Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Comparison of Dry, Wet and Microwave Digestion Procedures for the Determination of Heavy Metal in Yoghurt Samples

Authors: Aarti Bansal, Ram Bilas Meena, Monika Dakshene

DOI Link: https://doi.org/10.22214/ijraset.2024.63503

Certificate: View Certificate

Abstract

This work proposes a novel technique for utilizing the most suitable digestion process to determine concentrations of heavy metals such as Pb, Cd, Al, As, Zn, and Fe in Yoghurt samples using AAS. Conventional digestion techniques often involve time-consuming and tedious procedures, which leads to the loss of analyte and reduced accuracy. In this study, we propose the utilization of microwave-assisted digestion, a rapid and efficient technique that offers complete digestion of the samples and minimizes the risk of analyte loss. In order to get optimal efficiency and precision, this study outlines the optimization of the microwave-assisted digestion parameters, such as power, time, and reagent concentrations. The proposed method was validated by calculating the recovery % among dry, wet and microwave digestion methods. Results show that among all, the recovery percentage was found to be highest in the microwave digestion method.

Introduction

I. INTRODUCTION

Dairy products are a necessary component of the human diet, a number of environmental and processing conditions may cause heavy metal contamination in them [1,2]. Heavy metals such as lead, cadmium, and mercury may enter in dairy products from many different kinds of sources including soil, water, and agricultural procedures [3]. When heavy metals present in excess, including lead, cadmium, mercury, and arsenic can be extremely harmful to one's health [4]. In order to protect the public's health and uphold customer confidence, milk and dairy product quality and safety must be ensured. Because heavy metals are poisonous and can build up in the food chain, they constitute one of the biggest potential risks [5-7].

For the purpose of protecting the public's health, precise and effective techniques for heavy metal analysis in dairy products are thus necessary [8]. One common characteristic of traditional methodologies for heavy metal analysis in dairy products is that it takes more time for sample preparation.

This may result in insufficient digestion and complicate to precisely measuring the metal concentration by the use of atomic absorption spectrophotometry (AAS). To overcome these challenges, a novel approach utilizing microwave-assisted digestion has been developed with the aim of increasing the efficiency of dairy product digestion for precise heavy metal detection via AAS [9-11]. This new approach has been proposed that utilizes microwave-assisted digestion, which is an advanced technique for sample preparation that breaks down complex matrices fast and efficiently with the help of microwave energy [12, 13].

Compared to traditional methods, this technology ensures complete and thorough digestion of dairy samples in a fraction of the time by considerably speeding up the digestive process. As a result, there is a significantly lower chance of incomplete digestion, which enhances accuracy and precision in the heavy metal analysis that follows using AAS. For the detection of heavy metals, the atomic absorption spectrophotometry method provides good sensitivity and selectivity [14-16]. It is based on the idea of detecting the wavelengths of light that metal atoms in a vapour state absorb. Heavy metal concentrations in the dairy samples that have been digested can be precisely and reliably measured by measuring the quantity of light absorbed.

The main aim of this study is to compare the digestion techniques to analyse six heavy metals (Pb, Cd, Al, As, Fe and Zn) in Yoghurt samples collected from different areas of Jhalawar district, Rajasthan. In this paper, we report microwave digestion as the best technique among dry, wet and microwave digestion methods. A detailed methodology of the innovative microwave-assisted digestion approach and its applications are mentioned.

II. MATERIALS AND METHODS

A. Materials: Yoghurt Samples Collection

A total of 20 Yoghurt samples were collected from more polluted and less polluted sites in Jhalawar district. Individual farms and local shops in these areas were taken into account. All the Yoghurt samples were collected in PTFE bottles and kept at -20°C in a deep freezer until analysis.

B. Digestion Reagents

- Concentrated Nitric Acid (65% HNO3)

- Hydrogen peroxide (30% H2O2)

- Deionized or Distilled Water

- To prepare calibrated standards, a stock standard solution containing 1000 mg L-1 of each element was utilized. Just before analysis, the calibrated solutions were made from the stock solution using deionized water.

C. Digestion Techniques

The dairy product samples were subjected to three different types of digesting processes: dry, wet, and microwave digestion. The digestion procedures are given below.

- Dry Digestion

One gram of Yoghurt sample was placed in a porcelain crucible and dried in a furnace at 100 ?C. A gradual increase in temperature from 100?C to 500?C was made. After ashing the material for around seven or eight hours, a white or grey ash residue was obtained. 5 mL of 65% v/v HNO3 was used to dissolve the residue and the mixture was slowly heated to further dissolve the residue. After that, the mixture was poured into a 10-mL volumetric flask and brought to volume. A blank digest was carried out in the same way.

2. Wet Digestion

One gram of Yoghurt sample was treated with 5 ml of nitric acid (65% HNO3) and 2 ml of hydrogen peroxide (30% H2O2) and digested at 90ºC temperature on an electric hot plate. After that, the temperature increased up to 120ºC until brown fumes disappeared, which indicated the completion of oxidation of organic matter. The organic matrix of Yoghurt was destroyed and left the elements into a clear solution, after cooling, the clear solution was filtered into a volumetric flask of 25 ml capacity and made to the mark with DI water, and finally, the milk samples were ready to analyze by AAS.

