Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design, Analysis and Fabrication of Pick and Place Robotic Arm with Multipurpose

Authors: Dodla Manideep, Mettu Ranjith, Paka Sumanth, Pola Ravikumar, Chetla Venu Gopal, Dr. K. Siva Prasad

DOI Link: https://doi.org/10.22214/ijraset.2024.59281

Certificate: View Certificate

Abstract

This project is to design, develop and fabricate a \"pick and place robotic arm\" using Raspberry pi controller. It will pick and place an object from source to destination safely. This robot has a gripping technology that is used to lift, hold, grasp, and replace materials from one place to another. This robotic has revolute joints that allow the angular movement of the adjacent joint. The objective of this project is to design and build a more compact, usable and cheaper pick and place robotic arm for educational purpose. It uses Raspberry pi as the control system to control all the activities. Inputs to the Robotic arm are predefined. In the project we are applying this concept to the design of pick and place robotics system using SolidWorks Soft motion software. The software is used to design a Cartesian robot and an articulated industrial robotic arm with different grippers. The robot was designed using the SolidWorks’ 3D CAD software to shorten the robot development time, and improve the speed and quality of the robot design.

Introduction

I. INTRODUCTION

Robotics is a remarkable building science that deals with the design, modelling, analysis, and utilization. Today, robots are used everywhere in day-to-day life. A large family of robots is used in industries and manufacturing processes. Robots are used in supplying the motion required in manufacturing processes such as arc-welding, spray painting, cutting, polishing, milling, drilling, assembly, pick and place, packaging, palletising, product inspection and testing. Robots that can perform task productively are currently a prerequisite in many industries since they have high accuracy. In this way, there are currently expanding the requirement for better robots that can perform different assignments. There are mainly two types of robots one is a service robot and the other is an industrial robot.

A service robot is operated fully or semi-autonomously in order to perform intense tasks that ease human and equipment burden. While on the other hand, an industrial robot is fully autonomously controlled, multipurpose manipulator. Industrial robots are robotic arm systems which consist of various links, joints, actuators, sensors, controller and a software/hardware simulator. This typical robotic arm comprised of several metal segments, which are combined at joints. Processing units controls the robot by turning the individual servo motors connected to the joints. In the field of robotics, there are five sorts of robot setups that are SCARA, articulated, Cartesian, cylindrical and spherical SCARA (Selective Compliance Assembly Robot Arm).

It will help in deciding the critical parts in the assembly and the best materials for the robotic arm for application in industries. Furthermore, the plan and development of the robotic arm is supported by the results of the analysis.

A. Types

- Cartesian robot:-Three prismatic joints , whose axes are coincident with a Cartesian co-ordinate constitute a Cartesian robot. Arc welding, handling precision tools and pick and place work are some of its application.

- Cylindrical robot:-A robot having axes that forms a cylindrical co-ordinate system is called as cylindrical robot. Some of its applications include assembly operations, handling at machine tools, spot welding, and handling at die-casting machines.

- Spherical robot:-A robot having an axes that forms a polar co-ordinate system is called a spherical robot. It is used for applications such as handling machine tools, spot welding, die-casting, fettling machines, gas welding and arc welding etc.

- Scara Robot:-Two rotary joints which are parallel and are used to provide compliance in a plane constitutes a robot termed scara. Its applications include pick and place work, sealant, assembly operations and handling machine tools

- Articulated robot: - A robot consisting of an arm having at least 3 rotary joints is termed as Articulated. It is used in die-casting, assembly operations, fettling machines, gas welding, arc welding and spray painting. • Parallel Robot:-Arms having concurrent prismatic or rotary joints constitute a parallel robot. One of the use is a mobile platform handling cockpit flight simulators.

- Anthropomorphic robot:-A robotic arm which is similar to a human hand i.e. consists of independent fingers and thumbs is called as Anthropomorphic robot.

B. Uses

- Easily pick and place the industrial and agriculture object with quick and fast

- The robots are employed to pick products from a conveyor belt and place them into packaging container

- Pick and place robots are widely used in manufacturing and assembly lines.

