Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Improving M30 Concrete Performance with Recron 3S Fiber and Steel Slag: A Systematic Review

Authors: Priyanka Vishwakarma, Dr. Anil Suman

DOI Link: https://doi.org/10.22214/ijraset.2024.59375

Certificate: View Certificate

Abstract

This literature review delves into the potential for enhancing the performance of M30-grade concrete through the incorporation of Recron 3S fiber and steel slag aggregate to address sustainability issues in the construction industry. By systematically analyzing existing research, the review assesses the mechanical properties and sustainability implications of these substitutions. Recron 3S fibres offer improvements in tensile and flexural properties, reducing crack propagation and increasing ductility. In contrast, steel slag aggregate enhances compressive strength, durability, and resistance to alkali-silica reactions, all while utilizing recycled materials. The review synthesizes experimental methodologies, mechanical test results, and sustainability considerations, offering valuable insights into the feasibility and challenges of these sustainable alternatives. It emphasizes the need for further research to explore broader applications and assess environmental impacts across various concrete grades and construction scenarios. This review makes a significant contribution to the advancement of sustainable construction practices, providing valuable guidance to decision-makers, researchers, and practitioners seeking to adopt environmentally friendly approaches to concrete production and construction.

Introduction

I. INTRODUCTION

Concrete, as a cornerstone material in construction, faces increasing scrutiny regarding its environmental impact and sustainability. The conventional production of concrete, reliant on Portland cement and natural aggregates, is associated with significant carbon emissions and resource depletion.

In response to these challenges, researchers and practitioners have been exploring alternative materials and methods to enhance concrete performance while mitigating its environmental footprint. One promising avenue involves the integration of synthetic fibers and industrial byproducts into concrete mixes.

This literature review delves into the potential for enhancing the performance of M30 grade concrete by incorporating Recron 3S fiber and steel slag aggregate.

The focus on M30 grade concrete, commonly utilized in structural applications, allows for a comprehensive analysis of the mechanical properties and sustainability implications of these substitutions. Recron 3S fibers are known for their ability to improve tensile and flexural properties, thereby reducing crack propagation and increasing ductility. Conversely, steel slag aggregate offers enhancements in compressive strength, durability, and resistance to alkali-silica reaction, while also presenting a solution for recycling industrial waste.

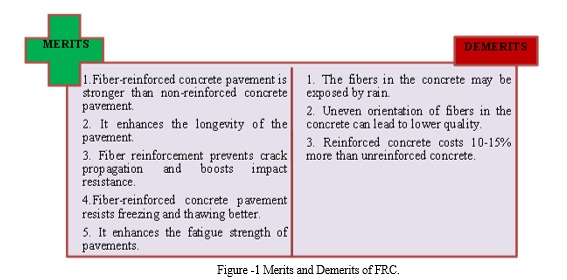

To effectively address these challenges, the concept of fiber-reinforced concrete (FRC) has been introduced, involving the incorporation of fibers to enhance crack resistance and overall properties. In this study, a comprehensive analysis is conducted to investigate the behaviour of concrete mixed with RECRON 3sFIBER and steel slag aggregate, in comparison to plain concrete. Fiber Reinforced Concrete (FRC) research began in India in the 1970s to improve cement-based materials[1]. Initially used for pavements and industrial floors, FRC is now widely used in bridges, tunnels, and more. Recron-3S fiber, a polyester fiber from Reliance Industries Limited, enhances concrete and mortar properties as merits and demerits depicted in Fig. 1. It comes in 6mm and 12mm lengths.

Through a systematic analysis of existing research, this review evaluates the efficacy of sustainable alternatives in enhancing concrete performance. By synthesizing experimental methodologies, mechanical test results, and sustainability considerations, it provides insights into the feasibility and challenges of incorporating Recron 3S fibre and steel slag aggregate into concrete mixes. Additionally, the review highlights the need for further research to explore broader applications and assess environmental impacts across different concrete grades and construction scenarios. Ultimately, this review aims to contribute to the advancement of sustainable construction practices, informing decision-makers, researchers, and practitioners in adopting environmentally friendly approaches to concrete production and construction.

This review primarily focuses on the analysis, challenges, and applications of enhancing M30 concrete performance with Recron 3S fiber and steel slag. The paper is organized as follows: Section 2 delves into the research methodology, literature references, screening research papers, and the ultimate selection of articles in this review. Sections 3 and 4 investigate the impact of steel slag and Recron 3S fiber on improving M30 concrete. Lastly, Section 5 provides the conclusion and future prospect.