3. Microwave Digestion

One gram of yoghurt sample was digested with 4 mL of HNO3 (65%) and 2 mL of H2O2 (30%) in the microwave digestion system. The digestions of samples were carried out at different conditions summarized in Table 1. Resulted solution was transferred into 10 mL volumetric flask and diluted with deionized water. A blank digest was carried out in the same way. All sample solutions were clear.

TABLE I

Microwave Digestion Conditions

|

Step |

Time (min) |

Power (W) |

|

1 |

2 |

200 |

|

2 |

2 |

200 |

|

3 |

4 |

400 |

|

4 |

6 |

400 |

|

5 |

8 |

600 |

|

6 |

8 |

VENT |

4. Method Validation

To get the best method among the dry, wet and microwave digestion methods, we conduct a recovery test in which a known concentration (spiked concentration) was added to the sample. The quantities for the spike chosen were only 5-8% to ensure that there would be no significant change from the amount normally present in the main sample. After analyzing these samples by AAS the recovery percentages were calculated by the using of following equation[17]:

The results are shown in Table 2 and were obtained using the above procedure to determine the various recovery percentages for various approaches.

TABLE II

Comparison of heavy metal contents (mg/L) in yoghurt samples determined by AAS after digestion using three different methods, n = 5

|

Metal |

Dry ashing M1 |

Recovery (%) |

Wet ashing M2 |

Recovery (%) |

Microwave M3 |

Recovery (%) |

|

Pb |

0.1121 |

91.95 |

0.1125 |

94.63 |

0.1129 |

97.31 |

|

Cd |

0.0268 |

82.61 |

0.0272 |

88.41 |

0.0278 |

97.10 |

|

Al |

0.0886 |

91.96 |

0.0891 |

93.30 |

0.0898 |

95.17 |

|

As |

0.0283 |

87.5 |

0.0284 |

89.58 |

0.0286 |

93.75 |

|

Fe |

1.1901 |

91.26 |

1.2008 |

93.17 |

1.2189 |

96.40 |

|

Zn |

0.8242 |

89.20 |

0.8269 |

90.14 |

0.8427 |

95.64 |

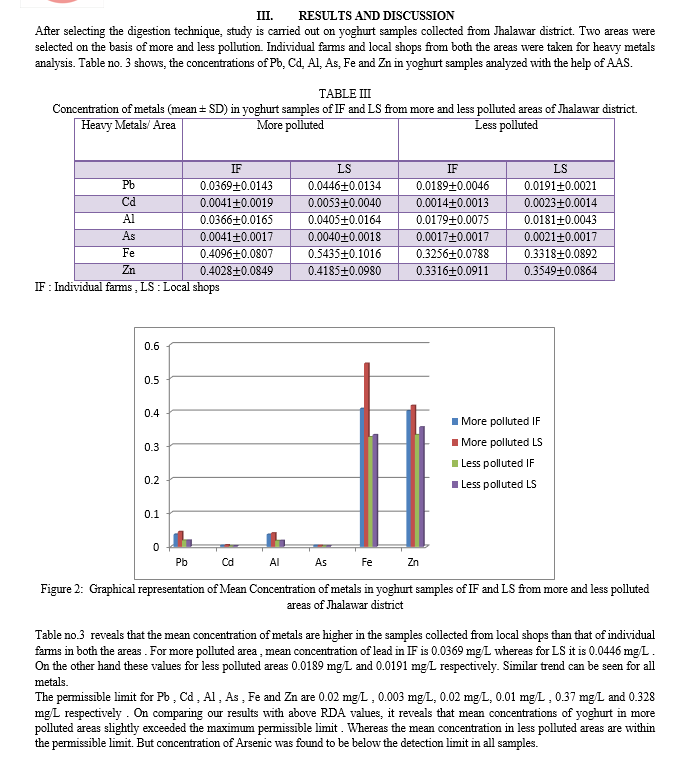

Table 2 shows that the recovery percentage for microwave digestion is greater than that of both dry and wet digestion methods. In dry digestion method it ranges from 82.61 % - 91.96 %, in wet digestion method it ranges from 88.41 % - 94.63 % where is in microwave digestion method it ranges from 93.75 % - 97.31 %. The approximate time required for dry, wet and microwave digestions were 8 hr, 3 hr and 30 min, respectively. In light of these results, the microwave digestion procedure was found to be the best digestion method and chosen for the whole study.

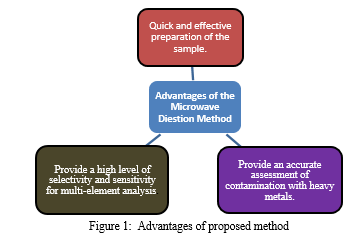

5. Advantages of the Proposed Method

By using this suggested approach, labs may effectively analyze several dairy product samples for the presence of heavy metals, ensuring accordance to food safety regulations and protecting the general public's health. The benefits of the suggested approach are shown in Figure 1 below.