- Used in agriculture for harvesting, sorting, seeding and planting, weeding.

The proposed system is capable of lifting only small weights, by introducing high torque providing motor large weights can be picked. Problem faced Agricultural pick and place robots aim to revolutionize traditional farming practices by automating tasks such as harvesting, planting, and sorting.

In the modern era, time and manpower are major constraints for task completion. The pick and place robotic arm is designed to handle industrial activities and hazardous operations quickly and safely. The soft catching gripper and low-power wireless communication technique like Bluetooth make the system more effective than other systems. The proposed system can lift small weights with high torque.

In the project of designing, analysing, and fabricating a Pick and Place Robotic Arm with Multipurpose functionality, Solid works played a pivotal role in the design phase. Leveraging the capabilities of Solid works, the entire robotic arm assembly was meticulously modelled in a three-dimensional environment. Solid works provided a user-friendly interface and a comprehensive suite of tools for creating complex parts and assemblies, allowing for precise design specifications to be achieved. Furthermore, Solid works facilitated the visualization of the robotic arm's functionality, enabling the exploration of various design iterations and ensuring compatibility with fabrication processes.

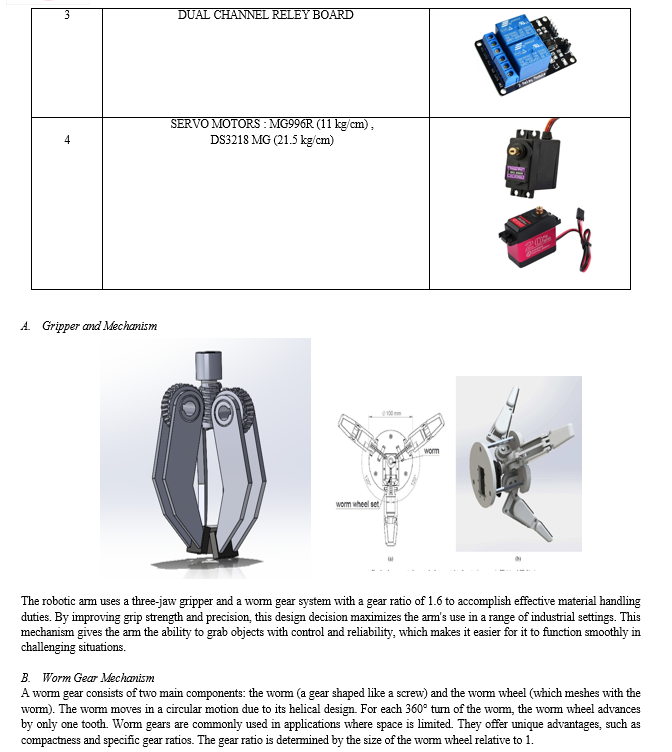

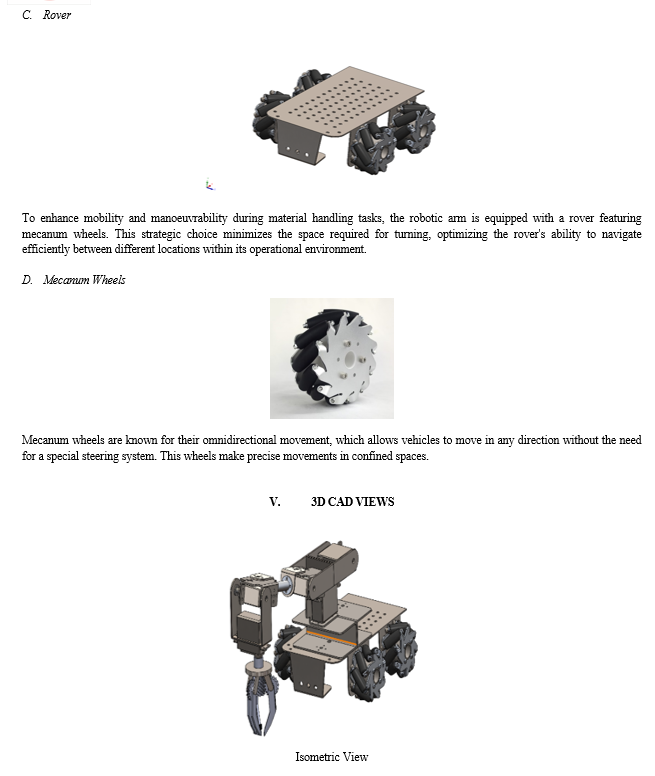

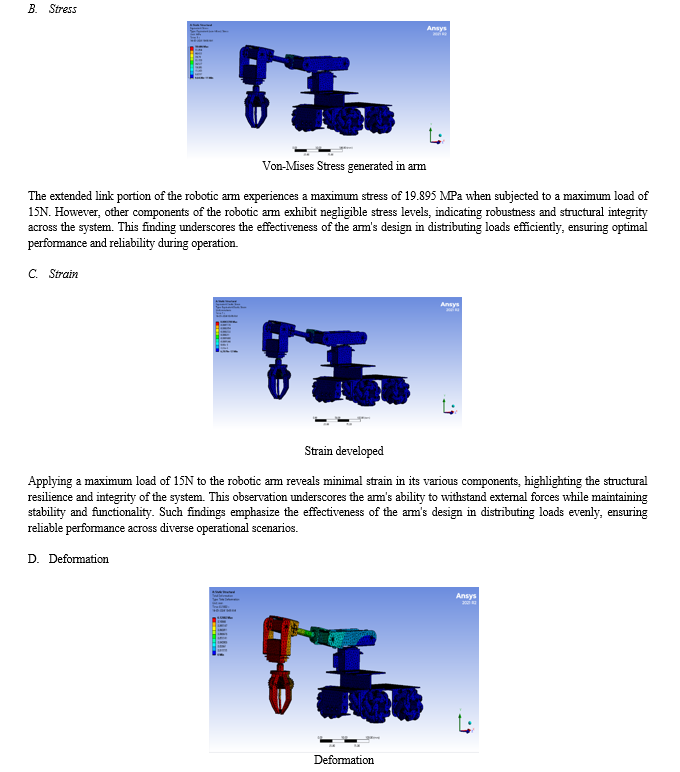

