Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experiment on Concrete by Adding Steel Fibers and Plastic Waste to Reduce Environmental Issues and Adding Strength to Concrete

Authors: Naveen Kumar Nadigatla

DOI Link: https://doi.org/10.22214/ijraset.2023.55997

Certificate: View Certificate

Abstract

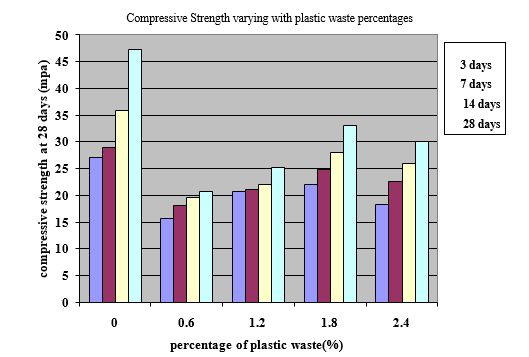

Concrete is the most commonly used material for construction in civil engineering. The project involves the proposed concrete which is made up of adding plastic in concrete may help to reuse the plastic as one of the constituent material of concrete. Due to rapid industrialization the amount of use and decomposition of plastic has increased. If we are able to utilize this waste under proper conditions as addition to concrete it will reduce the plastic waste up to some extent. By adding the steel fibers to the above mix it will increase the compressive strength of the concrete. M40 grade concrete is used in the whole procedure. Here, we used 4 different percentages of plastic waste (i.e., 0.6%, 1.2%, 1.8%, and 2.4%) of weight of cement and by taking quantity of steel fiber as constant (i.e., 2%) of weight of cement, and the aspect ratio of steel fibers is 60. The concrete cube of size 150mm×150mm ×150mm are prepared and tested at 3days, 7days, 14days and 28 days. The resulting data has been analyzed and compared with controlled specimens.

Introduction

I. INTRODUCTION

The importance of concrete in modern society cannot be underestimated. Look around you and you will find concrete structures every where such as buildings, roads, bridges and dams. There is no escaping the impact concrete mix on your everyday life. It is attractive in many applications because it offers considerable strength at a relatively low cost. Concrete can generally be produced of locally available constituents, can be cast into a wide variety of structural configurations, and requires minimal maintenance during surveys. Workability, strength and durability are the basics of concrete. Amount of useful internal work necessary to overcome internal friction to produce full compaction is called as workability. Size, shape, surface texture and grading of aggregates, water cement ratio, use of admixtures and mix proportions are important factors affecting workability.

Strength is to bear the desired stresses to bear within the permissible factor of safety in expected exposure conditions. The factors influencing strength are: Quality of cement, water cement ratio, grading of aggregates, degree of compaction, efficiency of curing, curing temperature, age at the time of testing, impact and fatigue. In the most of the structures, compressive strength is basically used to resist the compressive strength. Compressive strength is also used as qualitative measure for other properties of hardened concrete. Steel fibers can be defined as discrete, short length of steel having ratio of its aspect ratio in the range of 20 to 100. The steel fibers acts as crack arrestor and it will increase the tensile strength and toughness in concrete. It also reduces the maintenance cost and provides tough and durable surfaces.

Plastic is a synthetic material made from wide range of organic polymers such as polyethylene, PVC, nylon, etc... The plastic waste which we are using is of high density polyethylene. The density of polyethylene is ranges from 930 to 970 kg/m3. Generally, plastic takes more than 450 years to decompose. By the use of plastic waste in construction we can protect the environment and can also reduce the amount of disposal.

This study attempts to give a contribution to the effective use of domestic waste (plastic) in concrete as granules in order to prevent the environmental strains caused by them, also to limit the consumption of natural resources.

II. EXPERIMENTAL INVESTIGATION

In the present experimental investigation plastic waste and steel fibers has been used as addition of cement as an additional ingredients in concrete mixes. The effect of adding different percentiles of plastic waste and constant amount of steel fibers to concrete mixture and their compressive strength were studied. The details of project are as follows:

A. Materials

- Cement

- Fine aggregate (sand)

- Coarse aggregate (gravel)

- Plastic waste (microns)

- Steel Fibers (aspect ratio: 60)

- Water

5) Steel Fibers

Steel fiber concrete is one of the special concrete that normal concrete mix with discontinuous discrete steel fiber. There are abundant of small- scale fibers are distributed randomly during the concrete mix. The evolution of using steel fibers in the field is to replace and reduce the traditional reinforcement bar in the concrete members. Thus steel fiber tend to increase the tensile strength of the concrete by deflecting micro cracks which develop in the concrete under exterior force and load effects. The lengths of the steel fibers are usually small and short, this is because it wants to avoid inadequate workability of the concrete mixture.

The objective carry this research is to identify the steel fiber that affects the performance of steel fiber concrete which compare with the normal straight steel fibers. The challenge of using the straight steel fiber is the fiber may assemble at one location where they cannot function property which is used as load transfer. Since steel fiber consists of weight, during the mix the fibers will tend to stick to the sides in the rotary mixer, as the final aggregate in the mix. The addition of steel fiber to the concrete is normally can increase the compressive strength and tensile strength into 8% to15%. In additional steel for structural purpose steel fibers should be add as supplements to the reinforcement bars. This is because fibers able to limit the percentage of cracking that due to load. Thus it also can improve the resistance to material deterioration due to fatigue, shrinkage and thermal stresses.

III. LITERATURE REVIEWS

- Use of Recycled Plastic bag waste in the concrete

Youcef Ghernouti, Bahia Rabehi, Brahim Safi and Rabah Chaid

Journal of international scientific publications: Materials, Methods & Technologies ISSN(online): 13147269|Volume-8|2007

The possibility of re-cycling a plastic bag waste material (BBW) that is now produced in large quantities in the formulation of concrete as fine aggregate by substitution of a variable percentage of sand (10, 20, 30 and 40 %). The influence of the PBW on the fresh and hardened states properties of the concrete: workability, bulk density, ultrasonic pulse velocity testing, compressive and flexural strength of the different concretes, has been investigated and analyzed in comparison to the control concrete. The results showed that the use of PBW improves the workability and the density, reduces the compressive strength of concrete containing 10 and 20 % of waste by 10 to 24 % respectively, which have a mechanical strength acceptable for lightweight materials, remains always close to reference concrete (made without PBW). The results of this investigation consolidate the idea of the use of PBW in the field of construction, especially in the formulation of concrete.