II. METHODOLOGY

The methodology for this literature review paper involved a systematic search and analysis of relevant articles focusing on the integration of Recron 3S fibre and steel slag aggregate to improve the performance of M30-grade concrete. The following steps outline the methodology employed:

- Digital Databases and Keywords: The search for target articles was conducted using various digital databases, including but not limited to PubMed, ScienceDirect, Google Scholar, and Engineering Village. Keywords used in the search included "Recron 3S fiber," "steel slag aggregate," "concrete performance," "mechanical properties," "durability," and "sustainability."

- Article Selection Criteria: Articles were selected based on their relevance to the topic and their contribution to understanding the effects of Recron 3S fiber and steel slag aggregate on concrete performance. Priority was given to peer-reviewed research articles, conference papers, and scholarly publications that provided empirical data and experimental findings.

- Inclusion and Exclusion Criteria: Articles included in the review were those that specifically investigated the use of Recron 3S fiber and steel slag aggregate in concrete mixes, focusing on their impact on mechanical properties, durability, and sustainability. Studies that provided insights into the methodologies, results, and implications of incorporating these materials were considered. Articles not directly related to the topic or lacking empirical data were excluded.

- Data Extraction and Synthesis: Relevant information from selected articles was extracted, including author(s), publication year, methodologies employed, key findings, and implications. Data were synthesized to provide a comprehensive overview of the current state of research on the topic, highlighting trends, challenges, and future directions.

The literature review identified a total of 21 relevant papers published between 2002 and 2022, sourced from PubMed, ScienceDirect, Scopus, Web of Science, and Google Scholar databases. These papers encompass a broad range of applications, including high-strength concrete, structural applications, pavement, and environmental sustainability. The primary focus of the reviewed papers lies in investigating the durability and mechanical properties of steel slag aggregate concrete, as well as the applications of Recron 3S polyester fibers in concrete production.

III. STEEL SLAG IN M-30 CONCRETE

There has been an increasing interest in the integration of supplementary cementitious materials and alternative aggregates in the production of concrete. A promising method involves the partial replacement of cement with recron3s fiber and aggregate with steel slag. The objective of this literature review is to provide a thorough summary of the current research and studies concerning the effects of these materials on the characteristics of concrete. The primary focus will be on analyzing how these substitutions influence the characteristics of the concrete. The literature review presents a thorough overview of research studies that are dedicated to improving concrete performance, specifically by utilizing Recron 3S polyester fibers and steel slag aggregates. The subsequent synthesis offers a well-structured and cohesive summary of the main discoveries and observations from the chosen studies.

A. Durability and Mechanical Properties of Steel Slag Aggregate Concrete

Maslehuddin et al. (2002) [2] compared steel slag aggregate concrete to crushed limestone aggregate concrete, highlighting the superior durability characteristics and some physical properties of steel slag cement concrete. The study emphasized better performance despite the higher unit weight. This initial research established the groundwork for future studies by demonstrating a strong connection between the utilization of steel slag and the improvement of concrete properties. Expanding upon this foundation, Liu et al. (2011)[3] conducted a comprehensive investigation into the utilization of steel slag and scrap tire particles as alternatives to natural aggregates in concrete. Their experiments yielded commendable strength results in steel slag concrete, albeit with a minor decrease in flexural strength. The study underscored the promising advantages associated with employing steel slag as both coarse and fine aggregates, particularly in mitigating shrinkage and expansion. Furthermore, the successful incorporation of scrap tire particles as a partial substitute for fine steel slag aggregate demonstrated its efficacy in achieving satisfactory strength and maintaining volume stability. Fronek et al. (2012)[4] made a significant contribution to the existing body of literature by conducting a comprehensive examination of the utilization of steel slag aggregate in Portland Cement Concrete (PCC), primarily in controlled laboratory environments. Although the real-world implementation of this technique may be hindered by transportation regulations, the study concludes that aged steel slag has the potential to demonstrate nonexpansive characteristics in PCC. These findings highlight the economic viability of incorporating steel slag as a feasible alternative in concrete, thus warranting further deliberation and exploration.

In relation to environmental concerns, Hisham Qasrawi (2013)[5] has emphasized the importance of utilizing Recycled Concrete Aggregate (RCA) and steel slag as coarse aggregates in a highly effective manner. The study has shed light on the fact that incorporating steel slag as a significant substitute 67 % for RCA has proven to enhance the strength of concrete, thereby providing an environmentally conscious solution to the challenges of disposal. However, it is important to note that the study has also acknowledged the negative impact of RCA on air content and has suggested that the presence of slag alone cannot completely mitigate this issue. Despite the slight reduction in strength, the inclusion of steel slag in RCA mixes has been recommended as a means of enhancing the mechanical properties of hardened RCA concrete in a professional manner. V. Subathra Devia, B. K. Gnanavelb (2014) [6] discusses a study on using steel slag as a replacement for traditional aggregates in concrete. Optimal replacement percentages are 40% for fine aggregate and 30% for coarse aggregate. Increasing replacement decreases workability, though fine aggregate replacement shows better workability. Partial replacement of fine aggregate improves concrete strength, with slightly less improvement for coarse aggregate replacement. Steel slag also improves resistance to Hcl compared to H2SO4. It enhances resistance to deflection and vertical strain in RCC beams. Further research is suggested to enhance strength and acid resistance with admixtures. Pang et al. (2015) [7] have successfully developed carbonated granulated steel slag aggregate, which has shown significant enhancements in strength, volume stability, and compressive strength. Rondi et al. (2016) [8] have shed light on the favourable properties of Electric Arc Furnace (EAF) slag and have strongly recommended implementing a minimum ageing period to avoid any potential cracking issues. Nehvi and Kumar (2016) [9] have placed great emphasis on the environmental advantages of incorporating steel slag in alkali-activated concrete, albeit with the need for meticulous weathering considerations.

