Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Critical Factors for the Successful Usage of Fly Ash in Road Sectors, Analyzing Mega Projects of Pakistan

Authors: Shakeel Ahmad

DOI Link: https://doi.org/10.22214/ijraset.2024.63214

Certificate: View Certificate

Abstract

Fly Ash is known to be a hazardous material which can cause Water, Air & Soil Pollution. As per Previous study Fly Ash may be considered as a resourceful material (Alam & Akhtar, 2011; Sahay & Bansal, 2022). Twelve (12) Critical Factors are been identified, Studied, analyzed and then classified using Interpretive Structure modeling (ISM), which are presented as a model in this paper. These Critical Factors shown in Final Model is a strategic planning towards the successful usage of Fly Ash in road sectors of Pakistan. Also, MICMAC analysis will help to present managerial suggestions which is useful for stakeholders.

Introduction

I. INTRODUCTION

Fly Ash is a byproduct obtained from burning the coal in plants and industries which contains fine particles and flue gases (Sow et al., 2015). It is a pozzolanic material, which contains Aluminous and Siliceous materials (Joel, 2020). Previously Fly Ash was released in the atmosphere but now a days due to air pollution it is captured before released in the air (Ahmaruzzaman & Gupta, 2012).

The current annual production of coal ash worldwide is estimated around 600 million tones, with fly ash constituting about 500 million tones at 75–80% of the total ash produced (Wang et al., 2016)

A typical low-calcium fly ash was used as additive in mortar, replacing part of the volume either of Portland cement or aggregate. The development of the strength, heat, porosity, bound water, and calcium hydroxide content was measured. In aggregate replacement higher strengths were observed after 14 days, whereas in cement replacement higher strengths were observed after 91 days (Papadakis, 1999).

A. Types of Fly Ash

- Class C ashes are generally derived from sub-bituminous coals and consist primarily of calcium alumino-sulfate glass, as well as quartz, tricalcium aluminate, and free lime (CaO). Class C ash is also referred to as high calcium fly ash because it typically contains more than 20 percent CaO.

- Class F ashes are typically derived from bituminous and anthracite coals and consist primarily of an alumino-silicate glass, with quartz, mullite, and magnetite also present. Class F, or low calcium fly ash has less than 10 percent CaO.

II. OBJECTIVE OF THE PAPER

- To identify & analyze various critical factors of fly ash in Pakistan.

- To find the contextual relationships among identified Critical Factors.

- To create an ISM based Hierarchical model & Mic Mac analysis for the Critical Factors.

- To develop Final Model for utilization of Fly ash in road sectors of Mega projects of Pakistan.

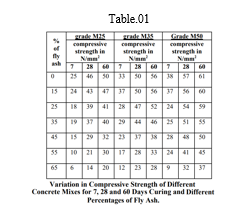

III. PERCENTAGE OF FLY ASH REPLACED WITH CEMENT

Different percentage of Fly Ash was replaced with cement and the compressive strength of the concrete has been observed as shown in the table 02.It has been observed that 15% of Fly Ash when replaced with cement produce higher strength than others. (RKDF Institute of Science& Technology et al., 2016).

IV. CRITICAL FACTORS

A. Government Support

Government Policies, regarding the allocation of funds, framing regulations and provide guidance & extending co-operation is having a significant influence on public as well as private organizations implementation of sustainable Fly Ash utilization Technology. (Tsai & Chou, 2004)

B. Material Availability

In Pakistan there are many coal-based plants which produces tons of Fly Ash per year. These Fly Ash must be utilized so to protect the environment and make it as a resource material. Replacing fifty percent cement of high calcium fly ash with steel slag and recycled aggregates has been observed resulting in concrete of high strength and without causing harm to the environment (Anastasiou et al., 2014).

C. Training & Education

Training and education play an important role in utilization of Fly Ash. People must be educate to not waste this hazardous by product but it can be used as resourceful material.

D. Protect Environment

There are very limited uses of Fly Ash in Pakistan, many industries and plants dispose off this by product without any proper disposal which may result in Pollution of water, air and soil.

