Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and Analysis of Connecting Rod Using Different Materials

Authors: Anand. R, S. Raghukumar

DOI Link: https://doi.org/10.22214/ijraset.2022.42153

Certificate: View Certificate

Abstract

Connecting rod is an important component in an engine. Connecting rod used to connect between piston and crankshaft. The purpose of the project was to analysis connecting rod fracture using Finite Element Analysis. The stress and thermal for connecting rod can analyzed with this software. With this software, can analysis the stress and thermal for connecting rod. Before that, draw the connecting rod using CATIA V5 W/F software, then exported to the finite element analysis (ANASYS software). This project focused on analysis. Overall, this project will acquire the analysis of fracture connecting rod. The connecting rod is under tremendous stress from the reciprocating load represented by the piston, actually stretching and being compressed with every rotation, and the load increases to the third power with increasing engine speed. Failure of a connecting rod, usually called „throwing a rod? is one of the most common causes of catastrophic engine failure in cars, frequently putting the broken rod through the side of the crankcase and thereby rendering the engine irreparable; it can result from fatigue near a physical defect in the rod, lubrication failure in a bearing due to faulty maintenance, or from failure of the rod bolts from a defect, improper tightening, or re-use of already used (stressed) bolts where not recommended . Connecting rod produced from alloy steel forging or aluminium alloy were used to a limited extend in early practice, the primary object being to reduce the loading on the big end and main bearing. Connecting rods used these days are the result of advancements in metallurgy and machining techniques. These rods are the critical part of an engine because even a small defect in it can lead to catastrophic engine failure in automobiles. Most of the automobile manufacturers are engaged in making superior and high performance connecting rods at economical process

Introduction

I. INTRODUCTION

Connecting rod used to connect between the piston rod with crankshaft. Connecting rod is an important component in the engine. Failure at the connecting rod causes the engine cannot be functioned. This conditions not safe and can cause accidents while driving.

The objectives of this project are to:

- Developed a geometrical model for connecting rod using CATIA V5 W/F software.

- Investigate the stress analysis of steel and aluminum alloy of connecting rod using ANASYS software.

- Investigate the maximum stress of connecting rod using ANASYS software.

The computational stress from finite element analysis will be carried out on a CATIA V5 w/f connecting rod design. The two different materials are chosen for analysis is structural steel and aluminum alloy. The geometry model for the connecting rod had drawn using CATIA V5 w/f software. The analysis was running using ANASYS software. The apply load for the analysis is 900 only.

II. MATERIAL USED FOR ANALYSIS

The connecting rods are most usually made of structural steel or aluminum alloy for production engines. These materials have different properties and suitable for different engines.

- Structural Steel

- Aluminium Alloy

- Titanium Alloy

- Forged Steel

- Beryllium

A. Structural Steel

Structural steel rods have some real advantages over Titanium and aluminum. They are much stronger than both aluminum and Titanium. The material itself is not lighter than titanium, but the added strength allows less material to be used. The end result can be a rod of equal strength to titanium and even lighter than many aluminum rods.

The structures are designed to withstand the forces of nature and to retain the shape of Components. Steel structures are of the following two types: braced structure and framed Structure. Steel structures can be statically determinate or hyper-static. The steel structure Forms a skeleton to withstand forces. The steel structure can undergo gross bucking or local buckling. Reinforced Cement Concrete (RCC) structures are labor intensive. The Construction time for RCC structures is longer than a comparable steel structure. In India, Steel structures are used widely for factory buildings. The connections of the steel structures can be riveted or bolted or welded. Welded connections are done in the factory or under Covered sheds. Bolted connections are done in the field (open to atmosphere). The bolted Connections can be bearing type or friction type. Bearing type of bolted connections is widely used in structural steel industries in India. Friction types of connections require high Quality parts and discipline among the working groups. The structure has a life of fifty years and shall be painted once in three years. The steel structure has the following three main Parts: beam, column and bracing. The following parts are also used: base plate, foundation Bolt, joints, foundation materials, purlin, rafter, eve's girder, roof girder, etc.