2. Use of plastic in concrete to improve its properties

Raghatate Atul M

International Journal of Advanced Engineering Research and Studies (IJAERS) ISSN (online): 2249-8974| Volume-1|Issue-3| June 2012

Plastic bags which are commonly used for packing, carrying vegetables, meat etc creates a serious environmental problem. Plastic bag last in environment up to 1000 years because of plastic bag last so long the number of plastic bag accumulated increases each year. Disposal of large quantity of plastic bag may cause pollution of land, water bodies and air. The proposed concrete which is made up by adding plastic in concrete may help to reuse the plastic bag as one of the constituent’s material of concrete, to improve the certain properties of concrete. The properties of concrete containing varying percentages of plastic are 0%, 0.2%, 0.4%, 0.6%, 0.8%, 1% were added and tested for compressive strength and Split tensile strength. For this,Compressive strength of concrete is affected by addition of plastic pieces and it goes on decreasing as the percentage of plastic increases addition of 1 % of plastic in concrete causes about 20% reduction in strength after 28 days curing.

The splitting tensile strength obserarvation shows the improvement of tensile strength of concrete. Up to 0.8 % of plastic improvement of strength recorded after that addition of strength of concrete decreases with addition of plastic. Thus it is conclude that the use plastic can be possible to increase the tensile strength of concrete.

3. An Experimental Study on Strength Behaviour of Cement Concrete with the Use of Plastic Fibre

Raju, Rajiv Chauhan

International Journal of Engineering Research and applications (IJERA) ISSN (online): 2248-9622|March -2014

Concrete is a basic material for all civil works which is made from cement sand and stones. Now a day’s collecting sand from natural beds of rivers and aggregates is becoming difficult due to environmental clearances. Replacement of fine aggregate or coarse aggregates in cement concrete with some industrial by-product is highly desirable. Due to its lower cost, it makes an attractive alternative if adequate performance can be obtained. They used polyethylene in fiber form with size 120 mm length and 4 mm width have been replaced by fine aggregate. The fine aggregate was replaced by plastic fiber with 1% by weight. It was observed the compressive strength of cement concrete decreased after the inclusion of plastic fiber. The inclusions of plastic fiber have no significant effect on tensile strength. It has been seen that there is a zilch chemical reaction of plastic fiber with the matrix during the hydration process. This was due to the density difference in fine aggregate and polyethylene. The compressive strength significantly decreased by 50.42% at 28 days. The tensile strength decreased by 8.52% which is nominal as compare to the compressive strength decrement rate.

4. Properties of Concrete by the Addition of Plastic Solid Waste

M. Muzafar Ahmed, Dr. S. Siddiraju

International journal of science and research (ISJR) ISSN (online): 2319-7064 volume-4|Issue-5|may2015

Concrete is a material which widely used in construction industry. The production of solid wastages is increasing day to day causing serious concerns to the environment. In this study, the recycled plastics are used in the concrete by partial replacement of coarse aggregate in concrete. The main purpose of this study is to investigate the properties of concrete such as workability, compressive as well as tensile strengths in the partial replacement of aggregate. And also thermal characteristics of the concrete are also studied. The results indicate that the use of plastic solid waste in the concrete results the formations of light weight concrete. The properties such as compressive as well as tensile strength are reduced with the addition of varying percentages of plastic waste of 0%, 10%, 20% in concrete. Further the thermal conductivity of concrete is also reduced, when it is mix with concrete. When this plastic used in concrete pavements it can be withstand at high temperature and also reduction in thickness achieved. The effect of water cement ratio on strength development is not predominant in case of plastic concrete.

5. Re-Use of Polyethylene plastic waste in concrete

M. Mahesh, B. Venkat Narsimha Rao, CH. Satya sri

International Journal of Engineering Development and Research (IJEDR) ISSN(online): 2321-9939|Volume-4|Issue-4|2016

The increase in population and the changed lifestyle has resulted in a significant rise in the quantity of plastic waste. This project in particular deals with the possibility of using the waste polyethylene as partial replacement of fine or coarse aggregate in concrete. Concrete with 2%, 4%, 6% pulverized/non pulverized polyethylene material is prepared after doing the mix design. The standard mechanical properties of concrete like compressive strength, split tensile strength are conducted. It is observed that for more percentage addition of plastics i.e 6% in the present case, the 7 day strength has been decreased when compared with conventional concrete. Specific gravity of waste plastic is less than that of fine aggregate, thus self weight of concrete reduces, thus it reduces the weight of the structure/structural component as a whole. Concrete with plastic waste can be used for less important works where concrete is not going to bear more loads.

6. Experimental Investigation on Partial Replacement Of waste plastic in concrete

Arivalagan. S

International Journal of Engineering Sciences & Research Technology (IJESRT) ISSN (online): 2277-9655|November 2016

The use of plastic is increasing day by day, although steps were taken to reduce its consumption. This create substantial garbage every day which is much unhealthy. A healthy and sustainable reuse of plastics offers a host of advantages. The initial questions arising of the bond strength and the heat of hydration regarding plastic aggregate were solved.

As 100% replacement of natural fine aggregate with plastic fine aggregate is not feasible, partial replacement at various percentage are of 5%, 10%, 15%, 20% were examined. The percentage substitution that gave higher compressive strength was used for determining the other properties such as modulus of elasticity, split tensile strength and flexural strength. Higher compressive strength was found with 10% natural fine aggregate replaced concrete. The density of concrete decreased when plastic content increased. Because plastic has more water tightness capacity when compared to natural aggregate this can help in arresting micro cracks. By using recycled waste plastic in concrete can reduce the land fill and environmental issues. This type of aggregate replacement is useful where aggregates are in crisis.

