Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Compaction Characteristics of Fly Ash and Pond Ash: A Comparative Analysis

Authors: Chandrakant ., Dr. R. R. L. Birali, Akhand Pratap Singh

DOI Link: https://doi.org/10.22214/ijraset.2024.64372

Certificate: View Certificate

Abstract

This study investigates the compaction characteristics of Fly Ash and Pond Ash, which are by-products of coal combustion in thermal power plants. Thermal power plants generate three types of ash: (a) Fly Ash, (b) Pond Ash, and (c) Bottom Ash. Fly Ash consists of fine particles carried out of the boiler with flue gases, while Bottom Ash is the residue that settles at the bottom of the boiler. In most coal plants, Fly Ash is captured using electrostatic precipitators and other filtration equipment before the flue gases are released through the chimney. Pond Ash, on the other hand, is a by-product of thermoelectric power plants, often regarded as waste material, posing significant environmental disposal challenges. The compaction characteristics of Fly Ash and Pond Ash are influenced by various factors, including specific gravity, moisture content, compaction energy, layer thickness, and mold area. In this study, Fly Ash collected from NTPC Sipat , Chhattisgarh exhibited an Optimum Moisture Content (OMC) ranging from 18% to 27% and a Maximum Dry Density (MDD) ranging from 0.90 to 1.59 gm/cc under standard Proctor compaction energy. Similarly, Pond Ash demonstrated an OMC ranging from 33% to 46% and an MDD ranging from 0.856 to 1.248 gm/cc under the same conditions. The findings indicate that variations in these factors significantly affect the dry density of both Fly Ash and Pond Ash. The study also aims to determine the geotechnical properties of these materials, providing insights into their potential applications in engineering and environmental management.

Introduction

I. INTRODUCTION

Fly ash in with the products of coal burning, consisting of good particles that are excluded from the boiling with fumes. The ash falls bottommost of the boiler is named as bottom ashes. Depending on the source and the composition of burnt coal, volatile ash components vary significantly but all volatile ash contains significant quantities of silicon dioxide (SiO2) (both uniformed and crystal-like), aluminum oxide (AL2O3) and calcium oxides. Flying ash component solidifies while deferred in use gasses and is possessed by electrostatic precipitators or refine baggage. Then fragments coagulate quickly though deferred now dissipate gasses, fly ash particles are normally rounded and vary from 0.5 to 300 microns. The main concern is that few hardening of the mineral has the time to crystallize and remain in the tempered amorphous glass. As a result, fly ash is a multifarious component.

A. Objective

- To evaluate how compaction impacts the geotechnical properties of fly ash and pond ash, including permeability, shear strength, and dry density in relation to moisture content.

- To examine how the chemical and mineralogical composition changes over time as a result of compaction.

II. REVIEW OF LITERATURE

Bera et al. (2007) declared that the properties of1changed compaction controlling parameters, i.e. mold area, layer width, moisture content, specific gravity, compaction energy and tank size on the dry density of1pond ash are explained. The MDD and OMC of pond ash differ in reach the area of 0.856 – 1.248 gm/cc and 29–46%, correspondingly. The strength of concentration at an OMC of1pond ash has been creating to differ in reach the area of163–89%. An empirical mode has been established to evaluation the dry density of pond ash, applying numerous regression studies, in terms of specific gravity, moisture content and compaction energy.

Jakkaetal.(2010) declared that energy and alternative geotechnical features of1pond ash specimen, possessed from invasion and streaming facts of1two ponds ash in India,are related to sandy soils in many forms. Strength characteristics were examined by means of undrained (CU) and consolidated drained (CD) triaxial tests through compacted specimen’s of1pond ash samples under different confining pressures, pore water pressure measurements and conducted on loose.

Ghosh (2010) declared that Class F pond ash only and become constant with changing % of lime (4, 6, and 10%) and phosphors gypsum (0.5 & 1.0), to study the suitability of stabilized pond ash for sub-base and road base construction. Modified & standard proctor tests had been directed to disclose the compaction characteristics of1the balanced pond ash. Equally the bearing ratio tests of soaked & unsoaked have been directed. The effect of PG content, curing period & lime on the bearing ratio of fixed pond ash. The empirical model has been established to estimate the bearing ratio for the stabilized mixes through numerous regression studies.

Singh and Sharan (2014) declared that the degree of1saturation on strength characteristics of1compacted pond ash and properties of compaction energy. The MDD & OMC consistently to different compactive energies were resolute by conventional compaction tests. The California bearing ratio (CBR), unconfined compressive strengths (UCS), shear strength parameters, and specimen’s values of compressed to different moisture content and dry densities were evaluated and described. The degree of saturation of shear strength parameters and effects of compaction energy i.e. angle of internal friction (?) values and unit cohesion (cu) and similarly the unconfined compressive strengths values are calculated and conferred.

III. MATERIAL AND METHODOLOGY

A. General

This part defines the method and materials well-known reach the objectives. The important resources in this survey are fly ash and pond ash; experiential procedure for the characterization of these materials is discussed. The following section of this chapter is a brief1introduction to materials and methodology.

1) Materials

- Fly ash (collected from NTPC Sipat, Chhattisgarh)

- Pond ash (collected from NTPC Sipat, Chhattisgarh)

- The samples were desiccated in an oven of 105 to 110º and shifted with a 4.75 mm Sieve.

- The compaction test, resistance and permeability parameters, and

- 2 mm IS sieve for per specific gravity

Figure 3.1:- Fly Ash

Figure 3.2:- Pond Ash

2) Physical Properties of Fly Ash and Pond Ash

Fly ash particles are very fine, lightweight (density 1.97-2.89 g/cc) and spherical (specific surface area 4000-10,000 cm2/g; diameter, 1-150μ), refractory and have the pozzolanic ability. Fly ash grey to blackish grey and is dependent on coal type and combustion process. Fly ash has dielectric property (dielectric constant, 104) and can be used in the electronic application.

Table 3.1: Physical Properties of1Fly Ash

|

Parameters |

Range |

|

Colour |

Grey |

|

Shape |

Rounded |

|

Optimum Moisture Content (%) |

18 -27% |

|

Maximum Dry Density (gm/cc) |

0.90 – 1.59 |

|

Specific gravity |

2.28 |

|

Plasticity Index, IP |

Non-plastic |

|

Coefficient of Curvature |

1.29 |

|

Uniformity Coefficient |

5.58 |

|

Mean Diameter |

0.05 mm |

Table 3.2: Physical Properties of1Pond Ash

|

Parameters |

Range |

|

Colour |

Light grey |

|

Shape |

Rounded/sub rounded |

|

Optimum Moisture Content (%) |

33 -46% |

|

Maximum Dry Density(gm/cc) |

0.856 – 1.248 |

|

Specific gravity |

2.18 |

|

Plasticity Index, IP |

Non-plastic |

|

Coefficient of Curvature |

1.27 |

|

Uniformity Coefficient |

5.69 |

|

Mean Diameter |

0.3 mm |

B. Test Procedures

1) Specific Gravity

According to a unique load of fly ash and pond ash was expect as IS: 2720 (Part III, Section 1) 1980, which was used a sample of 50 g fly ash and pond ash oven at 105-110 degrees, passing through a sieve of 2 mm and the weight nearest to 0.001 g. Three density bottle (pyknometers) of 50 ml, a dryer, and boiler to heat the density bottle remove the air foams and refined water.

