Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Bluetooth Control Grass Cutter Using Solar Power

Authors: M. Aravind, S. Manikanta, M. Vamshi, Ravi Kumar Panthangi

DOI Link: https://doi.org/10.22214/ijraset.2025.66824

Certificate: View Certificate

Abstract

The present technology commonly used for cutting the grass by using the manually handle device. The project aims to fabricate a grass cutting machine system controlled by android application using Bluetooth module feature which runs with the help of motor by using solar energy. In previous days, grass cutter machines are operated by fuel and electrical energy which are costly and requires high maintenance. The solar panel is used to charge the battery so that there is no need of charging it externally. The solar based energy source is easier to use, more advantageous compared to other energy and it is easy to work. By the use of solar panels, we can harness sunlight to generate electricity free of cost. The trapped solar energy is used to charge the battery for grass cutting operation. The movement of the machine is totally controlled by automatic mode or manual mode. The Bluetooth controller run this machine movement and direction through an android application. The controlling device of the whole system is microcontroller. Bluetooth module and DC motors are interfaced to the microcontroller. The data received from the android phone application by Bluetooth module is fed as input to the controller and the controller acts according on the DC motor of the solar grass cutter. In achieving the task, the controller is loaded with a program written using Embedded ‘C’ language.

Introduction

I. INTRODUCTION

In this solar based grass cutter, the advantage of powering a grass cutter by solar rather than by gasoline is mainly ecological. The advancements are mostly designed to reduce the manual work and save power by utilizing the solar power to generate the electricity. This project is designed to reduce the labour power required in grass cutting at residences, agricultural areas etc. Here the solar energy generated from solar panel is stored in the battery and used to run DC motor in the system. The DC motor is attached with blade to trim the grasses.

Nowadays, grass cutting machine becomes a very popular in urban India. This machine is most commonly used for furnishing the grass. DC motor, drivers’ circuits for controlling motors, battery, solar panel, blades, etc. are some main parts of our project. It is placed in a suitable structure in our project. The motors are connected to the electric supply by using wires. The linear cutter blades are attached to the motor. 'Providing a high-speed rotation to the blades, it helps to cut the grass' is main working principle of Grass cutter. Whenever increasing the rpm that time the blade will get kinetic energy and cut the grass. The cutting edges of the cutter are very smooth and accurate.

II. LITERATURE REVIEW

Siva Rao, T.J.S. Anand, Hanbali, Minhat, Faizul [1] presented a review of researches done on the subject of automated tractor. An autonomous tractor is a vehicle that can operate without or with minimal human control, self-propelled and guided automatically along a desired path. The benefits from such a system is useful for agriculture industry by reducing labour cost and time, as well as improving output efficiency by eliminating human errors.

Pratik Patil, Ashwini Bhosale, Prof. Sheetal Jagtap [2] described about an automatic lawn cutter that will help the user to cut the grass in their lawn with less efforts. The different sensors are used it will detect and avoid objects and humans while mowing. The main objective of this automatic lawn cutter is that the user can specify the area that is to be mown and also the height of grass as per there requirement by using the keypad. This design contains a microcontroller like AT mega 16, multiple sensors, LCD Display, Keypad.

Ernest L. Hall [3] discussed that The system operates on the same principle as the Lawn Ranger except it uses a cable beneath the surface of a person’s lawn. The mower uses this wire along with its sensors to allow the robot to makeover around while keeping the system on track. The mower will continue to operate as long as the mower has energy, from the sun. The robot is equipped with a flexible bumper that when activated backs the mower up and continues the robot on a different path. It has the advantage of cutting grass in the form of a mulch so that the use of a grass catcher or raking is not required.

III. THE OBJECTIVE OF PROJECT

The specific objective of this project was

- To develop an automatic grass cutting robot this would be able to help users in cutting the grass in gardens.

- It was also considered that it should be moderately cheap and easy to implement with the help of the microcontroller.

- Instead of requiring small details to be specified, the task in this project was carried out by considering the essential design features so that the system was

- able to autonomously execute its job in a manner that satisfies its desired task.

