Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Comparative Analytical study of GFRP strengthened Deep Beams

Authors: Irshad Khan, Rajkiran Singh

DOI Link: https://doi.org/10.22214/ijraset.2025.66444

Certificate: View Certificate

Abstract

Deep beams play a very significant role in the design of mega and as well as small structures. Sometimes for architectural purposes, buildings are designed without using any columns for a very large span. The flexural behavior of deep beams with and without web reinforcement and strengthened with GFRP strips and steel fiber-reinforced concrete (SFRC) was investigated in this paper. CFRP has been used extensively for strengthening of RCC structures. In this study GFRP strips are used as an alternative. GFRP strips have been used in place of CFRP strips. The four-point flexural response of one reference beam strengthened with high-performance fiber-reinforced concrete was investigated by carrying out a FEM analysis using ANSYS software and comparing it with theoretical calculation done as per ACI code using Strut Tie Model. The analytical and theoretical data (strain, load, etc.) are compared and discussed. For comparison the results from an earlier study [11] on CFRP strengthened deep beams is used as a reference. The RC and SFRC deep beams showed formation of compression struts. The deflection and shear stress values for FRC deep beam were comparatively lesser than RC deep beam and an increase in load carrying capacity was observed with reduced deflection. It was observed that the GFRC strengthened deep beams produced better results than the CFRC strengthened beams. SFRC-GFRP strengthened deep beam showed the highest ultimate load value compared to other options. While values of deflection were reduced in both GFRP strengthened RC and SFRC deep beams. RC-GFRP, SFRC- GFRP strengthened and SFRC showed reduction in shear stresses compared to RC deep beam.The study suggests that GFRP strengthened FRC deep beam is a better alternative to RC deep beams as it has better ultimate strength and shear stress values compared to RC deep beams and GFRP being an economical and sustainable option can be an alternative to strengthening with CFRP wraps.

Introduction

I. INTRODUCTION

Literature review and research suggests that Deep Beam behavior is different from that of normal beams. Type of failure in deep beams differs from that of a normal beam. Increase in web reinforcement increases the shear strength of the beam. Providing shear links in a deep beam is a practical complication so alternate methods of shear strengthening should be explored. Mechanisms of failure in a beam with or without web reinforcement remains the same and additional quantity of web reinforcement is required to change the failure mode. Hence it becomes imperative to explore other methods of shear strengthening. To avoid sudden failures and to achieve ductile failures steel fibre reinforced concrete is being used. CFRP wraps are being used as common retrofitting material for structural elements and it helps in shear strengthening and avoiding strut crushing in beams. Alternate materials like GFRP which are economically viable, sustainable and easily available for shear strengthening need to be investigated further.

Research work is available for comparison of RC and SFRC deep beams with and without CFRP wrapping, however use of GFRP wrap in place of CFRP needs to be further investigated. This project work intends on obtaining the analytical results of the behavior of RC and FRC deep beams having no web reinforcement and strengthened with GFRP wrapping. The main objectives of the analytical study are:

-

-

- To study the behavior of RC and SFRC deep beams without web reinforcement.

- To study the behavior of RC and SFRC deep beams with the GFRP strips.

- Comparing the behavior of RC and SFRC beams and with GFRP strengthening.

- Comparing the behavior of CFRP strengthened beams and GFRP strengthened beams.

-

II. METHODOLOGY

A. Design of the beam [11]

Design of Deep beam is carried out using ACI 318-014 by using STM method which claims that the deep beams develop struts between support and loading conditions and a tie is connecting horizontally between both supports.

The simply supported deep beep beam is designed according to ACI 318-14 [1].

B. Strengthening using GFRP wrapping

By replacing the 0.4% of web reinforcement the GFRP strips are to be provided both sides in shear span to prevent the diagonal cracking effectively. For designing the GFRP strips ACI-440R is used [2].

C. Steel Fiber Reinforced Concrete (SFRC)

Steel fibers are used to replace the web reinforcement in RC deep beams. The steel fiber is added to concrete to effective replacement of stirrups and to provide shear reinforcement into RC deep beams and to improve crack control. Hence the steel fibers 1% volume of concrete and 60 aspect ratio were used in M30 concrete and SFRC said to have young’s modulus of 41500 MPa.