For describing exact pressure, three frequency bottles has been taken and weighing near to 0.001 gram. Next 50-gram oven dry bottom ash were taken passes through 2 mm IS sieve, weighing nearby to 0.001gram. At that moment sampling and pyknometers equally weighing collectively, then the mass of pycnometers and distilled water were taking. By this method presented in IS 2720 (Part-3, section-1)1980 specific gravity resolute.

To determine the specific weight, they were taken and the first three heavy bottles closer to the density of 0.001 g. Then 50 g of fly ash and pond ash dried in the oven by passing through a sieve of 2 mm, measured approximately of 0.001 g. Then the sampling and pyknometer are measuring simultaneously, and then the mass of the pycnometer and refined water were taken. By this method presented in IS: 2720 (part 3, section-2), the specific weight of 1980 was defined.

2) Grain Size Analysis

Grain size analysis was performed in keeping with IS code: 2720 (part IV)-1985.For sieve analysis, 500-gram oven-dried specimen were taken and passing through sieve set which is: 75 μ, 150 μ, 212 μ, 300 μ, 425 μ, 600 μ, 1mm, 2mm, 4.75 mm. The mass of retained specimen was taken after that chart has been shown between passing percentage and width of the particle. Hydrometer analysis for the specimen which is passed through a sieve of 75 μ. Chart between the finest % and the diameter of the specimens was plotted. Both the chart was inserted and the ratio between the percentage passing and the width of the particle bending coefficient (Cc) and the coefficient of uniformity (Cu) was determined.

3) Permeability

The permeability was resolute according to fly ash and pond ash IS 2720 (part XVII) - 1986. Permeability is an influence by which water can flow through ash or soil due to consistent gaps. It is essential to estimate the amount of infiltration in different hydraulic conditions to investigate the stability analysis of ground and dam supporting structures that have undergone leakage. Hydraulic conductivity can be determined by two methods which are: Constant head test and Falling head test. According to current research, a constant head test in which the head remained constant between the input and output of the control device were defined by hydraulic conductivity.

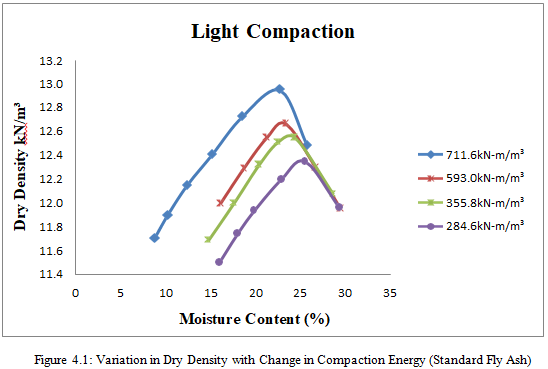

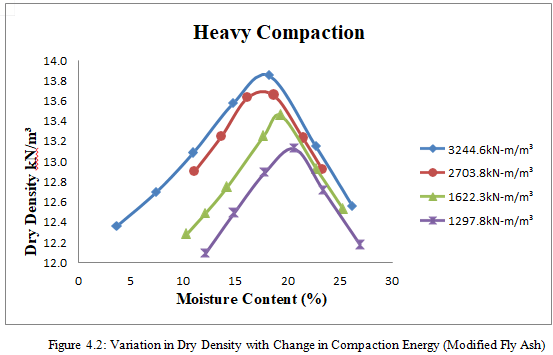

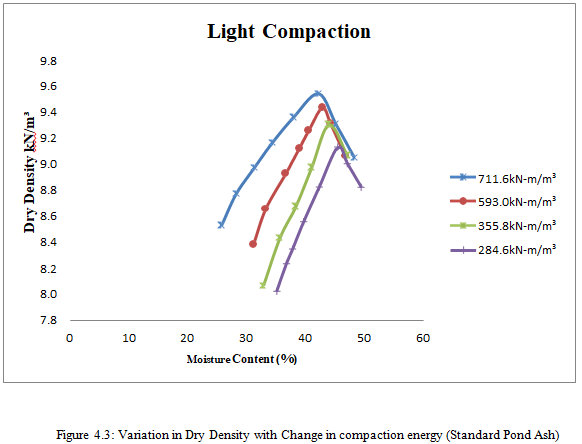

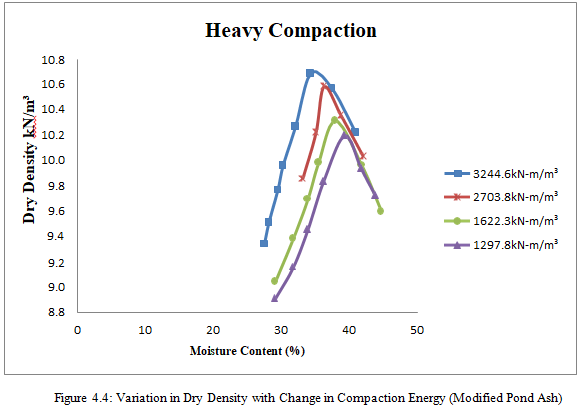

4) Compaction Test

The compaction of fly ash and pond ash has been done according to IS: 2720 (part 7) - 1980 for light compaction and IS: 2720(part 8)-1983 for heavy compaction. Compaction is a process if densification of a granular material by applying mechanical energy. This process involves packing the granular material together with reducing the volume of air voids. Densification of granular material controls other engineering properties such as permeability, compression, and shear strength. The dry density of the compacted material is a measure of the degree of compaction achieved. This is the function of the quantity and application method of energy, the amount of water taken through compaction and the characteristics of materials such as specific gravity, particle shape, plasticity, grain size distribution, & gradation. In the laboratory, the standard compaction test was performed using a molded diameter of 10 cm, 12.73 cm in height and 15 cm in diameter, 12.73 cm in height to give mold area variation. A 2.6 kg mass of hammer was used with a 310-millimeter drop to compact the ashes into the three-layer mold; each layer is subjected to 25 blows of the hammer drop mass providing 25 blows/layer. Modified compaction test uses the same mold in 5 layers of 4.9 kg of weight and a 450 mm drop mass providing 25 blows per layer.

5) Compaction Test: Proctor Mould

The impact of compaction controlling parameters testing on the dry density of variation of1these Parameters is Compaction energy variation (up to eight energy levels), specific gravity variation, layer thickness variation, compaction are a variation.

