmental Sustainability of Biofuels: A Review. Proc. R. Soc. A Math. Phys. Eng. Sci. 476. [25] Leipold, S., Petit-Box, A., Luo, A., Helander, H., Simoens, M., Ashton, W., Babitt, C., Bala, A., Bening, C., Birrrkved, M., Blomsma, F. (2021). Lesson, narratives and research directions for a sustainable circular economy. [26] Li, X.; Shi, Y.; Kong, W.; Wei, J.; Song, W.; Wang, S. (2022). Improving Enzymatic Hydrolysis of Lignocellulosic Biomass by BioCoordinated Physicochemical Pretreatment—A Review. Energy Rep. 8, 696–709. [27] Liu, Y.; Cruz-Morales, P.; Zargar, A.; Belcher, M.S.; Pang, B.; Englund, E.; Dan, Q.; Yin, K.; Keasling, J.D.(2021).Biofuels for a Sustainable Future. Cell 184, 1636–1647. [28] Loulergue, P.; Balannec, B.; Fouchard-Le Graët, L.; Cabrol, A.; Sayed, W.; Djelal, H.; Amrane, A.; Szymczyk, A.(2019). Air-Gap Membrane Distillation for the Separation of Bioethanol from Algal-Based Fermentation Broth. Sep. Purif. Technol. 213, 255–263. [29] Muhammad, M. L; and Saha, B.(2022) Recent Adraneen in Greener and energy efficient Alkene Expoxidation processes. Energies, 15(8). [30] da Nogueideiros, C; de Araujo Padilha, C.E; de Medeiros Dantas, J.M; de Medeiros, F.G.N; de Araujo Guilherme, A; de Santana Souza, D.F; dos Santos, E.S. (2021). In-situ Detoxification strategies to boost Bioalcohol production from lignocellulosic Biomass. Renew. Energy. 180, 914-936. [31] Qin, L.; Zhao, X.; Li, W.-C.; Zhu, J.-Q.; Liu, L.; Li, B.-Z.; Yuan, Y.-J. (2018). Process Analysis and Optimization of Simultaneous Saccharification and Co-Fermentation of Ethylenediamine-Pretreated Corn Stover for Ethanol Production. Biotechnol. Biofuels 11, 118. [32] Rafeenia, R., Lavagonolo, M. C., and Pivato. (2018). Pre-treatment Technologist for dark fermentative Hydrogen production. Current Advances and future direction. Waste manag. 71, 734-748. [33] Rezania, S.; Oryani, B.; Cho, J.; Talaiekhozani, A.; Sabbagh, F.; Hashemi, B.; Rupani, P.F.; Mohammadi, A.A.(2020). Different Pretreatment Technologies of Lignocellulosic Biomass for Bioethanol Production: An Overview. Energy , 199, 117457. [34] Robak, K.; Balcerek,M. (2021). Current State-of-the-Art in Ethanol Production from Lignocellulosic Feedstocks. Microbiol. Res. 240, 126534. [35] Robak, K; Balverek, M. (2019). Current State-of-the-Art in ethanol production from lignocellulosicS., Eds; Academic press: Cambridge, MA, USA, . 45-59. ISBN 978-0-12-813 [36] Rooni, V.R.M., and Kikas T. (2017). The freezing pre-treatment of lignocellulosic material: a cheap alternative for Nordic countries, Energy Procedia, 139, 1-7. [37] Safarian, S.; Unnthorsson, R. (2018). An Assessment of the Sustainability of Lignocellulosic Bioethanol Production from Wastes in Iceland. Energies 11, 1493. [38] Saha K, Maharana A, Sikder J, Chakraborty S, Curcio S, Drioli E (2019) Continuous production of bioethanol from sugarcane bagasse and downstream purification using membrane integrated bioreactor. Catal Today 331:68–77. [39] Sharma, B.; Larroche, C.; Dussap, C.-G.(2020). Comprehensive Assessment of 2G Bioethanol Production. Bioresour. Technol. 