In a study on alkali-activated concrete, Palankar et al. (2016) [10] found that steel slag aggregates are suitable for structural and highway applications despite a slight decrease in strength. However, replacing fly ash increased water absorption and permeable voids, impacting durability. Alkali-activated concrete with natural aggregates had lower water absorption and permeable void values compared to ordinary Portland cement concrete. It also showed superior resistance to acid and sulfate environments, although this was reduced when using steel slag aggregates. Overall, alkali-activated concrete with natural aggregates had a lower environmental impact and cost compared to OPCC, with further reduction when using steel slag aggregates. Proper weathering of steel slag aggregates is crucial to avoid durability issues, requiring mix design optimization and systematic testing and monitoring.

B. Steel Slag in High-Strength Concrete

The utilization of steel slag in concrete has been extensively researched, with numerous studies highlighting its favourable impact on various mechanical and structural properties. Guo et al. (2018) [11] have demonstrated that the incorporation of steel slag in cement concrete leads to improvements in static compressive strength, stiffness, and brittleness. Their findings indicate that the failure mode under impact loading is comparable to that of normal concrete, with two primary modes identified. Furthermore, the dynamic compressive strength increases with strain rate, surpassing that of conventional concrete. The optimal steel slag content has been identified as 20%, showcasing enhanced performance in both static and impact compression. It is important to note that no pre-treatment is considered necessary to achieve these improvements. Liu and Guo (2018) [12] conducted further investigations on the properties of paste and concrete containing steel slag. They observed that the paste with steel slag demonstrated enhanced fluidity and a comparable non-evaporable water content compared to the control sample. Moreover, both steel slag powder and steel slag aggregate displayed excellent bonding with the hardened paste. The researchers made a noteworthy observation that when the cement replacement ratio was limited to 10%, the proportion of larger pores in the hardened paste with steel slag powder was similar to that of the control sample. In the realm of ultra-high-performance concrete (UHPC), it was discovered that UHPC with steel slag powder exhibited satisfactory compressive strengths, while UHPC with steel slag aggregate demonstrated even higher compressive strengths. Building upon this foundation, again in the year 2019, Guo et al. (2019) [13] furthered the investigation to examine the effects of steel slag as a fine aggregate in both normal-strength and high-strength concrete. The study has shed light on the diverse influence of steel slag content on compressive strength in each type of concrete. Notably, steel slag has exhibited a more substantial impact on high-strength concrete, enhancing its toughness and energy absorption capacity. The research has indicated that a specific steel slag content may contribute to achieving optimal compressive strength and toughness, thus showcasing its potential as an environmentally friendly alternative for concrete structures. In a study conducted by Liu et al. (2020)[14], the researchers extensively explored the impact of steel slag on various properties of concrete. The results of their investigation demonstrated that a gradual increase in the steel slag content up to a specific threshold resulted in a remarkable enhancement in both strength and stiffness, thereby significantly improving the overall structural integrity of the concrete. It is crucial to note, however, that surpassing the optimal content had adverse consequences. Furthermore, the inclusion of steel slag influenced shrinkage and hydration, ultimately leading to the formation of a more condensed structure. Significantly, the substitution of limestone with steel slag emerged as a viable approach, offering both economic and environmental advantages.

C. Innovations with Steel Slag

In recent years, there has been significant attention given to the incorporation of steel slag in concrete due to its positive effects on various mechanical and durability aspects. [15] Saxena S’s research in the year 2018, highlights the reliability and safety of steel slag as an additive in concrete. The study emphasizes the improvement in both tensile and compressive strength, especially when using replacement percentages between 15 and 30%. Although there is a slight decrease in workability, this can be effectively managed by using suitable admixtures. Additionally, concrete with steel slag exhibits enhanced durability and freeze-thaw properties, making it a promising option for optimizing concrete performance. Importantly, the study suggests that incorporating 50 to 75% steel slag aggregates does not have a significant negative impact on overall durability. Expanding on this foundation, the research carried out by Lai, et. al, (2021) [16] extends the investigation into sustainable alternatives for concrete. Their main focus is on the use of Basic Oxygen Furnace Steel Slag (BOFSS) as a substitute for aggregates, thus making significant contributions to the development of eco-friendly concrete. The study involves a comprehensive evaluation of 15 different concrete mixtures, carefully examining their properties and microstructure. The study suggests optimal replacement ratios of 50% for coarse aggregates and 30% for fine aggregates, leading to improved strength and microstructure. By incorporating BOFSS, this research strongly supports the idea that including steel slag in concrete not only enhances performance but also aligns with the objectives of environmental sustainability.