B. Aluminium Alloy

Aluminum rods are popular among high rpm race engines. They are very light and strong, but they a short fatigue lift. In a limited use situation, they can last a long time and usually those types of engines see frequent tear downs anyway. High rpm is where aluminum rods offer advantages, so it can be preferred by most of the company’s .the aluminum alloys are less in weight and its expense is less than other materials.

In my opinion, high rpm is where aluminium rods offer advantages, so if you are not going to rev high, there is no sense in using aluminium. They also need more pistons to head clearance due to more rod stretch; a typical aluminium rod can stretch up to 0.008" more than a steel rod in a high rpm application. Since aluminium stretches more than steel, bearing retention is also a problem; the usual Tangs are not enough to be reliable. Aluminium rods must use a dowel pin to keep the bearings from spinning.

Pure aluminum is soft, ductile, and corrosion resistant and has a high electrical conductivity. It is widely used for foil and conductor cables, but alloying with other elements is necessary to provide the higher strengths needed for other applications. Aluminum is one of the lightest engineering metals, having strength to weight ratio superior to steel.

C. Titanium Alloy

Titanium alloys are metals which contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness (even at extreme temperatures). They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. However, the high cost of both raw materials and processing limit their use to military applications, aircraft, spacecraft, medical devices, connecting rods on expensive sports cars and some premium sports equipment and consumer electronics. Auto manufacturers Porsche and Ferrari also use titanium alloys in engine components due to its durable properties in these high stress engine environments.

Although "commercially pure" titanium has acceptable mechanical properties and has been used for orthopedic and dental implants, for most applications titanium is alloyed with small amounts of aluminum and vanadium, typically 6% and 4% respectively, by weight. This mixture has a solid solubility which varies dramatically with temperature, allowing it to undergo precipitation strengthening.

Table.no:1 Mechanical Properties of Titanium Alloy

|

MECHANICAL |

VALUES |

|

Ultimate Tensile Strength |

1280-1480 Mpa |

|

Yield Strength |

965-120 Mpa |

|

Young Modulus |

125-130 Gpa |

|

Poisson’s ratio |

0.33 |

|

Modulus of rigidity |

50 Gpa |

D. Forged Steel

This study investigates and compares fatigue behaviour of forged steel and powder metal connecting rods. A literature review on several aspects of connecting rods in the areas of load and stress analysis, durability, manufacturing, and optimization is also provided. The experiments included strain-controlled specimen testing, with specimens obtained from the connecting rods, as well as load-controlled connecting rod bench testing. Monotonic and cyclic deformation behaviours, as well as strain-controlled fatigue properties of the two materials are evaluated and compared.

Experimental S-N curves of the two connecting rods from the bench tests obtained under R = -1.25 constant amplitude axial loading conditions are also evaluated and compared. Fatigue properties obtained from specimen testing are then used in life predictions of the connecting rods, using the S-N approach. The predicted lives are compared with bench test results and include the effects of stress concentrations, surface finish, and mean stress. The stress concentrations factors were obtained from FEA, and the modified Goodman equation was used to account for mean stress effect.

In a reciprocating piston engine, the connecting rod connects the piston to the crank or crankshaft. In modern automotive internal combustion engines, the connecting rods are most usually made of steel for production engines, but can be made of aluminium (for lightness and the ability to absorb high impact at the expense of durability) or titanium (for a combination of strength and lightness at the expense of affordability) for high performance engines, or of cast iron for applications such as engine. The small end attaches to the piston pin, gudgeon pin (the usual British term) or wrist pin, which is currently most often press fit into the con rod but can swivel in the piston, a "floating wrist pin" design. The connecting rod is under tremendous stress from the reciprocating load represented by the piston, actually stretching and being compressed with every rotation, and the load increases to the third power with increasing engine speed. Failure of a connecting rod, usually called "throwing a rod" is one of the most common causes of catastrophic engine failure in cars, frequently putting the broken rod through the side of the crankcase and there by rendering the engine irreparable; it can result from fatigue near a physical defect in the rod, lubrication failure in a bearing due to faulty maintenance or from failure of the rod bolts from a defect, improper tightening, or re-use of already used (stressed) bolts where not recommended.