313, 123630 [40] Sharma, D; and Saini A (2020), Cellulosic ethanol feedstock; diversity and potential. Lignocellulosic Ethanol production from a Biorefinery perspective pp 23-63. [41] Sharma, B; Larroche, C., Dussap, C-G. (2022) Comprehensive Assesement of 2G Bioethanol Soccol, C.R, Brar, S.k, Faulds, C., Ramos, L.P., Eds [42] Shen, F.; Xiong, X.; Fu, J.; Yang, J.; Qiu, M.; Qi, X.; Tsang, D.C.W. (2020). Recent Advances in Mechanochemical Production of Chemicals and Carbon Materials from Sustainable Biomass Resources. Renew. Sustain. Energy Rev. 130, 109944. [43] Sheng, Y.; Lam, S.S.; Wu, Y.; Ge, S.; Wu, J.; Cai, L.; Huang, Z.; Le, Q.V.; Sonne, C.; Xia, C. (2021). Enzymatic Conversion of Pretreated Lignocellulosic Biomass: A Review on Influence of Structural Changes of Lignin. Bioresour. Technol.324, 124631. [44] Si, M; Liu, D; Liu, M; Yan, X; Gao, C; Chai, L; Shi, Y; (2019). Complementary effect of combined Biological-Chemical Pretreatment to promote Enzymatic digestibility of lignocellulose Biomass. Bioresor Technol. 272, 275-278. [45] Sidana, Y; Yadav, S.K (2020) Recent development in LCB pretreatment with a focus on eco-friendly, non-conventional methods. J. clean. Prod. 235; 130286 [46] Singhania, R.R.; Adsul, M.; Pandey, A.; Patel, A.K.(2017). 4—Cellulases. In Current Developments in Biotechnology and Bioengineering; Pandey, A., Negi, S., Soccol, C.R., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 73–101. [47] Singh A, Bajar S, Devi A, Pant D (2021) An overview on the recent developments in fungal cellulase production and their industrial applications. Bioresor Technol Rep 100652. [48] Singh N, Gupta A, Mathur AS, Barrow C, Puri M (2020) Integrated consolidated bioprocessing for simultaneous production of Omega-3 fatty acids and bioethanol. Biomass Bioenergy 137:105555. [49] Sigh, A , Bajar S , Dari A, Pant D (2021) An overview on the recent developments in fungal cellulose paltry and their ind. Applications. Bioresour Technol Rep 1000652. 301-324. [50] . Soares, L.B.; da Silveira, J.M.; Biazi, L.E.; Longo, L.; de Oliveira, D.; Furigo Júnior, A.; Ienczak, J.L. (2022). An Overview on Fermentation Strategies to Overcome Lignocellulosic Inhibitors in Second-Generation Ethanol Production Using Cell Immobilization. Crit. Rev. Biotechnol. 1–22. [51] Tiefenbacher, F, (2017). Technology of Main ingredients-Sweeteners and lipids. In the Technology of Wafers and Waffles: Operational Aspects, 123-225. [52] Toor M, Kumar SS, Malyan SK, Bishnoi NR, Mathimani T, Rajendran K, Pugazhendhi A (2020) An overview on bioethanol production from lignocellulosic feedstocks. Chemosphere 242:125080. [53] Ummalyma, S.B.; Supriya, R.D.; Sindhu, R.; Binod, P.; Nair, R.B.; Pandey, A.; Gnansounou, E.