Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental Investigation of Compressive Strength of Concrete through Conventional Concrete Mixer and Design of Automated Concrete Mixer with Machine Learning

Authors: Mr. Kamlesh Dayanand Patle, Ms. Mehvish Zabeen, Mr. Karan Ramesh Singh, Mr. Nikhil Sureshrao Surkar, Dr. Supriya Sawwashere, Prof. Atika Ingole

DOI Link: https://doi.org/10.22214/ijraset.2023.56333

Certificate: View Certificate

Abstract

Various issues with concrete mixing in concrete mixer machines have been observed. Engineers and employees can only make guesses and predictions based on the concrete they can see; they cannot determine the proper mixing of the concrete. However, there are times when the ratio is not kept even when the concrete is correctly mixed. In the difficult, multi-step process known as concrete mix design, we look for the ideal component ratio to produce concrete that functions properly. There are other ways to make concrete mixtures, but the Three Equation Method-based techniques are the most widely used. Compressive strength, which establishes the concrete class, is among the most significant characteristics of concrete. The compact strength that can be predicted is [4].

Introduction

I. INTRODUCTION

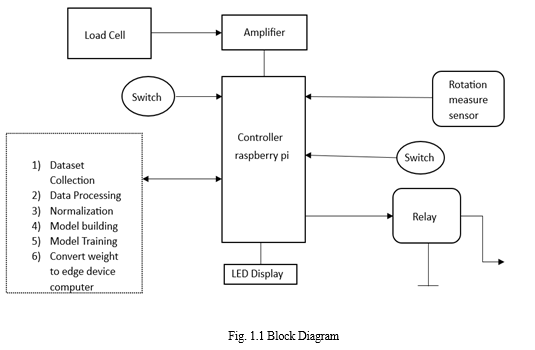

Concrete is building material which is in use worldwide. In this project we construct the machine or design the machine which is use in construction site to make the concrete. In this project we use drum tilting concrete mixture machine. We learn specification of concrete machine and install IOT sensors on concrete mixture machine, we use M20 grade of concrete with mix proportion and ratios of Cement, water, sand and aggregate. The concrete mixer has become one of the most important machines on construction sites due to the large scale and continuous demand for concrete. This also defines the grade or quality of the concrete that will be formed. We’ve seen a lot of issues with concrete mixing in the Concrete mixture machine, but the laborers and engineers aren’t sure if the concert is the perfect mix or not. This project applies IoT, ML (Internet of Things, and Machine Learning,) technology to concrete mixing plant equipment and proposes a creative IoT, and ML integrated system for concrete mixing plants. By using sand, cement, water, and aggregate as inputs, control engineering machine learning algorithms may automate the mixing of concrete. Multiple Linear Regression may be a suitable algorithm for predicting the time taken to become perfect in a concrete mix machine based on the input parameters of sand, cement, aggregate, water, and their ratios. Multiple Linear Regression assumes a linear relationship between the input variables and the output target, which is appropriate when the input variables are continuous and their relationship with the output target can be described as a linear combination. Additionally, with only six input variables, it may be feasible to interpret the coefficients of the model and determine the relative importance of each input variable. In this project, we are going to communicate with a raspberry PI with an Android-based smartphone using Bluetooth communication to control a concrete mixer.

II. LITERATURE REVIEW

Control engineering machine learning algorithms may automate the mixing of concrete by employing sand, cement, water, and aggregate as inputs. Learning for reinforcement A concrete mixture machine may call for both machine learning and control engineering in this sort of machine learning, where an agent learns to make decisions in an environment to maximize a reward signal. As part of this project, we'll use Bluetooth to connect an Android smartphone to a Raspberry Pi to drive a concrete mixer. Raspberry Pi is one of the most popular microcontroller-based electronics prototyping platforms available in the market.

The area of applications of Raspberry Pi is huge ranging from simple LED driving circuits to complex internet-based weather monitoring circuits. To allow communication between Raspberry Pi and Android-based smartphones, we need to use Bluetooth communication. Almost all Android-based devices have built-in Bluetooth communication modules. Hence, we need to use an external Bluetooth Module for the Raspberry Pi. The Raspberry Pi cannot be directly attached to the concrete mixture. The board's electronics could be harmed by the conductive components in the concrete mixture. Instead, we will operate the concrete mixture through a relay, which will serve as a conduit between the concrete mixture and the Raspberry Pi. Additionally, we employ several IoT components like sensors, module kits, cables, etc. for gathering the input data.

III. RESEARCH GAP

There is a lot of current research being done on the application of machine learning and IoT in civil engineering construction, particularly in automating concrete mixing machine sites and other related fields.