E. Utilization in mega Projects

The main objective of this research is to utilize the Fly Ash which is waste by product of Coal thermal Plants in mega projects of Pakistan. As we know that huge amount of cement quantity is used in these mega projects, it was mentioned earlier that total of 14% amount can be easily saved by replacing cement with Fly Ash.

F. Ease in Management

Fly Ash use is very difficult to manage as it requires proper mix design and technology. Fly Ash uses may also increase the workability of Concrete.

G. Promotion

Promotion of Fly Ash as a resourceful material is very important which play a significant and positive role in utilization of Fly Ash. It will help in awareness among many institutions, industries and end users also it will break the mental barrier towards adoption of this new technology.

H. Approved Rate

There must be an Approved rate for Fly Ash, when certain amount of Fly Ash is replaced with certain quantity of cement. Which will help and boost the utilization of Fly Ash in Construction Industries. Finance Department must add a Specific rate in Market Rate System (MRS).

I. Quality of Fly Ash

American Society for testing and Materials (ASTM), American Concrete Institute (ACI) and American Association of State highway and transportation Officials (AASHTOO) guidelines for testing the performance of Fly Ash in construction must be recommended to check the quality of Fly Ash. Certain guidelines must be provided to different industries and Plants so that to produce good quality of Fly Ash which can be further utilized and helps in Environmental protection.

J. Modern Technology

Modern technology plays an important key role in utilization of Fly Ash. There must be concrete plants installed at the construction site which will help to precisely use and mix the amount of Fly ash required so that to achieve certain strength of concrete. Also, there are many modern technologies which installation in different Fly Ash Producing Industries and plants will help to achieve good quality of Fly ash.

K. Economic Wealth

As it was discussed previously that Fly ash uses can save up to 14% the amount of cement used for different projects in Pakistan which will help in increase of Economic wealth. And this un necessary loss can be controlled by the use of Fly Ash in mega projects of Pakistan.

L. Mix Design

Mix Design will help in achieving the required strength while using Fly Ash in cement. With the help of proper mix design, we can also find out a specified rate which can be added to MRS.