D. Modelling and analysis

ANSYS is a finite element software which can be utilized for modelling and analyzing the RC and SFRC deep beams as well as the deep beams with GFRP strips. Modelling and analysis is carried out in ANSYS.

E. Comparison of results

The obtained results of shear strength and mode of failure as well as cracking patterns are the compared between RC-GFRP wrapped beam and SFRC deep beam as well as SFRC- GFRP wrapped beam. Also, a comparison is made for CFRP strengthened beams and GFRP strengthened deep beams.

III. DESIGN OF DEEP BEAM

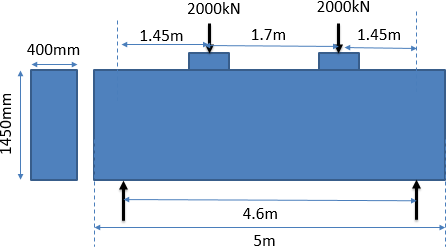

Deep beams cannot be analyzed using normal methods of flexural analysis. There will be a combined effect of shear and flexure. The beam was analysed using the strut tie model as per ACI 318-14. The girder shown in the following Fig.4.1 will be designed to resist the applied loads. The results obtained from a Strut-and-Tie Model following ACI 318-14 procedure, was then compared with numerical FEA results obtained from ANSYS. [11]

Design Data: Assumed ????????′ = 30 MPa, ????????= 415 MPa

Fig. Deep beam

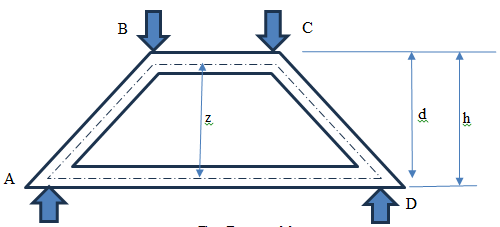

1) Truss Model

Fig. Truss model

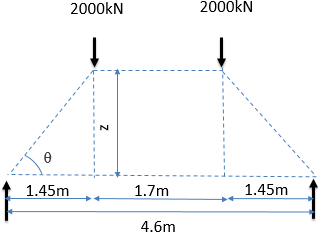

Fig. STM of the deep beam

2) Design Reinforcement for Tie Connecting Nodes:

Provide 12 no of 25mm diameter bars as tie reinforcement.

And 10mm dia stirrups @ 200mm c/c for the longitudinal tie reinforcement. And 10mm dia horizontal bars @ 200mm c/c on each side face as horizontal reinforcement.

3) GFRP Strengthening

Using GFRP strips to replace the horizontal web reinforcement. The total young’s modulus of 20 GPa of GFRP strips. The design shear strength of a concrete and GFRP should not exceed the required shear strength. The design shear strength is calculated as per ACI- 318 [1]. And strips are provided to increase the shear strength as per ACI-440.02R [2].

Using the equations from ACI-440R the GFRP strips were designed to be used for effective strengthening of deep beams are of 100mm wide 2mm thick with 200mm c/c spacing at an angle 45° placed on a width of 1.45m from either sides of supports. With effective bonding length of 400mm on either sides of the beam. And a total Young’s modulus of 20GPa of Glass FRP strips.

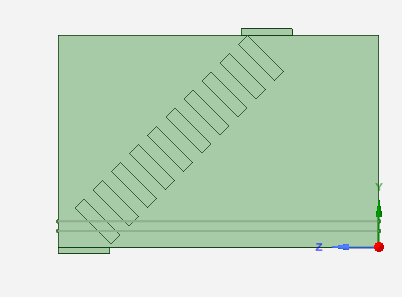

IV. MODELLING

3D deep beam models for RC deep beam (RC), fiber reinforced concrete deep beam (FRC), glass fiber strengthened reinforced concrete deep beam (RC-GFRP) and carbon fiber reinforced FRC deep beam (SFRC-GFRP) were created in ANSYS 18.1 space claim. The deep beams are designed with a width of 400mm, total depth of 1450mm and a total length of 5m. And the GFRP strips having 100mm width and 200mm center to center spacing and 400mm depth are modelled at an angle 45° located at shear span length.

Fig. GFRP strengthened deep beam model

Setup

Analysis is carried out in ANSYS. The models created in space claim were transferred to mechanical APDL to perform analysis and results were obtained. A load of 2000kN was applied on bearing plate. A simply supported connection was created as a boundary condition. Symmetry conditions were used to reduce computational time symmetry of beam taken at midspan.

