Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental Study of Conventional and Self-Healing Concrete

Authors: Sonu Jatav, Prof. Gaurav Shrivastava

DOI Link: https://doi.org/10.22214/ijraset.2025.66506

Certificate: View Certificate

Abstract

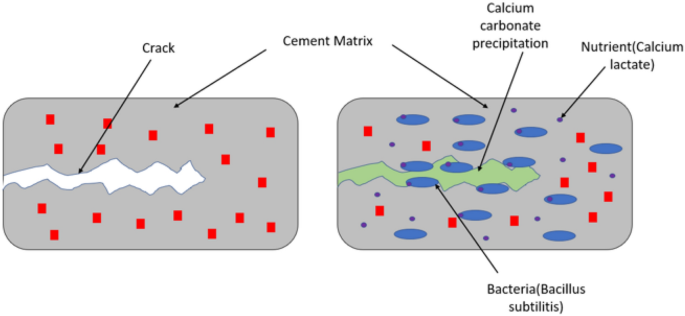

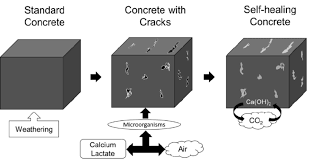

The service life of concrete structures exposed to the environment has diminished in the modern construction sector due to their low strength, durability, and other features. One special technique for fixing or healing cracks that have formed in the structures is the bio-mineralization of calcium carbonate with the aid of microbes like Bacillus. This study explains how the durability of concrete buildings may be improved by including bacterial cells and other nutrients required for the bio-remediation process. During calcification, calcium is created when carbonate ions and calcium precipitate released by microorganisms interact. As a result, the carbonate (calcite) layer cracks mend themselves. According to a study, employing concrete cubes that have been treated with microorganisms would make concrete constructions more resilient.

Introduction

I. INTRODUCTION

Concrete is the most commonly used construction material. It possesses the advantage of being readily shaped into any preferred form. Water, cement, and aggregate facilitate the treatment of the end product for hardening. Cement and its two primary constituents. Water that chemically interacts with one another to fracture an additional substance with practical strength. The strength of concrete relies on the characteristics, their proportions, and the methods of mixing, compacting, and curing. It can produce concrete by appropriately adjusting the amounts of cement, water, and aggregates according to certain parameters.

The functionality of the structures must be lawful and valid. Minor structural deficiencies should be circumvented to maintain serviceability, as they may ultimately result in significant issues. The building's fractures can be sealed without requiring repair. The self-healing mechanism for cracks enables the rehabilitation and regeneration of fissures, thereby preventing further damage.

Fig. 1 Self healing concrete

II. MATERIALS

The cement employed in the current research effort is OPC 53 grade, and all of its qualities fall within the parameters of IS 269-2015. Cement has a specific gravity of 3.09 and a fineness of 8g, a 34% cement consistency, and a first – setting time of cement takes 45 minutes to set completely, with IS383-2016 zone- II was used as fine amalgamations. The fine aggregate’s fineness modulus is 3.02 and the fine aggregate has a specific gravity of 2.61. The granite dust for coarse aggregate, stones with a nominal size of 20mm are used, and the properties comply with IS:2386-963 regulations

III. PREPARATIONS OF SPECIMENS

M 20 concrete mix proportions are used for the preparing the samples. Standard specimens were casted. Examples of bacteria whereby the water is substituted by 20%, 30%, 40% of the bacteria solution are also cast simultaneously. The samples were tapped cured. Tested with water at ambient temperature after 7, 14, and 28 days.

Fig. 2 Preparations of Specimens

Table 1 Mix composition of concrete samples

|

S.No. |

Ingredients |

Units(kg/m2) |

|

1. |

OPC |

500 |

|

2. |

Fine Aggregate |

534.76 |

|

3. |

Coarse Aggregate |

1345.567 |

|

4. |

Water |

190 |

IV. MECHANICAL TESTS ON CONCRETE

A. Ultrasonic Pulse Velocity

To evaluate the calibre of concrete, a non-destructive technique called ultrasonic pulse velocity is employed. According to IS: 13311-1 (1992), the strength and homogeneity of concrete can be evaluated using ultra-waves with sonic pulse velocity. Moreover, it is used to inspect internal flaws, the extent of cracks, the concrete structure’s honeycombing. The breadth of the sample with can be used to measure the pulse velocity. Higher velocities denote good concrete quality, but lower velocities imply that concrete is permeable.