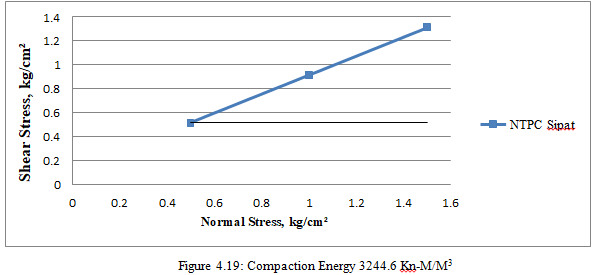

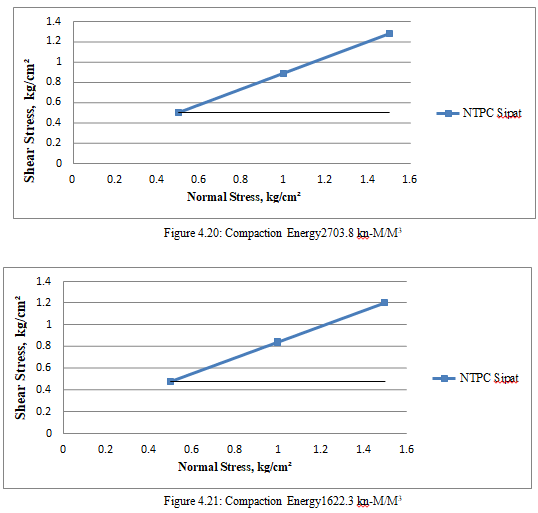

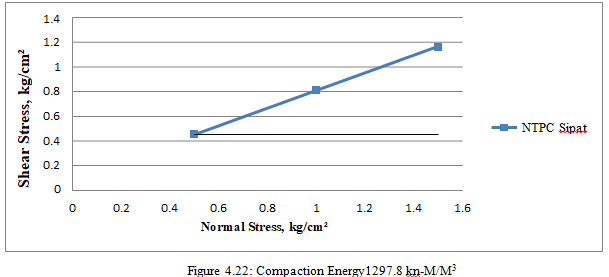

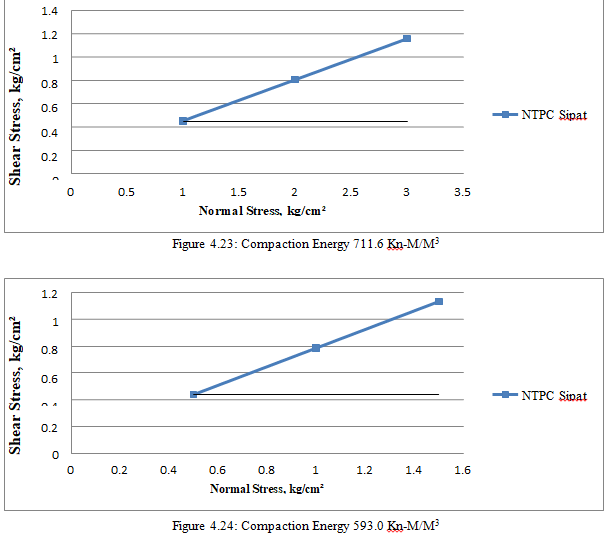

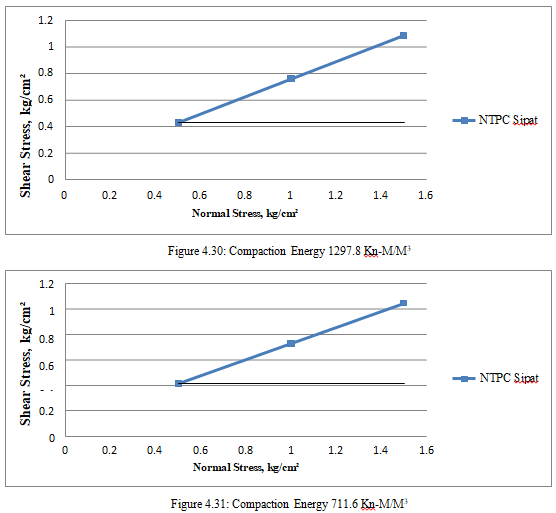

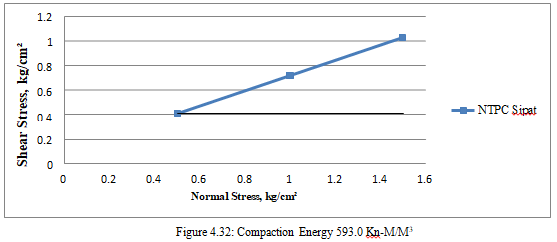

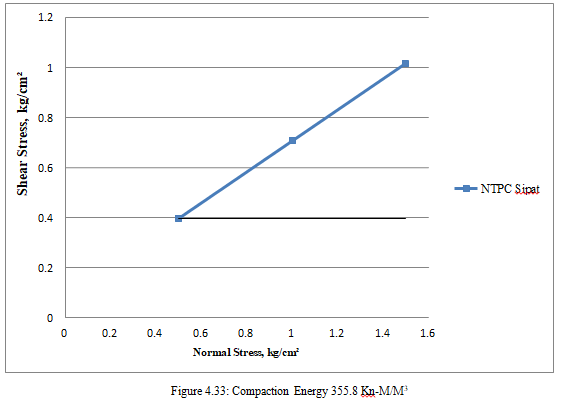

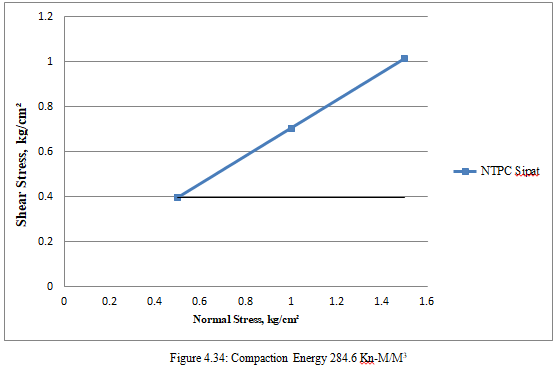

6) Direct Shear Test

Resistance parameters C & ? are resolute by the direct shear test according to IS: 2720 (part13) 1986. Samples were collected by inserting a sample size of 0.06 m x 0.06 m x 0.025 m in the samples collected in the sampler. This test consists of a casing of dimensions 60 x 60 x 50 mm. A specimen obtained in MDD OMC and subsequently prepared deformation trimming to maintain normal variable strain content. A graph has been drawn in the middle of shear stress against normal stress and cohesion (c) and internal friction angle (?) shows the chart. C and ? values were obtained with a light compacting energy and heavy compacting energy.

IV. RESULTS AND DISCUSSION

A. Index Properties

1) Specific Gravity

The specific gravity of coal ash mainly depends on its chemical composition. In specific gravity the value of coal ashes having a low when compared with those of soils that have specific gravity varying in a narrow range of 2.6-2.8.

In this study fly, ash and pond ash was collected and their specific gravity was found out as per IS: 2720 (Part-III, section-1)1980.

Table 4.1: Specific Gravity of Fly Ash & Pond Ash Collected From NTPC Sipat, Chhattisgarh

|

S. No. |

Sample |

Specific Gravity |

|

1 |

Fly Ash (NTPC Sipat) |

2.28 |

|

2 |

Pond Ash (NTPC Sipat) |

2.18 |

2) Compaction Test

Two different molds were done in Compaction test to give the variation in compaction area as (a) Proctor mold, (b) CBR mold. Compaction energy variation has been given for each compaction mold.

