Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Biogas Generation from Cotton Waste

Authors: Ajay Durge, Prashant Watkar, Balvir Chand, Kamaluddin Kazi, Dyaneshwar Jangitwar, Nikhil Durge

DOI Link: https://doi.org/10.22214/ijraset.2024.62591

Certificate: View Certificate

Abstract

The anaerobic treatability and methane generation potential of three altered cotton wastes namely, cotton stalks, cotton seed hull and cotton oil cake remained determined in batch reactors. In addition, the effects of nutrient and trace metal supplementation were similarly investigated. The conversion of organics of cotton stem into bioenergy could serve the dual part of renewable energy production and waste reduction. Composition analysis demonstrated that cotton stem is a suitable feedstock for both bioethanol and biogas production. Anaerobic digestion of cotton stem attained 40.35% total biogas with 12.76% increased net CH4 volume compared to co-digestion of cotton stem with buffalo dung. Chopped cotton waste was considered as prospected substrate for biogas production. Cotton stalk was used gradually to exchange gobar content as substrate. During the study of four months the digester performed well till 90% feeding of cotton waste substrate. The maximum biogas generation detected was 1.3 m3; this shows that chopped cotton waste has the potential to generate biogas. However, the digester was choked repeatedly and the concern of repetitive chocking of digester needs to be addressed.

Introduction

I. INTRODUCTION

Environmental and energy conservation pressure have led into severe search of green sources of energy. One of the best option being explored is generation of biogas from biodegradable waste. While functioning on biogas technology with farmers associated the data of crop cultivation in Maharashtra shows the majority crops like cotton soybean, bajra etc. As cotton waste and residues can't be further used as fodder or any other purposes except burning, it can be utilized for generation of biogas. Cotton waste can be chopped and further be used in form of cotton chips or the generation of biogas. Deficiency of conventional liquid fuels and alarming rate of emission from the internal combustions engines and subsequent environmental pollution have generated interest in the development for petroleum fuels. Biogas can be a decent source of revenue for farmers who cultivate the cotton on large scale. Biogas is a promising fuel for cooking, lightning, and power generation.

Biogas systems defend our air, water, and soil by recycling organic waste into renewable energy and soil products, while reducing GHG emissions. In India, there is an urgent need to accomplish the millions of tons of food, water and animal waste. Other words, biogas plants can help to fight climate change. As domestic and industrial users rely less on the energy produced with fossil fuels, greenhouse gas emissions become subordinate. At the same time, by gathering organic matter and controlling the fermentation process, fewer methane emissions get into the atmosphere for developed air quality.

Communities reach these results while managing food waste and avoiding garbage from ending up in landfills. Recycling organic waste means fewer odor’s, a minimum risk for spreading diseases, and threatened water bodies, among other things. Another advantage of biogas plants is eliminating the need for synthetic fertilizers, as they get replaced by digestate. It recirculates a series of nutrients, such as phosphorus, which is important for healthy crops. Besides the positive effects on the environment, biogas plants contribute to building a circular economy, in which additional industries can become sustainable and self-sufficient by using their waste to obtain energy or heat. As the number of facilities grows, new jobs are generated across multiple verticals, with a significant impact on the quality of life in numerous communities worldwide.

II. BACKGROUND OF THE PROJECT

Biogas is a mixture of methane, CO2 and small quantities of other gases formed by anaerobic digestion of organic matter in an oxygen free environment. Biogas is produced by anaerobic bacteria that degrade organic matter in four general stages: hydrolysis, acidification, acetic acid production, and methane production. The technology of biogas production was established in India by the joint efforts of Indian Agricultural Research Institute (IARI) and Khadi and Village Industries Committee (KVIC). Biogas can be produced by fermenting organic material in absence of air or oxygen with the help of bacteria to break down materials to intermediate stage such as alcohol and fatty acids and finally to methane, carbon dioxide and water this process is called anaerobic fermentation.

Biogas is cleaned up and progressed to natural gas standards, it's then known as bio methane and can be used in a similar way to methane; this can comprise for cooking and heating. Although, cattle dung has been recognized as the chief raw material for bio-gas plants, other materials like cotton waste, poultry litter and agricultural wastes can also be used. The components in biogas are as follows: Methane 50-75%, Carbon dioxide 25-50%, Nitrogen 0- 10%, Hydrogen 0-1%. Hence, methane is the major component in biogas.