B. Compressive Strength Test

For the concrete specimens, the compressive strength was evaluated after 7 and 28 days of curing. Concrete of the M25 grade has achieved the desired mean strength of 40.32 MPa .Exists an increased compressive strength for samples of bacterial mixtures compared to control samples, of 55.6 MPa. The constrictive up to 20% pf strength was recovered after 28 days of treatment. Cracking for bio concrete specimens due to settlement of calcite as a filling material in the inner portion of cracks on the concrete surface.

C. Split Tensile Strength

Comparable to compressive strength , split tensile strength for concrete sample was calculated after 7 and 28 days of curing. The split tensile strength of bacterial sample has increased by 16 % as compared to standard samples after 28 days treatment because of the Exopolysaccharide (ESP) layer production by the bacterial strain. The split tensile strength increased by 45.67 MPa from 36.89 MPa after cracks healing.

D. Flexural Strength

The concrete sample underwent a flexural strength test after 7 and 28 days of curing. For bacterial mix specimens, the flexural strength increases to 6.88 MPa from the standard value of 6.43 MPa of ordinary concrete samples. A 11% increase in flexural strength has been made after cracking for 28 days curing of bacterial mix specimens by the excretion of urease enzyme of biomaterial.

E. Water Absorption

The sizes of 150mm*150mm*150mm cubes were tested to determine the water adsorption percentage at the age of loading.

V. RESULTS AND DISCUSSIONS

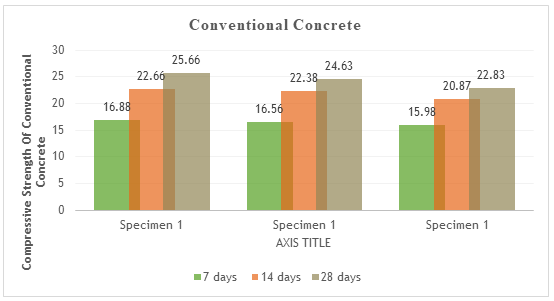

There was discussions and tabulation of the various results from the compressive strength test and the water adsorption tests. The findings charts were also made available. The table 1 shows the compressive strength of the conventional concrete cubes and table 2,3,4, are shows the compressive strength of the bacterial concrete cubes with 20%, 30%, 40% of the bacterial solution respectively. The table 5 represents the comparative results of the water absorption of the conventional and bacterial concrete.

Table 2- Conventional Concrete Cubes

|

Specimen |

Compressive strength N/mm2 |

||

|

7days |

14days |

28days |

|

|

1 |

16.88 |

22.66 |

25.66 |

|

2 |

16.56 |

22.38 |

24.63 |

|

3 |

15.98 |

20.87 |

22.83 |

Fig. 3 Compressive strength of conventional concrete

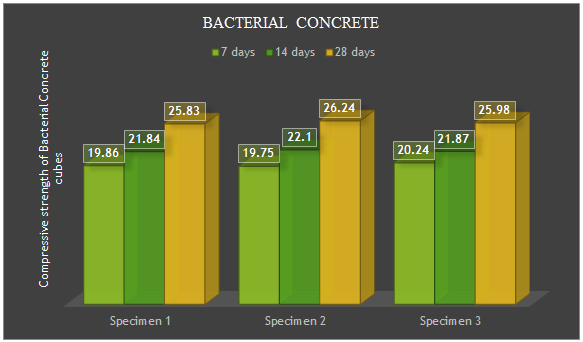

Table 3- Bacterial Concrete cubes with 20% of bacteria and 3 % of calcium lactate

|

Specimen |

Compressive Strength N/mm2 |

||

|

7days |

14days |

28days |

|

|

1 |

19.86 |

21.84 |

25.83 |

|

2 |

19.75. |

22.10 |

26.24 |

|

3 |

20.24 |

21.87 |

25.98 |

Fig. 4 Compressive strength of Bacterial Concrete cubes with 20% of bacteria

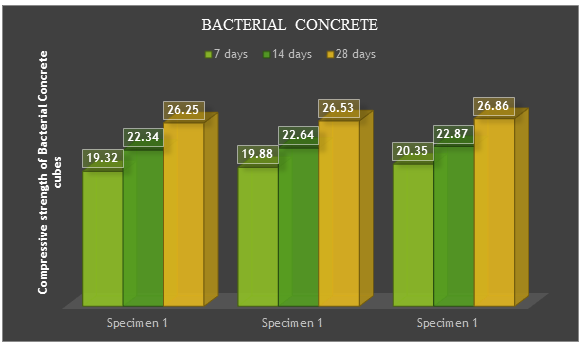

Table -4: Bacterial Concrete cubes with 30% 0f bacteria and 3% of calcium lactate