For Fly Ash

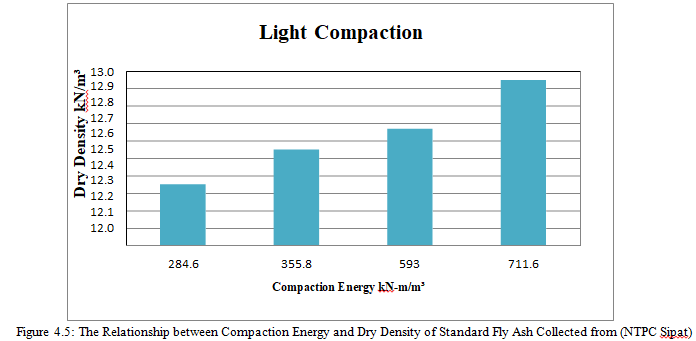

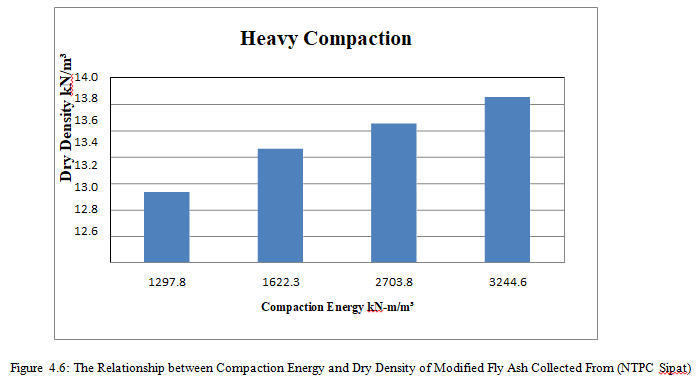

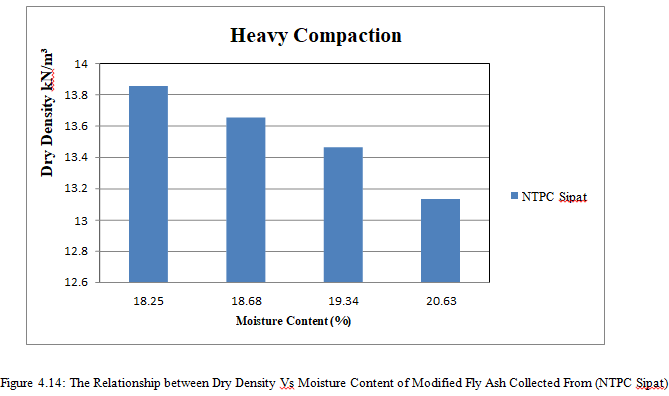

Table 4.2: Maximum Dry Densities of Samples, Subjected to Different Compacting Energies

|

S. No. |

No of blows/layer |

Compaction energy (kN-m/m³) |

Maximum Dry Density (kN/m³) |

Optimum Moisture Content (%) |

|

1 |

30 |

3244.6 |

13.83 |

18.25 |

|

2 |

25 |

2703.8 |

13.63 |

18.68 |

|

3 |

15 |

1622.3 |

13.43 |

19.34 |

|

4 |

12 |

1297.8 |

13.04 |

20.63 |

|

5 |

30 |

711.6 |

12.94 |

22.71 |

|

6 |

25 |

593.0 |

12.65 |

23.34 |

|

7 |

15 |

355.8 |

12.45 |

24.33 |

|

8 |

12 |

284.6 |

12.26 |

24.48 |

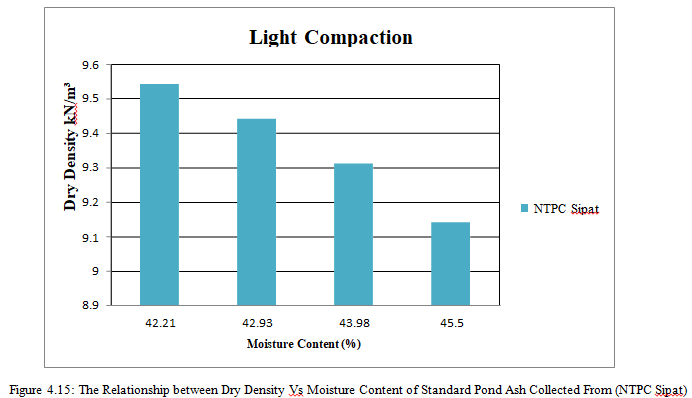

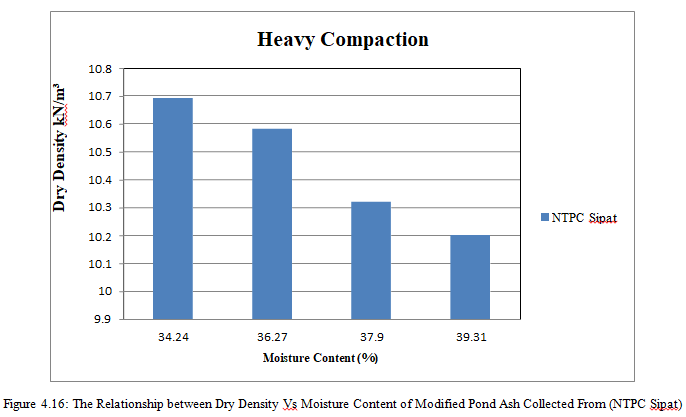

For Pond Ash

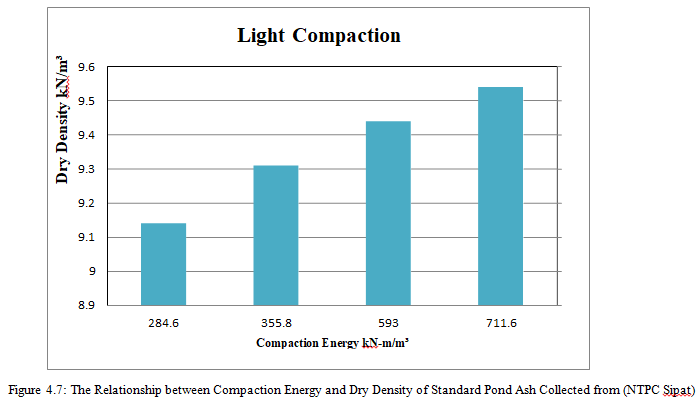

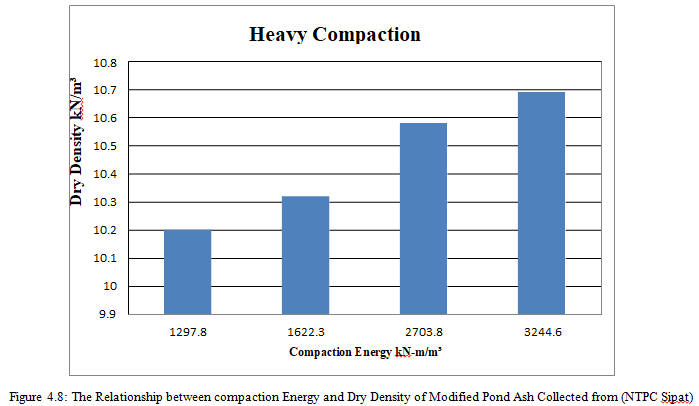

Table 4.3: Maximum Dry Densities of Samples Subjected to Different Compacting Energies.