E. Beryllium

The Connecting rod is the intermediate member between the piston and the Crank-shaft. Its primary function is to transmit the push and pull from the piston pin to the crank pin, thus converting the reciprocating motion of the piston into rotary motion of the crank. Existing connecting rod is manufactured by using Carbon steel. This project describes modelling and analysis of connecting rod. In this project connecting rod is replaced by Beryllium material.

A 2Dimensional drawing is drafted from the calculations. A parametric model of connecting rod is modelled using 3d modelling software called SOLIDWORKS 2016. Analysis is carried out by using ANASYS WORKBENCH R 2016 software. Finite element analysis of connecting rod is done by considering materials, via... Beryllium.

The structural parameters like Von misses stress and strain, Deformation for two wheeler Connecting rod were done in ANASYS. Compared to carbon steel, The Beryllium is found to have working factor of safety is high, to reduce the weight up to 25% to increase the stiffness by 40% and to reduce the stress by 30%.The objective of the present study is to design and analysis of two wheeler connecting rod and to find the best alternative material of connecting rod.

In the present study beryllium alloys and magnesium alloys have taken in place of currently using materials like aluminium 360 for CAE analysis and a meaningful comparison made among AL360, Beryllium alloy and Magnesium alloy for choosing the alternative of existing material using for manufacture the connecting rod of single cylinder 4 stroke combustion engines.

In this work, an analysis is done for aluminum alloy, magnesium alloy and beryllium alloy. Beryllium alloys feature high fatigue strength and resistance to wear, corrosion, galling, and stress relaxation

III. LITERATURE REVIEW

Mr.J.D.Ramani, Prof. Sunil Shukla In series of automobile engine components a connecting rod is highly critical and researchable one. The main idea of this study is to do analysis of connecting rod and get idea of stress producing during compressive and tensile loading. And then give idea about weight reduction opportunities for a production steel connecting rod. This has entailed performing a detailed load analysis. Therefore, this study has contain by two subjects, first, load and stress analysis of the connecting rod, and second, optimization for weight reduction. In the first part of the study, loads acting on the connecting rod and find out stress-time history at some critical point. The results were also used to determine the variation of Tensile and Compressive loading the component was optimized for weight reduction subject to space constraints and manufacturability.

H.B.RAMANI has do Analysis of Connecting Rod under Different Loading Condition Using ANSYS Software [1].In spite of the great power of FEA, the disadvantages of computer solutions must be kept in mind when using this and similar methods, they do not necessarily reveal how the stresses are influenced by important problem variables such as materials properties and geometrical features, and errors in input data can produce wildly incorrect results that may be overlooked by the analyst. Finite element codes are less complicated than many of the word processing and spreadsheet packages found on modern microcomputers. Nevertheless, they are complex enough that most users do not find it effective to program their own code. A number of prewritten commercial codes are available, representing a broad price range and compatible with machines from microcomputers to supercomputers.

PROF. N.P.DOSHI “analysis of connecting rod using analytical and finite element method”. The most common types of materials used for connecting rods are steel and aluminium. Connecting rods are widely used in variety of engines such as, in-line engines, v-engine, opposed cylinder engines, radial engines and oppose-piston engines. For the project work we have selected connecting rod used in light commercial vehicle of tata motors had recently been launched in the market. We found out the stresses developed in connecting rod under static loading with different loading conditions of compression and tension at crank end and pin end of connecting rod. Design of connecting rod which is designed by machine design approach is compared with actual production drawing of connecting rod. We found that there is possibility of further reduction in mass of connecting rod. [2]

WEBSTER ET AL. (1983) performed three dimensional finite element analysis of a high-speed diesel engine connecting rod. For this analysis they used the maximum compressive load which was measured experimentally, and the maximum tensile load which is essentially the inertia load of the piston assembly mass. The load distributions on the piston pin end and crank end were determined experimentally. They modelled the connecting rod cap separately, and also modelled the bolt pretension using beam elements and multi point constraint equations. [3]

