Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Crack Detection of Structures using Artificial Intelligence System

Authors: Dr. M. S. Kuttimarks, Chetan Mahadeva Krishna, Prof. R. Mahadeva Swamy, Dr. Menbere Aklilu

DOI Link: https://doi.org/10.22214/ijraset.2024.61958

Certificate: View Certificate

Abstract

Structural Health Monitoring (SHM) having wider scope of operations such as structural audit, rehabilitation of structures and along with it a major scope of crack detection is also included. Effective crack detection is vital for ensuring the safety and longevity of civil engineering structures. Crack Detection in existing methods is tedious process, it requires costly equipment’s as well as time consuming, and inaccuracy in mechanical equipment’s. The technological advancements especially in the field of Artificial Intelligence (AI) maybe an acceptable solution for crack identification through mobile app using Image processing techniques. The mobile app can be used to accurately identify crack pattern and measure the size of cracks in structures (concrete and steel). The app needed to capture and process data from diverse sources, such as images, in real time. It allows for real-time monitoring of structures and ensures safety and integrity of it. The image processing algorithm is used for to accurately identifying various types of cracks in different lighting, environmental conditions, effective and optimized solution. This project explained about real-time data processing for crack detection and its challenges. This demanded robust backend infrastructure and efficient data processing techniques to deliver prompt and accurate results. User Interface and Experience developing an intuitive and user-friendly interface for the app while maintaining high performance.

Introduction

I. INTRODUCTION

The development of a mobile app for crack detection in civil engineering structures marks a significant advancement in the field of structural integrity assessment. This innovative app utilizes state-of-the-art technology to accurately identify and analyze cracks in various civil engineering structures, providing engineers and inspectors with a powerful tool for ensuring the safety and stability of buildings, bridges, and other infrastructures. The development of such apps is motivated by the need for efficient and cost-effective methods to monitor the health and integrity of infrastructure. Technology serves as the cornerstone in the evolution of mobile applications designed for crack detection in structures, marking a significant shift towards enhanced efficiency, precision, and accessibility within the realm of structural inspections. Leveraging the computational prowess of mobile devices, coupled with cloud computing technologies, enables real-time analysis of images, empowering stakeholders to make timely interventions and mitigate potential risks promptly. Furthermore, these mobile applications are designed with seamless integration capabilities, allowing them to harmoniously interface with existing systems and software utilized across the construction and maintenance industries. This interoperability enhances the utility of the applications, facilitating streamlined workflows and ensuring consistency in data management practices. Machine learning algorithms stand as pivotal components in the development of mobile applications geared towards crack detection in structures. Their significance lies in their capability to significantly augment the accuracy, efficiency, and automation of the crack detection process.

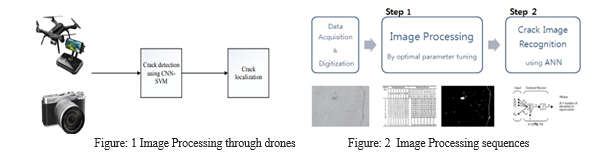

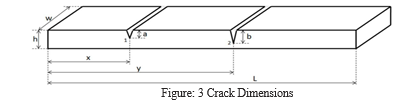

A. Algorithms in Machine Learning

Fundamentally, these algorithms are trained on extensive datasets comprising images of structures, both with and without cracks. Through this training, they learn to discern intricate patterns indicative of cracks, such as irregularities in texture, shape, or color. This acquired knowledge allows them to accurately identify cracks in new images, irrespective of varying environmental conditions or perspectives, thereby enhancing the reliability of crack detection processes. Machine learning algorithms are used for crack detection by training models on large datasets of annotated images. These models learn to recognize patterns associated with cracks and can classify images as either containing cracks or not. Image processing techniques are employed to enhance the captured images, detect cracks, and extract relevant features. This involves algorithms for edge detection, contrast enhancement, noise reduction, and image segmentation. Computer vision techniques enable the app to interpret visual data from images and videos captured by the device's (fFgure 1, 2) camera. This includes identifying different types of cracks (Figure 3 ), measuring crack dimensions, and assessing their severity. (NNM) Neural Network Model [10] The specimen considered here is a cantilever beam having length (L) = 300 mm and thickness (h) = 5 mm with two cracks. The geometry of a cantilever beam with double crack is shown in Figure 1. The parameters are as follows: Relative crack depth of 1st crack (cd1) = a / h, Relative crack depth of 2nd crack (cd2) = b / h Relative crack location of 1st crack (cl1) = x / L, Relative crack location of 2nd crack (cl2) = y / L