- The user should be able to operate this robot from a distance of 20feet. Grass height should me variable depending on the user’s choice.

IV. COMPONENTS

1) SOLAR PANEL

Solar PV panels are comprised of many small photovoltaic cells – photovoltaic meaning they can convert sunlight into electricity. These cells are made of semi-conductive materials, most often silicon, a material that can conduct electricity while maintaining the electrical imbalance needed to create an electric field.

When sunlight hits the semiconductor in the solar PV cell, the energy from the light, in the form of photons, is absorbed, knocking loose a number of electrons, which then drift freely in the cell. The solar cell is specifically designed with positively and negatively charged semiconductors sandwiched together to create an electric field. This electric field forces the drifting electrons to flow in a certain direction- towards the conductive metal plates that line the cell. This flow is known as an energy current, and the strength of the current determines how much electricity each cell can produce. Once the loose electrons hit metal plates, the current is then directed into wires, allowing the electrons to flow like they would in any other source of electric generation.12v 100 watts mono-crystalline solar panel is preferred for this project. This solar panel is selected by considering the required power input for the motor which are required for running the blades as well as the mower itself. We need 100 – 300 watts solar Panel is required.

Fig.1. Solar panel

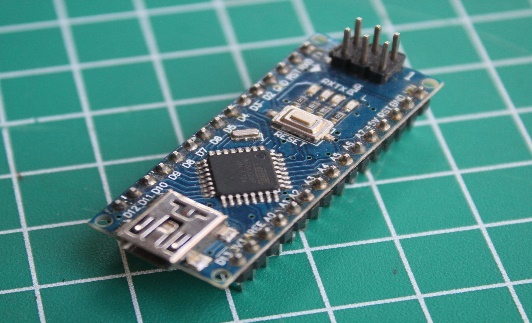

2) ARDUINO NANO:

The Arduino Nano is a compact and versatile microcontroller board based on the ATmega328P or ATmega168P microcontroller.

Here are key features and characteristics:

Microcontroller: Utilizes an ATmega328P or ATmega168P microcontroller, depending on the version.

Clock Speed: Typically operates at 16 MHz’s

Memory: Offers Flash memory of 32KB (ATmega328P) or 16KB (ATmega168P), and SRAM of 2KB.

Form Factor: Compact and breadboard-friendly, the Nano is designed for easy integration into various projects.

I/O Pins: Provides a set of digital and analogue I/O pins, as well as PWM (Pulse Width Modulation) outputs.

USB Connectivity: Includes a USB interface for programming and serial communication with a computer.

Fig.2. Arduino nano

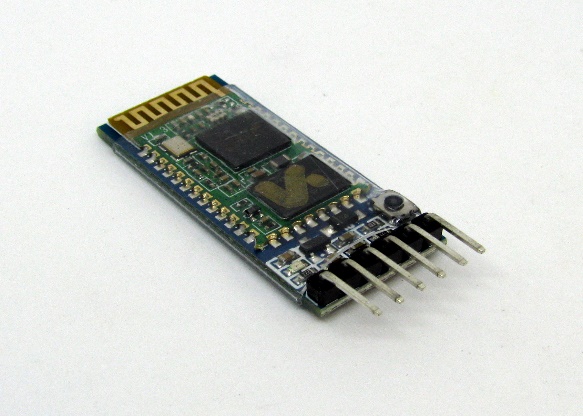

3) HCO5 BLUETOOTH MODULE:

The HC-05 is a popular Bluetooth module widely used for wireless communication between devices.

It operates in the 2.4 GHz frequency range and supports Bluetooth Classic communication.

The module has a range of around 10 meters and is commonly used in various electronic projects for data transmission between microcontrollers and other devices.

Fig.3. HC-05 Bluetooth module

4) RECHARGEBLE BATTERY:

A rechargeable battery, storage battery, or secondary cell, (or archaically accumulator) is a type of electrical battery which can be charged, discharged into a load, and recharged many times, as opposed to a disposable or primary battery, which is supplied fully charged and discarded after use. It is composed of one or more electrochemical cells. The term "accumulator" is used as it accumulates and stores energy through a reversible electrochemical reaction. Rechargeable batteries are produced in many different shapes and sizes, ranging from button cells to megawatt systems connected to stabilize an electrical distribution network. Several different combinations of electrode materials and electrolytes are used, including lead–acid, zinc–air, nickel–cadmium (NiCd), nickel–metal hydride (NiMH), lithium-ion (Li-ion), lithium iron phosphate (LiFePO4), and lithium-ion polymer (Li-ion polymer).