|

S. No. |

No of blows/layer |

Compaction energy (kN-m/m³) |

Maximum Dry Density(kN-m³) |

Optimum Moisture Content (%) |

|

1 |

30 |

3244.6 |

10.59 |

34.24 |

|

2 |

25 |

2703.8 |

10.49 |

36.27 |

|

3 |

15 |

1622.3 |

10.30 |

37.90 |

|

4 |

12 |

1297.8 |

10.10 |

39.31 |

|

5 |

30 |

711.6 |

9.51 |

42.21 |

|

6 |

25 |

593.0 |

9.41 |

42.93 |

|

7 |

15 |

355.8 |

9.22 |

43.98 |

|

8 |

12 |

284.6 |

9.12 |

45.50 |

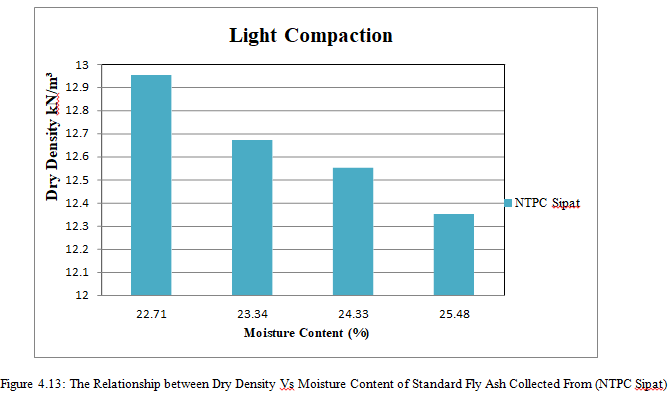

B. The Relationship between Compaction Energy Vs Dry Density

The effect of compaction energy on dry density has been shown in the figure, from the curve of compaction energy Vs dry density, it can be seen that as compaction energy increases, dry density increases until a critical point reached of dry density. The relationship between dry density and compaction energy is following:

For Fly Ash

For Pond Ash

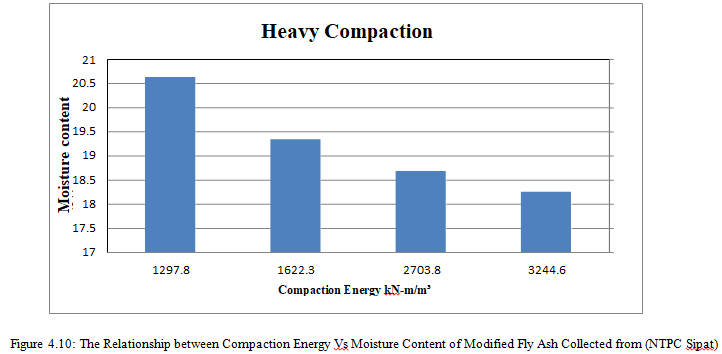

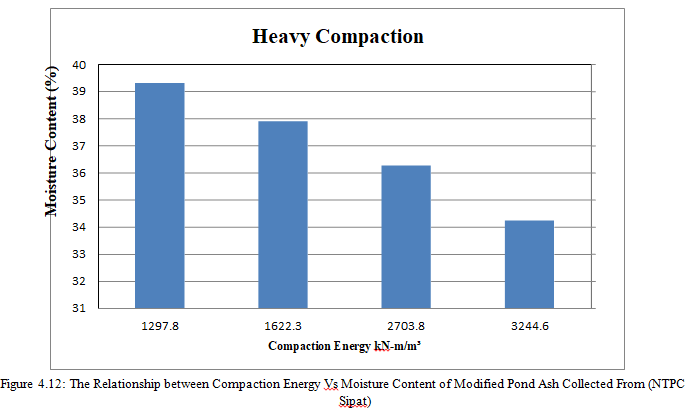

C. The Relationship Between Compaction Energy Vs Moisture Content

The curve has been plotted between compaction energy and moisture content. From the graph, it can be seen that as compaction energy increases, moisture content decreases.