7. Utilization of Waste Plastic in Concrete towards Sustainable Development

Rajat Saxena, Abhishek Jain and Yash Agrawal

International Journal of Engineering Research and Application (IJERA) ISSN (online): 2248-9622|Volume-6|Issue12|December-2016

In the present decade, one of the environmental issues in most regions of world is the existence of large number of bottles made from poly-ethylene terephthalate (PET) and huge quantities of plastic wastes deposited in domestic wastes and landfills. These plastic wastes are adversely effecting the environment and is a topic of serious concern for various concerned authorities. In spite of all efforts made to limit the use of plastic based products, their utility is increasing day by day and thus the amount of plastic waste generated is also increasing day by day. Various attempts were made through experimentation to check the feasibility of plastic waste to be use partially in concrete with respect to various properties of strength, workability, durability and ductility of concrete. Plastic waste has control on the workability property of concrete. Slump value and the compaction factor decreased with the increase in amount of plastic waste in concrete. Concrete produced by using plastic waste has durability properties comparable to that of reference concrete up to certain limits. Use of plastic waste in concrete mix proved exceptionally helpful to produce green sustainable concrete.

8. Use of Plastic Waste in Concrete mix

Mahaveer prasad, Devesh jaswal

International Research Journal of Engineering and Technology (IRJET) ISSN (online): 2395-0056| Volume-4|Issue-2|November 2017

Dumping of plastic waste in environment is considered to be a giant issue due to its very low biodegradability and existence in huge quantities. Present time use of such, industrial and urban wastes from polypropylene (PP) and polyethylene terepthalate (PET) were considered as substitute replacements of part of the conventional aggregates of concrete.

As a result, finding substitute methods of disposing waste by using affable methods are becoming a main research problem. In this research, high density polyethylene waste is added with varying percentages of 0%, 5%, 10% & 13% and mixed with Portland cement to examine the option to make plastic cement, and learn the outcome of replacing sand by fine polyethylene waste with different quantities and percentage on the properties of product. The research was done by using the waste of polyethylene parcels including bottle and food crates and other wastes. As much as 60% of both industrial and urban plastic waste is recycled which carried from various sources. The best compressive strength for product was found in the mixture has 5%, 10% and 13% polyethylene.

9. Utilization of waste plastics as fiber in concrete

A. Ananthi, A. Jay Tamil Eniyan, S. Venkatesh

International Journal of Concrete Technology (IJCT) Volume-3| Issue-1| 2017

The rapid urbanization and industrialization all over the world has resulted in large deposition of plastic waste. Disposal of plastic waste in an environment is considered to being hazard due to its very low biodegradability and presence in large quantities. In order to minimize the problem, the proposed concrete which is made by adding plastics in concrete may help to reuse the plastics and to study the properties of concrete with plastics.

In this project, they used plastic cups as a fiber with mean aspect ratio 158.75 and 26.49. The result proved that the addition of concrete increases the compressive strength and split strength. The compressive strength and split tensile strength increases to maximum when 0.9% of plastic fibers are added to conventional concrete.

10. Crushed Plastic waste in concrete

Dhaarani D, Shanmuganathan N, Gokila M, Akalya A, Abirami D, Dhilshath Begam J

International Research Journal of Engineering and Technology (IRJET) ISSN (online): 2395-0056|Volume-5|Issue-3|March-2018

Concrete is the most widely used construction material in the world, as well as the largest user of natural resources. Basically it consists of aggregates which are bonded together by cement and water. The major part of concrete besides the cement is the aggregate. Aggregate include sand and crushed stone.

Use of these conventional materials in concrete is likely to reduce the resources unless there is a suitable substitute. Plastic waste materials are often used as a partial replacement of coarse aggregate reducing the cost of construction and help to overcome the deficiencies associated with the use of crushed stones. Also, these materials are identified very harmful to the environment if it is disposal to the land and water.

Hence in this project they aimed to study the effectiveness of Plastics as substitute for coarse aggregate. Aggregate properties viz., specific gravity, water absorption were conducted to ascertain the properties of concrete specimens and has been casted and tested for concrete mix with various percentage of replacement (10%, 20% & 30%) and its viability for replacement were discussed. The compressive strength of Waste Plastic concrete with 10% replacement is 48.84 N/mm2; it is almost Equal strength of normal concrete 53.14 N/mm2 on 28th day. The compressive strength of Waste Plastic concrete with 20% replacement, it gives acceptable strength of 45.32 N/mm2.In the flexural strength test conducted on Waste Plastic concrete, it shows a decrease in strength when compared to the strength of normal concrete.

11. Experimental Study on Steel Fiber Reinforced Concrete for M40 Grade

A. M. Shende, A. M. Pande, M. Gulfam Pathan

International Refereed Journal of Engineering and Science (IRJES) ISSN 2319-183X, (Print) 2319-1821|Volume-1|Issue-1|September2012

Critical investigation for M40 grade of concrete having mix proportion 1: 1.43: 3.04 with water cement ratio 0.35 to study the compressive strength, flexural strength, split tensile strength of steel fiber reinforced concrete containing fibers of 0%, 1%, 2% and 3% volume fraction of hook stain fibers of 50, 60, 67 aspect ratio were used. A result data obtained has been analyzed and compared with a control specimen.

A relationship between aspect ratio Vs compressive strength, aspect ratio Vs flexural strength, aspect ratio Vs split tensile strength represented graphically result data clearly shows percentage increase in 28 days compressive strength, flexural strength and split tensile strength for M40 grade of Concrete. Fibers are generally used as resistance of cracking and strengthening of concrete. Even at 1% of steel fiber content flexural strength of 6.46 N/mm2 was observed against flexural strength 5.36N/mm2 at 0% hence increase of 1.1% flexural strength was obtained.