On the other hand, Ansys was instrumental in conducting detailed structural analysis of the Pick and Place Robotic Arm. Utilizing Ansys, finite element analysis (FEA) techniques were employed to evaluate the structural integrity and performance of the robotic arm under different loading conditions. By simulating real-world scenarios, Ansys provided insights into stress distribution, deformation behaviour, and overall structural stability. This analysis phase enabled the identification of potential design flaws or weak points, facilitating informed design modifications to enhance the arm's reliability and durability.

II. LITERATURE REVIEW

[1] Design and Implementation of Pick and Place Robotic Arm [Ravi Kumar Mourya, Amit Shelke et.al] International Journal of Recent Research in Civil and Mechanical Engineering (IJRRCME) 2015. This project aims to design and implement a 4-DOF pick and place robotic arm, which can be self-operable for tasks such as gripping, lifting, placing, and releasing. The project focuses on a 4-DOF articulated arm with revolute joints for angular movement between adjacent joints. Four servo motors are used to perform four degrees of freedom (4-DOF). Robot manipulators are designed to execute required movements and their controller design is equally important. The AT mega 16 Development board is used for servo motor action. The project successfully completed the design and fabrication of a 4-DOF manipulator, using computer-aided designing tools like Creo 1.0 and AutoCAD. Theoretical analysis of inverse kinematics was conducted to determine the end effectors position and orientation, and FE Analysis was performed using Ansys software. The project demonstrates the importance of robotic manipulators in positioning and orienting objects for useful tasks.