Rechargeable batteries typically initially cost more than batteries, but have a much lower total cost of ownership and environmental impact, as they can be reduced. Recharged inexpensively many times before they need replacing. Some rechargeable battery types are available in the same sizes and voltages as disposable types, and can be used interchangeably with them.

Fig.4. Rechargeable battery

5) MOTOR DRIVER:

The L293D is a widely used motor driver IC (Integrated Circuit) designed to control two DC motors or a single stepper motor.

Key features include:

Motor Control: It can drive two DC motors bidirectionally or one stepper motor.

Current Sensing: The L293D has built-in flyback diodes and can handle motor currents up to 600mA per channel (1.2A peak).

Logic Compatibility: It is compatible with TTL (Transistor-Transistor Logic) and CMOS (Complementary Metal-Oxide-Semiconductor) levels, making it easy to interface with microcontrollers or other digital systems.

Internal H-Bridge Configuration: The IC contains two H-bridges, allowing control of motor direction by changing the logic levels on its input pins.

Protection Features: It includes thermal overload protection and can handle motor voltages up to 36V.

Versatility: Popular in robotics and other projects requiring motor control, the L293D is versatile and commonly used due to its ease of use and reliability.

When using the L293D, it's crucial to follow the datasheet specifications and wiring diagrams to ensure proper functionality and prevent damage to the IC and connected components.

Fig.5. Motor Driver

6) DC MOTOR

A DC motor is any of a class of rotary electrical motor that converts direct current electrical energy into mechanical energy. The most common types rely on the forces produced by magnetic fields. Nearly all types of DC motors have some internal mechanism, either electromechanical or electronic; to periodically change the direction of current in part of the motor.

In this project we choose 12v dc motor.

It can provide 1000 rpm.

Fig.6. DC Motor

7) SINGLE CHANNEL RELAY:

Single-channel relay is an electromagnetic switch commonly used to control high-power devices with a low-power signal, such as from a microcontroller or a digital circuit.

Key features include :

Switching Capability: It typically has one switching channel, allowing it to control a single device or circuit.

Contacts: The relay has at least one pair of contacts (normally open and normally closed) that change state (open or closed) when the relay is energized.

Coil: The relay coil is the component that, when energized, generates a magnetic field, causing the contacts to switch.

Input Voltage: It requires a specified input voltage to energize the coil and activate the switch. Common relay types operate with 5V or 12V input.

Isolation: Relays provide electrical isolation between the control circuit and the high-power device, enhancing safety and protecting the controlling components.

Fig. 7. Single-channel relay

8) BLADES:

They cut against a fixed blade at the bottom. The cylinder should have multiple blades – three or more is best. Cylinder lawnmowers are best for flat lawns that you want to keep short and well-manicured. They can be electric, petrol-powered and push mowers

We are using s type blades for this project.

Fig. 8. Blade

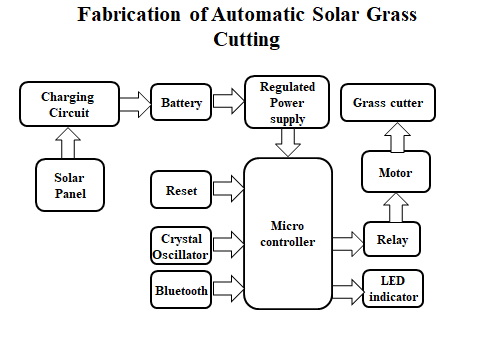

V. BLOCK DIAGRAM

Fig. 9. Block Diagram

VI. WORKING

Bluetooth control grass cutter consists of a motor, gear arrangement of a cutting tool. For this system the power gets from the solar panel with respective battery. By using Bluetooth module, forward and reverse direction can be controlled. Forward and reverse program already prewritten in the microcontroller. From the PIC controller it is fed from the relay if any fault occurring in the electronic switches it will rectify by using a relay operation in it. Finally, the dc shunt motor is connected to the cutting tool and it starts working.