The probable of the cotton waste started to draw researchers’ attention, the usefulness and feasibility of using cotton waste for various applications became the subject of many studies in the last years. Various studies have absorbed on the use of cotton waste as livestock feed, composting, paper production and energy production. In spite of the new methods for its use, today much of the available cotton waste in the world is still disposed of by returning it back to the originating cropland. The field operations, on the other hand, are energy intensive and tend to destroy soil structure and increase the potential for erosion. Therefore, cotton waste must be utilized if sustainable agriculture is targeted. Even though high cotton waste potential for energy production is known, researchers usually focused on the production of ethanol and the production of fuel pellets or briquettes. There were a few studies on the subject of biogas production from cotton wastes. El-Shinnawi et al., studied biogas generation and changes in total and volatile solids using different kinds of crop residues (maize, rice and cotton stalks) enriched with partially digested cattle dung.

In their study, maize stalks gave the highest values of cumulative yield of methane (fermented material). A two-stage digestion technique for biogas production from combinations of organic wastes was also studied by El-Shinnawi et al. Constant amounts of stalks (rice, maize and cotton) were mixed with different amounts of cow dung and pre-digested at numerous time intervals before fermentation for biogas production. The fermentation results showed that the biogas potential of maize stalk mixture was the uppermost and the greatest evolution of biogas was obtained from the feed materials pre-digested for 1 week. Dry anaerobic fermentations of different organic wastes including cotton stalks and treated cotton stalks were studied by Radwan et al. The cotton stalks were varied with cow dung in a 1:1 ratio and optimum conditions for the maximum biogas production were determined. At the optimum conditions obtained (37 °C, 21% total solid, 2% CaCO3, 11% starter), it was found that the rice straw was the greatest organic residue for biogas production, but water hyacinth was the best based on methane production. Funk et al. investigated converting cotton gin and dairy wastes to methane. Gin and dairy waste were combined in a two-phase anaerobic system to determine the combinations of temperature, rewetting interval and mixture ratio that maximize potential methane gas production and decrease process completion time. The authors reported that combining manure and gin trash resulted in 35% advanced gas production per unit of digester volume compared to manure only.

The objective purpose of this study was to examine the anaerobic treatability and methane generation potential of cotton stalks, cotton seed hull and cotton oil cake by performing a biochemical methane potential test. In addition, the effects of nutrient and trace metal supplementation on the biogas yield were also observed.

One of the most important developments in the biogas industry is the push to green the natural gas grid, an important step in reducing fossil-driven GHG emissions and offsetting consumption of fossil natural gas. A typical biogas methane concentration of 50-65% must be progressed to 95% or better before it can be used in the gas grid or in natural gas vehicle engines. There are a number of techniques used to undertake the separation, including physical and chemical adsorption, differential pressure, and membrane separation (see figure). In respectively case the CO2 is separated out, leaving almost pure methane to pass through as renewable natural gas.

III. MATERIALS AND METHODS

A. Materials

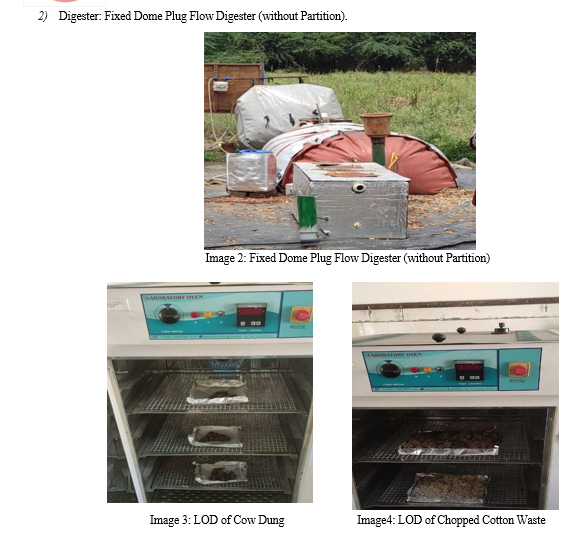

1) Substrate for biogas production: Chopped Cotton Waste

The cotton waste provided to me was harvested from Rahuri, Maharashtra.

