Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- References

- Copyright

Car Washing System using raspberry Pi Pico as PLC

Authors: Hardik Shah, Deep Patel, Mohammed Saluji, Vidya Harpude

DOI Link: https://doi.org/10.22214/ijraset.2024.59688

Certificate: View Certificate

Abstract

Using the Raspberry Pi Pico microcontroller, we have designed and implemented an automatic vehicle wash system in this work. By automating steps including scrubbing, rinsing, drying, and applying soap, the system seeks to expedite the automobile washing process. We go over the Raspberry Pi Pico, actuators, and sensor hardware configuration in addition to the software architecture that controls the system. We also emphasize the advantages of utilizing Raspberry Pi Pico for this application, such as its affordability, portability, and versatility. The efficacy and dependability of the suggested automatic car wash system are shown by the experimental results.

Introduction

I. INTRODUCTION

Automation technologies have advanced significantly in the automotive industry with the goal of enhancing customer experience, convenience, and efficiency. The process of washing cars is one where automation can have a big influence. Hand washing a car by hand takes a lot of time and labour, as well as a lot of materials and physical exertion. Furthermore, conventional car wash techniques cannot always produce reliable and acceptable outcomes.

By automating the cleaning process, automatic car wash systems provide a solution to these problems. These systems usually use a combination of actuators, sensors, and control mechanisms to carry out different activities like cleaning, rinsing, drying, and applying soap. These devices can automate the car wash process and offer a number of advantages, such as improved productivity, less water usage, and By automating the car washing process, these systems can provide several benefits, including increased efficiency, decreased water use and enhanced cleaning performance.

In this research, we propose to use the Raspberry Pi Pico microcontroller for the design and construction of an automatic vehicle wash system. An inexpensive development board with flexible input-output capabilities, the Raspberry Pi Pico is based on microcontrollers and provides an excellent foundation for managing the many parts of an automated car wash system. The system's goal is to show that automating the car wash process with a Raspberry Pi Pico is both feasible and practical, enhancing both user experience and efficiency. [2]

II. LITERATURE REVIEW

Automatic vehicle wash systems are superior than manual car wash techniques in a number of ways, their popularity has grown. These systems use cutting-edge technologies like microcontrollers, sensors, and actuators to automate the whole vehicle wash process from beginning to end. These elements enable automated vehicle wash systems to effectively carry out jobs like scrubbing, rinsing, drying, applying soap, and spraying water—all without the need for human assistance.

Improving efficiency is one of the main goals of automatic vehicle wash systems. These systems can finish the work of washing an automobile in a fraction of the time it would take a human to do so by automating the different steps of the process. This not only saves time for customers and companies alike, but it also makes it possible to wash a larger number of cars in a shorter amount of time.

Furthermore, water conservation is taken into consideration in the design of automatic car wash systems. These systems can drastically save water consumption when compared to manual washing techniques since they can accurately regulate the amount of water used at each stage of the washing process. This is made possible by the use of sensors and actuators that control water flow and modify settings in response to variables like vehicle size and dirtiness level.

Moreover, automatic car wash systems use sophisticated cleaning detergents, scrubbing mechanisms, and drying procedures to improve the quality of the cleaning. These features enable these systems to efficiently clean the vehicle's surface of dirt, grime, and other impurities, leaving it shining and clean.

The Raspberry Pi Pico has become a well-liked option for installing automated car wash systems in recent years. A few benefits of this microcontroller are its price, small size, and adaptability. It is therefore ideally suited for managing and regulating the several parts of an automated vehicle wash system, including pumps, motors, sensors, and display screens.

Developers can design cost-effective, easily deployable, and customizable automatic vehicle wash systems that meet various criteria by utilizing the features of the Raspberry Pi Pico.