Here are some examples of recent research:

- A review article published in Frontiers in Built Environment in February 2023, titled “Machine Learning in Concrete Technology: A Review of Current Researches, Trends, and Applications” by Yaser Gamil, discusses the current applications and trends of machine learning techniques and applications in concrete technology1. The article highlights that machine learning techniques have been used to characterize materials based on image processing techniques, develop concrete mix designs based on historical data, and predict the behavior of fresh concrete, hardening, and hardened concrete properties based on laboratory data [1].

- A study published in 2023 in the Journal of Umm Al-Qura University for Engineering and Architecture used machine learning to determine the mix design method for normal strength concrete. The study, titled “Application of Artificial Neural Networks for Mix Design of Normal Strength Concrete,” used artificial neural networks (ANNs) to develop a mix design method for normal strength concrete. The results showed that the ANN model could accurately predict the mix proportions of normal strength concrete.[2]

- Another study published in 2019 in the Asian Journal of Civil Engineering compared various machine learning methods to predict the compressive strength of high-performance concrete. The study, titled “Comparison of Machine Learning Methods for Predicting Compressive Strength of High-Performance Concrete,” compared the performance of six machine learning methods: artificial neural networks (ANNs), support vector machines (SVMs), k-nearest neighbors (k-NN), decision trees (DTs), random forests (RFs), and gradient boosting machines (GBMs). The results showed that GBMs had the best performance in predicting the compressive strength of high-performance concrete.Here are the key points that differentiate our project from previous research in the field[3].

- Use of IoT applications: This project integrates IoT sensors into the concrete mixing machine to gather real-time data on factors such as material properties and equipment performance. This data can then be fed into machine learning algorithms to make accurate predictions about the time required to complete the perfect mixing of concrete.

- Focus on process optimization: This project aims to optimize the concrete mixing process itself by predicting the time required for perfect mixing and automatically turning the machine on and off based on this prediction. This is different from previous research, which has primarily focused on using machine learning techniques to predict the properties of concrete after it has been mixed.

- Combination of machine learning and IoT: By combining machine learning algorithms with IoT applications, our project can gather and analyze real-time data to make accurate predictions and optimize the concrete mixing process.

- Overall, our project represents a novel and innovative approach to improving the efficiency and accuracy of the concrete mixing process. By combining machine learning algorithms with IoT applications, we can gather and analyze real-time data to make accurate predictions and optimize the concrete mixing process

IV. PROBLEM STATEMENT

The mixer machine mixes the concrete but labor and Engineer are not sure either concert perfectly mix or not labor are just imagined and predicted after seeing the concrete. Improper mixture of concrete can damage in several ways. The traditional approach to prevent concrete and mix properly.

3) Benefits

- Improved efficiency: By predicting the time required for perfect mixing and automatically turning the machine on and off based on this prediction,this project can help improve the efficiency of the concrete mixing process. This can save time and resources while ensuring consistent quality.

- Data-driven Insights: The integration of IoT sensors into the concrete mixing machine allows for the collection of real-time data on factors such as material properties and equipment performance. Machine learning algorithms can analyze this data to provide actionable insights for optimizing processes and making informed decisions.

- Predictive Maintenance: The use of IoT sensors to monitor the condition of construction equipment can enable predictive maintenance, preventing costly breakdowns and improving equipment uptime.

- Enhanced safety: Machine learning algorithms can analyze data from IoT sensors to identify potential safety risks and hazardous conditions. This proactive approach can enhance on-site safety by allowing for timely interventions.

- Reduced Environmental Impact: Your project can help reduce the environmental impact of construction by optimizing resource allocation and reducing waste. Machine learning algorithms can analyze data from IoT sensors to provide insights into material usage, energy consumption, and waste generation.

4) Drawback

- Costs: The implementation of machine learning algorithms and IoT applications can involve significant upfront costs, including the purchase of sensors, software development, and staff training. It is important to carefully assess the costs and benefits to determine the feasibility of the project.

- Reliability: The reliability of machine learning algorithms and IoT applications can be affected by factors such as data quality, algorithm design, and sensor performance. It is important to regularly monitor and evaluate the performance of the system to ensure its reliability.

- Maintenance: The maintenance of IoT sensors and machine learning algorithms can require specialized knowledge and skills. It is important to ensure that staff are adequately trained and equipped to maintain the system

5) Future Scope

- The future scope of this project, which uses machine learning algorithms and IoT applications to predict the time required to complete the perfect mixing of concrete mixture, is vast. Here are some potential future developments and applications:

- Expansion to other construction processes: This project can be expanded to optimize other construction processes, such as material transportation, equipment scheduling, and resource allocation. By applying the same principles of machine learning and IoT integration, you can improve the efficiency and accuracy of these processes.

- Integration with Building Information Modeling (BIM): This project can be integrated with Building Information Modeling (BIM) systems to provide real-time data and insights into the construction process. This can help improve collaboration and decision-making among project stakeholders.

- Development of predictive maintenance algorithms: This project can be extended to develop predictive maintenance algorithms for construction equipment. By analyzing data from IoT sensors, machine learning algorithms can predict maintenance needs and prevent costly breakdowns.