B. Methods

- Determination of moisture content or total solids present in cow dung/chopped cotton waste by using Loss on Drying (LOD) method:

- On a silver foil weigh 100 grams of cow dung/chopped cotton waste using analytical balance and note it.

- Place it in a hot air oven at 105°C and weigh after every one hour until the weight comes constant.

a. Determination of biogas yield:

The digester was first inoculated with activated cow dung slurry to activate the biogas plant.

Next, the feeding of biogas plant is done daily with homogenized mixture of cow dung, chopped cotton waste and water

Gas generation data monitoring:

- Daily readings are noted for the data from the device called Gas Meter.

- Gas Meter is used to measure the volume of gas produce per day.

- Biogas is measured in cubic meters (m3), 1m3 generation of gas shows feasibility of the biogas plant.

b. Determination of pH and temperature:

The pH was measured using pH meter and was noted monthly. The temperature depends on the climatic conditions which were also noted monthly.

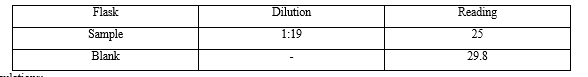

c. Determination of chemical oxygen demand:

- Aim: To determine the Chemical Oxygen Demand (COD) to understand the digestibility of the substrate.

- Requirements:

- Given sample - Chopped cotton slurry and Blank

- 10ml 0.25 N K2Cr2O7 (Potassium Dichromate)

- 30 ml Concentrated H2SO4 (Sulphuric Acid)

- Pinch of Ag2SO4 (Silver Sulphate)

- Ferroin Indicator

- N Ferrous Ammonium Sulphate (FAS)

- Reflux assembly and heating plate

Procedure:

- Take 20ml of diluted sample (1:19 dilution) in one COD flask and 20ml of distilled water in another COD flask.

- Add 10ml of 0.25 N K2Cr2O7 and 30ml of concentrated H2SO4 in each of the flask with a pinch of A2SO4.

- Mix the reflux mixture thoroughly by shaking and cool it.

- Add 2 to 3 glass beads to avoid excessive boiling and connect the flask to the condenser and reflux for 1 to 2 hours at 150°C. (Depending upon the organic matter in the sample).

- Cool and double dilute the reflux mixture with distilled water.

- Add 4 to 5 drops of Ferroin Indicator and titrate the mixture with standardized 0.1 N Ferrous Ammonium Sulphate.

- There is sharp colour change from bluish green to reddish brown (Blue colour may reappear with few minutes)

- Record the ml of FAS required for the sample as well as for the blank.

d. Observation Table for Chopped cotton slurry:

Calculations:

COD in mg/l (ppm) = (B-S) × 8 ×1000 × N / V

where, B = 29.8ml of FAS blank

S = 25ml of FAS sample

8 = Atomic weight

N = Normality (0.1)

V = Volume of sample used (1ml)

COD = (29.8-25) × 8 × 1000 × 0.1 / 1

= 4.8 × 8 × 1000 × 0.1 / 1

COD = 3,840 ppm (mg/l)

IV. RESULTS AND DISCUSSION

A. Effect of Moisture Content:

After the harvest of the cotton stalk, the waste collected had a huge amount of moisture present in it. Further the chopped cotton waste was uncovered to the atmospheric conditions resulting in evaporation of half of the moisture. Although it was important to calculate the Moisture Content i.e., Loss on Drying of the chopped cotton waste and cow dung (as cow dung also contains a huge amount of moisture present in it), in order to determine the total volume of feeding in the digester as per the schedule and to maintain the Total Dry Matter Percentage (i.e., 7.5).

|

LOD of Cow Dung |

LOD of Chopped Cotton Waste |

||

|

Hours |

Weight |

Hours |

Weight |

|

0 |

100gms |

0 |

100gms |

|

1 |

68.5gms |

1 |

96.0gms |

|

2 |

42.0gms |

2 |

94.5gms |

|

3 |

27.5gms |

3 |

94.5gms |

|

4 |

24.0gms |

- |

- |

|

5 |

23.0gms |

- |

- |

|

6 |

23.0gms |

- |

- |

Table 1: Change in LOD after every one hour

B. Determination of Biogas Yield:

As per the Percentage of Total Dry Matter shown in the Table, the Average Biogas Yield can be observed and further used as a baseline data for biogas production.