Car Washing System Steps

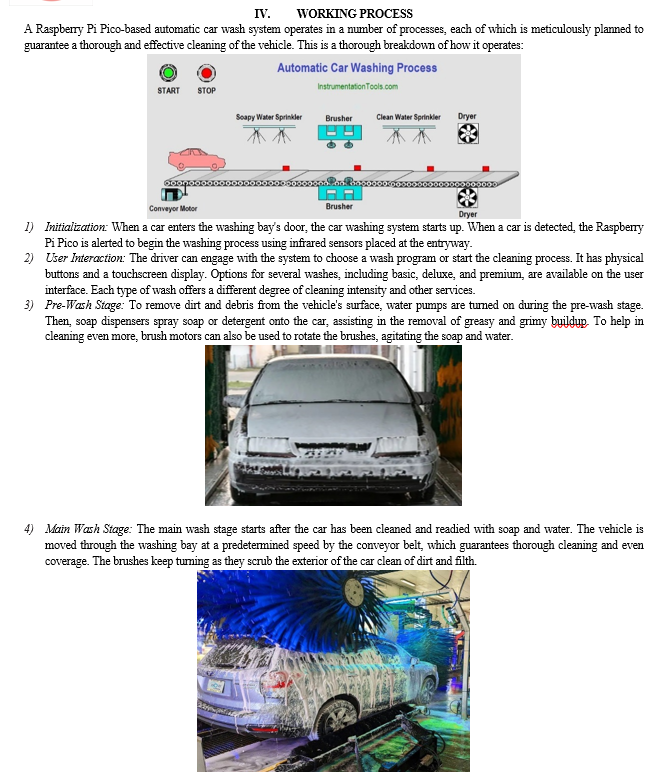

There are multiple steps in the automatic car wash system's washing operation, which include:

- Vehicle Detection: When a car approaches the washing bay, sensors are employed to identify its presence. This step starts the vehicle's cleaning sequence and makes sure it stays safe throughout.

- Water Spraying: To remove loose dirt and debris from vehicle's surface, water pumps and solenoid valves are turned on.

- Application of Soap: To remove obstinate dirt and grime, soap or detergent is applied to the vehicle's surface. Controlling the flow of soap solution with solenoid valves guarantees uniform coverage.

- Scrubbing: Actuators are connected to motorized brushes that clean the outside of the car, stirring soap and removing dirt particles.

- Rinsing: The vehicle's surface is left spotless and clean after one more round of water spraying removes any remaining soap and debris.

- Drying: The surface of the car is dried with blowers or blow dryers to get rid of extra moisture and stop water stains. [4]

V. Top of FormVISION CAPABILITIES

Vision capabilities in an automated car wash system refer to the use of cameras or other sensors to provide the system the ability to "see" and comprehend its surroundings. These cameras are placed strategically at important locations, including the washing bay's entrance and exit, to take pictures of passing cars. After these pictures are taken, the system examines them to see if any cars are there, where they are, and how correctly they should be positioned in the washing bay. With the help of this knowledge, the system will be able to clean the car efficiently by accurately directing brushes, water sprays, and other parts where they are needed. Additionally, the system's visual skills allow it to identify any barriers or impediments in the washing bay, like protruding vehicle parts or foreign items. The technology can prevent any collisions and guarantee the security of the equipment and the vehicle by identifying these impediments. In order to maintain high levels of cleanliness, the system can also use these cameras for quality control, evaluating the vehicle's cleanliness both before and after the wash. Incorporating visual feedback into the user interface also improves the operator and customer experience overall. Through the provision of real-time photos or status updates regarding the washing process, operators can more efficiently monitor the system's performance and make necessary adjustments. Similar to this, clients might feel more satisfied with the car wash process because they can rely on the system's accuracy and thoroughness. All things considered, the efficiency, security, and user happiness of automated car wash systems depend heavily on vision capabilities. They make it possible for the system to run precisely, uphold hygienic standards, and improve user and customer satisfaction overall. [7]

VI. INTEGRATION

To fully utilize visual capabilities in automated vehicle wash systems, integration is necessary. Through the smooth integration of vision sensors with other system elements including the actuators, user interface, and central control unit, the system may efficiently leverage visual data to enhance the washing procedure. Using vision sensors, for example, in conjunction with the central control unit enables real-time picture processing and prompt decision-making based on observed data. Through this connection, the system is able to precisely and efficiently clean vehicles by coordinating the movements of the brushes, drying fans, and water pumps based on visual feedback received. Additionally, by allowing operators to monitor system performance and provide visual feedback on the washing process, combining vision capabilities with the user interface improves the overall user experience. All things considered, integration makes sure that the automatic car wash system's vision capabilities are smoothly integrated, enhancing its efficacy, dependability, and efficiency. This data is subjected to methods that identify objects of interest and yield spatial information. The robotic arm-powered manipulation device makes precise movements and interacts with this data. [8]