Dong et. al, [17] study conducted in the year 2021 extensively explores the combined effects of Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) slag in concrete. Despite the similarities in composition and properties between BOF and EAF slag, it is important to note the nuanced disparities presented by Low-Grade Furnace (LF) slag. Steel slag aggregate (SSA) is recognized for its high density and rough surface, which significantly contribute to the enhancement of concrete strength. However, it is crucial to implement specific treatment and adjustments to the cement/water ratio to effectively address any potential reductions in workability and durability. The study suggests that a well-designed SSA concrete, incorporating appropriate admixtures and modifications, can successfully mitigate these concerns. In addition, the research highlights the numerous benefits of SSA concrete, including its excellent conductivity, effectiveness in radiation shielding, and potential use in self-sensing concrete. With its environmentally friendly and sustainable characteristics, as well as its cost-effectiveness and reduced environmental impact, SSA concrete presents itself as a promising area for extensive research and development. The study concludes by emphasizing the urgent requirement for additional research to maximize the recycling advantages, thus indicating a promising avenue for future exploration and optimization of concrete performance.

|

Table 1 Summary of literature Survey related to Steel Slag in M-30 Concrete |

|||||||

|

Area of Study |

Author and Year |

Study Focus |

Key Objective |

Material/Method Used |

Key Findings/ Result |

Shortcomings |

Recommendations |

|

Durability and Mechanical Properties of Steel Slag Aggregate Concrete |

Maslehuddin et al. (2002) [2] |

Concrete with steel slag and crushed limestone aggregates |

Performance comparison, durability, physical properties |

Steel slag as aggregate, comprehensive testing |

The superior durability of steel slag concrete and better performance despite higher unit weight with strength results are commendable, with a minor decrease in flexural strength. |

Real-world implementation challenges due to transportation regulations, and potential non-expansive characteristics in PCC. |

Further exploration of economic viability and utilization in concrete. |

|

Liu et al. (2011)[3] |

Steel slag and scrap tire particles as alternatives in concrete |

Strength results, shrinkage, expansion |

Steel slag as both coarse and fine aggregates, scrap tire particles |

Promising advantages of steel slag in mitigating shrinkage and expansion, successful incorporation of scrap tire particles with commendable strength results in steel slag concrete. |

Transportation regulations may hinder real-world implementation. |

Continued exploration of steel slag and scrap tire particles in concrete. |

|

|

Fronek et al. (2012)[4] |

Steel slag aggregate in Portland Cement Concrete |

Utilization in PCC, controlled laboratory environment |

Aged steel slag in PCC, comprehensive examination |

Aged steel slag has the potential for nonexpansive characteristics in PCC, and economic viability is highlighted. |

Transportation regulations may hinder real-world implementation. |

Further deliberation and exploration are recommended. |

|

|

Hisham Qasrawi (2013)[5] |

Recycled Concrete Aggregate (RCA) and steel slag as aggregates |

Strength enhancement, environmental concerns |

Steel slag as 67% substitute for RCA, comprehensive testing |

Strength enhancement in concrete, the environmental solution to disposal challenges, and a slight reduction in strength. |

Acknowledged the negative impact of RCA on-air content. |

The inclusion of steel slag in RCA mixes is recommended for mechanical properties. |

|

|

V. Subathra Devia, B. K. Gnanavelb (2014) [6] |

Steel slag as a replacement for traditional aggregates |

Optimal replacement percentages, workability, acid resistance |

Steel slag as replacement for fine and coarse aggregates, comprehensive study |

Optimal replacement percentages for fine and coarse aggregates, improved resistance to Hcl, deflection, and vertical strain. |

Decrease in workability with increasing replacement. |

Further research suggested enhancing strength and acid resistance with admixtures. |

|

|

Pang et al. (2015) [7] |

Carbonated granulated steel slag aggregate |

Strength, volume stability, compressive strength |

Development of carbonated granulated steel slag aggregate |

Significant enhancements in strength, volume stability, and compressive strength of concrete. |