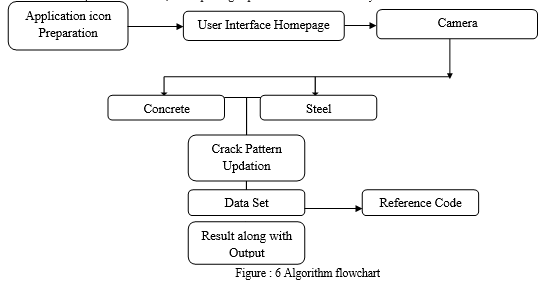

These applications leverage an array of advanced image processing techniques, including but not limited to edge detection, thresholding, and pattern recognition. Through the integration of such sophisticated algorithms, these applications can meticulously analyze images captured by mobile devices, scrutinizing them with remarkable accuracy to swiftly identify cracks and other structural anomalies. Moreover, the incorporation of machine learning algorithms further augments the efficacy and automation of crack detection processes. By training these algorithms on extensive datasets comprising various types of cracks and structural deformities, the system can develop a discerning eye, recognizing nuanced patterns indicative of potential issues. This not only refines the precision of crack detection but also expedites the analysis process, facilitating quicker and more informed decision-making by engineers and inspectors. The Main Objective of this research is to identify cracks formed in structures, Classify the cracks, and remedies for cracks detected by Artificial Intelligence also the Scope of Research is to developed the application of AI Based software interface for crack detection in structures through mobile app by image processing technique.