|

Specimen |

Compressive Strength N/mm2 |

||

|

7days |

14days |

28days |

|

|

1 |

19.32 |

22.34 |

26.25 |

|

2 |

19.88 |

22.64 |

26.53 |

|

3 |

20.35 |

22.87 |

26.86 |

Fig. 5 Compressive strength of Bacterial Concrete cubes with 30% of bacteria

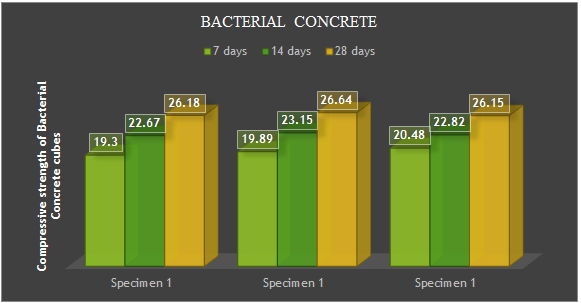

Table -5: Bacterial Concrete cubes with 40% of bacteria and 3% of calcium Lactate

|

Specimen |

Compressive Strength N/mm2 |

||

|

7days |

14days |

28days |

|

|

1 |

19.30 |

22.67 |

26.18 |

|

2 |

19.89 |

23.15 |

26.64 |

|

3 |

20.48 |

22.82 |

26.85 |

Fig. 6 Compressive strength of Bacterial Concrete cubes with 40% of bacteria

Table -6: Comparison of Compressive Strength results

|

S.No. |

Average Compressive Strength N/mm2 |

|||

|

Conventional Concrete |

Bacterial concrete |

|||

|

20% |

30% |

40% |

||

|

1 |

24.64 |

26.01 |

26.48 |

26.42 |

Table -7: Water absorption of concrete cubes in percentage

|

S.No. |

Water Absorption in % |

|||

|

|

Conventional Concrete |

Bacterial Concrete |

||

|

20% |

30% |

40% |

||

|

1 |

2.458 |

1.214 |

1.009 |

1.345 |

|

2 |

2.462 |

0.985 |

1.224 |

1.287 |

|

3 |

2.443 |

1.251 |

1.124 |

1.087 |

Table -8:Comparison of Water adsorption results

|

S.No. |

Average Water Absorption in % |

|||

|

Conventional concrete |

Bacterial concrete |

|||

|

20% |

30% |

40% |

||

|

1 |

2.454 |

1.150 |

1.119 |

1.238 |

Table-9: Ultrasonic Pulse Velocity Test Result

|

Specimen |

Bacterial Concrete |

Conventional Concrete |

|

1. |

35.90 Microsecond,4174 m/s |

49.20 Microsecond,3089 m/s |

|

2. |

34.90 Microsecond 4298 m/s |

44.10 Microsecond,3450 m/s |

|

3 |

35.40 Microsecond 4232 m/s |

42.20 Microsecond,3670 m/s |

Conclusion

The research paper asserts that bacterial concrete may represent the optimal solution for microbial-induced calcite precipitation owing to its numerous distinctive characteristics. The method of self-healing through the incorporation of bacteria into concrete offers the broader advantage of reducing the necessity for human inspection and maintenance, hence conserving time and financial resources, while enhancing the structure\'s durability. Minor imperfections in the structures can be rectified, and it was shown that the compressive strength of bacterial concrete far surpasses that of traditional concrete. The incorporation of bacteria in concrete enhances its durability by reducing water absorption. Due to the utilisation of only 20%, 30%, and 40% of bacterial solutions in this study, further research is necessary to ascertain the requisite proportion for bacterial solution replacement. Along with that the Nondestructive testing by using Ultrasonic pulse velocity test also shows better results in comparison with that of conventional concrete of the strength test The study revealed that many therapeutic agents have benefits and drawbacks, implying that future research as a follow-up study is required.