- Enhancement of safety protocols: This project can be used to enhance on-site safety by identifying potential risks and hazardous conditions. Machine learning algorithms can analyze data from IoT sensors to provide real-time alerts and enable timely interventions.

- Reduction of environmental impact: This project can help reduce the environmental impact of construction by optimizing resource allocation and reducing waste. Machine learning algorithms can analyze data from IoT sensors to provide insights into material usage, energy consumption, and waste generation.

Conclusion

In conclusion, when it comes to running high-level machine-learning algorithms, Arduino is not the best option due to its limited processing power and memory. However, it can be used for implementing simpler machine-learning models. Additionally, collecting a good dataset is a critical step in any data-driven project or machine-learning application, and it can be challenging and time-consuming. Therefore, we are continuously working to collect a good dataset for our machine-learning algorithm. It\'s also crucial to carefully consider the data\'s characteristics and problem requirements before selecting a machine-learning algorithm. Finally, multiple regression is used in our case because it can handle multiple input features and provide insights into the strength and direction of their relationship with the output variable.

References

[1] Gamil Y (2023), Machine learning in concrete technology: A review of current researches, trends, and applications. Front. Built Environ. 9:1145591. doi: 10.3389/fbuil.2023.1145591 [2] Lauren Hinkel | MIT-IBM Watson AI Lab,Publication Date:,December 7, 2021 [3] M.A. DeRousseau a, E. Laftchiev c, J.R. Kasprzyk a, B. Rajagopalan a b, W.V. Srubar III a ,Mitsubishi Electric Research Labs, 201 Broadway FL8, Cambridge, MA 02139, USA ,Received 3 March 2019, Accepted 5 August 2019, Available online 27 August 2019, Version of Record 27 August 2019. [4] Patryk Ziolkowski* and Maciej Niedostatkiewicz,Materials (Basel). 2019 Apr; 12(8): 1256., Published online 2019 Apr 17. doi: 10.3390/ma12081256, PMCID: PMC6515295,PMID: 30999557 “Machine Learning Techniques in Concrete Mix Design” [5] Desai, Arjun, Harsh Bhutani, Abhishek Chavan, Atharva Chitnis, and Dharmesh Chowdhary. “Design and Analysis of a Portable Concrete Mixer.” International Research Journal of Engineering and Technology, no. July (2021): 4371–76. www.irjet.net. [6] Min Min Shwe Sin. “Design and Calculation of a Concrete Mixer (100 Kg).” International Journal of Engineering Research And V7, no. 08 (2018): 253–57. https://doi.org/10.17577/ijertv7is080085 [7] State of practice of automation in precast concrete production Sara Reichenbach *, Benjamin Kromoser Institute of Structural Engineering, University of Natural Resources and Life Sciences Vienna, Peter-Jordan-Straße 82, 1190, Vienna, Austria [8] Design and Fabrication of Automatic Dishwasher Machine R.B.Venkatesh UG Scholar: Department of Mechanical Engineering, K.L.N. College of Engineering, Pottapalayam-630612, India V.SivaramKumar Associate Professor: Department of Mechanical Engineering, K.L.N. College of Engineering Pottapalayam-630612, India [9] A Review Paper on Raspberry Pi and its Applications 1Hirak Dipak Ghael, 2Dr. L Solanki, 3Gaurav Sahu 1 Student, 2 Principal, 3 Assistant Professor, 123Department of Electronics and Communication Engineering, 123BKBIET, Pilani, India. Date of Submission: 25-12-2020 Date of Acceptance: 06-01-2021 [10] IOP Conf. Series: Materials Science and Engineering 981 (2020) 042009 IOP Publishing doi:10.1088/1757-899X/981/4/042009 1 Bluetooth and GSM based Smart Security System using Raspberry Pi Kashaboina Radhika1 , Dr. Velmani Ramasamy 2 1 PG Scholar, Department of ECE, Siddartha Institute of Technology and Sciences, Hyderabad, Telangana,India 2 Associate Professor and Head, Department of ECE, Siddartha Institute of Technology and Sciences, Hyderabad, Telangana, India [11] Weight-based Load Balancing in Raspberry Pi MPICH Heterogeneous Cluster with Fuzzy Estimation of Node Computational Performance Dmytro Zubov 1 and Andrey Kupin 2 1 University of Central Asia, 138 Toktogul St., Bishkek, 720001, Kyrgyzstan 2 Kryvyi Rih National University, 11 Matusevycha St., Kryvyi Rih, 50027, Ukraine

Copyright

Copyright © 2023 Mr. Kamlesh Dayanand Patle, Ms. Mehvish Zabeen, Mr. Karan Ramesh Singh, Mr. Nikhil Sureshrao Surkar, Dr. Supriya Sawwashere, Prof. Atika Ingole. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET56333

Publish Date : 2023-10-27

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online