II. LITERATURE REVIEW

The research papers, data, books, web references, resource person’s details are explained briefly in this chapter year and author wise. AravindKumar S (2023) this model is trained using self-collected road surface crack images (19300 images) from the Outer Ring Road of Chennai, Tamil Nadu, India. The collected road images are pre-processed using various conventional image processing techniques to identify the ground-truth label of the cracks. Multi-tasking Faster- RCNN based approach is deployed with the Global Average Pooling (GAP) layer and Region of Interest (RoI) Align techniques to detect the road cracks. The RoI Align is used to avoid quantizing the stride. So that the information loss can be minimized and the bi-linear interpolation can be used to map the proposal to the input image. The resulting features from RoI Align are given as input to the GAP layer which drastically reduces the multi-dimension features into a single feature map. The output of the GAP layer is given to the fully connected layer for classification (softmax) and also to a regression model for predicting the crack location using a bounding box. RCNN model was used for pre-processing of images captured is done to identify the required labels from images. Crack Fore Cast (CFC) Dataset is used in order to specifically highlight only crack from Road surfaces. Manikanta Reddy (2023) The cracks such as fibre breaking and delamination may occur during impact and also while using the self-piercing riveting technique. It is very essential to detect these cracks to monitor the crack growth and to take preventive measures. The presence of a crack in the structure creates local discontinuities in structural stiffness which alters a structure's dynamic response. This change in dynamic response can be used to detect a crack in structural elements. There are various non-destructive techniques available to monitor the structures. Non-destructive techniques such as ultrasonic, acoustic emission, and thermography are local-based damage detection techniques. These local damage detection techniques require prior knowledge of the vicinity of the crack and also they are time-consuming. Vibration-based techniques are global-based damage detection techniques and these are robust and inexpensive in damage detection. In vibration-based damage detection, the changes in modal parameters are considered. The modal parameters such as modal frequency, modal damping, and mode shape are influenced by the change in mass, damping, and stiffness. Main objective of this study was to detect surface crack in metallic beams and edge cracks in composite beam using Artificial intelligence modal parameters such as modal frequency, damping, and mode shape are influenced by the change in mass, damping, and stiffness. And observed and database regarding these changes occurring was created. Saveeth R (2023) The expansion of cracks in aeroplane constructions is significantly influenced by fatigue. Additionally, wear issues and corrosion damage can cause skin problems and rupture on the structures. Appropriate upkeep and regular predetermined tests can prevent unexpected failure. In recent decades, composite material, a new alloying ingredient is commonly used in fracture resistance design of aircraft structures. It is crucial to create real-time and visible monitoring systems for the structural safety. Techniques including Lamb waves, acoustic emission, infrared thermography, infrared piezoelectric transducers, infrared thermography, infrared acoustic emission, and Digital Image Correlation (DIC) have all been widely used to assess aircraft structural safety. However, their use in large-scale and complex structural components has been constrained due to the limited sensor size, expensive and sophisticated measuring equipment, as well as difficult processing methods. The evaluation of fatigue damage urgently requires full field, real-time, and visible Structural Health Monitoring (SHM) approaches. Techniques like acoustic emission, infrared thermography, infrared piezoelectric transducers, and Digital Image Correlation (DIC) have all been widely used to assess aircraft structural safety. However they cannot be used for very huge parts of aircrafts as well as due to their complexity hence machine learning was implemented and have achieved success crack pattern detection. Sunil Kumar T (2013) Currently available Non Destructive Testing (NDT) methods, such as acoustic, ultrasonic and magnetic field methods are time consuming. Vibration analysis based technique has been proved quick and inexpensive for crack identification. The vibration analysis of a physical system consists of four major steps namely mathematical modeling of a physical system, formulation of governing equations, mathematical solution of the governing equation, and physical interpretation of the results. In the present work, an attempt has been made to develop a mathematical model of cracked composite beams based on elasto-plastic fracture mechanics techniques in order to consider the crack tip plasticity in the analysis. Irwin’s plastic zone correction factor is considered for crack model. A finite element model has been developed to formulate the stiffness matrices for single edge cracked structural elements using transfer matrix theory. These matrices take into account, the effects of axial, flexural and shear deformations due to crack presence. The composite beam with edge crack and transverse loading is considered. The bending stiffness matrix of composite beam is developed. Eigen values of laminated composite beams at different crack depth and location are calculated. The variations in the Eigen-nature of cracked composite beams at different crack depth and location are evaluated. A finite element mathematical model using transfer matrix theory to formulate stiffness matrices showing the effects of axial, flexural and shear deformations due to crack presence. Data Acquistion systems (NI9234) convert analog waveforms into discrete values for processing. Image processing:- It may be possible to classify cracked and non-cracked images directly from the original images by using Artificial Neural Network (ANN). However, the method using only ANN without image processing will require more computation time, since the training images have so many information. Thus it is required to include the image processing before applying ANN step in order to develop an effective process. Image processing step for concrete crack detection consists of the following procedures. (1) Transformation of the acquired digital color image into a gray-level image; (2) Improved subtraction method for the image in uniform brightness; (3) Gaussian filtering for smoothing; (4) Binarization; (5) Morphological processing using closing and labeling. Classification of a crack image using neural network:- In this step, the image can be automatically divided with a cracked and non-cracked concrete image using multi-layer artificial neural network (ANN). The required data of ANN are obtained from the processed images in section 2; the data is arranged by the matrix containing features of the each object in each image such as the number of pixels and the ratio of the major axis to minor axis for connected pixels area. When the object has many pixels and high ratio of the major axis to minor axis, there is a strong possibility that it is a crack object.[8] Convert images to grayscale and increase the resolution:- The reason for using grayscale images is to make it easier to analyzes, reduce noise in images, use simple programming code to reduce image data, allow using cheaper hardware, convert images to grayscale, and increase resolution. In this dataset, the images are taken in grayscale and color (jpg) formats and all of them are of the same size (256 × 256). Therefore, using the MATLAB Toolbox image processing command, all images are converted to grayscale, and the resolution of images is increased. The rgb2gray function in MATLAB converts RGB images to grayscale by eliminating the hue and saturation information while retaining the luminance. Then, using the command I = imadjust(I), it increases the resolution and quality of images. This function maps the intensity values in the grayscale image I to new values such that 1% of data is saturated at low and high intensities of (I).