VII. CHALLENGES AND SOLUTIONS

While incorporating vision capabilities into automated vehicle wash systems presents a number of challenges, there are also workarounds. It is challenging to provide precise detection of vehicles coming into and going out of the washing bay, especially when there is uneven lighting or when the vehicles are different in terms of color and shape. To overcome this, advanced image processing techniques can be applied to increase the accuracy of vehicle recognition regardless of the environment. Another challenge is the possibility of making mistakes or safety hazards during the washing process due to false detections or misinterpretations of obstacles. Two approaches to overcome the problem are to apply advanced algorithms that can distinguish between cars and other objects, and to provide redundancy to the sensing system to confirm detections. Maintaining vision sensor functionality in harsh environments, such as extremely high or low temperatures or exposure to chemicals and water, can also be tough. This can be addressed by the use of ruggedized camera enclosures and protective coatings, as well as routine maintenance and calibration procedures. All things considered, these challenges can be overcome with the help of robust technology and thoughtful design concepts, allowing automatic car wash systems to effectively take advantage of vision capabilities for improved user experience and performance.

VIII. IMPORTANCE OF COORDINATION

When it comes to optimizing the vision capabilities of automatic vehicle wash systems, coordination is essential. To guarantee accurate and effective vehicle cleaning, it entails coordinating the data from vision sensors with the operations of other system components. For example, the system can react instantly by starting the washing process when the vision sensors identify a vehicle entering the washing bay. In order to properly clean the car, the system uses coordination to turn on the proper water sprays and brush movements at the proper times and locations. The system is able to accomplish comprehensive cleaning outcomes and optimize the washing process by coordinating the operations of its many components according to the information obtained from the vision sensors. Similarly, vision sensor and other component synchronization are critical if an obstruction is identified during the washing process. The system is able to swiftly modify its operations in order to prevent possible harm when it detects an obstruction, such as a projecting portion of the car or a foreign object in the washing bay. Through this coordination, the safety of the equipment and the vehicle is maintained by ensuring that the system reacts to unforeseen circumstances quickly and correctly. Coordination improves the vehicle wash system's overall dependability and performance. The system can operate more smoothly and provide clients with superior cleaning results by coordinating the movements of its various components and properly integrating vision capabilities with them. This makes washing cars more enjoyable and guarantees that they are clean and well-maintained when they exit the washing facility.

IX. EXPERIMENTAL SETUP AND RESULTS

A. Experimental Setup

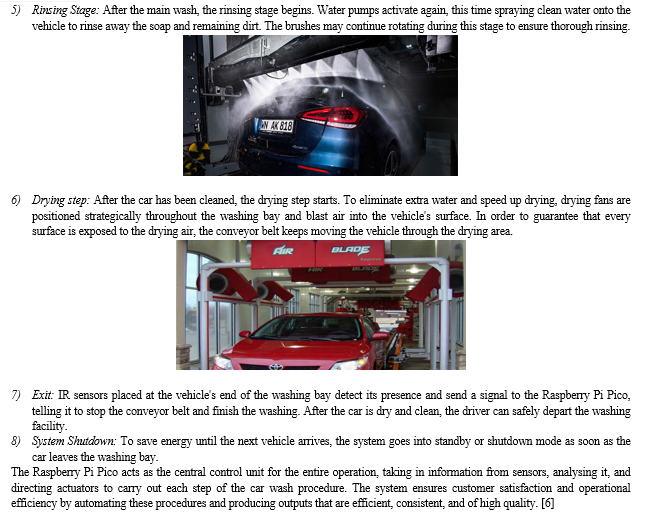

A prototype automatic car wash system with sensors, actuators, and a Raspberry Pi Pico microprocessor make up the experimental setup. A remote control or manual switch is used to start the washing process after a test car is positioned inside the bay.

B. Result

A number of real-world trials are carried out to assess the effectiveness of the automatic car wash system. The experimental setting replicates environmental factors, vehicle sizes, and levels of soiling that are commonly found in commercial car wash facilities.