- |

- |

|

|

Rondi et al. (2016) [8] |

Electric Arc Furnace (EAF) slag |

Favourable properties, minimum ageing period |

Use of EAF slag in concrete, the recommendation for a minimum ageing period |

Favourable properties of EAF slag, need for a minimum ageing period to avoid potential cracking issues. |

- |

- |

|

|

Nehvi and Kumar (2016) [9] |

Environmental advantages of steel slag in alkali-activated concrete |

Alkali-activated concrete, weathering considerations |

Incorporation of steel slag in alkali-activated concrete |

Environmental advantages of steel slag in alkali-activated concrete, need for meticulous weathering considerations. |

- |

- |

|

|

Palankar et al. (2016) [10] |

Alkali-activated concrete with steel slag aggregates |

Structural and highway applications, environmental impact |

Alkali-activated concrete with steel slag aggregates |

Suitable for structural and highway applications, lower environmental impact compared to OPCC. |

- |

Proper weathering of steel slag aggregates is crucial for durability. |

|

|

Steel Slag in High-Strength Concrete |

Guo et al. (2018) [11] |

Incorporation of steel slag in cement concrete |

Compressive strength, stiffness, brittleness Inclusion of steel slag in cement concrete Improvements in static compressive strength, stiffness, brittleness, and dynamic compressive strength increase with strain rate. |

Optimal steel slag content was identified as 20%. |

No pre-treatment is necessary for improvements along with further exploration of recycling advantages and optimization of concrete. |

||

|

Liu and Guo (2018) [12] |

Properties of paste and concrete with steel slag |

Fluidity, non-evaporable water content, cement replacement ratio |

Paste and concrete with steel slag, varying cement replacement ratio |

Enhanced fluidity, comparable non-evaporable water content, satisfactory compressive strengths in UHPC and cement replacement ratio of 10% showed similar pore proportion. |

Limitations if cement replacement exceeds optimal content. |

Optimal steel slag content is crucial, with potential for UHPC application. |

|

|

Guo et al. (2019) [13] |

Effects of steel slag as fine aggregate in concrete |

Compressive strength, toughness, energy absorption capacity |

Steel slag as fine aggregate in normal-strength and high-strength concrete |

The diverse influence of steel slag content on compressive strength has, a more substantial impact on high-strength concrete. |

- |

Optimal steel slag content is crucial for compressive strength and toughness. |

|

|

Liu et al. (2020)[14] |

Impact of steel slag on various concrete properties |

Strength, stiffness, shrinkage, hydration |

Gradual increase in steel slag content enhances strength and stiffness, condensed structure formation. |

Remarkable enhancement in strength and stiffness along with adverse consequences if optimal content is surpassed. |

Substitution of limestone with steel slag offers economic and environmental advantages. |

||

|

Innovations with Steel Slag |

Saxena S.(2018) [15] |

Reliability and safety of steel slag as an additive in concrete |

Tensile and compressive strength, workability, durability, freeze-thaw properties |

Steel slag as an additive in concrete |

Improved tensile and compressive strength, enhanced durability and freeze-thaw properties along with 15-30% replacement percentages for optimal results. |

Slight decrease in workability. |

The use of suitable admixtures can manage workability. |

|

Lai, et. al, (2021) [16] |

Basic Oxygen Furnace Steel Slag (BOFSS) as aggregate |

Replacement ratios, strength, microstructure |

Use of BOFSS as a substitute for aggregates in concrete |

Optimal replacement ratios of 50% for coarse aggregates and 30% for fine aggregates, improved strength and microstructure. |

- |

The inclusion of BOFSS aligns with environmental sustainability objectives. |

|

|

Dong et. al, [17] |

Combined effects of Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) slag in concrete |

Composition, properties, conductivity, self-sensing concrete |

Combined use of BOF and EAF slag in concrete |

Well-designed steel slag concrete can mitigate concerns, has excellent conductivity, and has potential use in self-sensing concrete. |

Specific treatment is required for Low-Grade Furnace (LF) slag. |

Further research for recycling advantages and concrete optimization is recommended. |

|

The Table 1 emphasizes the benefits of using steel slag in concrete mixes, showcasing its potential for enhancing performance and durability. Further research is recommended to address challenges and optimize utilization. Steel slag can positively impact compressive strength, stiffness, toughness, and energy absorption in concrete mixes. Determining the optimal steel slag content is crucial for concrete mix design, with environmental advantages supporting sustainable construction practices.

III. RECRON 3S POLYESTER FIBER IN M-30 CONCRETE

This section demonstrates the favorable impact of Recron 3S fibers on different facets of concrete performance, including compressive strength, split tensile strength, and flexural strength. Additionally, it addresses factors such as workability and sustainability. These findings collectively enhance our understanding of the potential advantages and obstacles associated with the use of Recron 3S fibers in concrete applications. The study seeks to investigate the potential advantages and disadvantages associated with the integration of Recron3's fibers in concrete blends. Recron3s fibers, created from polyester, have been utilized in rigid pavements to manage cracking and boost durability. By incorporating them into concrete mixes, these fibers can enhance the pavement's ability to withstand temperature changes and drying, minimizing shrinkage cracks.

