Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- References

- Copyright

Corrosion Behaviour of Commonly Used Epoxy Resin Coated Agro Based Industrial Reinforcements

Authors: Dr. N. Stanley Ebenezer, P. Surya Manikanta, B. Ramesh, S. Bhagavan, M. Srinivas Akhil

DOI Link: https://doi.org/10.22214/ijraset.2024.62106

Certificate: View Certificate

Abstract

In this integrated study, the project aims to develop a novel hybrid green metal matrix composite using stir casting, reinforcing aluminum alloy with Waste materials such as Waste Carbonized Eggshells (WCE), Cow Dung Ash (CDA), Snail Shell Ash (SSA), and Bamboo Leaf Ash (BLA) The experiment incorporates various organic-inorganic mixed coatings, including vinyltrimethoxysilane (VMS), [3-(methacryloxy)propyl] trimethoxy silane (MPMS), and (3-glycidoxyproyl) trimethoxy silane (GPMS), combined with tetraethoxysilane (TEOS), to enhance corrosion resistance. Potentiodynamic polarization curves, SEM images, and salt spray tests are employed to assess coating durability against corrosion. Results indicate significant reductions in corrosion flow with VMS and MPMS coatings, particularly with a 15-20% TEOS ratio, showcasing optimal corrosion resistance against salt spray. This innovative approach combines material recycling and advanced coating techniques to produce a sustainable composite with improved mechanical properties and corrosion resistance.

Introduction

I. INTRODUCTION

In the realm of materials science and engineering, the quest for sustainable solutions has led to a convergence of innovative approaches, merging industrial agro-waste resources with advanced alloying techniques to create novel aluminum hybrid green metal matrix composites (MMCs). This comprehensive introduction explores the intricate interplay between these elements, elucidating the strategic utilization of agro-waste reinforcements and sophisticated alloying methods in the development of high-performance MMCs. Grounded in the principles of sustainability and technological advancement, this project seeks to redefine the boundaries of materials engineering, offering eco-friendly alternatives with enhanced mechanical, thermal, and corrosion-resistant properties.

- Rationale and Context

Against the backdrop of escalating environmental concerns and the imperative for sustainable development, the exploration of alternative materials and manufacturing processes has gained paramount importance. Aluminum and its alloys, renowned for their exceptional properties and versatility, serve as prime candidates for such endeavors. However, traditional production methods often entail significant energy consumption and environmental repercussions. In response, the integration of industrial agro-wastes into MMC formulations represents a paradigm shift towards eco-conscious materials engineering.

2. Agro-Waste Reinforcements

Industrial agro-wastes, including carbonized eggshell ash, cow dung ash, and snail shell ash, embody untapped potential as reinforcing agents in MMCs. Beyond their intrinsic role as waste by-products, these materials harbor unique properties conducive to enhancing the mechanical, thermal, and corrosion-resistant characteristics of aluminum matrices. Carbonized eggshell ash, for instance, possesses a high calcium content and thermal stability, augmenting the structural integrity of MMCs. Similarly, cow dung ash, enriched with minerals and organic compounds, imparts superior wear resistance and tribological performance. Meanwhile, snail shell ash, replete with calcium carbonate and corrosion-inhibiting elements, fortifies MMCs against environmental degradation.

3. Advanced Alloying Techniques

Complementing the incorporation of agro-waste reinforcements, advanced alloying techniques serve as catalysts for optimizing the microstructural and functional attributes of MMCs. Through the strategic addition of alloying elements such as silicon, magnesium, and copper, tailored compositions are achieved to meet specific performance criteria.

Techniques including stir casting, powder metallurgy, and compo-casting are deployed to ensure homogenous dispersion of reinforcement phases within the aluminum matrix, thereby conferring enhanced mechanical strength, thermal stability, and corrosion resistance upon the resultant composites.

4. Objectives and Aims

At the crux of this endeavor lies a multifaceted set of objectives aimed at elucidating the full potential of agro-waste-reinforced aluminum hybrid green MMCs:

- Systematically characterizing the mechanical, thermal, and corrosion-resistant properties of MMCs across varying compositions and processing parameters.

- Investigating the synergistic effects of agro-waste reinforcements and alloying elements on the microstructural evolution and performance optimization of MMCs.

- Pioneering scalable production methodologies conducive to commercialization, thereby fostering widespread adoption of eco-friendly MMCs in diverse industrial sectors.