(2019). Biological Pretreatment of Lignocellulosic Biomass—Current Trends and Future Perspectives. In Second and Third Generation of Feedstocks; Basile, A., Dalena, F., Eds.; Elsevier: Amsterdam, The Netherlands, 197–212. [54] Usmani, Z; Sharma , m; A wasth I, A.K; Lukk, T; Tuohy, M.G, Gong, L; Nguyen-Tri, P;Goddard, A.D; Bill, R.M; Nayak; S.C Gupta V.K (2021). Lignocellulosic biorefineries; the current state of challenge and strategies for efficient commercialization. Renew sustain Energy Rev. 148; 111258 [55] Vasic´, K.; Knez, Ž.; Leitgeb, M. (2021). Bioethanol Production by Enzymatic Hydrolysis fromDifferent Lignocellulosic Sources. Molecules. 26, 753. [56] Veza, I.; Hoang, A.T.; Abbas, M.M.; Tamaldin, N.; Idris, M.; Djamari, D.W.; Sule, A.; Maulana, E.; Putra, N.R.; Opia, A.C.(2022). Microalgae and Macroalgae for Third-Generation Bioethanol Production. InLiquid Biofuels: Bioethanol; Biofuel and Biorefinery. [57] Wei, W.; Jin, Y.; Wu, S.; Yuan, Z. (2019). Improving Corn Stover Enzymatic Saccharification via Ferric Chloride Catalyzed Dimethyl Sulfoxide Pretreatment and Various Additives. Ind. Crops Prod.140, 111663. [58] Xie, C.; Gong, W.; Yang, Q.; Zhu, Z.; Yan, L.; Hu, Z.; Peng, Y (2017). White-Rot Fungi Pretreatment Combined with Alkaline/Oxidative Pretreatment to Improve Enzymatic Saccharification of Industrial Hemp. Bioresour. Technol. 243, 188–195. [59] Xu, Y., Chi, P., Bilat, M., and Cheng, H. (2019). Biosynthetic strategies to produce xylitol: an economical venture. Appl. Microbiol. Biotechnol. 103, 5143-5160. [60] Yan, X.; Wang, Z.; Zhang, K.; Si, M.; Liu, M.; Chai, L.; Liu, X.; Shi, Y.(2017). Bacteria-Enhanced Dilute Acid Pretreatment of Lignocellulosic Biomass. Bioresour. Technol. 245, 419–425. [61] Yang, R.-J.; Liu, C.-C.; Wang, Y.-N.; Hou, H.-H.; Fu, L.-M. (2017). A Comprehensive Review of Micro-Distillation Methods. Chem. Eng. J. 313, 1509–1520. [62] Yoon, L.W.; Rafi, I.S.; Ngoh, G.C. (2022). Feasibility of Eliminating Washing Step in Bioethanol Production Using Deep Eutectic Solvent Pretreated Lignocellulosic Substrate. Chem. Eng. Res. Des.179, 257–264. [63] Yogalakshmi KN, Sivashanmugam P, Kavitha S, Kannah Y, Varjani S, AdishKumar S, Kumar G (2022) Lignocellulosic biomass-based pyrolysis: A comprehensive review. Chemosphere 286(2):131824. [64] Zhao, C.; Shao, Q.; Chundawat, S.P.S. (2020). Recent Advances on Ammonia-Based Pretreatments of Lignocellulosic Biomass.Bioresour. Technol. 298, 122446. [65] Zhang B, Gao, Y. Zhang, L; Zhou, Y (2021). The plant cell wall, biosynthesis, constructrion and function J. Integer. Plant Bio l; 63:251-272. [66] Zhang, H.; Zhang, S.; Yuan, H.; Lyu, G.; Xie, J. (2018). FeCl3-Catalyzed Ethanol Pretreatment of Sugarcane Bagasse Boosts Sugar Yields with Low Enzyme Loadings and Short Hydrolysis Time. Bioresour. Technol. 249, 395–401. [67] Zhang, Y, Li, T, Shen, Y; Wang, L, Zhang, H; Qian, H; Qi, X; (2020). Extrusion followed by altresound as chemical free pretreatment method to enhance emzymatic hydrolysis of rice hull for fermentable sugar production. Ind Crops prod 149; 112356

Copyright

Copyright © 2024 Abdulsalam A. A., Aliyu S., Bashar B. L., Danillela U. Y., Ahmad Z. U., Aminu M. B., Gbadamosi L. A.. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63555

Publish Date : 2024-07-05

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online