Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Circuit Breaker System Using IOT Based Smart Load Control

Authors: T. Sagarika, S. Aravind Sai, Mohammed Khaja Nawaz, B. Vennela

DOI Link: https://doi.org/10.22214/ijraset.2024.63025

Certificate: View Certificate

Abstract

The idea of using Internet Access of Things (IoT) to monitor and regulate circuit breakers is presented in this paper. An essential part of the industrial electrical system is the circuit breaker. It is employed for switching as well as protection. Because of this, a circuit breaker\'s operational reliability is crucial. Circuit breakers deteriorate with time and with usage. This casts questions on the reliability of the circuit breaker. At certain periods, periodic preventive maintenance is performed to ensure the reliability of the circuit breaker. The current technique of utilizing circuit breakers with hardwired control logic increases the size of a control or metering cabinet and hinders the integration of the web of things. Currently, remote terminals and other proprietary technologies are used to monitor circuit breakers.

Introduction

I. INTRODUCTION

In an industrial electrical system, circuit breakers are utilized for switching and protection. Thus, a circuit breaker's ability to operate reliably is crucial. A circuit breaker failure can seriously harm an industrial electrical system, resulting in fatalities and lost revenue. Circuit breakers are put under a lot of strain when they operate since they have a lot of mechanical and electrical parts, must carry valued or fault power, and use arc quenching techniques. Because of this, the circuit breaker ages with time and usage. This raises questions about how consistently circuit breakers operate. Preventative maintenance is typically performed at predetermined times to ensure the dependability of circuit breakers. Programs for preventative maintenance involve taking circuit breakers out of operation regularly and measuring their parameters, such as spring charging motor current, trip coil current, and close coil current, with specialized diagnostic equipment. Its operational mechanism, tripped coils, closure coil, springs charging motor, fixed connection, moving contact, and other parts are also visually inspected and cleaned to guarantee its health. The system experiences more downtime even though its circuit breaker is in good condition because this maintenance method is time-based. Circuit breakers require more expensive maintenance when specialized diagnostic tools are used. The fact that hardwired control logic is used to provide switchgear control results in larger control and metering cabinets for circuit breakers and hinders Internet of Things integration, which is another significant problem with circuit breakers. Any adjustment made to a circuit breaker's control circuit promptly is restricted by this technique. Additionally, because data on circuit breakers is not readily available, the decision-making process is limited. International Journal of Applications Research India Publications, Engineering Research, Volume 13, Number 10, 2018, pp. 7806-781, ISSN 0973-4562. The website for Republication 7807 Proprietary solutions like SCADA and remote terminal units could make this a reality. However, after-sales support costs for proprietary solutions are a cause for concern. Furthermore, since the user cannot access the proprietary solution's backend implementation, the security and dependability of the safety-related and strategic applications are a problem. A comparable event has been brought about in Iran by the destructive computer worm known as "Stuxnet." In 2010, Kaspersky Lab discovered the malicious computer worm known as Stuxnet. No nation has publicly acknowledged being responsible for Stuxnet up until this point. Targeting controllers with programmable logic (PLCs) in particular, Stuxnet enables automation of electromechanical operations, including those that run centrifuges, amusement rides, and factory assembly lines. Stuxnet operates by first searching for Siemens Step7 software on machines running Microsoft Windows and then focusing on those machines/networks. The fast-spinning centrifuges broke apart as a result of

Stuxnet allegedly broke into Iranian PLCs and gathered data on industrial systems. The architecture and design of Stuxnet are not domain-specific, and it may be modified to serve as a platform for assaulting contemporary PLC and SCADA (supervisory control and data acquisition) systems (found, for example, in manufacturing assembly lines or power plants). It is reported that over 25% of the country of Iran's nuclear centrifuges were destroyed by Stuxnet. The worm, which was designed to attack industrial control systems, infected more than 200,000 computers and physically damaged 1,000 devices. If a development environment is transparent and entirely under the control of the user, this problem can be avoided.