12. Performance of Steel Fiber Reinforced Concrete.

Milind V. Mohod.

International Journal of Engineering and Science (IJES) ISSN (Online): 2278-4721|Volume-1|Issue-12|December 2012.

Cement concrete is the most extensively used construction material in the world. Ordinary Cement possesses a very low tensile strength, limited ductility and little resistance to cracking. Internal micro cracks leading to brittle failure of concrete. It is now established that one of the important properties of steel fiber reinforced concrete is superior resistance to cracking and crack propagation.

In this paper effect of fibers on the strength of concrete for M30 grade have been studied by varying the percentage of fibers in concrete fiber content were varied by 0.25%, 0.50%, 0.75%, 1%, 1.5%, 2% by volume of cement cubes of size 150X150X150mm to check compressive strength.

All specimens were cured for the period of 3, 7, 28 days before crushing. The results of fiber reinforced concrete for 3 days, 7days, 28days curing with varied percentage of fiber were studied and it has been found that there is significant strength improvement in steel fiber reinforced concrete. The optimum fiber content while studying the compressive strength of cube is found to be 1% and 0.75% for flexural strength of beam. Also it has been observed that with the increase in fiber content up to the optimum value increases the strength of concrete. The slump cone test results revealed that workability gets reduces with the increase in fiber content.

13. Studies On Steel Fiber Reinforced Concrete.

Vasudev R, Dr. B. G. Vishnuram.

International Journal of Scientific and Engineering Research (IJSER) ISSN (Online):2229-5518|Volume-4|Issue-5|May-2013.

Concrete is one of the most versatile building materials concrete is strong under compressive but weak under tension. As such a form of reinforcement is needed.

The most common type of concrete reinforcement is by steel bars the advantage in using concrete include high compressive strength, good fire resistance, high water resistance, low maintenance and long service life. Reinforcement bars, grids, fibers both organic and inorganic as well as composites have been incorporated to strengthen the concrete in tension. Steel fiber reinforced concrete comprises cement, aggregates and steel fibers.

Properties of SFRC in both freshly mixed and hardened state including durability are a consequence of its composite nature. Fibers are usually used in concrete to control cracking due to both plastic shrinkage and drying shrinkage they also reduced permeability of concrete and thus reduce bleeding of water. Steel fibers have a relatively high strength and modulus of elasticity. They are protected from corrosion by the alkaline environment of cementations matrix and their bond to the matrix can be enhanced by mechanical anchorage or surface roughness. The split tensile strength was increased by 20 - 22% of concrete samples with 0.5% fiber content in M20 and M30 grade mixes. From the investigation it was clear that 0.5% fiber content has a pronounced effect on the properties of concrete.

14. Experimental Work on Steel Fiber Reinforced Concrete.

Abdul Ghaffar, Amit S. Charhan, Dr. R. S. Tatwawadi.

International Journal of Engineering Trends and Technology (IJETT) ISSN: 2231 -5381|Volume-9|Issue-15|March-2014.

The objective of the study was to determine and compare the differences in properties of concrete containing without fibers and concrete with fibers. The investigation was carried out using several tests, compressive test and flexural test. Hooked steel fibers were tested to determine the enhancement of mechanical properties of concrete, the workability of concrete significantly reduced as the fiber dosage rate increases.

The maximum percentage increase in compressive strength, flexural strength achieved are 6.15, 7.94 respectively at 30%, 40%, of fiber volume fractions. Durability of concrete is found to increase with inclusion of fibers at higher fiber content the width of crack is found to be less in SFRC than that in plain cement concrete. Critical investigation for M40 grade of concrete having mix proportion 1: 1.43: 3.04 with water cement ratio 0.35 to study the compressive strength, flexural strength, split tensile strength of steel fiber reinforced concrete containing fibers of 0%, 1%, 2%, and 3% volume fraction of hook taint steel fibers of 50, 60 aspect ratio were used. Steel fibers have a relatively high strength and modulus of elasticity. Experimental investigations and analysis of results were conducted to study the compressive and tensile behavior of composite concrete with varying percentage of such fibers added to it. The concrete mix adopted M40 with varying percentages of fibers ranging from 0%, 0.25%, 0.5%, 0.75%, 1%.The results of compressive strength of cubes increases compared to plain concrete.

15. Study of Fiber Reinforced Concrete.

Dr. A. Z. Chitade, Sandeep R. Gaikwad

IOSR Journal of Engineering (IOSRJEN) ISSN (Online): 2250-3021|Volume-25|Issue-1|2015.

In recent years an emerging technology termed Fiber reinforced concrete has become popular in the construction industry. Concrete is a common building material, generally weak in tension, often ridden with cracks due to plastic and drying shrinkage. The introduction of short discrete fibers in to the concrete can be used to counteract and prevent the propagation of cracks. Furthermore incorporation of fibers in concrete results in reduction in the shrinkage and creep deformation of concrete. Application of fiber reinforced concrete is continuously growing in various application fields. FRC is widely used in structures; Due to the property that fiber enhances toughness of concrete. FRC is used on large scale for structural purpose. The fiber is described by a convenient parameter called aspect ratio. A constant fiber volume fraction of 2% was used throughout this investigation. The water cement ratios were varied from 0.30 to 0.65. They have proposed an equation to quantify the effect of fiber on compressive strength of concrete in terms of fiber reinforcing parameter. In their model the compressive strength ranging from 30 to 50 Mpa with fiber volume fraction of 0%, 0.5%, 0.75% and 1% and aspect ratio of 55 and 82 were used. It is observed that the flexural strength increases with increase in the fiber content up to 2%. The maximum increase in this strength i.e. 23.34 at 2.0% fiber content over that of normal content.