C. Performance Metrics

Metrics called performance metrics are used to assess the effectiveness of automatic car wash systems that have vision capabilities. These metrics include the frequency of false alarms, the accuracy with which vehicles are detected, and the speed at which the system reacts to occurrences. By tracking these metrics, operators can identify areas for improvement and ensure the system is delivering clean and satisfactory washes efficiently and safely. [9]

D. Validation Against Mission Objectives

The usage of vision capabilities in automatic car wash systems is validated against mission objectives to make sure it is in line with the primary objectives of the system. This entails setting precise goals, creating performance measures, and evaluating the vision capabilities to determine whether these goals are accomplished. For instance, we may examine the system's accuracy in identifying cars and reacting to obstructions. We can find opportunities for development and make system modifications by contrasting the outcomes with the mission objectives. Feedback and constant observation make sure the system keeps working well to accomplish its objectives throughout time. All things considered, validation in relation to mission objectives guarantees that vision capabilities have a favorable impact on the effectiveness, caliber, and security of automated car wash systems.

E. Applications and case studies

Application and case studies demonstrate the efficient application of vision capabilities in automated vehicle wash systems. These systems precisely identify cars and position them for washing by placing cameras or other sensors at strategic locations, such as the entrance and exit. Empirical instances illustrate how incorporating vision sensors lowers wait times, boosts throughput, and improves customer satisfaction. Moreover, through identifying barriers and averting collisions, vision capabilities are essential for enhancing safety. These innovations are priceless resources in contemporary operations since they improve car wash facilities' overall productivity, client experience, and safety.

X. SUMMARY

An automated car wash system that makes use of the Raspberry Pi Pico microprocessor provides a simplified and effective method of cleaning cars. The technology improves the car wash process by automating steps including water spraying, soap application, scrubbing, rinsing, and drying. The Raspberry Pi Pico is a great option for system control because of its price, small size, and versatility. Accurate control and effective functioning are made possible by the microcontroller's integration with sensors and actuators. The system proves its dependability and efficiency in providing high-quality car washes through experimental validation. All things considered, the use of Raspberry Pi Pico in automated car wash systems represents an economical and successful solution for businesses and consumers alike, improving the quality of the car wash experience. [10]

XI. ACKNOWLEDGMENT

My sincere gratitude goes out to everyone who helped us finish this vehicle wash system project successfully. My sincere appreciation is extended to my mentors and advisors for their crucial advice and steadfast support along the development process. Additionally, I would want to express my gratitude to the committed team members that helped design the Raspberry Pi Pico-based automatic vehicle wash system. A special thank you is given to the research centers and institutes that supplied necessary materials and a testing-friendly atmosphere. Their assistance has been crucial to the system's effective implementation and validation.

References

[1] Mohsin, Mian Muhammad, Aditya Goel, and Sulaiman Mohiuddin. \"Automated Car Wash System.\" PROCEEDINGS OF THE BRIC: 56. [2] Pinjari, T., et al. \"Automatic Car Washing System using Microcontroller.\" International Research Journal of Engineering and Technology 7.6 (2020): 2711-2714 [3] Sarmadi, Mohammad, et al. \"Efficient technologies for carwash wastewater treatment: a systematic review.\" Environmental Science and Pollution Research 27.28 (2020): 34823-34839. [4] Mumtaz, Farhan, et al. \"Autonomous car washing station based on PLC and HMI control.\" (2021): 103-107. [5] Saleh, Yazan, Amin Manna, and Mohab Emer. \"Automatic Car Washing Machine.\" (2019). [6] Vidyasagar, K., R. Prasad, and P. Nagasekhar. \"RFID-GSM autonomous car washing system.\" International Journal of Computer Applications 121.2 (2015): 30-33. [7] Zhang, Maomao. \"Design of Automatic Car Washing Machine System based on Image Processing.\" Academic Journal of Engineering and Technology Science 2.4 (2019): 30-35. [8] Yu, Yang, Laksono Kurnianggoro, and Kang-Hyun Jo. \"Design of intelligent car washing system.\" 2015 54th Annual Conference of the Society of Instrument and Control Engineers of Japan (SICE). IEEE, 2015. [9] Singh, Raj Deepak, et al. \"Design and implementation of automatic car washing system using PLC.\" International Research Journal of Engineering and Technology 5.5 (2018): 4183-4185. [10] Zaneti, Rafael, Ramiro Etchepare, and Jorge Rubio. \"Car wash wastewater reclamation. Full-scale application and upcoming features.\" Resources, Conservation and Recycling 55.11 (2011): 953-959.

Copyright

Copyright © 2024 Hardik Shah, Deep Patel, Mohammed Saluji, Vidya Harpude. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59688

Publish Date : 2024-03-31

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online