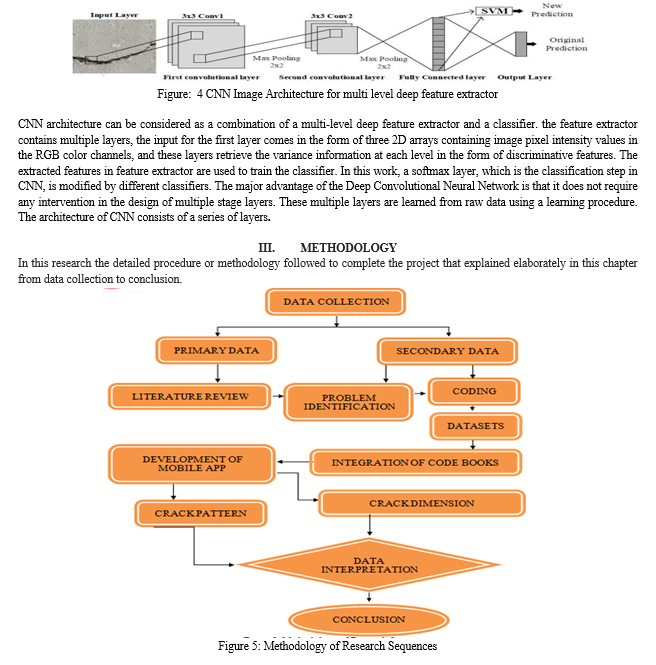

This increases the contrast of the output images. This step is similar to cleaning the data and adjusting them to the input neural network. The Neural Network purpose of this research is Pattern recognition networks are feed-forward networks that can be trained to classify inputs according to target classes. The target data for pattern recognition networks consist of vectors of all zero values except 1 in the element I, where i is the class, they are to represent. After introducing the dataset to the ANN for pattern recognition, the image features are extracted using HOG**. This function is a feature descriptor used in computer vision and image processing for object detection. The technique counts occurrences of gradient orientation in localized portions of an image. This method is similar to that of edge orientation histograms, scale-invariant feature transform descriptors, and shape contexts. However, its results are different from those computed on a dense grid of uniformly spaced cells and use overlapping local contrast normalization for improved accuracy. Learning is a process by which the free parameters (i.e., synaptic weights and bias levels) of a neural network are adapted through a continuing process of stimulation by the environment in which the network is embedded. The type of learning is determined by how the parameter changes take place. In a general sense, the learning process may be classified as Learning with a teacher (also referred to as supervised learning) or learning without a teacher (also referred to as unsupervised learning). In this study, we used supervised learning with feedforward backpropagation neural networks. A feedforward neural network is an ANN wherein connections between the nodes do not form a cycle. [9] Artificial Neural Networks (ANN) based modeling which is a subfield of artificial intelligence. The evolutions in the ANN have brought up various new potential in the arena of complex problems. In ANN modeling, networks can be built directly from experimental data using its self-organizing capabilities which is the main advantage of using ANN. This paper tries to predict multiple cracks in cantilever beam using soft computing technique. The crack location and crack depth of two cracks are the output parameters and the first three relative natural frequencies are the input parameters to the neural network. The result sets obtained from the finite element analysis (FEA) are used to train the network and the simulated results are obtained. It has been found that the maximum error percentage between the analytical and the ANN outputs is very less which shows that the ANN can well build to predict the characteristics of the multiple crack. This paper proposes a good approach for multiple damage detection in cantilever beam.[10] Firstly, images are acquired using a UAV and a DSLR camera, Then, images are classified by a crack detection system based on CNN as a feature extractor and SVM as a classifier. The results from the crack detection module can then be used to localize cracks in the final module. Each module in the proposed system is explained below. In recent years, UAVs have been utilized in surveying as an alternative to conventional surveying methods since they are faster, simpler and cheaper. UAVs can also be utilized to collect images for inspection as shown in this paper. We collected images from a stupa from Wat Chai Watthanaram, which is located in Ayutthaya in Thailand. The images were collected using a DJI Phantom 4 drone. The drone was programmed to fly around the stupa to collect images at two different heights. At the ground level, a DSLR camera were used to collect images of the stupa near the ground. Sample images taken from the drone the top of the stupa cannot be easily reach by human inspectors, and utilizing the drone to collect images around this area clearly provides great benefits for data collection. In the proposed crack detection system, we applied Convolutional Neural Network (CNN) as it has ability in solving many real-world problems efficiently. The multilevel deep feature extractor and a classifier are the two main tools of the CNN architecture. The role of multilevel deep feature extractor is to retrieve discriminant features from image pixel intensity values presented in the RGB colour channels and SVM is used as a classifier for the purpose of classification. In our proposed CNN architecture, Keras sequential model was used, which was composed of convolutional, activation and max pooling layers.[11] The drone was pre-programmed to take pictures every 2-3 seconds to ensure that an overlap between consecutive images is at least 50%. Fig. 3(b) shows the second strategy, the Point of Interest (POI) strategy, in which the drone flew around a fixated object in a circular motion. This strategy is suitable for capturing images of an individual building, and in this method, the drone’s camera was programmed to fixate its viewing angle to the main pagoda located in the center of the temple. The drone took pictures every 2-3 seconds when it moved around the temple at the pre-determined radius. Pictures were collected at two levels of predetermined height, and the images at the ground level were collected manually by researchers who took pictures around the temple in approximate a circular path, similar to the drone motion. In this work, the drone flight paths were pre-programmed in an IOS application call Auto Flight Logic. The application requires input parameters, including altitude, radius, velocity, and camera viewing angles. It is important to note that the drone flight path should be planned carefully so that it can complete the tasks within the flight time of 28 minutes for a single battery pack. It is also worth mentioning that a 3D model created from images can be registered with GPS, unlike the models created from videos. Agisoft is an image-based 3D reconstruction system, which takes input as a set of images and the output will be a 3D point cloud of an interested scene or objects. The software is based on Structure from Motion (SFM). The detection system consists of two main modules, feature extraction, and classification. In this paper, feature extraction was conducted using the convolutional neural network (CNN). CNN is currently a state of the art for most vision problem and it is expected to outperform the traditional feature extraction technique.