16. Experimental Work on Steel Fiber Reinforced Concrete

Avinash joshi, Pradeep reddy, Punith kumar and Pramod hatker

International Journal of Scientific and Engineering Research (IJSER) ISSN (Online): 2229-5518|Volume-7|Issue-10|October 2016.

The various aspects covered are the materials, mix proportioning for M20, M25, M30, M40 grades of concrete. As the concrete is weak in tension, a work has been carried out to investigate the improvement in tensile, shear, flexure and even compressive strength of concrete and also to investigate the cracking strength and reserve strength of concrete and FRC M20, M25, M30, M40 grades of concrete have been added to investigate the compressive strength, tensile strength and shear strength of concrete steel fibers acts as a bridge to retard their cracks propagation and improve several characteristics and properties of concrete fibers are known to significantly affect the workability of concrete. The aspect ratio of (50) and variable in this study were percentage of volume fraction of steel fibers compressive strength, splitting tensile strength and flexural strength of the concrete were determined for the hardened properties. The main purpose is to increase the energy absorption capacity and toughness of the material but also increase in tensile and flexural strength is often the primary objective. A marginal improvement in ultimate strength was observed. The addition of fiber enhanced the ductility significantly.

17. Experimental Studies on Fiber Reinforced Concrete (FRC).

E. Arunakanthi, J. D. Chaitanya Kumar.

International Journal of Civil Engineering and Technology (IJCIET) ISSN (Online) - 0976-6316. |Volume-7|Issue-5|september-2016.

Concrete is one of the most widely recognized development material for the most part delivered by utilizing locally accessible ingredients .The present trend in concrete technology towards increasing the strength and durability of concrete to meet the demands of the modern construction. The main aim of the study is to study the glass fiber and steel fibers in the concrete.FRC has the high tensile strength and fire resistant properties thus reducing the loss of damage during fire accidents. In the present work the strength studies are carried out to compare the glass and steel fiber concrete. The FRC is added 0.5%, 1%, 2% and 3% are added for M20 grade concrete result shows the percentage increases in compressive strength, flexural strength and split tensile strength for 28 days .Flexural behavior of high strength composite incorporating long hook end steel fibers. In this research long hooked steel fibers have been added to mix and compressive strength, flexural strength of concrete have been found out for 7, 14, 28 days. According to various research papers, it has been found that steel fibers give the maximum strength in comparison to glass and fibers. Even at 1% of steel fiber content flexural strength of 6.46 N/mm2 was observed against flexural strength 5.36N/mm2 at 0% hence increase of 1.1% flexural strength was obtained.

18. Use of Steel Fiber Reinforced Concrete.

Mohd. Gulfan Pathan, Ajay Swarup

International Journal of Advance Research in Science and Engineering. (IJARSE) Volume-6| Issue-1| December-2017.

Concrete is extensively used material in Construction because of good workability and ability to be moulded to any shape. The concrete shows the brittle behavior and fails to handle tensile loading hence leads to internal micro cracks which are mainly responsible for brittle failure of concrete. Typically steel fibers have equivalent diameters from 0.15mm to 2mm and lengths from 7 to 75mm.Aspect ratio generally range from 20 to 100.concrete mix of M25 grade and crimped steel fibers with aspect ratio 50 are used. The fibers volume fraction is varied from 0.5% to 4.5% at an interval of 0.5% by weight of cement. All the strengths are found to be increasing continuously with increase in fiber volume fraction. Concrete mix of M40 grade of concrete having mix proportion 1:4:3 with water cement ratio 0.35 to study the compressive strength, flexural strength, split tensile strength of steel fibers containing 0%, 1%, 2%, 3% volume fraction of hooks the result shown that steel fiber reinforced concrete increases strength, toughness, ductility and flexural strength of concrete. Concrete containing steel fiber have been shown to have substantially improved resistance to impact and greater ductility of failure in compression, flexure and torsion. It has been extensively used in various civil engineering structures.

19. Awareness of Steel Fiber Reinforced Concrete.

Pramod Kawde, Abhijit warudkhar.

International Journal of Science and Engineering (IJSE). ISSN: 277-9665|Volume-3|Issue-4|January-2017.

Despite the increased awareness of steel fiber reinforced concrete in practice and research, SFRC is yet to find common application in load bearing building structural elements.

In this paper, result are presented on shear test which have been conducted on ten 5m long by 0.3m wide by 0.7m high rectangular simply supported beams with varying transverse and steel fiber reinforcement ratios. It is well known that concrete is characterized by its high compressive strength, yet its brittle made of failure is considered as a drawback of high strength concrete. When it is subjected to impact dynamic loads. Crimped and hooked and steel fiber of length 50mm and an aspect ratio equal to 50 was added to concrete in different proportions 0%, 0.5%, 1.0%, 1.5% with water cement ratio of 0.42. Fibers are generally used as resistance of cracking and strengthening of concrete. According to various research papers, it has been found that steel fibers give the maximum strength in comparison to glass and fibers. Even at 1% of steel fiber content flexural strength of 6.46N/mm2 was observed against flexural strength 5.36N/mm2, Hence increase in 1.1% flexural strength was obtained. It can be concluded with addition of steel fibers are a good alternative to traditional concrete, because both its strength, and its behavior in case of fire and improved delaying the appearance and explosive concrete spalling.

20. An Experimental Study on Steel Fiber Reinforced Concrete.

Ankur Yadav, Satish Parihar

International Journal of Science Technology and Engineering (IJSTE) ISSN (Online): 2349-784X|Volume-4|Issue-11|March-2018.