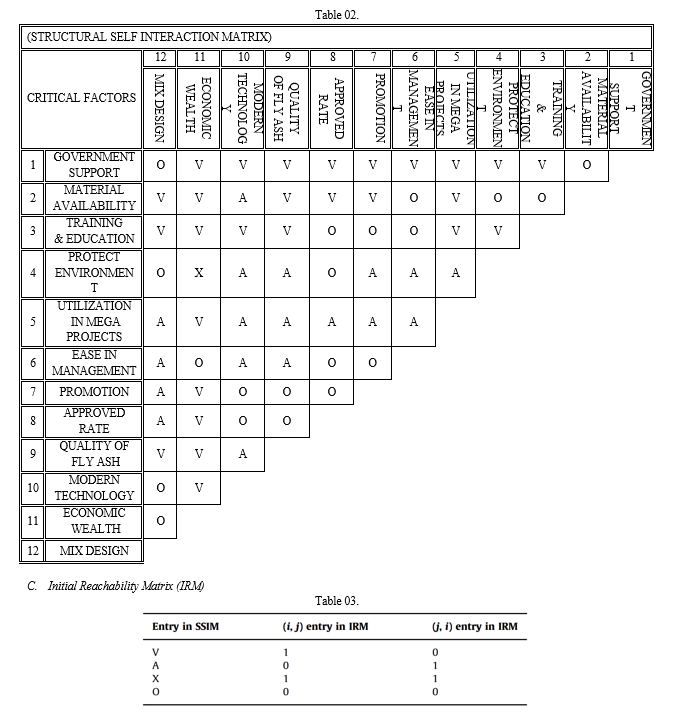

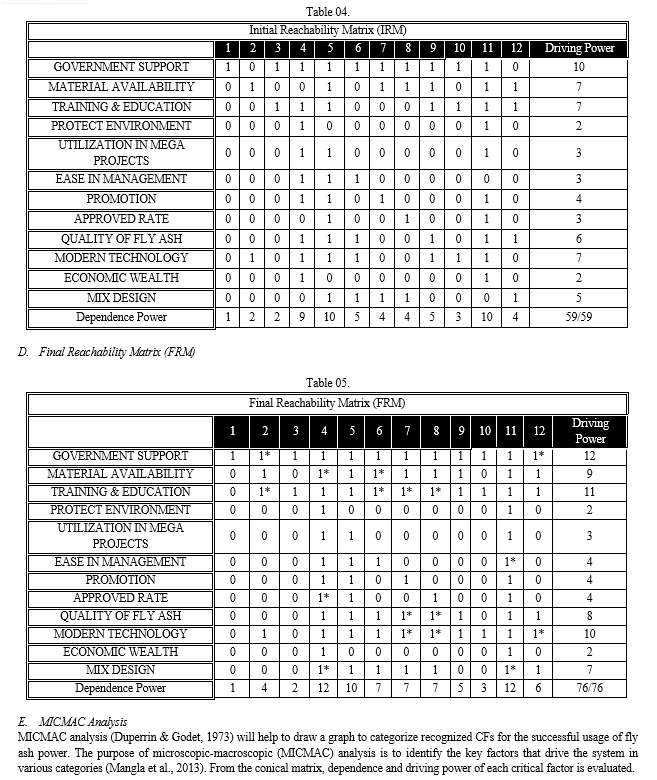

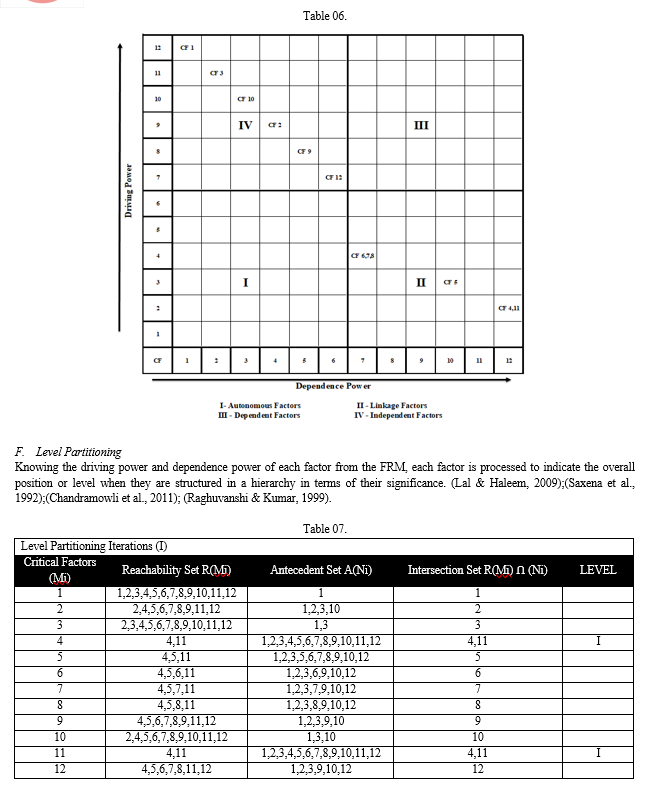

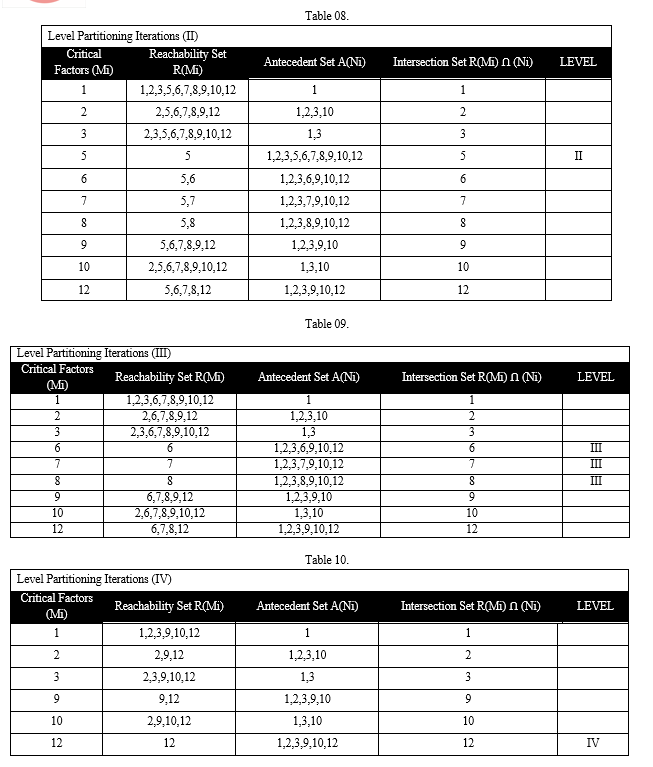

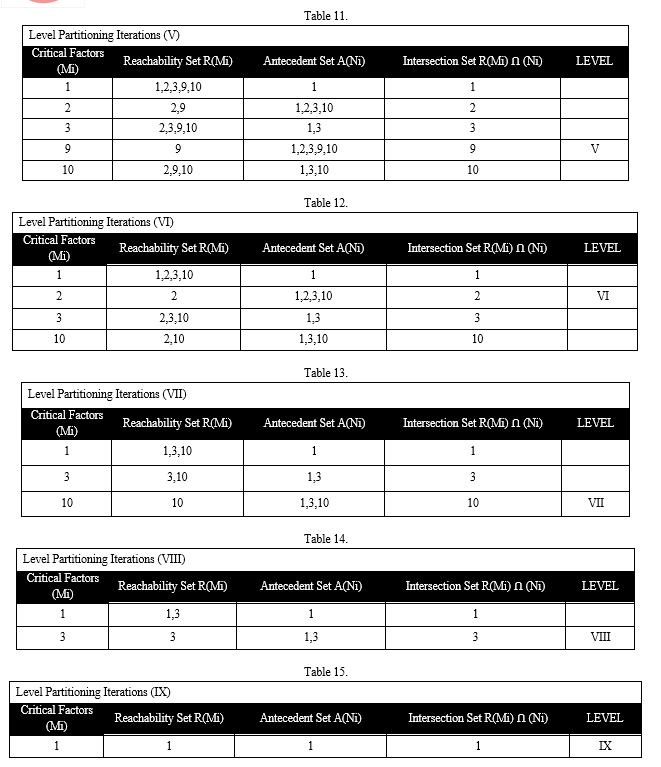

V. INTERPRETIVE STRUCTURE MODELING

The identified Critical factors discussed above need to understand the hierarchy and relationships between those critical factors that are playing a helpful role in the better utilization of fly ash in the road sector of Pakistan. These critical factors are discussed with experts and the ISM technique seems to be the most appropriate tool for developing a model (Haleem et al., 2016). These factors will also be analyzed using matrice d’impacts croisés multipication appliquée a? un classment (MICMAC) analysis. The experience and involvement of experts is the critical success factor for the effectiveness of the model. (Saurikhia et al., 2018).

Total of 12 Critical Factors are identified during the brainstorming session that are considered to drive Fly Ash utilization in road sectors of Pakistan. Interpretive structural modelling (Haleem et al., 2012; Lendaris, 1980; Raghuvanshi & Kumar, 1999) is an effective method of understanding complex situations and finding solutions to complex problems. It aims to identify the direction and order of complicated interactions between the variables of the system (Warfield, 1974). It is a technique for making a "road-map" of complicated circumstances when there are several factors to take into account.

A. Steps in Interpretive Structure Modeling

- Finding the relation between Critical Factors.

- Develop Structural Self Interaction Matrix (SSIM).

- Develop Initial Reachability Matrix (IRM).

- Check for Transitivity to find the Final Reachability Matrix, A=B=C (FRM).

- MICMAC Analysis.

- Level Partition.

- Hierarchy Model.

B. Structural Self Interaction Matrix (SSIM)

Symbols to define relationships:

V = Row variable influences corresponding column variable.

A = Row variable is influenced by corresponding column variable.

X = Row and corresponding column variable influence each other.

O = Row and corresponding column variable have no relationship.