In the classification step, once features are extracted from the previous step, a classifier is used to determine whether the extracted features belong to a crack class. The classification process is also done by using three different classifiers in this study, a softmax layer in the CNN itself, Randomized Forest (RF) and Support Vector Machine (SVM) for comparison purpose. In this paper, there are two labels, crack and non-crack classes. As shown in the figure, the input to the system is an image patch, and the output is a label to determine if a patch belongs to as a crack or non-crack class. In this paper, CNN is used for feature extraction(Figure 4). Convolutional Neural Network (CNN) is a type of multilayer feed forward biologically inspired or an influenced variant of the artificial neural network, which has shown their significance in solving realworld problems.

IV. ANALYSIS

In this Chapter step by step procedures of methodology of entire project sequence data interpretations, codes, datasets, technological advancements are discussed in detail. Importance of Crack Detection in Civil Engineering Structures– Case Study Safety and Structural Integrity:- Allows for the early identification of potential weaknesses, preventing catastrophic failures and ensuring the structural integrity of buildings, bridges, and infrastructure. Economic Impact Effective crack detection contributes to the overall economic stability and sustainability of infrastructure projects. Cost-Effective Maintenance By addressing minor issues before they escalate, engineers can avoid extensive repairs and minimize disruptions to the functionality of the structures. Public Trust and Confidence Regular crack detection and maintenance demonstrate a commitment to safety and quality management, enhancing public confidence in the reliability of structures and infrastructure. Computer Vision: Computer vision techniques enable the app to interpret visual data from images and videos captured by the device's camera. This includes identifying different types of cracks, measuring crack dimensions, and assessing their severity. User Interface: The user interface of the mobile app should be intuitive and user-friendly, allowing users to easily capture images, analyze them for cracks, and view the results. Features such as real-time feedback, annotation tools, and reporting capabilities enhance usability.

Integration with Cloud Services: Some mobile apps may integrate with cloud-based services for data storage, processing, and collaboration. This allows for the efficient management of large datasets, remote access to analysis results, and sharing of information among multiple users. Deployment and Maintenance: Once developed, the mobile app needs to be deployed to end-users through app stores or enterprise distribution channels. Regular updates and maintenance are necessary to address bugs, improve performance, and incorporate new features. Challenges and Limitations: Developing a reliable mobile app for crack detection poses several challenges, including variations in lighting conditions, surface textures, and environmental factors. Furthermore, ensuring compatibility across different devices and operating systems can be challenging.