This paper deals with the experiment study for M25 grade of concrete mix proportion 1: 1: 2 with water cement ratio 0.44 to study the compressive strength of steel fiber reinforced concrete containing fibers of 0%, 0.45%, 0.95%, 1.45% and 1.95% volume fraction of hook end steel fibers were used result data obtained has been studied, analyzed and compared with a control specimen (0% fiber). A relationship between compressive strength Vs days represented with the help of tables and graphs. Result data clearly shows percentage increase in compressive strength for M25 grade of concrete in 24 hours, 7, 14, 28 days with respect to the variation in % addition of steel fibers. This research is based on use of steel fiber in structural concrete to enhance the mechanical properties of concrete. The objective of the study was to determine and compare the differences in properties of concrete containing without fibers and concrete with fibers. This investigation was carried out using several tests, compressive test and flexural test. A total of 11 mixes tested to determine the enhancement of mechanical properties of concrete. The workability of concrete significantly reduced as the fiber dosage rate increases.

21. Awareness of Steel Fiber Reinforced Concrete.

Study of Strength Property of concrete Using Waste plastics and Steel fiber Khilesh sarwe

International Journal of Engineering And Science (IJES) ISSN(online):2319-1819|Volume-3|Issue-5|2014

The rapid Urbanization and Industrialization all over the world has resulted in large deposition of Plastic waste. This waste can be utilized under proper condition as content in Concrete. In this paper we study that compressive strength of concrete using waste plastics and also add steel fiber with waste plastics. M-20 grade of concrete having mix proportion 1:1.66:3.33 with water cement ratio 0 .50 to study the compressive strength of concrete using waste plastics and waste plastic + steel fiber. The plastic waste and steel fibers are added to concrete with equal percentages like 0%, 0.2%, 0.4%, 0.6%, 0.8%, 1% . Then the compressive strength of cubes is tested. By adding plastic waste more to the concrete the compressive strength is reduced.

IV. PLANNING AND COSTING

A. Planning

Planning is a fundamental and challenging activity in the management and execution of construction projects.

- It involves the choice of technology, the definition of work tasks, the estimation of the required resources.

- A good construction plan is the basis for developing the budget and the schedule for work. ? Developing the construction plan is a critical task in the management of construction.

- It may also be necessary to make organizational decisions about the relationships between project participants and even which organizations to include in a project.

- For example, the extent to which sub-contractors will be used on a project is often determined during construction planning.

Project scheduling and project monitoring:

a. Strategic Planning: It involves the high- level selection of the project objectives.

b. Operational Planning: It involves the detailed planning require to meet the strategic objectives.

c. Scheduling: Detailed operational plan on a time scale set by the strategic objectives.

B. Costing

- Cost estimating is an iterative process that uses a variety of estimating techniques to determine the total cost of completing a project.

- Once you have created satisfactory estimates, you can finalize and approve the project budget.

- Cost managers typically release budgeted amounts in stages according to the level.

C. Quality Assurance

- Quality assurance can be defined as” part of quality.management focused on fulfilling quality requirements”.

- Quality assurance is for entire life cycle.

- The main aim to prevent the defects and focus on the process used to make the product.

- Everyone involved in the developing a product are responsible for the quality assurance.

Quality Control

Quality control can be defined as “part of quality management focused on fulfilling quality requirements”.

a. Reduction of scrap and rework.

b. Quality caution at all levels.

c. To check the variation during manufacturing.

d. To improve the poor- quality product reaching to costumer.

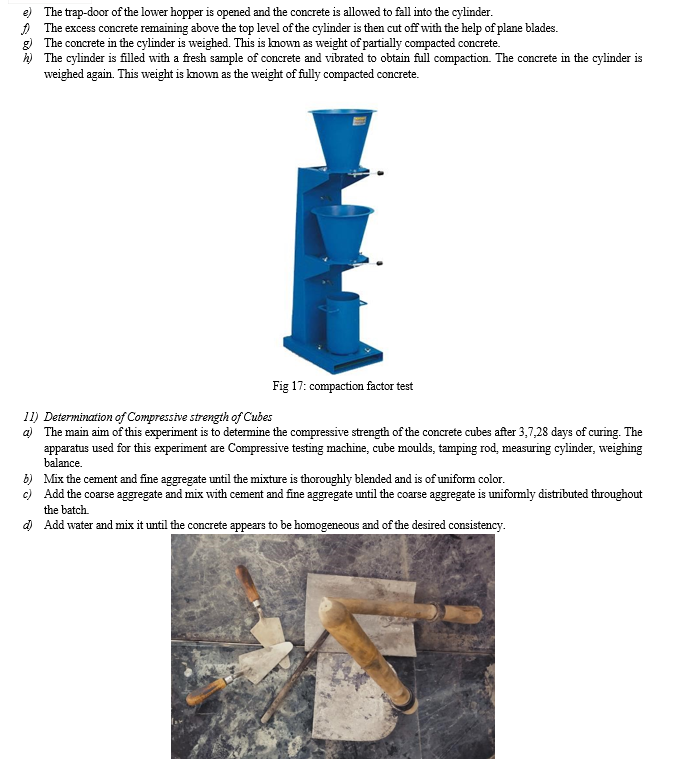

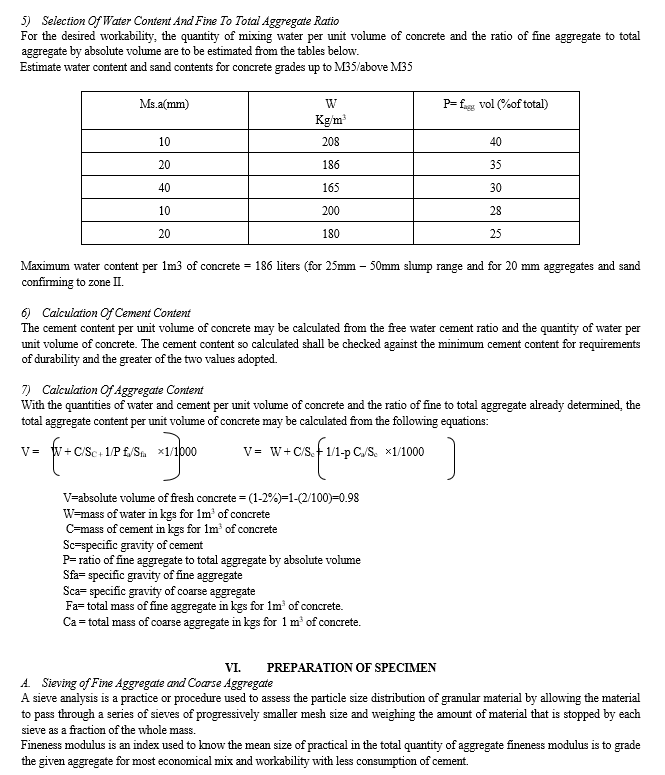

D. Experiments Conducted in Quality Control lab

1) Determination of Fineness of cement

a. The main aim of this experiment is to determine the number of cement particles larger than 90µm.. and the apparatus used for this experiment are Weighing balance, sieve set

b. Take a sample of cement and rub the cement with the hands. The test sample should be free of lumps

c. Now take 100 g of cement (W1).