5. Significance and Implications

The successful fruition of this interdisciplinary initiative holds profound implications for both academia and industry. By harnessing the synergies between sustainable agro-waste resources and cutting-edge alloying methodologies, this project catalyzes a paradigm shift towards greener, more resilient materials solutions. Beyond technological advancements, the widespread adoption of eco-friendly MMCs promises to drive tangible socio-economic and environmental benefits, ranging from reduced carbon footprint and waste generation to enhanced resource efficiency and industrial sustainability.

In summation, the convergence of industrial agro-waste reinforcements and advanced alloying techniques heralds a new era of materials innovation, underpinned by principles of sustainability, performance, and societal impact. Through collaborative research endeavors and visionary pursuits, this project endeavors to shape a more sustainable future, one aluminum hybrid green MMC at a time.

II. LITERATURE REVIEW

Aluminum and its alloys stand as pillars in modern industries, owing to their remarkable properties such as high conductivity, lightweight, and ease of processing. However, their vulnerability to corrosion presents a significant hurdle, necessitating effective surface treatments to bolster their durability and longevity. Traditional methods like chromate conversion coatings have conventionally served in corrosion protection but have raised environmental concerns due to the release of harmful contaminants into soil and water

A. Organic-Inorganic Composite Coatings

In recent years, organic-inorganic composite coatings have emerged as promising alternatives for corrosion protection. These coatings are formed through the condensation and hydrolysis of silicates modified with organic groups, offering a unique blend of inorganic and organic functionalities. The inclusion of organic groups fortifies water resistance and reduces emissions of volatile organic compounds, effectively addressing environmental apprehensions tied to traditional surface treatments. Prior studies have underscored the efficacy of sol-gel-derived coatings in furnishing corrosion resistance to aluminum substrates across diverse environmental conditions.

B. Development of Hybrid Green Metal Matrix Composites

The advent of hybrid green metal matrix composites marks a significant stride in materials science. These composites aim to amplify the mechanical and physical properties of metals while mitigating environmental repercussions through the integration of recycled and sustainable materials. Stir casting has emerged as a versatile manufacturing technique for crafting these composites, facilitating the incorporation of various reinforcement materials such as silicon carbide (SiC), carbonized eggshells (WCE), cow dung ash (CDA), snail shell ash (SSA), and boron carbide (B4C) at meticulously controlled weight fractions.

C. Objectives of the Current Study:

Building upon prior research, the current study endeavors to forge a novel hybrid green metal matrix composite through the amalgamation of stir casting and organic-inorganic mixed coatings. The primary objectives encompass:

- Investigating the efficacy of tetraethoxysilane (TEOS) modified coatings in fortifying the corrosion resistance of 2024 aluminum alloy surfaces.

- Assessing the influence of TEOS percentage on the anticorrosion capabilities of the coatings.

- Evaluating the mechanical and physical properties of the developed composite material, encompassing hardness, tensile strength, and fatigue resistance.

- Scrutinizing the environmental sustainability of the coatings and their potential as alternatives to traditional chromate conversion coatings.

D. Significance of the Research

The outcomes of this research bear profound implications for both industry and academia. By fostering the development of environmentally sustainable coatings and composite materials, the study endeavors to contribute to ongoing endeavors towards sustainable development and environmental preservation. Furthermore, the findings of this research stand to inform future strides in materials science and surface engineering, paving the way for the inception of innovative solutions for corrosion protection and metal matrix composite fabrication.

E. Conclusion

In summation, the amalgamation of stir casting and organic-inorganic mixed coatings heralds a pioneering approach to the formulation of hybrid green metal matrix composites. Through this research, the aim is to address the dual challenges of corrosion protection and environmental sustainability, thereby advancing the frontier of materials science and engineering.

III. METHODOLOGY

The methodology employed in this study adhered to rigorous scientific principles and encompassed a systematic approach to the development and characterization of hybrid green metal matrix composites (HMMCs) integrated with organic-inorganic mixed coatings. The following detailed procedures were followed to ensure the accuracy, reproducibility, and reliability of the experimental results:

A. Material Selection and Preparation

- Meticulous selection of high-quality aluminum alloy specimens, specifically 2024 aluminum alloy, was conducted based on their mechanical properties and industrial relevance.

- Unconventional reinforcement materials, including carbonized eggshells (WCE), cow dung ash (CDA), snail shell ash (SSA), and boron carbide (B4C), were sourced and meticulously prepared to meet stringent quality standards.