V. RESULTS AND DISCUSSIONS

RC and FRC deep beams with and without GFRP strengthening were analyzed in the ANSYS mechanical APDL and results were compared for maximum deflections at an applied load. Normal and shear stresses developed were compared in order to check if there was any additional shear strengthening due to GFRP used instead of CFRP. Cracking patterns for RC and FRC deep beams were compared. Finally CFRP and GFRP strengthened beams are compared.

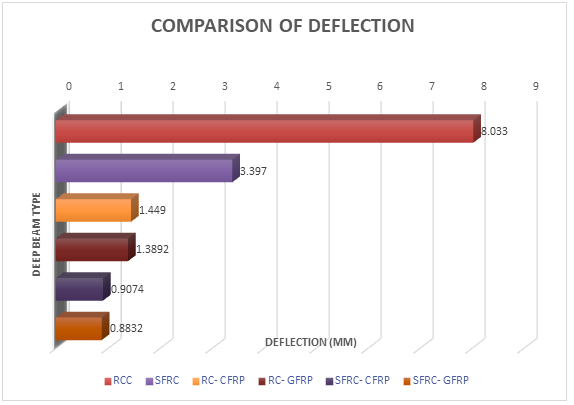

A. Deflection

The mid span deflection of the deep beams were obtained after analyzing in ASYS18.1 at a load of 2000kN. As shown in table 2 the deflection values obtained in the FRC deep beams were relatively lesser compared to RC deep beam and the GFRP strengthened RC deep beams showed lower values for Deflection. SFRC-GFRP had the lowest deflection for the applied load. Hence without any web reinforcement the GFRP Strengthened deep beams showed better results compared to their respective RC and SFRC deep beams and those strengthened with CFRP.

Table Comparison of Max mid span Deflection in Deep Beam

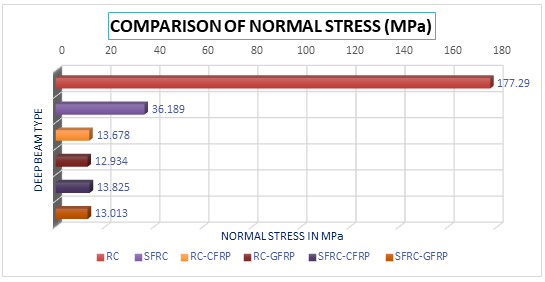

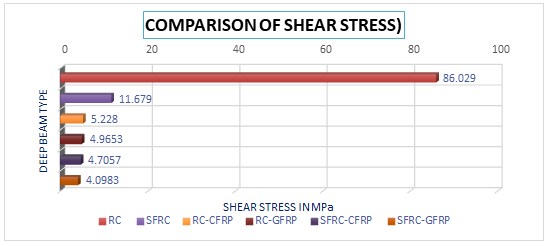

B. Comparisons of Normal stress and shear Stress

Normal and shear stresses in the modelled beams were compared. GFRP strengthened deep beams showed lower values of the stresses produced due to applied loading compared to their respective RC and FRC deep beams. FRC however showed better results compared to RC deep beams. It indicates that the shear capacity of the beams were considerably improved by the use of GFRP strips in the shear span region as the stress contours depicted that the maximum shear stress and equivalent stresses and strains were observed at the shear span region forming struts. Hence GFRP strips effectively resists the stresses in struts more than CFRP strips.