The utilization of fibers in concrete has garnered considerable attention in recent years due to their capacity to enhance various mechanical properties. V. Prahatheswaran and Dr P. Chandrasekaran (2017) [18] conducted a comprehensive investigation into the effects of Recron3s fibers on concrete properties. Their findings demonstrate a significant increase in compressive strength when 0.5% of Recron3s fibers are added to the concrete mix, resulting in a 1.12 times enhancement. Additionally, the study reveals that a slightly higher improvement of 1.13 times can be achieved by incorporating 1% Recron3s fibers. Furthermore, the split tensile strength exhibits substantial improvements, with 0.5% and 1% fiber contents resulting in enhancements of 1.05 and 1.06 times, respectively. This suggests that the utilization of Recron3s fiber-reinforced concrete exceeds the performance of regular concrete, particularly in terms of load capacity. Expanding on this foundational research, KA Kumar and GS Rao (2017) [19] have emphasized the utmost importance of carefully considering the quantity of Recron3 fibers in the mixture to optimize the desired properties of concrete. Their extensive study has shed light on the fact that an increase in the amount of Recron3 fibers has a direct impact on the workability and compaction factor of the concrete. Through their research, they have determined that the optimal proportion of Recron3 fibers, which ensures the highest benefits in terms of compressive strength, split tensile strength, and flexural strength in Recron3 fiber-reinforced concrete, is 0.3%. This valuable insight provides valuable information for professionals seeking to strike a balance between the positive effects of fiber reinforcement and the practical considerations of workability.

In addition, Susmit Marde and Hardik Wade (2021)[20] expanded the scope of their research to examine the impact of Recron3s fibers on higher-grade concrete mixes (M40 and M60). Their findings revealed that the inclusion of Recron3s fibers at a ratio of 1% to the weight of cement in fiber-reinforced concrete resulted in significantly improved levels of compressive, flexural, and durability strength. The study demonstrated a noteworthy increase of 8 to 13% in compressive strength compared to conventional concrete, as well as substantial enhancements in flexural strength ranging from 7.25% to 20%. These findings suggest that the advantages of Recron3s fiber reinforcement extend beyond M30 grade concrete, highlighting its efficacy in enhancing the performance of higher-grade mixes.

In their study, Nanda et al. (2020)[21] broadened the scope of inquiry by examining the collective impact of fly ash, metakaolin, and Recron 3S fiber as partial substitutes for Portland slag cement. The optimum blend, comprising 10% fly ash, 5% metakaolin, and 0.2% Recron 3S fiber, exhibited enhancements in compressive strength, split tensile strength, and flexural strength in contrast to conventional concrete. These findings underscore the potential of sustainable concrete methodologies. MK Kumari and N Sinha (2022) [22] presented a comprehensive analysis highlighting the advantages of integrating fibers, specifically Recron 3S, into concrete. The authors underscored the notable enhancements in compressive and split tensile strength, crediting these positive outcomes to the uniform dispersion of stress, which effectively minimizes the occurrence of cracks and fortifies resistance against external forces. Although there were some limitations observed regarding the improvement of flexural strength, the overall inference strongly advocates for the prolongation of concrete structure durability through fiber reinforcement.

|

Table 2 Summary of Literature Survey related to Recron3s fiber in M-30 Concrete |

|||||||

|

Recron 3S Polyester Fiber Reinforced Concrete |

V. Prahatheswaran and Dr P. Chandrasekaran (2017) [18] |

Recron3s fibers in concrete |

Compressive strength, split tensile strength, fiber content optimization |

Addition of Recron3s fibers to a concrete mix, various fiber contents |

Significant increase in compressive and split tensile strength with Recron3s fibers, optimal fiber content determined with 0.5% - 1.13 times improvement in strength. |

Increased fiber content affects workability and compaction factor. |

Optimal proportion of 0.3% Recron3 fibers is recommended for desired properties. |

|

KA Kumar and GS Rao (2017) [19] |

Quantity of Recron3 fibers in concrete |

Workability, compaction factor, fiber quantity optimization |

Varying quantities of Recron3 fibers in concrete mixtures |

Optimal proportion of 0.3% Recron3 fibers for highest benefits in compressive, split tensile, and flexural strength. |

Increased fiber content impacts workability and compaction. |

Consideration of fiber quantity is crucial for optimizing concrete properties. |

|

|

Susmit Marde and Hardik Wade (2021)[20] |

Recron3s fibers in higher-grade concrete mixes |

Compressive, flexural, and durability strength |

Inclusion of Recron3s fibers in M40 and M60 concrete mixes |

Significant improvement in compressive, flexural, and durability strength with 1% Recron3s fibers with 8% to 13% increase in compressive strength. |