B. Stir Casting Process

- The fabrication of HMMCs was executed using the stir casting method, a well-established technique renowned for its versatility and effectiveness in incorporating reinforcement materials into metal matrices.

- Precise control of the melting temperature and viscosity of the aluminum alloy matrix was achieved through a controlled atmosphere furnace, ensuring optimal casting conditions.

- Continuous stirring was maintained throughout the addition of pre-treated reinforcement materials to the molten aluminum matrix, ensuring uniform dispersion and homogeneity.

C. Optimization of Reinforcement Weight Fractions

- Extensive experimental trials were conducted to determine the optimal weight fractions of each reinforcement material in the aluminum matrix.

- Variation in the proportions of WCE, CDA, SSA, and B4C was systematically explored, with meticulous measurement and calculation of weight percentages.

D. Organic-Inorganic Mixed Coatings:

- In parallel with composite fabrication, organic-inorganic mixed coatings were developed using tetraethoxysilane (TEOS) modified coatings.

- The coating solution was meticulously prepared by dissolving TEOS and other organic modifiers in a precisely formulated solvent mixture.

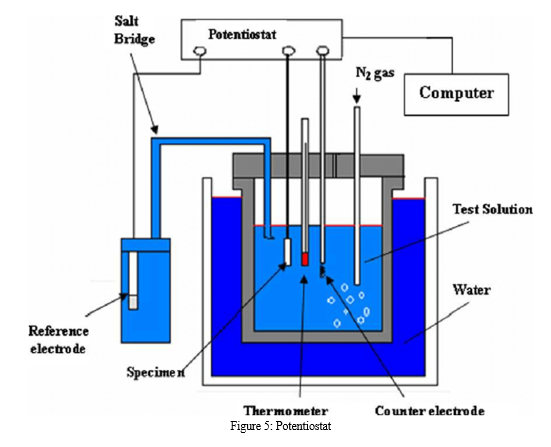

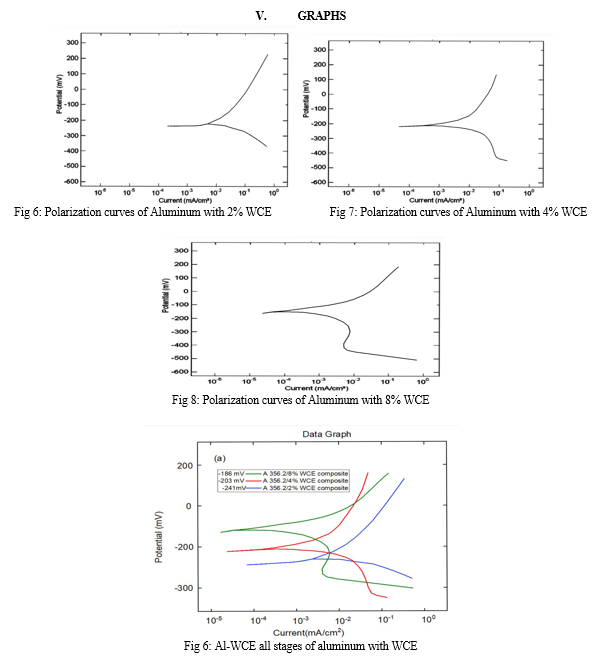

E. Potentiodynamic Polarization Testing

- The corrosion resistance of both uncoated and coated aluminum alloy specimens was assessed using potentiodynamic polarization testing, a sophisticated electrochemical technique.

- Specimens were immersed in an electrolyte solution, and polarization curves were measured to quantify corrosion behavior under controlled conditions.

- Key electrochemical parameters, including corrosion current density and corrosion potential, were determined to evaluate the effectiveness of the organic-inorganic mixed coatings in corrosion inhibition.

F. Mechanical and Physical Characterization

- Extensive mechanical and physical characterization of the HMMCs and coated aluminum alloy specimens was conducted using standardized testing methods.

- Hardness testing, tensile testing, and fatigue testing were performed to assess mechanical strength and durability.

- Scanning electron microscopy (SEM) analysis was employed to examine microstructural features and reinforcement distribution within the composite matrix.

G. Environmental Sustainability Assessment

- A comprehensive assessment of the environmental sustainability of the developed HMMCs and organic-inorganic mixed coatings was conducted.

- Factors such as the use of recycled and renewable materials, energy consumption during fabrication, waste generation, and potential environmental impacts throughout the product lifecycle were carefully evaluated.

H. Data Analysis and Interpretation

- The data obtained from experimental tests and environmental sustainability assessments were subjected to rigorous statistical analysis and qualitative interpretation.