References

[1] U.J. Umesh,M. Lahoti, Z. Chen, J. Qiu, B. Cao, E.H. Yang, Viability of bacterial sporesand crack healing in bacteria-containing geopolymer, Constr. Build. Mater.169(2018) 716–723, https://doi.org/10.1016/j.conbuildmat.2018.03.039. [2] C.S.S. Durga, N. Ruben, A Review of the Mechanical Behavior of SubstitutionMaterials in Self-healing Concrete, in: B. Das, N. Neithalath(Eds.),Sustainable Construction and Building Materials, Lecture Notes in CivilEngineering, Springer, Singapore, 2019, https://doi.org/10.1007/978-981-13-3317-0_12. [3] N. Ganesh Babu, S. Siddiraju, An experimental study on strength and fractureproperties of self-healing concrete, Int. J. Civ. Eng. Technol. (IJCIET) 7 (3) (2016)398–406, ISSN Print: 0976-6308 and ISSN Online: 0976-6316. [4] C.C. Hung, Y.F. Su, Y.M. Su, Mechanical properties and self-healing evaluationof strain-hardening cementitious composites with high volumes of hybridpozzolan materials, Compos. Part B: Eng. 133 (2018) 15–25, https://doi.org/10.1016/j.compositesb.2017.09.005. [5] X. Jing, X. Wang, B. Wang, Biochemical process of ureolysis-based microbialCaCO3 precipitation and its application in self-healing concrete, Appl.Microbiol. Biotechnol.102 (7) (2018) 3121–3132, https://doi.org/10.1007/s00253-018-8779-x. [6] J. Luo, X. Chen, J. Crump, H. Zhou, D.G. Davies, G. Zhou, N. Zhang, C. Jin,Interactions of fungi with concrete: significant importance for bio-based self-healing concrete, Constr. Build. Mater.164 (2018) 275–285, https://doi.org/10.1016/j.conbuildmat.2017.12.233. [7] A. Ali, Z.B. Bundur, Use of corn-steep liquor as an alternative carbon source forbiomineralization in cement-based materials and its impact on performance,Constr. Build. Mater.165 (2018) 655–662, https://doi.org/10.1016/j.conbuildmat.2018.01.070. [8] X. Jing, X. Wang, Self-healing of concrete cracks by use of bacteria-containinglow alkali cementitious material, Constr. Build.Mater.167 (2018) 1–14,https://doi.org/10.1016/j.conbuildmat.2018.02.020. [9] M.V. Seshagiri Rao, V. Srinivasa Reddy, M. Hafsa, P. Veena and P. Anusha, June (2013), “Bioengineered Concrete - A Sustainable Self-Healing Construction Material” International science association congress, Research Journal of Engineering Sciences- ISSN 2278 – 9472, Vol. 2(6), 45-51. [10] P. Tiano, L. Biagiotti, G. Mastromei, “Bacterial biomediated calcite precipitation for monumental stones conservation: methods of evaluation”, published by Journal of Microbiological Methods, Vol.36, Issues 1–2, 1999. [11] Rajesh K. Verma, Leena Chaurasia, VishakhaBisht, Manisha Thakur (2015) “Bio-Mineralization and Bacterial Carbonate Precipitation in Mortar and Concrete”, American Institute of Science (AIS) and Bioscience and Bioengineering, Vol. 1. [12] S. Soundharya, Dr. K. Nirmalkumar, (July 2014), “Study on the Effect of Calcite-Precipitating Bacteria on Self-Healing Mechanism of Concrete”, International Journal of Engineering Research & Management Technology (IJERM), ISSN: 2348-4039, Volume 1, Issue-4. [13] S. Silvia Hanah, N. Sakthieswaran (May 2015), “Mechanical Properties of Bio Mineralized Concrete”, International Journal of Research in Technology (IJRET), eISSN: 2319-1163 | pISSN: 2321 -7308, Volume: 04 Issue: 05. [14] Srinivasa Reddy V, Sreenivasa Rao D, SeshagiriRao M V, Sasikala Ch. “Permeation Properties of Bacterial Concrete” published in IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) e-ISSN: 2278 -1684 Volume 5, Issue 6 (Mar. - Apr. 2013), PP 08-12. [15] S. Sunil Pratap Reddy, M.V. Seshagiri Raob, P. Aparnac and Ch. Sasikalac. “Performance of standard grade bacterial (bacillus subtilis) concrete” published in asian journal of civil engineering (building and housing) vol. 11, no. 1 (2010).

Copyright

Copyright © 2025 Sonu Jatav, Prof. Gaurav Shrivastava. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET66506

Publish Date : 2025-01-13

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online