d. Pour 100 g of cement in 90 µm sieve and close with the lid.

e. Now shake the sieve with the hands by agitating the sieve in planetary and linear movements in 15 minutes.

f. Next, weight the residue retained on the 90 µm(W2).

g. Then calculate the percentage of weight of cement retained on sieve (Wt). ? Repeat the above experiment with different samples of cement.

Conclusion

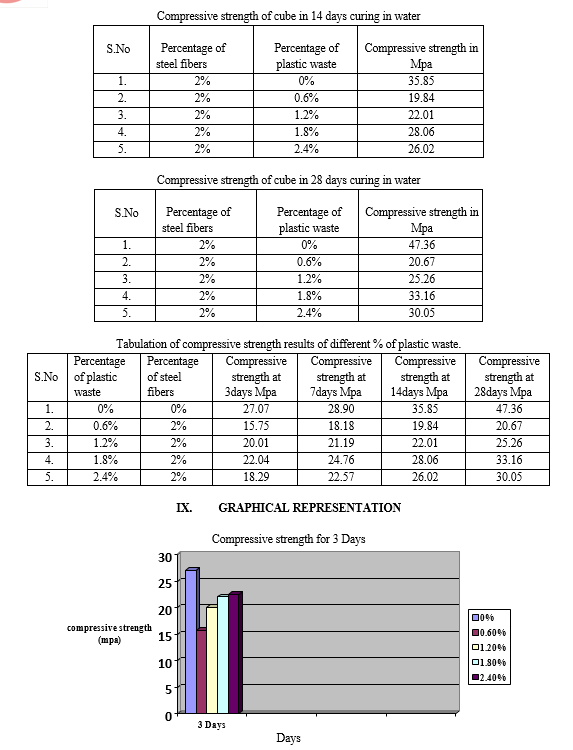

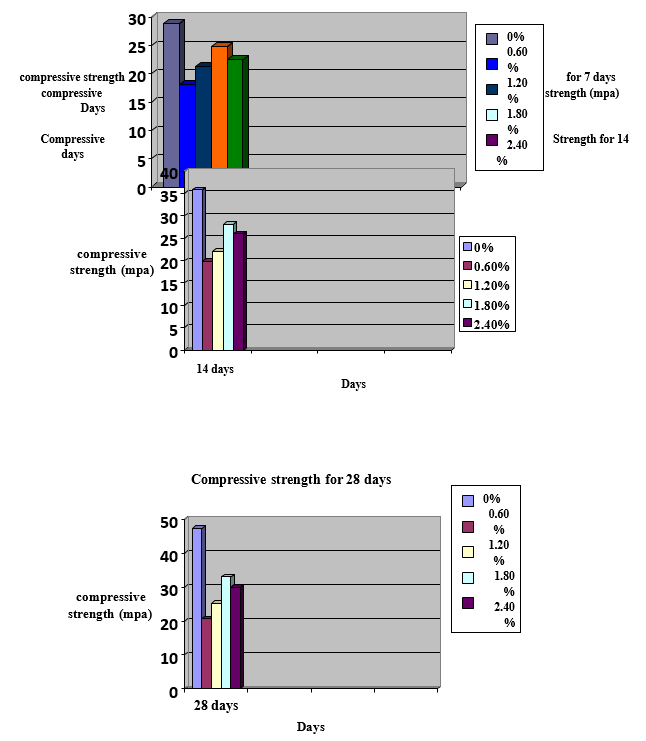

Based on the results the following calculations are made: 1) The compressive strength of concrete after 3days is reduced by 11.32%, 7.06%, 5.03% and 8.78% by adding 0.6%, 1.2%, 1.8%, 2.4% of plastic waste respectively to plain concrete mix. 2) The compressive strength of concrete after 7 days is reduced by 10.72%, 7.71%, 4.14% and 6.33% by adding 0.6%, 1.2%, 1.8%, 2.4% of plastic waste respectively to plain concrete mix. 3) The compressive strength of concrete after 14 days is reduced by 16.01%, 13.84%, 7.79% and 9.83% by adding 0.6%, 1.2%, 1.8%, 2.4% of plastic waste respectively to plain concrete mix. 4) The compressive strength of concrete after 28 days is reduced by 26.69%, 22.10%, 14.20% and 17.31% by adding 0.6%, 1.2%, 1.8%, 2.4% of plastic waste respectively to plain concrete mix. 5) By adding 1.8% of plastic waste to concrete is suitable for adding plastic waste to concrete. More than 1.8% of plastic waste the compressive strength is reduced. A. List Of Is Codes 1) I.S. 12269-1989---Specification for grade ordinary Portland cement 2) I.S. 383-1970 ---Specification for Coarse & Fine Aggregate from Natural Sources for 3) Concrete 4) I.S.456-2000---Indian Standard Plain & Reinforced Concrete Code of Practice 5) I.S. 516-1959---Methods of test for strength of concrete 6) I.S. 2386-1963---Methods of Test for Aggregates of Concrete (all parts) 6. I.S. 3085-1965---Methods of Test for Permeability of Cement & Concrete 7) I.S. 13270-2013---Indian Standard Specification for Steel fibers. 8) I.S. 10262-1982---Recommended guide lines for concrete mix design 9) I.S. 4031-1988---Methods for physical tests for hydraulic Cements :( PT2) Part 2 Determination of fineness by specific surface by Blaine’s air permeability method 10) I.S. 4031-1988---Methods for physical tests for hydraulic cements: (PT5) Part 5 Determination of initial and final setting times. 11) I.S. 4031-1988---Methods for physical tests for hydraulic cements: (PT3) Part 3 Determination of soundness 12) I.S. 1199-1959---Methods of sampling and analysis of concrete 13) I.S.5512-1983---Specifications for flow table for use in tests of hydraulic cements & Pozzolanaic materials 14) 5514-1969---Apparatus used in “Le Chatelier” test. 15) 5513-1966---Vicat Apparatus.