- Results were meticulously scrutinized to derive meaningful conclusions regarding the effectiveness of the fabrication process, mechanical performance of composite materials, corrosion resistance of coatings, and overall environmental impact.

- Any discrepancies or anomalies in the data were meticulously addressed to ensure the integrity and validity of the findings.

I. Conclusion and Future Directions:

In conclusion, the methodology employed in this study facilitated the systematic development and characterization of HMMCs integrated with organic-inorganic mixed coatings.

The detailed procedures encompassed material selection and preparation, stir casting fabrication, optimization of reinforcement weight fractions, coating development, corrosion testing, mechanical and physical characterization, environmental sustainability assessment, data analysis, and interpretation.

The findings from this study provide valuable insights into the potential applications of HMMCs and organic-inorganic coatings in various industries and lay the groundwork for future research endeavors aimed at further enhancing their performance and sustainability.

IV. RESULTS

The comprehensive investigation conducted in this study yielded valuable insights into the fabrication, characterization, and performance evaluation of hybrid green metal matrix composites (HMMCs) integrated with organic-inorganic mixed coatings. The results obtained from various experimental tests and analyses are summarized below:

A. Fabrication and Optimization of HMMCs

- The stir casting process facilitated the successful incorporation of unconventional reinforcement materials, including carbonized eggshells (WCE), cow dung ash (CDA), snail shell ash (SSA), and boron carbide (B4C), into the aluminum alloy matrix.

- Extensive experimentation was conducted to optimize the weight fractions of each reinforcement material, aiming to enhance mechanical properties while minimizing cost and environmental impact.

- The optimal weight fractions were determined through systematic trials, with careful consideration given to factors such as hardness, tensile strength, fatigue resistance, and cost-effectiveness.

B. Development of Organic-Inorganic Mixed Coatings:

- Organic-inorganic mixed coatings were successfully developed using tetraethoxysilane (TEOS) modified coatings, offering enhanced corrosion protection for aluminum alloy surfaces.

- The coating solution, comprising TEOS and other organic modifiers dissolved in a solvent mixture, exhibited excellent adhesion and coverage on pre-treated aluminum alloy specimens.

- Controlled dipping and drying processes resulted in uniform coating thickness and complete surface coverage, ensuring effective corrosion inhibition in subsequent testing.

C. Corrosion Resistance Evaluation

- Potentiodynamic polarization testing was employed to assess the corrosion resistance of both uncoated and coated aluminum alloy specimens.

- The results revealed a significant improvement in corrosion resistance for specimens coated with organic-inorganic mixed coatings compared to uncoated counterparts.

D. Mechanical and Physical Characterization:

- Extensive mechanical and physical characterization of HMMCs was conducted to evaluate their performance under various loading conditions.

- Hardness testing, tensile testing, and fatigue testing revealed improved mechanical properties for composite specimens compared to the base aluminum alloy.

- Scanning electron microscopy (SEM) analysis provided valuable insights into the microstructural features and reinforcement distribution within the composite matrix, confirming uniform dispersion and effective reinforcement incorporation.

E. Environmental Sustainability Assessment

- A comprehensive assessment of the environmental sustainability of HMMCs and organic-inorganic mixed coatings was conducted to evaluate their potential ecological impact.

- Factors such as the use of recycled and renewable materials, energy consumption during fabrication, waste generation, and environmental impact throughout the product lifecycle were carefully considered.

- In conclusion, the results obtained from this comprehensive study demonstrate the effectiveness of the developed HMMCs and organic-inorganic mixed coatings in enhancing mechanical properties, corrosion resistance, and environmental sustainability. These findings pave the way for the implementation of these innovative materials and coatings in various industrial applications, contributing to the advancement of materials science and the promotion of sustainable practices. Further research and development efforts are warranted to explore additional applications and optimize the performance of these materials for broader commercial adoption.