A. Sample Code For Mobile Application Through Image Processing

Code for Opening of App

from tkinter import Tk, Label, PhotoImage # Create the main window

window = Tk()

# Set the window title window.title("Crack Detection App") # Set the window size window.geometry("500x500")

# Load the icon image

icon = PhotoImage(file="icon.png") # Set the window icon window.iconphoto(True, icon)

# Create a label for the loading screen

loading_label = Label(window, text="Loading...", font=("Arial", 24)) loading_label.pack()

# Run the main event loop window.mainloop()

- Brief Explanation of Start code

We start by importing the necessary modules: Tk for creating the main window, Label for creating the loading label, and photoimage for loading the icon image. We create the main window using the Tk() constructor and assign it to the window variable. We set the title of the window using the title() method. We set the size of the window using the geometry() method. In this example, the window size is set to 500x500 pixels.

We load the icon image using the photoimage() constructor and assign it to the icon variable. The image file should be in the same directory as the Python script. We set the window icon using the iconphoto() method. The first argument True indicates that the icon should be used for both the window icon and the taskbar icon. We create a label for the loading screen using the Label() constructor. The label text is set to "Loading..." and the font is set to "Arial" with a size of 24. The label is then packed using the pack() method to display it on the window. Finally, we run the main event loop using the mainloop() method. This method listens for events and updates the GUI accordingly. It keeps the window open until the user closes it.

B. Main Body Code

import cv2

import numpy as np

def detect_cracks(image):

# Preprocess the image

gray = cv2.cvtColor(image, cv2.COLOR_BGR2GRAY) blurred = cv2.GaussianBlur(gray, (5, 5), 0)

edges = cv2.Canny(blurred, 50, 150) # Find contours of cracks

contours,_=cv2.findContours(edges,cv2.RETR_EXTERNAL, cv2.CHAIN_APPROX_SIMPLE)

# Analyze each contour for contour in contours:

# Calculate length and width of the contour x, y, w, h = cv2.boundingRect(contour) length = w

width = h

# Classify the crack as structural or non-structural

if length > threshold_length or width > threshold_width: classification = "Structural"

else:

classification = "Non-Structural" # Display the crack information

print(f"Crack Length: {length} units") print(f"Crack Width: {width} units") print(f"Classification: {classification}")

# Suggest remedial measures based on classification if classification == "Structural":

print("Possible Remedial Measures: Reinforcement, Repair, or Replacement") else:

print("Possible Remedial Measures: Sealing or Filling") # Load the image from the mobile phone's camera image = cv2.imread("crack_image.jpg")

# Set the threshold values for crack classification threshold_length = 10

threshold_width = 2

# Detect and analyze cracks in the image detect_cracks(image)

- Main Body Code Explanation

Preprocesses the image by converting it to grayscale, applying Gaussian blur, and detecting edges using the Canny edge detection algorithm. Finds contours of the detected edges. Analyzes each contour by calculating its length and width using the bounding rectangle method. Classifies the crack as either structural or non-structural based on the length and width thresholds. Displays the crack information, including length, width, and classification. Suggests possible remedial measures based on the crack classification. The main code section loads an image captured from the mobile phone's camera using the cv2.imread function. Threshold values for crack classification are set using the threshold length and threshold width variables. The detection of cracks function is called with the loaded image as an argument to detect and analyze cracks in the image. Loading the image: We load the image from the mobile phone's camera using the cv2.imread function. Make sure to replace "crack_image.jpg" with the actual path to the image captured by the mobile phone's camera. Detecting cracks in the image: We call the detection of cracks function and pass the loaded image as an argument. The function will analyze the image and provide the crack classification and suggested remedial measures. By using this code as a starting point, you can further enhance the mobile app by integrating it with a user-friendly interface, allowing users to input crack details and receive instant analysis and suggestions for remedial measures.