For Fly Ash

For Pond Ash

D. The Relationship Between Dry Density Vs Moisture Content For Fly Ash

For Pond Ash

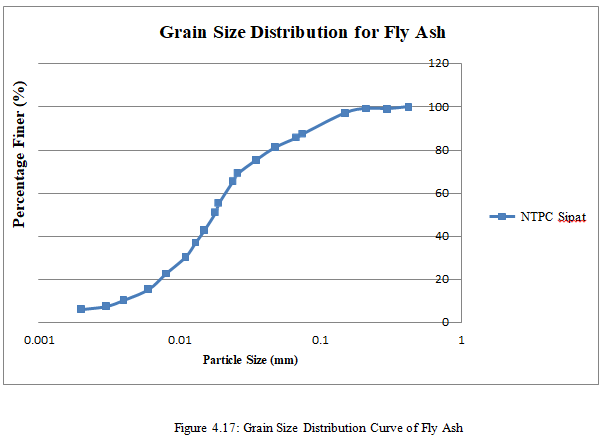

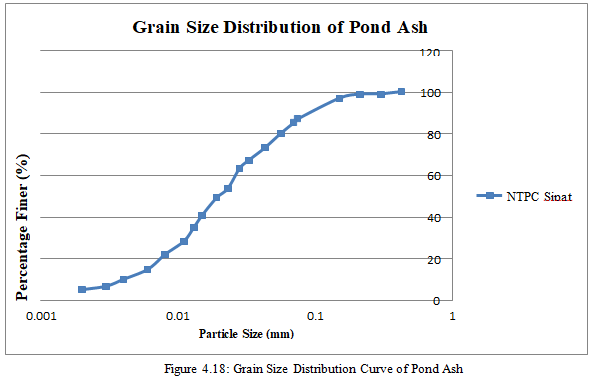

E. Grain Size Analysis

For Fly Ash

Table 4.4: Uniformity Coefficient and Coefficient of Gradation of Fly Ash

|

Parameters |

Value |

|

D10 |

0.0038 |

|

D30 |

0.0109 |

|

D60 |

0.0212 |

|

Coefficient of uniformity, Cu |

5.58 |

|

Coefficient of curvature, Cc |

1.25 |

For Pond Ash

Table 4.5: Uniformity Coefficient and Coefficient of Gradation of Pond Ash

|

Parameters |

Value |

|

D10 |

0.0039 |

|

D30 |

0.0114 |

|

D60 |

0.0261 |

|

Coefficient of uniformity, Cu |

5.69 |

|

Coefficient of curvature, Cc |

1.27 |

F. Permeability Test (Variable Head Method)

For Fly Ash

Table 4.6: Hydraulic Conductivity of Fly Ash

|

SI. No. |

Compaction energy (kN-m/m3) |

Sample (Fly ash) |

|

1 |

Increased modified 30 blows/layer (3244.6 kN-m/m3) |

2.93?10-5 |

|

2 |

Modified 25 blows/layer (2703.8 kN-m/m3) |

3.23?10-5 |

|

3 |

Reduced modified 15 blows/layer (1622.3 kN-m/m3) |

3.71?10-5 |

|

4 |

Reduced modified 12 blows/layer (1297.8 kN-m/m3) |

3.98?10-5 |

|

5 |

Increased standard 30 blows/layer (711.6 kN-m/m3) |

4.57?10-5 |

|

6 |

Standard 25 blows/layer (593.0 kN-m/m3) |

3.82?10-5 |

|

7 |

Reduced standard 15 blows/layer (355.8 kN-m/m3) |

2.74?10-5 |

|

8 |

Reduced standard 12 blows/layer (284.6 kN-m/m3) |

2.53?10-5 |

For Pond Ash

Table 4.7: Hydraulic Conductivity of Pond Ash

|

S. No. |

Compaction Energy (kN-m/m3) |

Sample (Pond ash) |

|

1 |

Increased modified 30 blows/layer (3244.6 kN-m/m3) |

4.37?10-4 |

|

2 |

Modified 25 blows/layer (2703.8 kN-m/m3) |

4.70?10-4 |

|

3 |

Reduced modified 15 blows/layer (1622.3 kN-m/m3) |

5.11?10-4 |

|

4 |

Reduced modified 12 blows/layer (1297.8 kN-m/m3) |

5.43?10-4 |

|

5 |

Increased standard 30 blows/layer (711.6 kN-m/m3) |

5.61?10-4 |

|

6 |

Standard 25 blows/layer (593.0 kN-m/m3) |

5.83?10-4 |

|

7 |

Reduced standard 15 blows/layer (355.8 kN-m/m3) |

6.08?10-4 |

|

8 |

Reduced standard 12 blows/layer (284.6 kN-m/m3) |

6.39?10-4 |

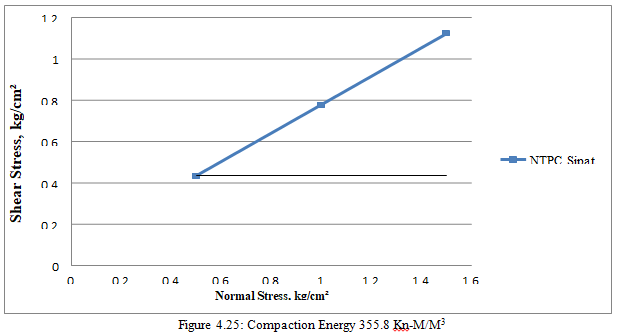