Conclusion

Based on analysis following conclusions are drawn: The dry and wet digestion methods are more time consuming and complicated than the microwave digestion method. The microwave heating provides complete sample digestion and reduces the overall analysis time providing better and safer method for sample preparation. The combination of microwave digestion with AAS provides high accuracy and sensitivity for heavy metal analysis in yoghurt samples. The results shows that the mean concentration of heavy metals is found comparatively higher in more polluted areas. The above study clearly indicates that the concentration of heavy metals in yoghurt influenced by the anthropogenic activity.

References

[1] Wang, J., Zhang, Q., Jin, M., Li, P., & Wang, Q. (2011). Fast digestion and determination of heavy metals in dairy products by microwave digestion-ICP-MS. Journal of Food Composition and Analysis, 24(8), 1178-1183. [2] Bai, L., Li, P., Li, Q., Zhang, Y., Wang, F., & Li, J. (2017). Development and validation of an improved method for determination of heavy metals in milk by high-resolution inductively coupled plasma mass spectrometry. Food Analytical Methods, 10(3), 585-594. [3] Moros, J., Maestre, S. E., Todolí, J. L., & De La Guardia, M. (2017). Rapid and simultaneous determination of essential and toxic metals in dairy products by vortex-assisted liquid-liquid microextraction and electrothermal atomic absorption spectrometry. Talanta, 167, 471-478. [4] Borowska, E. J., & Polkowska, ?. (2011). Direct slurry sampling for multi-element analysis of dairy products by inductively coupled plasma atomic emission spectrometry (ICP-AES). Analytical Methods, 3(9), 2018-2023. [5] Dakshene Monika & Meena Ram(2022). Assessment of Lead in Raw Milk of Rural and Urban Areas of Kota, Rajasthan International Journal of Engineering Research & Technology (IJERT) Vol. 11 Issue 12, December 2022. [6] Pérez-Fernández, R., García-Sartal, C., & Martínez-Carballo, E. (2014). Heavy metal speciation in milk and dairy products: a review. Food Additives & Contaminants: Part A, 31(10), 1624-1635. [7] Dakshene Monika & Meena Ram(2023). Assessment of Cadmium in Raw Milk of Rural and Urban Areas of Kota, Rajasthan. Ijsrm. Human, 2023; Vol. 23 (3): 1-10. [8] Bárány, E., Derdáková, M., Šimon, P., Ondrašovi?ová, O., & Šimonová, A. (2012). Determination of trace elements in milk and dairy products by ICP-MS and ICP-OES in relation to dairy cows\' feed. Acta Chimica Slovaca, 5(2), 135-141. [9] Petrovi?, S., Doder, R., Vu?urevi?, N., & Risti?, M. (2015). The application of FAAS and GFAAS for determination of heavy metals in infant milk formula and dairy products. Food Analytical Methods, 8(8), 2040-2048. [10] Hao, J., Deng, Y., Song, X., Chen, S., & Wang, J. (2014). Optimization of microwave digestion for the determination of trace elements in milk powder and dairy products by ICP-MS. Food Analytical Methods, 7(8), 1719-1728. [11] Risticevic, S., Lord, H., & Pawliszyn, J. (2016). The impact of sample preparation in the analysis of melamine in dairy products by liquid chromatography with mass spectrometric detection. TrAC Trends in Analytical Chemistry, 80, 465-473. [12] Park, J. H., Kim, M. J., & Han, S. H. (2018). Effect of dairy products on heavy metals in vegetables and plants. Journal of Agriculture & Life Sciences, 52(1), 9-18. [13] Ashraf, M. A., Maah, M. J., & Yusoff, I. (2018). Heavy metals accumulation in vegetables with the application of different types of wastewater: A review. Environmental Science and Pollution Research, 25(7), 1-14. [14] Shahin, K., Stafilov, T., & Sajn, R. (2018). Multi-element determination of essential and non-essential elements in milk and dairy products from the Republic of Macedonia by ICPOES and ICP-MS. Journal of the Serbian Chemical Society, 83(8), 999-1011. [15] Y?lmaz, E., Apak, R., & Ünal, O. F. (2012). Microwave-assisted digestion of milk and dairy products for multi-element analysis by inductively coupled plasma optical emission spectrometry (ICP-OES). Talanta, 101, 452-460. [16] Montoro, R., Ruiz-Medina, A., & de la Guardia, M. (2015). Simple and rapid microwave digestion of milk and dairy products for flame atomic absorption spectrometry and direct determination of toxic metals. Talanta, 137, 83-88. [17] Muhib, M. I., Chowdhury, M. A. Z., Easha, N. J., Rahman, M. M., Shammi, M., Fardous, Z., & Alam, M. K. (2016). Investigation of heavy metal contents in cow milk samples from area of Dhaka, Bangladesh. International journal of food contamination, 3, 1-10.

Copyright

Copyright © 2024 Aarti Bansal, Ram Bilas Meena, Monika Dakshene. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63503

Publish Date : 2024-06-29

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online