To integrate the Internet of Things, an open-source Mega 2560 Arduino embedded microcontroller and Ethernet Shield were used to construct a monitoring and control strategy for a standard circuit breaker in this research. Circuit breaker parameters are tracked, including the current at the load, trips coil current as well as close coil current, spring charged motor current, and the quantity of tripping and closing operations. Circuit breaker data is made instantly available for efficient decision-making by uploading the monitored data to the IoT platform called "Thing Speaks." Circuit breaker parameters that are monitored are utilized to assess the condition of the breaker, ensuring dependable functioning and identifying any maintenance or replacement requirements. The goal of this study is to develop automation circuit breaker monitoring and control systems that can instantly diagnose a breaker's mechanical and electrical health. The concept of maintenance is changing from being time-based to being as-needed. As needed maintenance is replacing time-based maintenance in the maintenance paradigm. This change has the advantage of keeping circuit breaker performance appropriate while cutting down on total maintenance expenses and needless downtime.

II. LITERATURE REVIEW

Every industrial sector places a high premium on safety since even minor system flaws might cause things to go worse sooner rather than later. Notwithstanding its high efficiency, human monitoring systems have limitations since errors in the accuracy of the processes they verify and monitor are unavoidable. In industrial settings, complete accident prevention is unachievable; however, we can strive for near-perfect preventive measures. Lowered random and human errors are produced during the validation process when a system is designed with a variety of technological devices, for example, sensor-based internet-integrated monitoring devices. To prevent these catastrophic events, common causes that cause problems, like gas leaks, fire explosions, and unlawful access, can be identified with the highest degree of precision. Presented a method that would allow only authorized individuals to access a certain password and manage the circuit breaker. With an 8KB ROM, a matrix keypad for password entry, and a relay driver to turn on and off loads via relays, the microcontroller is in complete control of the system. The design of an online monitor and diagnosis system for electrical equipment is presented by Bhagwan Kharat [2], who also suggests a method for gathering, transferring, and processing data concerning the equipment under observation. Several systems and applications locally can be recorded using an interface that is created. The controller will provide circuit breaker parameters to the control room continually. These data will also be shown on the computer monitor. Additionally, following a C.B. trip, an SMS will be delivered to the subscribed mobile phone. The operator or another authorized person will provide a command such as for setting or resetting the breaker as soon as they get the notification. The circuit breaker's lifespan and dependability are increased as a result of reduced fault-clearing times and improved maintenance techniques. To integrate IOT, Abhijit Das [3] suggested a system that uses a Mega 2560 Arduino-embedded microcontroller and an Ethernet shield to construct a monitoring and control scheme for a standard circuit breaker.

Real-time diagnostics of a circuit breaker's mechanical and electrical condition are made easier by the system. It makes use of an open-source platform, which removes any worries about the security and dependability of the safety-related or strategic application because the user has full access to the source code implementation. An approach put out by Lakshmi Devdas [4] guarantees that the lineman operates in a more secure environment, prevents unwanted access, and prevents the line from switching. Man 11 is capable of operating the line as needed. Through the use of an IOT, parameters having an ON/OFF state, such as voltage and current, may be seen on a webpage. Athira Nair [5], has put out a plan that prioritizes lineman safety so they won't get an unexpected electric shock while working. Many incidents can be prevented if linemen and substations work together effectively. The project's goal was to offer a remedy that would guarantee the security of maintenance workers. When a lineman finds a defect in the electrical line, an SMS is sent to the substation employees, who turn the line back on when the issue has been fixed.

III. PROPOSED MODEL

To prevent the generator from overloading, we must create this system to identify users who use more electricity than is permitted during peak hours. IoT integration is achieved by using an Ethernet shield and the open-source Arduino mega-integrated microcontroller. The advantage of this is that total maintenance costs and needless downtime are decreased while circuit breaker functionality is maintained. completely accessible and user-controlled, removing any doubt about dependability and safety security. The suggested method enables automated control and monitoring of circuit breakers, which diagnoses the Circuit breakers' mechanical and electrical health in real-time. As-needed maintenance is replacing time-based maintenance in the maintenance paradigm. This change has the advantage of keeping circuit breakers operating at an appropriate level while cutting down on total maintenance expenses and needless downtime.