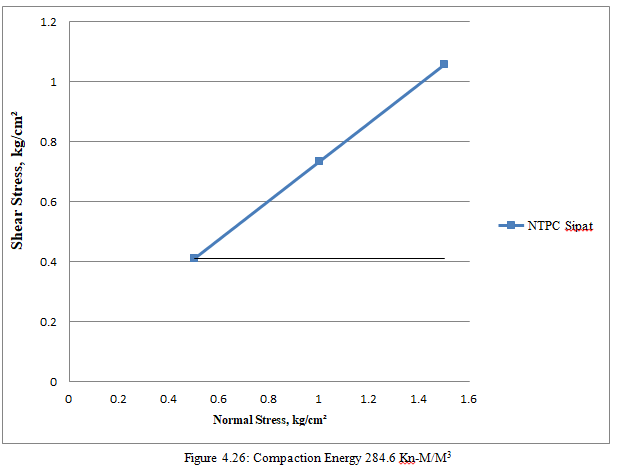

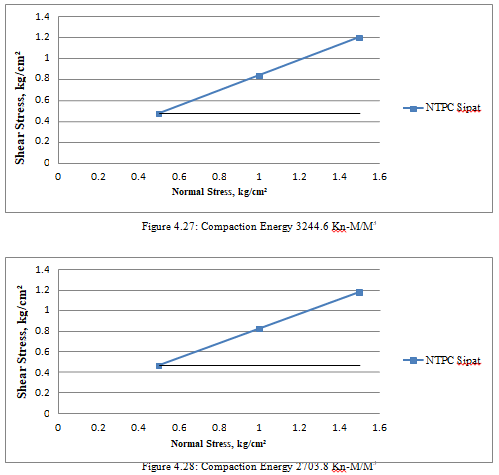

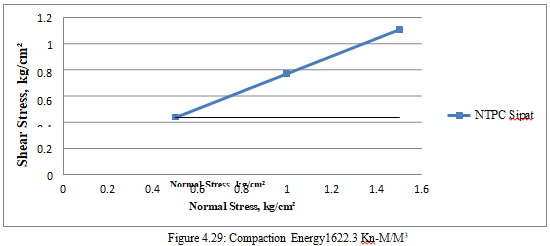

G. Direct Shear Test

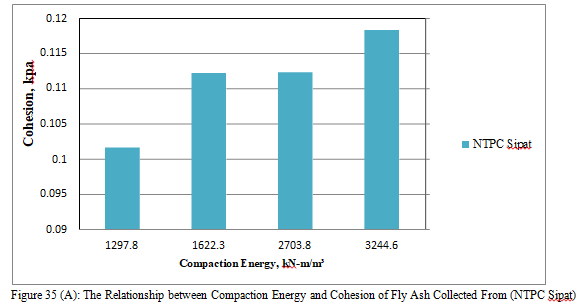

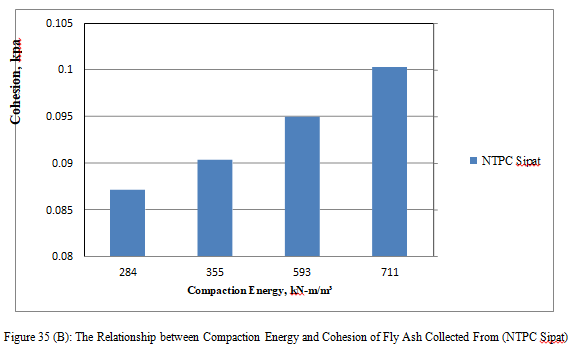

For Fly Ash

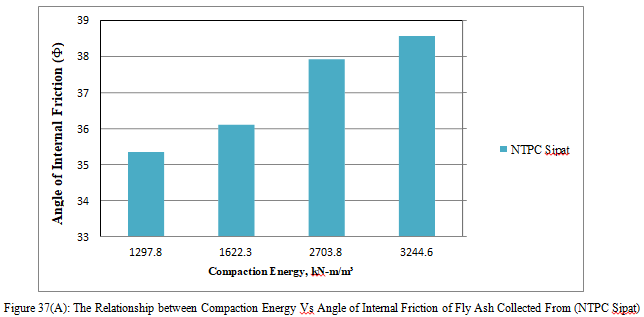

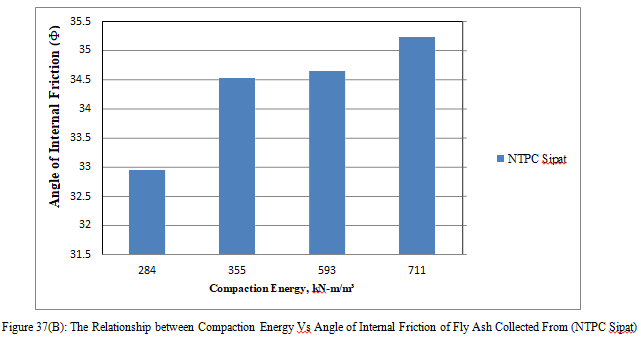

Table 4.8: Strength Parameters of Fly Ash

|

S. No. |

Compaction Energy (kN-m/m3) |

Sample |

|

|

Fly Ash (NTPC Sipat) |

|||

|

Cohesion (Kpa) |

Angle of Internal friction (?) |

||

|

1 |

Increased modified 30 blows/layer (3244.6 kN-m/m3) |

11.83 |

38.55 |

|

2 |

Modified 25 blows/layer (2703.8 kN-m/m3) |

11.23 |

37.91 |

|

3 |

Reduced modified 15 blows/layer (1622.3 kN-m/m3) |

11.22 |

36.09 |

|

4 |

Reduced modified 12 blows/layer (1297.8 kN-m/m3) |

10.16 |

35.33 |

|

5 |

Increased standard 30 blows/layer (711.6 kN-m/m3) |

10.02 |

35.22 |

|

6 |

Standard 25 blows/layer (593.0kN-m/m3) |

9.49 |

34.64 |

|

7 |

Reduced standard 15 blows/layer (355.8 kN-m/m3) |

9.03 |

33.22 |

|

8 |

Reduced standard 12 blows/layer (284.6 kN-m/m3) |

8.71 |

32.94 |

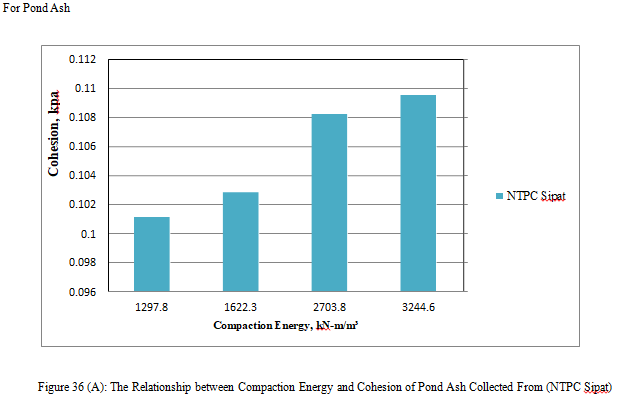

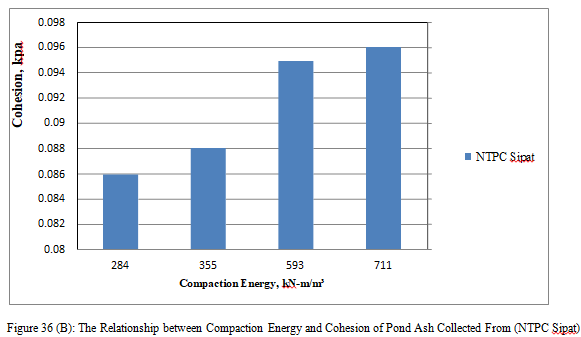

For Pond Ash

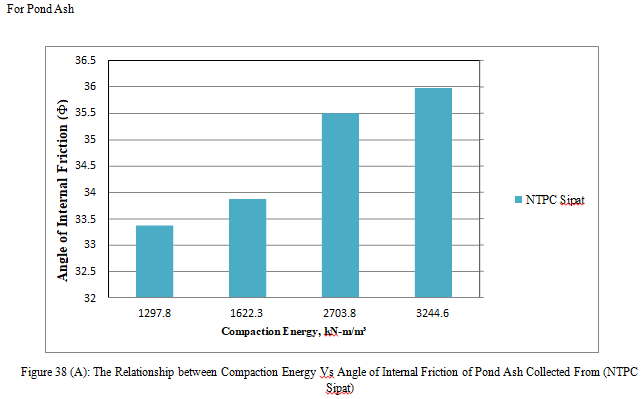

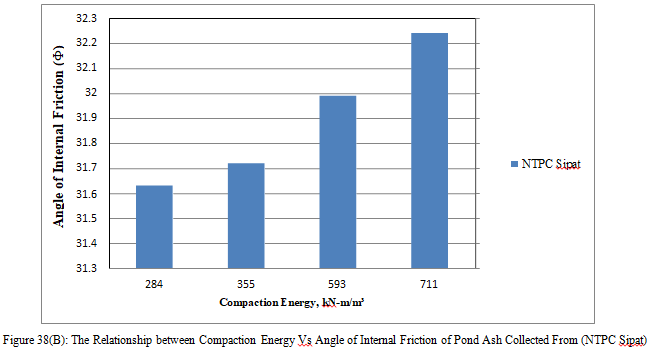

Table 4.9: Strength Parameters of Pond Ash

|

Sl. No. |

Compaction Energy (kN-m/m3) |

Sample |

|

|

Pond Ash (NTPC Sipat) |

|||

|

Cohesion (kpa) |

Angle of internal friction (?) |

||

|

1 |

Increased modified 30 blows/layer (3244.6 kN-m/m3) |

10.95 |

35.97 |

|

2 |

Modified 25 blows/layer (2703.8 kN-m/m³) |

10.82 |

35.49 |

|

3 |

Reduced modified 15 blows/layer (1622.3 kN-m/m³) |

10.28 |

33.86 |

|

4 |

Reduced modified 12 blows/layer (1297.8 kN-m/m³) |

10.11 |

33.36 |

|

5 |

Increased standard 30 blows/layer (711.6 kN-m/m³) |

9.6 |

32.24 |

|

6 |

Standard 25 blows/layer (593.0kN-m/m³) |

9.49 |

31.99 |

|

7 |

Reduced standard 15 blows/layer (355.8 kN-m/m³) |

8.80 |

31.72 |

|

8 |

Reduced standard 12 blows/layer (284.6 kN-m/m³) |

8.59 |

31.63 |

The Relationship between Compaction Energy Vs Cohesion

For Fly Ash

The Relationship between Compaction Energy Vs Angle of Internal Friction (?)