[2] Design Analysis of a Remote Controlled “Pick and Place” Robotic Vehicle [B.O.OmijehAndR.Uhumwamgho] International Journal of Engineering Research and Development 2014. This paper presents a design analysis of a Remote Controlled "Pick and Place" Robotic vehicle, focusing on safety precautions in the workplace and environment. The vehicle has a five-degree robotic arm with a base on top and four drive wheels that are selectively powered to propel it. The design methodology includes hardware, software, and implementation. A prototype was built to validate the design specifications, and the results were satisfactory. Robots are highly recommended for industries for safety and productivity reasons. The design of the robot makes it easier for humans to handle hazardous objects in their environment and workplace, achieving complex and complicated duties faster and more accurately.

[3] Pick and Place Robotic Arm: A Review Paper [Sharath Surati, Shaunak Hedaoo et.al] International Research Journal of Engineering and Technology (IRJET) 2021. This paper presents a design analysis of a Remote Controlled "Pick and Place" Robotic vehicle, focusing on safety precautions in the workplace and environment.

The vehicle has a five-degree robotic arm with a base on top and four drive wheels that are selectively powered to propel it. The design methodology includes hardware, software, and implementation. A prototype was built to validate the design specifications, and the results were satisfactory. Robots are highly recommended for industries for safety and productivity reasons. The design of the robot makes it easier for humans to handle hazardous objects in their environment and workplace, achieving complex and complicated duties faster and more accurately.

[4] Pick and Place Robotic Arm Implementation Using Arduino [Ashly Baby1, Chinnu Augustine et.al] IOSR Journal of Electrical and Electronics Engineering (IOSR-JEEE) 2017. A robotic arm is designed using Arduino to safely pick and place objects via user commands. The arm features a soft catching gripper that doesn't apply extra pressure to the objects. The robot is controlled using Android-based smart phones via Bluetooth, and the robot moves accordingly based on user commands. At the receiver end, four motors are interfaced with the micro controller, two for vehicle movement and the remaining two for arm and gripper movement. The Blue control app is used for controlling the robot.

[5] Position Control Method For Pick And Place Robot Arm For Object Sorting System [Khin Moe Myint, Zaw Min Min Htun] International Journal Of Scientific & Technology Research Volume 2016. This paper about the increasing number of industries in developing countries necessitates more labourers, leading to the need for advanced robot arms to reduce labour costs and increase manufacturing capacity. This journal aims to eliminate manual control for object sorting systems using two joints, three links, and servo motors. A microcontroller generates the required PWM signal for servo motors. The position control of the robot arm is designed using kinematic control methods, which can explain the geometry motion of the manipulator without considering forces or moments causing movements. Metal detectors are used for sorting systems.

[6] Robotic Arm For Pick And Place Application [Kaustubh Ghadge, Saurabh More] International Journal of Mechanical Engineering and Technology (IJMET) 2018. The project aims to create a compact, usable, and affordable robotic arm for pick and place applications using a Node MCU controller. The project combines electronic and electrical knowledge to create a robust, lightweight, and programmable arm with four degrees of freedom. The arm is designed for educational purposes and can be reprogrammed for various applications. The Node MCU controller is used to control all activities, and input devices like Android applications send signals to the Nod MCU, which responds by turning on or off output signals to servo motors. The design is compact, cheap, and practical. The paper focuses on the CAD modelling aspect of the robot and assembly parts.

[7] Simulation of Pick and Place Robotics System Using SolidWorks’ Soft motion [Rosidah Sam, Kamarul Arrifin]

International Conference on System Engineering and Technology 2012. This paper presents the design of a pick and place robotics system using SolidWorks Soft motion software. The system includes a Cartesian robot and an articulated industrial robotic arm with different grippers. The SolidWorks 3D CAD software was chosen for its ability to shorten the development time and improve the speed and quality of the robot design. The software includes four sections: manual drawing, part module, assembly module, and drawing module. The results of simulation Xpress study and motion study of the modelled articulated robot arm part and assembly demonstrate the pick and place robotics system. The SolidWorks software was found to be a suitable tool for designing robotic systems quickly and efficiently. The simulation Xpress study enabled stress analysis to ensure the safety of the modelled parts, while the motion study allowed users to develop the most efficient movement by minimizing displacement to shorten the time to reach the targeted positions.