References

[1] Youcef ghernouti, Rahia Rabehi et al.(2007) Use of recycled plastic bag waste in the concrete, Journal of international scientific publications: Materials, Methods & Technologies, ISSN (online):1314-7269,Volume 08. [2] Raghatate Atul M (2012) use of plastic in concrete to improve its properties, international journal of advanced Engineering Research and Studies (IJAERS) ISSN (online):22498974, Volume 01, Issue 03. [3] M.muzafar Ahmed, Dr.S. Siddiraju (2013) properties of concrete by the addition of plastic solid waste, International Journal of science and research (ISJR), ISSN(online):2319-7064. [4] Raju, Rajiv Chauhan (2014) An Experimental Study on Strength Behavior of Cement Concrete with the Use of Plastic Fiber, International Journal of Engineering Research and applications (IJERA), ISSN (online): 2248-9622 [5] M.Mahesh, B.venkat Narsihma Rao, ch.Satya sri (2016) Re-use of polyethylene plastic waste in concrete, International Journal of Engineering Development and Research (IJEDR), ISSN (online):2321-9939, volume 04, Issue 04. [6] Arivalagan.S (2016)Experimental Investigation on Partial Replacement Of waste plastic in concrete International Journal of Engineering Sciences & Research Technology (IJESRT), ISSN (online): 2277-9655. [7] Rajat Saxena, Abhishek Jain and Yash Agrawal (2016)Utilization of Waste Plastic in Concrete towards Sustainable Development, International Journal of Engineering Research and Application (IJERA), ISSN (online): 2248-9622, Volume 06, Issue-12. [8] Mahaveer Prasad, Deresh Jayaswal (2017), use of plastic waste in concrete mix, International Research journal of engineering and technology, Volume 04,Issue 11,ISSSN (online):2395-0056. [9] A.Ananthi, A. Jay Tamil Eniyan, S. Venkatesh (2017) Utilization of waste plastics as fiber in concrete International Journal of Concrete Technology (IJCT) Volume 03 Issue 01. [10] Dhaarani D, Shanmuganathan N, Gokila M, Akalya A et al.(2018) Crushed Plastic waste in concrete, International Research Journal of Engineering and Technology (IRJET), ISSN (online): 2395-0056|Volume 05,Issue 03. [11] A. M. Shende, A. M. Pande, M. Gulfam Pathan (2012) Experimental Study on Steel Fiber Reinforced Concrete for M40 Grade, International Refereed Journal of Engineering and Science (IRJES), ISSN 2319-1839, (Print) 2319-1821|Volume 01,Issue 01. [12] Milind V, Mohod (2012) Performance of Steel Fiber Reinforced Concrete. International Journal of Engineering and Science (IJES), ISSN (Online): 2278-4721, Volume 01, Issue 12. [13] Vasudev R, Dr.B.G vishnuram Studies on Steel Fiber Reinforced Concrete. International Journal of Scientific and Engineering Research (IJSER), ISSN (Online):2229-5518, Volume 04, Issue-5|May2013 [14] Abdul Ghaffar, Amit S, Charhan, Dr.R.S. Tatawawadi Experimental Work on Steel Fiber Reinforced Concrete. International Journal of Engineering Trends and Technology (IJETT), ISSN: 2231 -5381, Volume 09, Issue 15, March-2014 [15] Dr.A.Z. Chitade, Sandeep R, Gaikwad (2015) Study of Fiber Reinforced Concrete, IOSR Journal of Engineering (IOSRJEN), ISSN (Online): 2250-302, Volume 25, Issue-1. [16] E.Arunakanthi, J.D.chaitanya kumar (2016),Experimental Studies on Fiber Reinforced Concrete (FRC), International Journal of Civil Engineering and Technology (IJCIET), ISSN (Online) - 0976-6316. |Volume07, Issue 05. [17] Avinash joshi, Pradeep reddy, Punith kumar and Pramod hatker (2016), Experimental work on steel fiber reinforced concrete International Journal of Scientific and Engineering Research (IJSER), ISSN (Online): 2229-5518, Volume 07, Issue 10. [18] Mohd, Gulfan pathan, Ajay swarup (2017) Use of Steel Fiber Reinforced Concrete. International Journal of Advance Research in Science and Engineering. (IJARSE), Volume 06, Issue 01. [19] Pramod Kawde, Abhijit Warudhkar (2017), wareness of Steel Fiber Reinforced Concrete, International Journal of Science and Engineering (IJSE). ISSN: 277-9665, Volume 03, Issue 04. [20] Ankur Yadav, Satish Parihar (2018) an Experimental Study on Steel Fiber Reinforced Concrete, International Journal of Science Technology and Engineering (IJSTE), ISSN (Online): 2349-7840, Volume 04, Issue 11. [21] Khilesh sarwe (2014), study of strength property of concrete using waste plastics and steel fiber, International Journal of Engineering and Science (IJES), ISSN (online):2319-1813, Volume 03, Issue 05.

Copyright

Copyright © 2023 Naveen Kumar Nadigatla. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET55997

Publish Date : 2023-10-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online