A. Objective

a) This paper's primary goal is to employ an open-source platform for continuous user-accessible circuit breaker monitoring and control. b) As-needed maintenance is replacing time-based maintenance as the paradigm for maintenance is changing. This change has the advantage of keeping circuit breaker performance appropriate while cutting down on total maintenance expenses and needless downtime.

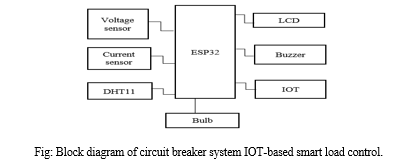

B. Block Diagram of the proposed system

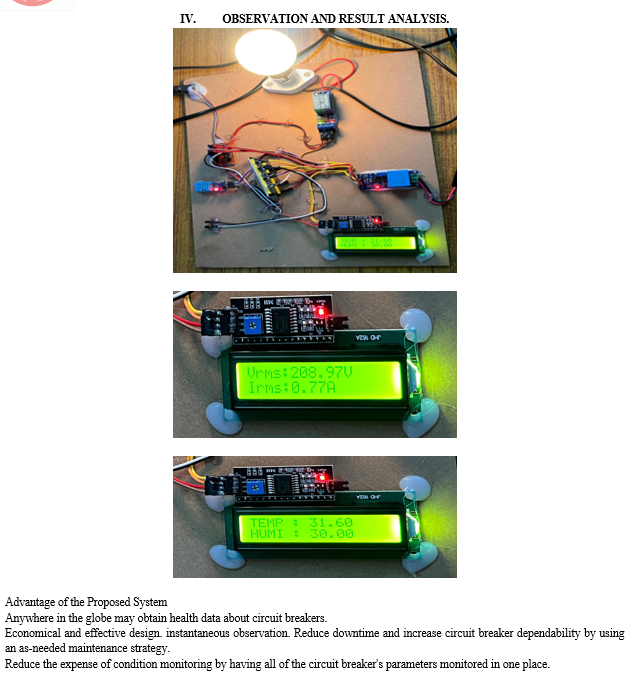

What's included in the block diagram is Because it has several important uses, the ESP-32 microcontroller is widely utilized. Measures the voltage level of electrical impulses using a voltage sensor that is attached to an esp32. Measuring the amount of electric current flow in a circuit is accomplished via an ESP32 interfaced current sensor. The DHT11 humidity and temperature sensor is used to measure the temperature and humidity of the surrounding air. It is compatible with microcontrollers such as the esp32. Information display and visual feedback are two functions of LCDs (Liquid Crystal Displays). Buzzer. It is used to provide audio warnings, alerts, or feedback in a variety of electrical systems. Connecting gadgets to the Internet of Things (IoT) with ESP32 accomplishes several goals. internet and speak with one another. Lays are frequently employed as a connection between the high-power electrical systems or devices and the digital data signals of the ESP32.

Measurement of the electrical current flow in a circuit is done with a current sensor. Utilizing a current sensor, one may keep an eye on and quantify the ESP32 module's operational current consumption in the context of this microcontroller. In many electronic applications, the DHT11 humidity and temperature sensor is a cheap option. The NTC (Negative temperature coefficient) thermistor is used to detect temperature, and a humidity sensor is also included. It is useful for a variety of applications as the LCD with ESP32 improves the interface for users and offers a visual way to communicate information. Information is frequently displayed visually in electronic devices through the usage of LCDs. The ESP32 microcontroller is inexpensive, low-power, and has integrated Bluetooth and Wi-Fi. It is the replacement for the ESP8266, a low-cost Wi-Fi microprocessor with significantly fewer capabilities.