Conclusion

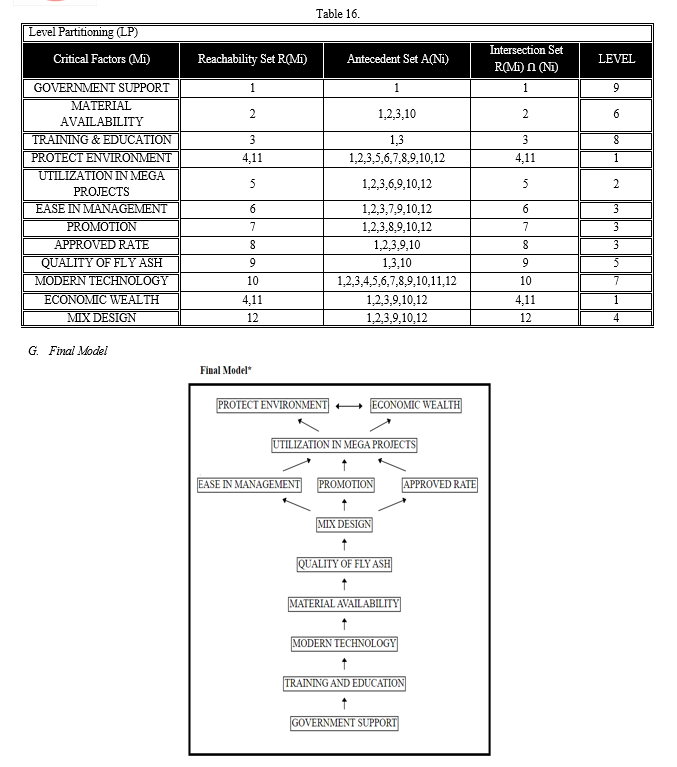

1) When 15% of Fly Ash is replaced with cement it is having less or no effect on the strength of concrete (RKDF Institute of Science& Technology et al., 2016) , and it can save up to 14% of the amount of cement in Mega Projects. 2) The first step in the final model is government support which plays a crucial role in supporting the utilization of fly ash in the road sector. Through various policies, regulations, and financial incentives, the government encourages the use of fly ash as a sustainable and cost-effective material in road construction. One of the main reasons for government support in the utilization of fly ash in the road sector is its environmental benefits. By promoting the use of fly ash, the government contributes to reducing carbon emissions and mitigating environmental hazards associated with its disposal. Furthermore, the utilization of fly ash in road construction helps in conserving natural resources and reducing the dependency on traditional construction materials like cement and aggregates. 3) The second step which is necessary in utilization of Fly Ash is to educate and Train people which will help in awareness. 4) The third step is with the help of training and education, people will understand the role of modern technology in utilization of Fly Ash without which the utilization of Fly Ash is difficult. 5) In fourth step through modern technology, Education & Government support the Material availability may be increased as the demand for Fly Ash will be increased. 6) In fifth step after material availability & installation of Modern Technology good quality of Fly Ash can be produced which can be further utilize as resourceful material in construction industry. 7) In Sixth step with the help of proper Mix design ease in management can be increased and it will also help to find out a specified rate for Fly Ash mix Concrete. 8) In seventh step mix design will further help in Promotion & understanding of this new technology 9) In the next step Fly Ash can be easily utilized in Mega projects of Pakistan without any hurdles. The use of Fly Ash in Mega project will not Only Protect the environment but it will also improve the Economic wealth of the country.