[8] Designing and Implementing a Versatile Agricultural Robot: A Vehicle Manipulator System for Efficient Multitasking in Farming Operations [Sandeep Kumar, Santha kumar Mohan] publisher of scholarly open access journals 2023. This paper presents a detailed design of a skid-steering mobile platform with four wheels and a Cartesian serial (PPP) manipulator, designed to perform various tasks in the agricultural process. The parallel manipulator is designed to handle heavy materials in the agricultural field, and an experimental robotic harvesting scenario was conducted using parallel manipulator-based end-effectors to handle heavy fruits such as watermelon or muskmelon. The design specifications and parametric values were utilized during the manufacturing stage, and the mobile manipulator was simulated on undulating terrain profiles using ADAMS software. The fabrication and prototype development involved calibration tests at various X-, Y-, and Z-axis frame mounting stages to minimize lateral and longitudinal deviation between the parallel linear motion (LM) rails. Field testing was conducted, and the grippers utilizing parallel mechanisms demonstrated their ability to handle sizable cylindrical and spherical fruits or vegetables, as well as other relevant objects.

[9] Design and development of robotic arm for cutting trees [Aimn Mohamed Ahmed GHIET, Mukhtar Abdussalam DAKHIL] University of Turkish Aeronautical Association 2016. Robots are programmable multifunctional manipulators designed to move material, parts, and tools through variable programmed tasks. In the fast-growing industrial age, companies seek speed in manufacturing to meet client needs.

Robotic manipulators or robotic arms are commonly used in industry, consisting of rigid links interconnected by movable joints. A machine was designed and fabricated for cutting a tree trunk smoothly, using a mechanize motor system on the carrier machine. Two direct current (DC) motors were used for the carrier machine, and the cutting machine consisted of a mechanism for cutting and a cutting blade. A reciprocating mechanism was used in this project due to its added advantages. The ATmega2560 microcontroller was used to control the cutting system. The robot arm successfully completed a simple task of rotating, lower, and raising its arm. The weights of all motors were considered when calculating torque by each joint, ensuring they were arranged in a way that would produce enough torque to carry the succeeding load. The use of a DC motor at the base brought us closer to solving the problem of insufficient torque to carry the arm.

[10] Pick and Place Robotic ARM using PLC [Kunal Chopade, Jitendra Gaikwad] International Journal of Engineering Research & Technology (IJERT) 2019. This paper discusses the pick and place robotic arm, an automated material handling system that synchronizes the movement of a robotic arm to pick objects on conveyor belts. Despite the use of advanced robots in industries, controlling is often done manually or using processors like Arduino or microcontrollers. However, microprocessors have disadvantages, which can be overcome by using Programmable Logic Controllers (PLCs). The paper analyses and considers various problems in programming and designing the pick and place robotic arm, which functions similarly to a human arm. The arm is easily programmable and can be operated manually. The project aims to find solutions for industrial automation challenges, including material handling, object sorting, welding, grinding, and spray painting. A successful model of the Pick and Place Robotic Arm has been designed using PLC.

[11] Design And Simulation of Pick and Place System Using Solid works Simulation[Wan Muhamad Auf B. Wan Mohd Raziff, Rosidah Sam, Marianah Masrie, Zuriati Janin] IEEE 5th International Conference on Smart Instrumentation, Measurement and Applications (ICSIMA 2018). This paper presents the design and analysis simulation of a pick and place system using Solid works Simulation software. Solid works is utilized for designing various components of the system such as cylinders and sliders with different grippers, and the design is subsequently analysed using simulation Xpress study and motion study. The utilization of three-dimensional design (3D CAD) software enhances skills and knowledge in designing automation and industrial robots, significantly reducing development time, and enhancing design quality and speed. Solid works software encompasses four key sections: manual drawing, part module, assembly module, and drawing module. By employing Solid works simulation software, the pick and place system's performance is simulated and analysed. The results of the simulation and motion study are presented to showcase the system's capabilities. Solid works 3D CAD software proves suitable for creating various parts within the pick and place system, including the arm base, sliders, Y-axis cylinders, grippers, and products, which are integrated into the main assembly during the modelling phase. Assembly simulation ensures error detection and facilitates movement study, while Xpress simulation studies assess part abilities and analyse applied pressures for design security. Through simulation analysis, design efficiency is enhanced, providing valuable knowledge for students exposed to Solid works 3D CAD software.