Fig. Normal Stress Comparison

Fig. Shear Stress Comparison

Conclusion

1) The RC and SFRC deep beams showed formation of compression struts. The deflection and shear stress values for SFRC deep beam were comparatively lesser than RC deep beam. A total of 43% decrease in deflection and 74% decrease in shear stress was observed in SFRC deep beam. The ultimate load capacity increased by 33% in SFRC deep beam compared to RC deep beam. Diagonal shear cracks were observed in RC deep beam along shear span ratio and reduction of such cracks were observed in SFRC and crack progression also decreased.[11] 2) The CFRP strengthened RC and FRC deep beams showed reduction in size of compression struts. The deflection values in strengthened beams were comparatively lesser, a total of 74.4% and 82% decrease compared to RC deep beam. The shear stress was observed to be decrease by 92% and 93.5% in strengthened RC, SFRC deep beam compared to RC deep beam model. While the ultimate load capacity increased by 29.45% and 42.47% in CFRP strengthened RC and SFRC deep beam compared to RC deep beam.[11] 3) As compared to CFRP strengthened beams GFRP strengthened beams show better results for the same configurations. It was observed that the RC-GFRC beams show a reduction in 4.12% in deflection as compared to RC-CFRP beams whereas SFRC-GFRP strengthened deep beams show a reduction of 2.66% in the deflection values as compared to SFRC-CFRP strengthened beams. 4) The RC-GFRC beams show a reduction in 5.44 % in normal stress as compared to RC-CFRP beams whereas SFRC-GFRP strengthened deep beams show a reduction of 5.87 % in the Normal stress values as compared to SFRC-CFRP strengthened beams. 5) In shear too GFRC strengthened beams fared slightly better than CFRP strengthened beams. The RC-GFRC beams show a reduction in 5.02 % in Shear stress as compared to RC-CFRP beams whereas SFRC-GFRP strengthened deep beams show a reduction of 12.90 % in the Shear stress values as compared to SFRC-CFRP strengthened beams. The analytical study suggests that GFRP can be used as an alternate to CFRP to strengthen Deep beams, also SFRC Deep beams with GFRP strengthening is a better alternative as it has better ultimate strength and shear stress values compared to SFRC-CFRP.

References

[1] ACI 318, Building Code Requirements for Structural Concrete. 2014. [2] ACI 440.2R, Guide for the Design and Construction of Externally Bonded FRP Systems. 2008. [3] IS 456 – 2000 : Code of practice for Plain and reinforced Concrete. [4] Zhe Li,Ye Li, Wei-Jian Yi “Shear Mechanism and Size Effect of RC Deep Beams without Stirrups Based on Crack Kinematics in Tests” Journal of Structural engineering – ASCE, 1 Nov 2023. [5] Julian Carrillo, Eyli Salcedo, Fabian Rojas “Evaluating Direct Shear Performance of Steel fibre Reinforced concrete” Journal of Materials in Civil Engineering, 2024. [6] Mohammad Panjehpour, H. K. Chai, and Y. L. Voo, “Strut deformation in CFRP- strengthened reinf. concrete deep beams,” Sci. World J., vol. 2014, pp. 1–9, 2014. [7] Zahid Hussain Khaskheli, Antonio Nanni, “Strut and tie method for GFRP-RC Deep members” International Journal of Concrete Structures (Springer Nature) - Vol. 18, Iss: 1 Dated 11 July 2024. [8] Aref A Abadel, “Shear strengthening of deficient RC deep beams using NSM FRP system: Experimental and numerical investigation” Materials Science Poland - Vol. 42, Iss: 1, pp 140-15, 1 March 2024 [9] S. Park and R. Aboutaha, “Strut-and-Tie Method for FRP strengthened deep RC members,” Bridge Maintainance, Saf. Manag. Heal. Monit. Informatics - IABMAS ’08, vol. 135, no. 6, pp. 632–643, 2008. [10] Yasar Ameer Ali, Tameem Mohammed Hashim, Alaa Hussein Ali, “Finite Element Analysis for the Behavior of Reinforced Concrete T-Section Deep Beams Strengthened with CFRP Sheets’ Key Engineering Materials, 857:153-161. doi: 10.4028/www.scientific.net/kem.857.153 [11] Hiremath, G., and Yendigeri, A. N. (2022). “A Parametric Study on the Behavior of RC and FRC Deep Beams with and without CFRP Strengthening using ANSYS” i-manager’s Journal on Structural Engineering, 11(2), 15-22. [12] Aref A Abadel Abdulrahman S. Albidah. “Investigation of shear Reinforcement schemes for Deep Beams” Arabian journal of Science and Engineering, 21 December 2020, Volume 46, pages 4747–4763, (2021) [13] M. K. Dhahir, “Shear strength of FRP reinforced deep beams without web reinforcement,” Compos. Struct., vol. 165, pp. 223–232, 2017.

Copyright

Copyright © 2025 Irshad Khan, Rajkiran Singh. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET66444

Publish Date : 2025-01-09

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online