References

[1] Ahmaruzzaman, M., & Gupta, V. (2012). Application of coal fly ash in air quality management. Industrial & Engineering Chemistry Research, 51(47), 15299–15314. [2] Alam, J., & Akhtar, M. (2011). Fly ash utilization in different sectors in Indian scenario. Int J Emerg Trends Eng Dev, 1(1), 1–14. [3] Anastasiou, E., Filikas, K. G., & Stefanidou, M. (2014). Utilization of fine recycled aggregates in concrete with fly ash and steel slag. Construction and Building Materials, 50, 154–161. [4] Chandramowli, S., Transue, M., & Felder, F. A. (2011). Analysis of barriers to development in landfill communities using interpretive structural modeling. Habitat International, 35(2), 246–253. [5] Duperrin, J.-C., & Godet, M. (1973). Méthode de hiérarchisation des éléments d’un système: Essai de prospective du système de l’énergie nucléaire dans son contexte sociétal [PhD Thesis]. Centre national de l’entrepreneuriat (CNE); CEA. [6] Haleem, A., Luthra, S., Mannan, B., Khurana, S., Kumar, S., & Ahmad, S. (2016). Critical factors for the successful usage of fly ash in roads & bridges and embankments: Analyzing indian perspective. Resources Policy, 49, 334–348. https://doi.org/10.1016/j.resourpol.2016.07.002 [7] Haleem, A., Sushil, Qadri, M. A., & Kumar, S. (2012). Analysis of critical success factors of world-class manufacturing practices: An application of interpretative structural modelling and interpretative ranking process. Production Planning & Control, 23(10–11), 722–734. [8] Jabbar, D. N., Hasan, A. M., & Abed, M. K. (2021). Self-Compaction concrete behaviour containing nano fly ash used in rigid pavement. IOP Conference Series: Earth and Environmental Science, 779(1), 012018. [9] Joel, S. (2020). Compressive strength of concrete using fly ash and rice husk ash: A review. Civil Engineering Journal, 6(7), 1400–1410. [10] Lal, R., & Haleem, A. (2009). A structural modelling for e-governance service delivery in rural India. International Journal of Electronic Governance, 2(1), 3–21. [11] Lendaris, G. G. (1980). Structural modeling a tutorial guide. IEEE Transactions on Systems, Man, and Cybernetics, 10(12), 807–840. [12] Longarini, N., Crespi, P. G., Zucca, M., Giordano, N., & Silvestro, G. (2014). The advantages of fly ash use in concrete structures. In?ynieria Mineralna, 15(2), 141–145. [13] Mangla, S., Madaan, J., & Chan, F. T. (2013). Analysis of flexible decision strategies for sustainability-focused green product recovery system. International Journal of Production Research, 51(11), 3428–3442. [14] Papadakis, V. G. (1999). Effect of fly ash on Portland cement systems: Part I. Low-calcium fly ash. Cement and Concrete Research, 29(11), 1727–1736. [15] Raghuvanshi, P., & Kumar, S. (1999). On the structuring of systems with fuzzy relations. IEEE Transactions on Systems, Man, and Cybernetics, Part B (Cybernetics), 29(4), 547–553. [16] RKDF Institute of Science& Technology, Chakraborty, J., & Banerjee, S. (2016). Replacement of Cement by Fly Ash in Concrete. International Journal of Civil Engineering, 3(8), 58–60. https://doi.org/10.14445/23488352/IJCE-V3I8P110 [17] Sahay, D. K., & Bansal, S. (2022). Use of Fly Ash—A Resourceful Byproduct in Road Embankment: A Review. Advances in Construction Materials and Sustainable Environment: Select Proceedings of ICCME 2020, 539–550. [18] Saurikhia, A., Ahmed, S., Haleem, A., Gangopadhyay, S., & Khan, M. I. (2018). Evaluating technology management factors for fly-ash utilization in the road sector using an ISM approach. International Journal of Management Science and Engineering Management, 13(2), 108–117. https://doi.org/10.1080/17509653.2017.1314202 [19] Saxena, J., Vrat, P., & others. (1992). Scenario building: A critical study of energy conservation in the Indian cement industry. Technological Forecasting and Social Change, 41(2), 121–146. [20] Sow, M., Hot, J., Tribout, C., & Cyr, M. (2015). Characterization of Spreader Stoker Coal Fly Ashes (SSCFA) for their use in cement-based applications. Fuel, 162, 224–233. [21] Tsai, W., & Chou, Y. (2004). Government policies for encouraging industrial waste reuse and pollution prevention in Taiwan. Journal of Cleaner Production, 12(7), 725–736. [22] Wang, L., Sun, H., Sun, Z., & Ma, E. (2016). New technology and application of brick making with coal fly ash. Journal of Material Cycles and Waste Management, 18, 763–770. [23] Warfield, J. N. (1974). Developing subsystem matrices in structural modeling. IEEE Transactions on Systems, Man, and Cybernetics, 1, 74–80.

Copyright

Copyright © 2024 Shakeel Ahmad. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63214

Publish Date : 2024-06-09

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online