Table 1 Sequencing of Crack Patterns, type of investigation method, width of crack

|

Investigation type |

Crack Pattern |

Crack Width |

|

Thresholding Techniques |

Straight Cracks |

0.1 mm-5mm |

|

Edge Detection: |

Hairline Cracks |

<1mm |

|

Segmentation |

Diagonal Cracks |

<1mm or >5mm |

|

Feature Extraction |

Radial Cracks |

2-3mm |

|

Texture Analysis |

Stair-step Cracks |

<1mm or >5mm |

|

Machine Learning and Deep Learning |

Pattern Cracks |

<1mm or >5mm |

|

Change Detection |

Vegetation-induced Cracks |

>5mm |

V. ACKNOWLEDGEMENT

The authors would like to express their gratitude to all the faculty members from civil engineering department who have helped us our research work in timely completion and valuable suggestions during the discussions.

Conclusion

In summary, the research underscores the significance of efficient crack detection in civil engineering structures for ensuring safety, minimizing economic impact, facilitating cost- effective maintenance, and maintaining public trust. The adoption of a mobile application equipped with artificial intelligence and image processing technologies provides advantages in terms of accessibility, cost-efficiency, effectiveness, accuracy, documentation, and remote monitoring. Nevertheless, obstacles like detection limitations, user proficiency, structural intricacies, equipment compatibility, data protection, and ongoing development issues must be resolved to effectively implement the mobile app for crack detection. along with required visual representation like images of datasets have been included which shows both cracked and uncracked condition for structures as well as tentative images of results after scanning of images have also been included. Along with the images working of ACNN model has also been discussed and detection of cracks by this model as well as how the crack is identified by feature extraction method of CNN model as well as how the image is processed after being captured by camera.

References

[1] AravindKumar S \"Development of Automatic Intelligent Road Transportation System for crack detection segmentation and forecasting using deep learning models\", Faculty of Information and Communication Engineering Anna University, (2023). [2] Manikanta Reddy \"Vibration based crack detection in Beam like structures using Artificial intelligence techniques\" Faculty of Mechanical Engineering Anna University, (2023). [3] Saveeth R \"Certain investigations on machine Learning techniques for crack Identification in composite Material images\" Faculty of Information and Communication Engineering Anna University, (2022). [4] Sunil Kumar T (2013) \"Theoretical and experimental investigation of Crack Identification in fiber reinforced composite beams using vibration analysis\", Faculty of Mechanical Engineering Andhra University, 2013. [5] https://www.google.com/search?q=ni+9234+data+acquisition+system&rlz=1C1CHBD_enN1008IN1008&oq=ni+9234+data+acquisition+system&gs_lcrp=EgZjaHJvbWUyBggAEEUYOTIHCAEQIRigATIHCAIQIRigATIHCAMQIRigATIHCAQQIRigATIHCAUQIRigAdIBCTE0NzE0ajBqN6gCALACAA&sourceid=chrome&ie=UTF-8 [6] https://shodhganga.inflibnet.ac.in [7] https://www.kaggle.com/datasets/aniruddhsharma/structural-defects-network-concrete- crack-images [8] Hyeong-Gyeong Moon and Jung-Hoon Kim \"Inteligent Crack Detecting Algorithm on the Concrete Crack Image Using Neural Network\". [9] Majid Mirbod, Maryam Shoar, \"Intelligent Concrete Surface Cracks Detection using Computer Vision, Pattern Recognition, and Artificial Neural Networks\", 4th International Conference on Industry 4.0 and Smart Manufacturing, Procedia Computer Science 217 (2023) 52–61. [10] M Maurya , R Mishra , I Panigrahi \"Multi crack detection in structures using artificial neural network\", 2nd International conference on Advances in Mechanical Engineering (ICAME 2018). [11] Machines, Krisada Chaiyasarn , Wasif Khan , Luqman Ali , Mayank Sharma , Daniel Brackenbury and Matthew DeJong \"Crack Detection in Masonry Structures using Convolutional Neural Networks and Support Vector\", 35th International Symposium on Automation and Robotics in Construction (ISARC 2018). [12] Krisada Chaiyasarn, Mayank Sharma, Luqman Ali, Wasif Khan and Nakhon Poovarodom \"Crack Detection in Historical Structures Based on Convolutional Neural Network\", International Journal of GEOMATE, Nov., 2018.

Copyright

Copyright © 2024 Dr. M. S. Kuttimarks, Chetan Mahadeva Krishna, Prof. R. Mahadeva Swamy, Dr. Menbere Aklilu. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET61958

Publish Date : 2024-05-11

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online