|

Chopped Cotton Waste Feeding (Percentage of Total Dry Matter) |

Schedule |

Average Biogas Yield |

|

10% |

2nd Feb to 14th Feb |

0.44 m3 |

|

25% |

15th Feb to 26th Feb |

0.80 m3 |

|

50% |

27th Feb to 14th March |

1.01 m3 |

|

75% |

15th March to 2nd May |

0.86 m3 |

|

90% |

3rd May to 31st May |

0.65 m3 |

Table 2: Average Biogas Yield

C. Effect of pH

To sustain a constant supply of gas, it is necessary to preserve a suitable pH range in the digester. pH of the slurry changes at various stages of the digestion. In the initial acid development stage in the fermentation process, the pH is around 6 or less and much of CO2 is given off. In the latter 2-3 weeks times, the pH upturns as the volatile acid and N2 compounds are digested and CH4 is produced. The digester is usually buffered if the pH is continued between 6.5 and 7.5. In this pH range, the micro – organisms will be very active and digestion will be very efficient.

D. Effect of temperature

Temperature disturbs the rate of reaction happening inside the digester. Increase in the ambient temperature increases the rate of reaction thus increasing the biogas production as well. Methane bacteria work greatest at a temperature of 350 – 380 C. The fall in gas production starts at 200C and stops at a temperature of 100C.

|

Monthly Observation |

Temperature |

|

February |

33°C |

|

March |

36°C |

|

April |

38°C |

|

May |

38°C |

Table 4: Monthly change in temperature

E. Chemical Oxygen Demand:

The COD of slurry acquired is 3,840 ppm (mg/l) that indicates there is an active digestion process going inside the digester though it is fed with chopped cotton waste as a substrate.

V. FUTURE SCOPE

- To check culture adaptation for cotton waste.

- To optimize anaerobic digester for possible maximum biogas yield.

- To set optimum organic loading rate and reduce Hydraulic Retention Time (HRT) as much as possible.

- With success of these experiments, this technology will help to avoid burning of crop residues, soil contamination and air pollution with revenue generation for farmers with production of biogas.

- Furthermore, biogas plants produce nutrient-rich slurry which can be used as organic fertilizer, promoting sustainable agriculture practices and soil health.

Conclusion

Chopped cotton waste was considered as prospected substrate for biogas production. Cotton stalk was used gradually to replace gobar content as substrate. During the study of four months the digester performed well till 90% feeding of cotton waste substrate. The extreme biogas generation observed was 1.3 m3; this shows that chopped cotton waste has the potential to generate biogas. However, the digester was choked repeatedly and the problem of repetitive chocking of digester needs to be addressed.

References

[1] Han Zhang, Enhancement of methane production from Cotton Stalk using different pretreatment techniques, 2018. [2] K Shahzad, Green ethanol production from cotton stalk, 2019. [3] Sundarraj Chockalingam, Bio Gas from Textile Cotton Waste-An Alternate Fuel for Diesel Engines, 2009. [4] Shubhada Nayak, The impact of aerobic pretreatment of agro and industrial wastes on their bio methanation potential in Nisargruna technology, 2021. [5] Colin M. W., Chemical Oxygen Demand Analysis of Anaerobic Digester Contents, 2015. [6] Lena Breitenmoser, Anaerobic digestion of biowastes in India: Opportunities, challenges and research needs, 2019. [7] Tom Bond, History and future of domestic biogas plants in the developing world, 2011. [8] Tien Ngo, The Current Status, Potential Benefits and Future Prospects of the Australian Biogas Sector, 2021. [9] Simon Jayaraj, STUDY ON THE EFFECT OF pH ON BIOGAS PRODUCTION FROM FOOD WASTE BY ANAEROBIC DIGESTION, 2014. [10] Osita Obiukwu, The Optimum Mesophilic Temperature of Batch Process Biogas Production from Animal-based Wastes, 2014.

Copyright

Copyright © 2024 Ajay Durge, Prashant Watkar, Balvir Chand, Kamaluddin Kazi, Dyaneshwar Jangitwar, Nikhil Durge. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62591

Publish Date : 2024-05-23

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online