[12] Design and Control of a Robotic Manipulator for Pick and Place Applications[Adham Mohamed, Ahmed Abd-Elmonen, Ahmed Asem, Ahmed Atef, Ahmed Kamal Mohamed, El-Hussein Abd El Ghani, Mohamed Yasser, Mostafa Ashraf, and Omar Mohamed] 6th IUGRC International Undergraduate Research Conference, Military Technical College, Cairo, Egypt, Sep. 5th – Sep. 8th , 2022. This paper introduces the design and control of a robotic manipulator tailored for pick and place applications, featuring remote monitoring and management capabilities. Utilizing an Arduino Mega board as the controller, the manipulator comprises three stepper motors for moving three links and two servo motors for controlling the gripper's actions. Both forward and backward kinematics are established to determine the relationship between the end-effector's Cartesian position and the joint angles, forming trajectories for the controller to track. SolidWorks is employed for constructing the manipulator's parts, with stress analysis conducted on each component. The Arduino IDE programming language is utilized to develop the controller system on the Arduino Mega board, facilitating tasks such as choosing and positioning objects in manufacturing processes while monitoring and tracking the arm's path. The design objective was to create a compact yet robust robot consisting of four mechanical parts: link 1, link 2, link 3, and the gripper, powered by stepper motors for swift movement and servo motors for gripper control. The motors are connected to motor drivers powered by a (220V-24V) supply, with the Arduino Mega providing signals to rotate the motors as per desired coordinates. An application is developed to control the robot's movement by inputting data, subsequently transmitted to the microcontroller for execution. Ultimately, the development of this pick and place robotic arm addresses the increasing need for accuracy, efficiency, and safety in various industries, aiming to enhance work precision, reduce manual effort, and minimize time consumption, all while prioritizing the well-being and integrity of individuals.

[13] STRUCTURAL DESIGN AND ANALYSIS OF PICK-AND-PLACE ROBOTICS COMPONENTS USING ANSYS SOFTWARE FOR AGRICULTURAL APPLICATIONS [J PRUDHVIRAJU, K. HUSSAI BABU, G. V. V. NAGARAJU] International Journal of Multidisciplinary Engineering in Current Research – IJMEC,2023The system described is a Tracking System designed to record and report discrete activities within a process, complemented by a methodology for robot direction control in non-linear systems using wireless communication techniques. Utilizing Catia V5 for modelling and Ansys or Hyper Mesh Workbench for analysis, the project employs aluminium and steel materials around a microcontroller acting as the control unit. The transmitter emits control signals while the receiver, placed on the robot, interprets these signals to adjust the robot's direction accordingly. Notably, the microcontroller plays a crucial role in directing the robot based on received signals. Stress analysis conducted using Ansys reveals minimal displacement in robot components with stress levels below acceptable thresholds, demonstrating the accuracy of design parameters. This project is particularly applicable where wireless point-to-point communication is needed to control the direction of automated devices. Overall, the development process reflects an incremental approach while embodying a paradigm shift towards mechanization for autonomous machines, emphasizing innovative solutions tailored to specific needs rather than simply modifying existing techniques.