- |

The advantages of Recron3s fibers extend beyond M30-grade concrete. |

|

|

Nanda et al. (2020)[21] |

Fly ash, metakaolin, and Recron 3S fiber in Portland slag cement |

Compressive, split tensile, and flexural strength |

Partial substitution of fly ash, metakaolin, and Recron 3S fiber |

Optimum blend enhances strength properties compared to conventional concrete. |

- |

Potential for sustainable concrete methodologies. |

|

|

MK Kumari and N Sinha (2022) [22] |

Integration of Recron 3S fibers into concrete |

Compressive and split tensile strength, stress dispersion |

Integration of Recron 3S fibers into concrete mixtures |

Notable enhancements in compressive and split tensile strength, stress dispersion minimizes crack occurrence. |

Some limitations were observed in flexural strength improvement. |

Prolongation of concrete structure durability through fiber reinforcement. |

|

The Table 1 and Table 2 shows the summary of the literature review that highlights the significant potential of steel slag aggregates and Recron 3S polyester fibers in enhancing concrete performance. Steel slag provides improved durability, strength, and sustainability, while Recron 3S fibers contribute to enhanced mechanical properties and longevity. The inclusion of these materials presents a promising opportunity for the development of environmentally friendly and high-performance concrete. Further research is encouraged to explore optimization techniques, address potential limitations, and expand the range of real-world applications.

Conclusion

A. Conclusion The synthesis of the literature highlights the significant potential of steel slag aggregates and Recron 3S polyester fibers in enhancing concrete performance. Steel slag offers improved durability, strength, and sustainability, while Recron 3S fibers contribute to enhanced mechanical properties and longevity. The inclusion of these materials presents a promising opportunity for the development of environmentally friendly and high-performance concrete. However, further research is encouraged to explore optimization techniques, address potential limitations, and expand the range of real-world applications. Additionally, ongoing efforts are needed to assess the long-term durability and environmental impact of concrete mixes incorporating Recron 3S fiber and steel slag aggregate. Further exploration and optimization of these materials hold promise for advancing sustainable construction practices and meeting the evolving demands of the construction industry. B. Future Prospect The findings of this study present opportunities for future research and development in the field of concrete technology. Several potential areas for further exploration could be considered: 1) Durability Studies: Conduct an extensive investigation into the long-term durability of concrete specimens incorporating steel slag and Recron 3S fiber. This study will encompass crucial aspects such as corrosion resistance, resilience against freeze-thaw cycles, and resistance to chemical exposure. 2) Economic Analysis: Conduct a thorough economic analysis to evaluate the cost-effectiveness of integrating steel slag and Recron 3S fiber into concrete production, taking into account the potential long-term savings and environmental advantages. 3) Optimization of Mix Proportions: We will further optimize the mix proportions to determine the most efficient combination of steel slag and Recron 3S fiber in order to enhance the performance of the concrete, while also ensuring economic feasibility. 4) Field Applications: Perform field trials to validate the laboratory findings in real-world construction scenarios, while taking into account practical challenges and variations in environmental conditions. 5) Environmental Impact Assessment: Conduct an evaluation of the environmental impact associated with the utilization of steel slag and Recron 3S fiber in concrete production, specifically focusing on the reduction of carbon footprint and the overall sustainability of the developed concrete mix. By examining these aspects, future research has the potential to make a valuable contribution to the comprehensive comprehension and effective implementation of sustainable and high-performance concrete within the construction industry. Declaration Statement Conflicts of interest: The author affirms that there are no conflicts of interest in relation to the publication of this article.