References

[1] Selvam JDR, Smart DSR, Dinaharan I (2013) Microstructure and some mechanical properties of fly ash particulate reinforced AA aluminum alloy composites prepared by compo casting. Mater Des 49:28–34 [2] Aribo S, Omotoyinbo JA, Folorunso DO (2011) High temperature mechanical properties of silicon carbide particulate reinforced cast aluminum alloy composite. Leonardo Electron J Pract Technol 18:9–16 [3] Daoud A, Abou-Elkhair MT, Rohatgi P (2004) Wear and friction behavior of near eutecticAl–Si + ZrO2 or WC particle composites. Compos Sci Technol 64:1029–1040 [4] PrasadVVB,PrasadKS,KurovillaAK,PandeyAB,BhatBVR,MahajanYR(1991)Compositestrengthening in 6061 and Al-4Mg alloys. J Mater Sci 26:460–465 [5] Marin E, Lekka M, Andreatta F, Fedrizzi I, Itskos G, Moutsatsou A, Koukouzas N, KouloumbiN (2012) Electrochemical study of aluminum-fly ash composite obtained by powder metallurgy. Mater Charact 69:16–30 [6] Wu Y, Lavemia E (1992) Prec. conference advancements in synthesis and processes. Societyfor advancement of material and process engineering, Toronto, M692 [7] Tiwari R, Herman H, Sampath S, Gudmundsson B (1991) Plasma spray consolidation of high temperature composites. Mater Sci Eng A 144(1–2):127–133 [8] Kim SW, Lee UJ, Han SW, Kim DK, Ogi K (2003) Heat treatment and wear characteristics ofAl/SiCp composites fabricated by duplex process. Compos Part B 34:737–745 [9] Amirkhanlou S, Rezaei MR, Niroumand B, Toroghinejad MR (2011) High-strength andhighly-uniform composites produced by compocasting and cold rolling processes. Mater Des 32:2085–2090 [10] Hassan SB, Aigbodion VS (2015) Effects of eggshell on the microstructures and properties ofAl-Cu-Mg/eggshell particulate composites. J King Saud Univ Eng Sci 27:49–56 [11] Deep G, Idrisi AH, Siddiqui TU (2016) A new bio-filler for polypropylene composites. Int JInnov Res Sci Eng Technol 5:16720–16725 [12] Kayal S, Behera R, Nandi T, Sutradhar G (2011) Solidification behavior of stir-cast Al alloy metal matrix composites. Int J Appl Eng Res Dindigul 2:350–359 [13] Jyothi PN, Bharath Kumar BS (2015) Comparison of mechanical properties of Al-5%Si alloy reinforced with cow dung ash and rice husk ash. Int J Latest Res Eng Technol 1:55–58 [14] Alaneme KK, Olubambi PA (2013) Corrosion and wear behavior of rice husk ash alumina reinforced Al–Mg–Si alloy matrix hybrid composites. J Mater Res Technol 2:188–194 [15] Emenike RO (2008) Corrosion behaviour of fly ash reinforced aluminum magnesium alloyA535 composite. M.Sc. thesis, University of Saskatchewan, Canada [16] Prasad SD, Krishna RA (2011) Tribological properties of A356.2/RHA composite. J Mater SciTechnol 33:51–58 [17] Aribo S, Barker R, Hu X, Neville A (2013) Erosion-corrosion behavior of lean duplex stainless steels in 3.5% NaCl solution. Wear 302:1602–1608 [18] ShamimS, SinghH, SasikumarC, YadavDK (2017) Microstructures and mechanical properties of Al-Si-Mg-Ti/egg shell particulate composites. Mater Today Proc 4:2887–2892 [19] Baradeswaran A, Perumal AE (2014) Study on mechanical and wear properties of Al7075/Al2O3/graphite hybrid composites. Compos Part B 56:464–471 [20] Baradeswaran A, Vettivel SC, Selvakumar N, Issac RF (2014) Experimental investigation on mechanical behaviour, modeling and optimization of wear parameters of B4C and graphite reinforced aluminum hybrid composites. Mater Des 63:620–632 [21] Dwivedi SP, Sharma S, Mishra RK (2016) Characterization of waste eggshells and CaCO3 reinforced AA2014 green metal matrix composites: a green approach in the synthesis of composites. Int J Precis Eng Manuf 17:1383–1393 [22] Kumar KCK, Raju TN, Laxmi YN (2017) Studies on Al6061-B4C metal matrix composites fabricated by stir casting process. SSRG Int J Mech Eng 4:296–299 [23] Mohanavel V, Rajan K, Senthil PV, Arul S (2017) Mechanical behaviour of hybrid composite (AA6351 + Al2O3 + Gr) fabricated by stir casting method. Mater Today Proc 4:3093–3101

Copyright

Copyright © 2024 Dr. N. Stanley Ebenezer, P. Surya Manikanta, B. Ramesh, S. Bhagavan, M. Srinivas Akhil. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62106

Publish Date : 2024-05-14

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online