[14] Analysis of remote-controlled pick and place robotic vehicle [ Dr. T. Sunil kumar, M. Gangadri, D. Nagarjuna, Y. Sai Kumar and Ch. Ashok] 2nd National Conference on Recent Trends in Mechanical Engineering, GIST, Nellore. This work highlights the importance of prioritizing safety measures in both workplace and environmental settings, particularly when handling specific tasks. The paper introduces a Remote-Controlled Pick and Place Robotic vehicle equipped with a two Degree of Freedom robotic arm, capable of traversing various terrains and overcoming obstacles. Structural analysis conducted using Ansys software validates the design specifications, demonstrating satisfactory results. By combining concepts from automobile and robotics, the vehicle efficiently picks and places objects using power transmission mechanisms such as gear meshing and worm drives. The structural analysis, conducted under different loads, reveals increased equivalent stress and total deformation at the gripper as loads escalate. Nevertheless, the overall performance remains satisfactory, paving the way for the development of larger, more effective mobile robots tailored for industrial applications.

[15] MECHANICAL ENGINEERING OF ROBOTIC SYSTEMS BY SOLIDWORKS [ Ciprian Dragne, Corina Radu (Fren?), Mihaiela Iliescu] International Journal of Modern Manufacturing Technologies. This article discusses the comprehensive approach to modern product design, utilizing professional CAD software like Solid works throughout all stages of development. The software enables modelling, simulation, and evaluation, facilitating quicker product realization. Specific focus is given to mechanical component design for robots and mechatronic systems, ensuring precise motion requirements are met. Case studies demonstrate the software's capabilities in achieving accurate results, such as minimizing path errors and optimizing acceleration. Solid works, with its diverse functionalities, serves as a comprehensive tool for engineering tasks, including assembly tolerance assessment, kinematics, and structural analysis, among others. The integration of MATLAB, Solid works, and user-defined programming routines further enhances the design process. Looking ahead, proficiency in computer-aided design will be crucial, as technology continues to evolve, becoming more sophisticated and integral to manufacturing processes.

III. METHODOLOGY

A. Design Phase:

Determine the required degrees of freedom for the robotic arm to perform pick and place tasks efficiently.

Consider the reach, payload capacity, and precision needed for the application. Design the robotic arm components to ensure compatibility with the rover and Omni wheels.

B. Fabrication Techniques

Utilize 3D printing technology for fabricating precise components of the robotic arm, ensuring accuracy and cost-effectiveness. Fabricate parts such as links, grippers, and supporting structures using appropriate materials like acrylic or metal.

C. Assembly Process:

Assemble the base of the robotic arm by attaching servo motors and necessary components. Connect the different segments of the robotic arm to create a multi-degree-of-freedom structure capable of picking and placing objects. Integrate the gripper mechanism with servo motors for precise gripping functionality

D. Integration with Rover

Connect the fabricated robotic arm to a rover platform equipped with Omni wheels for mobility Ensure proper alignment and stability between the robotic arm and the rover to facilitate seamless movement during pick and place operations.

Under a maximum load of 15N, the gripper portion of the robotic arm exhibits a maximum deformation of 0.12002mm, while negligible deformations are observed in other components of the arm. This indicates the robustness of the arm's design in withstanding applied loads, with minimal impact on its structural integrity. Such findings affirm the arm's capability to maintain stability and functionality, even under demanding operational conditions, enhancing its reliability and performance in material handling tasks.

Conclusion

The project aims to create a compact, usable, and cost-effective robotic arm for educational purposes. It utilizes SolidWorks software for design and Ansys for analysis. The robotic arm is crucial for various industrial tasks like arc-welding, spray painting, cutting, and assembly. Different types of robots are discussed, including Cartesian, cylindrical, spherical, SCARA, articulated, parallel, and anthropomorphic robots. The literature review highlights the importance of robotic manipulators in positioning and orienting objects efficiently. The usage of powerful software tools like as SolidWorks and Ansys highlights how technology is integrated into the design and analysis of robotic systems. Overall, this research advances robotics technology for both instructional and practical uses.