References

[1] M.?; Khan, M.?; Bilal, H.?; Jadoon, S.?; Khan, M. N. Fiber, S. Bashir, A. J. Sangi, S. Fareed, M. Anas, M. Khan, H. Bilal, S. Jadoon, and M. N. Khan, “Fiber Reinforced Concrete: A Review,” Engineering Proceedings 2022, Vol. 22, Page 3, vol. 22, no. 1, p. 3, Sep. 2022. [2] M. Maslehuddin, A. M. Sharif, M. Shameem, M. Ibrahim, and M. S. Barry, “Comparison of properties of steel slag and crushed limestone aggregate concretes,” Construction and Building Materials, vol. 17, no. 2, pp. 105–112, Mar. 2003. [3] C. Liu, K. Zha, and D. Chen, “Possibility of Concrete Prepared with Steel Slag as Fine and Coarse Aggregates: A Preliminary Study,” Procedia Engineering, vol. 24, pp. 412–416, Jan. 2011. [4] B. Fronek, P. Bosela, and N. Delatte, “Steel Slag Aggregate Used in Portland Cement Concrete,” https://doi.org/10.3141/2267-04, no. 2267, pp. 37–42, Jan. 2012. [5] H. Qasrawi, “The use of steel slag aggregate to enhance the mechanical properties of recycled aggregate concrete and retain the environment,” Construction and Building Materials, vol. 54, pp. 298–304, Mar. 2014. [6] V. Subathra Devi and B. K. Gnanavel, “Properties of Concrete Manufactured Using Steel Slag,” Procedia Engineering, vol. 97, pp. 95–104, Jan. 2014. [7] B. Pang, Z. Zhou, and H. Xu, “Utilization of carbonated and granulated steel slag aggregate in concrete,” Construction and Building Materials, vol. 84, pp. 454–467, Jun. 2015. [8] L. Rondi, G. Bregoli, S. Sorlini, L. Cominoli, C. Collivignarelli, and G. Plizzari, “Concrete with EAF steel slag as aggregate: A comprehensive technical and environmental characterisation,” Composites Part B: Engineering, vol. 90, pp. 195–202, Apr. 2016. [9] R. Nehvi, P. Kumar, and U. Z. Nahvi, “Effect of Different Percentages of Polypropylene Fibre (Recron 3s) on the Compressive, Tensile and Flexural Strength of Concrete,” International Journal of Engineering Research and, vol. V5, no. 11, Nov. 2016. [10] N. Palankar, A. U. Ravi Shankar, and B. M. Mithun, “Durability studies on eco-friendly concrete mixes incorporating steel slag as coarse aggregates,” Journal of Cleaner Production, vol. 129, pp. 437–448, Aug. 2016. [11] Y. Guo, J. Xie, W. Zheng, and J. Li, “Effects of steel slag as fine aggregate on static and impact behaviours of concrete,” Construction and Building Materials, vol. 192, pp. 194–201, Dec. 2018. [12] J. Liu and R. Guo, “Applications of Steel Slag Powder and Steel Slag Aggregate in Ultra-High Performance Concrete,” Advances in Civil Engineering, vol. 2018, 2018. [13] Y. Guo, J. Xie, J. Zhao, and K. Zuo, “Utilization of unprocessed steel slag as fine aggregate in normal- and high-strength concrete,” Construction and Building Materials, vol. 204, pp. 41–49, Apr. 2019. [14] J. Liu, B. Yu, and Q. Wang, “Application of steel slag in cement treated aggregate base course,” Journal of Cleaner Production, vol. 269, p. 121733, Oct. 2020. [15] S. Saxena and A. R. Tembhurkar, “Impact of use of steel slag as coarse aggregate and wastewater on fresh and hardened properties of concrete,” Construction and Building Materials, vol. 165, pp. 126–137, Mar. 2018. [16] M. H. Lai, J. Zou, B. Yao, J. C. M. Ho, X. Zhuang, and Q. Wang, “Improving mechanical behavior and microstructure of concrete by using BOF steel slag aggregate,” Construction and Building Materials, vol. 277, p. 122269, Mar. 2021. [17] Q. Dong, G. Wang, X. Chen, J. Tan, and X. Gu, “Recycling of steel slag aggregate in portland cement concrete: An overview,” Journal of Cleaner Production, vol. 282, p. 124447, Feb. 2021. [18] P. Prahatheswaran, V & Chandrasekaran, “Study on Structural Behaviour of Fiber Reinforced Concrete With Recron 3s Fibers,” SSRG International Journal of Civil Engineering- (ICRTECITA), no. Special Issue-March 2017, 2017. [19] R. G. Kumar KA, Yajdani DS, “Study on Properties of Concrete using Recron 3s Fiber,” International Journal of Science Technology & Engineering, vol. Sep, no. 4(3), pp. 54-62., 2017. [20] S. Marde, H. Wade, H. Jadhav, A. Thakur, and S. C. Mailpatil, “Study on Properties of Concrete Using Recron3s Fibre,” International Journal of Innovations in Engineering and Science, vol. 6, no. 6, pp. 29–37, Jun. 2021. [21] R. P. Nanda, A. K. Mohapatra, and B. Behera, “Influence of metakaolin and Recron 3s fiber on mechanical properties of fly ash replaced concrete,” Construction and Building Materials, vol. 263, Dec. 2020. [22] M. K. Kumari and N. Sinha, “Comparative Study of Natural Fibres Coconut, Polypropylene Fibres Recron 3s & Steel Fibres on Strength of Concrete,” International Research Journal of Modernization in Engineering Technology and Science, vol. 4, no. 5, p. 3170, 2022.

Copyright

Copyright © 2024 Priyanka Vishwakarma, Dr. Anil Suman. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59375

Publish Date : 2024-03-24

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online