A grass cutting robot is basically a land moving vehicle with 4 wheels. These 4 wheels are driven by 4 dc motors of low speed. There is another dc motor with high power and high speed which will be used for the cutter assembly. A grass cutting mechanisms will be attached to it. This motor will be relatively low speed. There will be another motor that will be used to set the height of the grass cutting level. This motor is coupled with a rack and pinion mechanism to adjust the height. All the DC motors are 12V-DC motors. The driver circuits will provide the required current for the motors. The battery used here is a 12V/1.5Ah rechargeable dry battery. This battery power is used to power the machine and to all components. There will also a solar panel that will convert the solar radiation into electrical power using the photo voltaic cells. The solar panel rating is12V-5W. It will be sufficient to charge the battery during the day time. We can also provide a dc charger for charging the battery when solar power is just not enough, i.e., during conditions. User will be provided with a remote android mobile which will work on Bluetooth communication. The user can give command to the robot using various keys on the controlling Android App. The functions like forward, reverse, left, right, stop, cutter ON, cutter OFF, height increase and height decrease. The user has to first pair the Bluetooth once and then start controlling the grass cutter. The use of IOT technology also significant here. It is used to display the battery charging status over the website. There will be a voltage sensor connected to the battery terminals that will sense the battery voltage and give it to the ADC (Analog to Digital Converter) IC. It will convert the analog voltage value into the 8bit digital value for the microcontroller. The microcontroller we are using here is a 8bit microcontroller. The microcontroller will work according to the program that we write into it. The major function of the controller here is to take data from sensor and display it on the LCD display and to transmit it over that WIFI module. It also receives the signal from the Bluetooth module and send the signal to the motor driver circuit to rotate the motors in appropriate direction at appropriate time.

VII. FUTURE SCOPE

- The solar panel can be fixed with light sensor, thus depending upon the arrangement of sun; the panel will be slanting such that the sun rays are incident normally at 90degree to the solar panel.

- If panel used of high watt than the machine can be used during night time for garden lighting.

- By connecting box type transponder we can also use it to transport file, books other stuffs from one place to another place.

- We can use camera for capturing the covered area.

VIII. ADAVANTAGES

- Easy to move from one place to another place

- Operating principle is simple

- non-skilled person also operates this machine

- No fuel consumption

- Compact size and easy to portable.

Conclusion

Here we get pollution free and hazard free grass cutting machine. Some of the features of this machine is very unique and innovative. The height adjustment feature is really helpful for the user. The Bluetooth control provides remote access to the user. It is equipped it the advanced technology like the IoT. Solar panel makes charging of the battery effortless.

References

[1] Sivarao, T J S Anand, Hambali, Minhat, Faizul, “Review of Automated Machines towards Devising a New Approach in Developing Semi-Automated Grass Cutter”, International Journal of Mechanical and Mechatronics Engineering IJMME-IJENS, 2010. [2] Pratik Patil, Ashwini Bhosale, Prof. Sheetal Jagtap, “Design and Implementation of Automatic Lawn Cutter”, International Journal of Emerging Technology and Advanced Engineering, 2014. [3] Technical Solutions, J. Hammond and R. Rafaels, “Build the Lawn Ranger”, Radio Electronics, June 1990, pp. 31-49 [4] Ms Lanka Priyanka, Mr Prof J Nagaraju, Mr Vinod Kumar Reddy, “Fabrication of Solar powered Grass Cutting Machine”, International Journal & Magazine of Engineering, Technology, Management and Research ,2015. [5] Ernest L. Hall, “A Survey of Robot Lawn Mowers”, Ernest L. Hall, 06 October 2015.

Copyright

Copyright © 2025 M. Aravind, S. Manikanta, M. Vamshi, Ravi Kumar Panthangi. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET66824

Publish Date : 2025-02-04

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online