For Fly Ash

Conclusion

A. Summary and Conclusion The study highlights the significant impact of variation in compaction energy on the dry density and optimum moisture content (OMC) of both Fly Ash and Pond Ash, collected from NTPC Sipat, Chhattisgarh. It was observed that with an increase in compaction energy, the maximum dry density (MDD) of the materials increases, while the OMC decreases. This inverse relationship is a critical factor in achieving optimal compaction in geotechnical applications. For Fly Ash, subjected to Standard Proctor compaction energy, the MDD varied between 0.90 to 1.59 gm/cc, with an OMC range of 18% to 27%. Similarly, Pond Ash exhibited a lower MDD, ranging from 0.856 to 1.248 gm/cc, while its OMC was significantly higher, between 33% and 46%. These variations indicate that Fly Ash achieves higher densities at lower moisture content compared to Pond Ash under the same compaction energy, suggesting Fly Ash may be more suitable for stabilization applications where higher densities are required. The hydrometer analysis was conducted to assess the grain size distribution of materials passing through a 75 ?m sieve. The plot of percentage finer versus particle diameter was used to determine the soil gradation characteristics. The coefficient of curvature (Cc) and coefficient of uniformity (Cu) were found to be 1.26 and 5.66, respectively, indicating moderately well-graded particles. These parameters are crucial in predicting the compaction behavior and the material\'s suitability for use in road construction and embankments. B. Scope For Further Research 1) Long-Term Performance Evaluation: Future studies should focus on the long-term performance of Fly Ash and Pond Ash in field applications, particularly in road sub-base layers and embankment construction. Monitoring settlements, strength parameters, and moisture variations over time will provide valuable insights into their durability and performance under real-life conditions. 2) Compaction Energy Optimization: Research can be directed towards optimizing compaction energy for both Fly Ash and Pond Ash for specific engineering applications. Varying the energy levels beyond the Standard Proctor test can help identify an optimal balance between MDD, OMC, and energy efficiency, reducing the cost of compaction without compromising material stability. 3) Blended Materials: Further research can explore the potential of blending Fly Ash and Pond Ash with other stabilizing agents, such as lime, cement, or bitumen emulsions, to enhance their mechanical properties. Investigating the chemical and physical improvements in such blends will contribute to more robust road construction and stabilization techniques. 4) Environmental Impact Assessment: Considering the growing concern over the environmental impacts of ash disposal, a detailed environmental assessment of using Fly Ash and Pond Ash in construction can be a significant future study. Evaluating leachate characteristics, carbon footprint, and sustainability in comparison to conventional materials could help promote the use of these industrial by-products. 5) Advanced Geotechnical Analysis: Incorporating advanced geotechnical analysis techniques such as cyclic triaxial testing and resilience modulus testing can provide a deeper understanding of the material behavior of Fly Ash and Pond Ash under repetitive loading conditions, especially for applications in high-traffic roads and pavements. 6) Field Application and Scale-Up Studies: Pilot projects should be conducted to assess the real-world applicability of the materials studied in this research. A detailed cost-benefit analysis, construction feasibility, and lifecycle performance of Fly Ash and Pond Ash under different climatic and loading conditions would offer comprehensive data for large-scale implementation. 7) Hydraulic and Erosion Resistance Studies: Future research can also evaluate the hydraulic conductivity and erosion resistance of Fly Ash and Pond Ash when used in embankments or as part of land reclamation projects. Understanding these characteristics is essential in designing stable, long-lasting infrastructure projects, especially in flood-prone areas. 8) Suitability in Non-Motorized Transportation Infrastructure: Given the increasing focus on sustainable transportation, Fly Ash and Pond Ash can be explored as potential materials for constructing pavements and pathways in non-motorized transportation infrastructure. Their performance in low-load bearing, yet critical projects, can enhance sustainable urban infrastructure development.

References

[1] Bera, A. K., Ghosh, A., and Ghosh, Amalendu (2007). “Compaction characteristics of pond ash”. J. Mater. Civ. Eng. 2007.19:349-357. [2] Gray, D. H., and Lin, Y. K. (1972). “Engineering properties of compacted fly ash.” J. Soil Mech. and Found. Div., 98(4), 361–380. [3] Gurtug, Y., and shridharan, A. (2004). “Compaction behavior and prediction of its characteristics of fine grained soils with particular reference to compaction energy,” Soils and Foundation, 44(5), 27-36. [4] Omar, M., Abdallah, S., Basma, A., and Barakat, S. (2003). “Compaction characteristics of granular soil in the United Arab Emirates.” Geotechnical and Geological engineering, 21(3), 283-295. [5] Osman, S., Togrol, E., And Kayadelen, C. (2008). “Estimating compaction behavior of fine-grained soils based on compaction energy,” Canadian Geotechnical Journal, 4(6), 877-887. [6] Patra, C. R., Sivakugan, N., and Das, B M. and Rout, S. K. (2010). “Relative density and median grain-size correlation from laboratory compaction tests on granular soil”. International journal of geotechnical engineering 10.3328/IJGE.2010.04.02. [7] Patra, C. R., Sivakugan, N., and Das, B M. (2010). “Relative density and median grain-size correlation from laboratory compaction tests on granular soil\". International journal of geotechnical engineering 10.3328/IJGE.2010.04.01. [8] Singh S. P., Sharan A. (2013), Strength characteristics of compacted pond ash, Geo mechanics and Geo engineering: An International Journal, Vol 9, No. 1, 9 – 17. [9] Das, S. K., Yudhbir. (2005). “Geotechnical characterization of some Indian fly ashes.” Journal of Materials in Civil Engineering, ASCE, 17(5), 544-552. [10] Gray D. H. and Lin Y. K. (1972). “Engineering properties of compacted fly ash.”J. Soil Mech. Foundation Engineering, ASCE, 98, 361–380. [11] McLaren R.J. and Digioia A.M. (1987). “The typical engineering properties of fly ash.” Proc., Conf on Geotechnical Practice for Waste Disposal, ASCE, New York, pp:683-697 [12] N.S Pandian, C. Rajasekhar and A. Sridharan (1998), “Studies on the specific gravity of some Indian coal ashes”, J. Testing Evaluation, ASTM, 26, pp: 177-186. [13] Pandian, N.S. (2004). “Fly ash characterization with reference to geotechnical applications.” J. Indian Inst. Sci., 84, pp:189-216 [14] Sridharan, A., Pandian, N.S. and Srinivasa Rao, P. (1998),”Shear strength characteristics of some Indian fly ashes”, Ground Improvement, Vol. 2, No. 3,pp:141-146 [15] Sridharan, A., Prakash, K., (2007), “Geotechnical Engineering characterization of coal Ashes. CBS publishers Ltd. [16] IS: 2720 (Part-3, section-1)1980 “Determination of specific gravity Section 1 fine grained soils”. [17] IS 2720 :( 1980-Part-III/sec2) Method of test for soil, Determination specific gravity. [18] IS: 2720 (part 8)-1983 “Determination of Water Content-Dry Density Relation Using Heavy Compaction”. [19] IS: 2720 (part 7)-1980 “Determination of Water Content-Dry Density Relation Using Light Compaction”. [20] IS code: 2720 (part4)-1985 “Grain size analysis”. [21] IS 2720 (part13) 1986 “Direct shear test”. [22] IS: 2720 (part17)-1986 “Laboratory Determination of Permeability”.

Copyright

Copyright © 2024 Chandrakant ., Dr. R. R. L. Birali, Akhand Pratap Singh. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64372

Publish Date : 2024-09-27

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online