References

[1] Ravikumar Mourya, Amit Shelke, Sourabh Satpute, Sushant Kakade, Manoj Botre, “Design and Implementation of Pick and Place [2] Robotic Arm”, International Journal of Recent Research in Civil and Mechanical Engineering (IJRRCME), 2015. [3] B.O.Omijeh and R.Uhunmwangho, “Design Analysis of a Remote Controlled Pick and Place Robotic Vehicle”, International Journal of Engineering Research and Development, 2014. [4] Sharath Surati, Shaunak Hedaoo, Tushar Rotti, Vaibhav Ahuja, Nishigandha Patel, “Pick and Place Robotic Arm: A Review Paper”, International Research Journal of Engineering and Technology (IRJET), 2021. [5] Ashly Baby, Chinnu Augustine, Chinnu Thampi, Maria George, Abhilash A Pss, Philip C Jose, “Pick and Place Robotic Arm Implementation Using Arduino”, IOSR Journal of Electrical and Electronics Engineering (IOSR-JEEE),2017. [6] Khin Moe Myint, Zaw Min Min Htun, Hla Myo Tun, “Position Control Method For Pick And Place Robot Arm For Object Sorting System”, INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH, 2016. [7] Kaustubh Ghadge, Saurabh More, Pravin Gaikwad, “ROBOTIC ARM FOR PICK AND PLACE APPLICATION”, International Journal of Mechanical Engineering and Technology (IJMET), 2018. [8] Rosidah Sam, Kamarul Arrifin, Norlida Buniyamin, “Simulation of Pick and Place Robotics System Using Solid works Soft motion”, International Conference on System Engineering and Technology,2012. [9] Sandeep Kumar , Santhakumar Mohan , and Valeria Skitova, “Designing and Implementing a Versatile Agricultural Robot: A Vehicle Manipulator System for Efficient Multitasking in Farming Operations”, Molecular Diversity Preservation International (MDPI), 2023. [10] Aim n Mohamed Ahmed GHIET, Mukhtar Abdussalam DAKHIL, Almehdi Khalifa DAYAB, Alauldin ali SAEID and Abdellatif BABA, “Design and development of robotic arm for cutting trees”, University of Turkish Aeronautical Associaiton,2016. [11] Abhiraj Bhalerao, Prasad Doifode, Kunal Chopade, Jitendra Gaikwad, “Pick and Place Robotic ARM using PLC”, International Journal of Engineering Research & Technology (IJERT), 2019 [12] Wan Muhamad Auf B. Wan Mohd Raziff; Rosidah Sam, Marianah Masrie; Zuriati Janin, “Design and Simulation of Pick and Place System Using Solid works Simulation”, IEEE 5th International Conference on Smart Instrumentation, Measurement and Applications (ICSIMA 2018),2018. [13] Adham Mohamed, Ahmed Abd-Elmonen, Ahmed Asem, Ahmed Atef, Ahmed Kamal Mohamed, El-Hussein Abd El Ghani, Mohamed Yasser, Mostafa Ashraf, and Omar Mohamed, “Design and Control of a Robotic Manipulator for Pick and Place Applications”, 6th IUGRC International Undergraduate Research Conference, Military Technical College, Cairo, Egypt, Sep. 5th – Sep. 8th, 2022. [14] J PRUDHVIRAJU, K. HUSSAI BABU, G. V. V. NAGARAJU, “STRUCTURAL DESIGN AND ANALYSIS OF PICK-AND-PLACE ROBOTICS COMPONENTS USING ANSYS SOFTWARE FOR AGRICULTURAL APPLICATIONS”, International Journal of Multidisciplinary Engineering in Current Research – IJMEC, 2023. [15] Dr. T. Sunil kumar, M. Gangadri, D. Nagarjuna, Y. Sai kumar and Ch. Ashok, “Analysis of remote-controlled pick and place robotic vehicle”, 2nd National Conference on Recent Trends in Mechanical Engineering, GIST, Nellore, 2022. [16] Ciprian Dragne, Corina Radu (Fren?), Mihaiela Iliescu, “MECHANICAL ENGINEERING OF ROBOTIC SYSTEMS BY SOLIDWORKS”, International Journal of Modern Manufacturing Technologies, 2022.

Copyright

Copyright © 2024 Dodla Manideep, Mettu Ranjith, Paka Sumanth, Pola Ravikumar, Chetla Venu Gopal, Dr. K. Siva Prasad. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59281

Publish Date : 2024-03-21

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online