IoT smart load control in the implementation of a circuit breaker system Many Internet of Things applications frequently employ the widely used ESP32 microcontroller and system-on-a-chip (SoC). A vast array of characteristics and features are included in the ESP32, an enhanced replacement for the ESP8266. Built-in Bluetooth and Wi-Fi connectivity are among the ESP32's primary features. Wi-Fi and Bluetooth are both supported. Due to this, it is perfect for Internet of Things applications that need wireless connectivity. The ESP 32 microcontroller receives the code dump, and the associated light is turned on. To control the status of an LED, an ESP32 microcontroller must establish a communication link with the LED. With built-in Bluetooth and Wi-Fi, the ESP32 is a multipurpose device that can be configured to control a range of peripherals. To begin with, The LED and one of the ESP32's pins for the GPIO are physically connected. This pin will serve as the interface for control, deciding when to turn on and off the LED. In terms of software, the coder sets up the pin on the GPIO as an output and then flips its state to operate the LED. Libraries and functions are provided by the ESP32's Software environment, which frequently uses Micro Python or Arduino, to make this process easier. Additionally, the ESP32 may be configured to manage more intricate situations, including adjusting LED brightness with PWM (Pulse Width Modulation). Simulating various brightness levels entails altering the duration of the GPIO pin's high state within a designated time frame. In general, the interface process combines software and physical components, creating a communication link between the LED and the ESP32 to enable dynamic state control of the LED according to the logic that has been written.

Conclusion

The development of automatic circuit breaker monitoring and control systems for instant detection of the health of electricity and electrical systems is a revolution in monitoring and control, from timely maintenance to the need for maintenance. The benefit of this change is to maintain the efficiency of electricity supply while reducing overall maintenance costs and unnecessary downtime. Additionally, using an open platform eliminates concerns about security/security/trust and safety of practical use since the implementation of the code is open and acquired and controlled by the user. one one Documents one

References

[1] Lakshmi Devdas, Sreelakshmi V.G, Amal Kotter, Jinendhu Justin, Automatic Circuit Breaker with IoT Interface, IOSR Engineering Magazine, 2018 Page 11. 29-32: kuv. [2] Brent L. Carper, Chief Engineer, âÂ?Â?X, Y and Z of Circuit Breaker Control,âÂ? 34th Annual Relay Application School Report, March 2017. one [3] B. Sai Kumar, G. Vijay Kumar, G. Sai Krishna, J.V.S. Nanda, M.V.S.S.R. Sunandh, âÂ?Â?Password Based Circuit Breaker Using ArduinoâÂ?Â, Pramana Research Journal, Volume 10, Issue 4, 2020, p. [4] \"Design and Implementation of Password-Protected IoT-Based Circuit Breaker\" by N. K. Bansal, P. Kumar, and R. Kuma. [5] Santosh Ashok Kamble, Jayashri Shrirang Bhagwat, and Nilima Shrikrishna Bakde, \"IoT Based Circuit Breaker\", International Journal of Innovative Technology and Exploring Engineering (IJITEE), Vol. 9, Issue 2, December 2019. [6] Manohara H. C, Dr. Gopiya Naik. S, Tejaswni K. P, Shana C. M, Kowsalya. S, Meghana. R N, âÂ?Â?OTP based Lineman Security SystemâÂ?Â, International Journal of Engineering Research & Technology (IJERT),ISSN:2278-0181,Volume-9,Isuue-02,Febuary-2020. [7] Musa Baba Lawan, Yau Alhaji Samaila, Ibrahim Tijjani, â??Automatic Load Sharing and control systemâ? Using a Microcontroller. American journal of modern energy. Vol. 3, No. 1, 2017, pp. 1-9. [8] Snehal K. Gosavi, Khushbu D. Badgujar, Prafulla P. Chaudhari â??Electricity and load shedding monitoringâ? ,International journal of Advanced Research in electronics and Communication Engineering (IJARECE) Volume 4, Issue 3, March 2015. [9] Dwijen Rudrapa 1 â??SMS based Load Shedding Period Control Systemâ? International Journal of Computer Applications Volume 29-No.7, sep2011.

Copyright

Copyright © 2024 T. Sagarika, S. Aravind Sai, Mohammed Khaja Nawaz, B. Vennela. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63025

Publish Date : 2024-05-31

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online