YOO ET AL. (1984) used vibrational equations of elasticity, material derivative idea of continuum mechanics and an ad joint variable technique to calculate shape design sensitivities of stress. The results were used in an iterative optimization algorithm, steepest descent algorithm, to numerically solve an optimal design problem. The focus was on shape design sensitivity analysis with application to the example of a connecting rod. The stress constraints were imposed on principal stresses of inertia and firing loads. But fatigue strength was not addressed. The other constraint was the one on thickness to bound it away from zero. They could obtain 20% weight reduction in the neck region of the connecting rod. [4]

IV. WORKING PRINCIPLE

Connecting rod is a vital component of any internal combustion engine. This is the component which carries the power from the piston to the crank-shaft and thus giving movement to the engine.

The connecting rod is attached to the crank-shaft by crank pin and the other end of the connecting rod is connected to the piston with the piston pin.

The connecting rod takes the power thrust from the reciprocating piston and carries it to the crank pin which in turn transmits the power / motion to the crank-shaft in the form of rotary motion which makes the vehicle move. It is utmost important that the connecting rod should be of correct weight and size so that there is no vibration in the connecting rod while transmission of power. Also the dimensional parameters and the heat treatment parameters should be strictly maintained to ensure trouble free running of the engine.

The small end attaches to the piston pin, gudgeon pin or wrist pin, which is currently most often press fit into the connecting rod but can swivel in the piston, a "floating wrist pin" design.

The big end connects to the bearing journal on the crank throw, in most engines running on replaceable bearing shells accessible via the connecting rod bolts which hold the bearing "cap" onto the big end. Typically there is a pinhole bored through the bearing and the big end of the connecting rod so that pressurized lubricating motor oil squirts out onto the thrust side of the cylinder wall to lubricate the travel of the pistons and piston rings.

The connecting rod is under tremendous stress from the reciprocating load represented by the piston, actually stretching and being compressed with every rotation, and the load increases to the square of the engine speed increase. Failure of a connecting rod, usually called "throwing a rod" is one of the most common causes of catastrophic engine failure in cars, frequently putting the broken rod through the side of the crankcase and thereby rendering the engine irreparable; it can result from fatigue near a physical defect in the rod, lubrication failure in a bearing due to faulty maintenance, or from failure of the rod bolts from a defect, improper tightening.

- Connecting Rod Nut

- Piston Pin Bolt

- Notched Bolt

- Connecting Rod Bearing Cap

- Spacer Washer

A. Comparision Of Materials

Density Comparison

The connecting rod has a tremendous field of research. In addition to this, vehicle construction led the invention and implementation of quite new materials which are light and meet design requirements. And the optimization of connecting rod had already started as early year 1983 by Webster and his team. There are many materials which can be used in connecting rod for optimization. In modern automotive internal combustion engines, the connecting rods are most usually made of steel for production engines, but can be made of aluminium (for reducing the weight and the ability of absorbing high impact at the expense of durability) or titanium (for a high performance engines) or of cast iron for applications such as motor scooters. In this study materials compared are Forged Steel, Beryllium 25, aluminium 360, Titanium alloy, Magnesium alloy. In this comparison we replace Beryllium alloy by Titanium alloy.

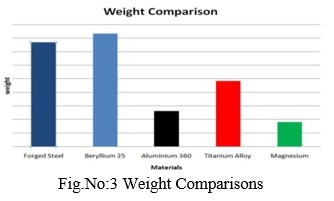

B. Weight Comparison

Compared five materials used for manufacturing of connecting rod these are Al360, Magnesium alloy, Beryllium 25, Forged Steel and Titanium alloy. The modelling and analysis of connecting rod was done. FEM analysis was carried out by considering three materials AL360, beryllium alloy and magnesium alloy. In his study he found out that out of above three material beryllium alloys is the best suitable material for connecting rod of two wheeler.

V. ANALYSIS OF CONNECTING ROD USING TITANIUM ALLOY

The connecting rods are most usually made of steel for production engines, but can be made of aluminium (for lightness and the ability to absorb high impact at the expense of durability) or titanium (for a combination of strength and lightness at the expense of affordability) for high performance engines, or of cast iron for applications such as motor scooters.

A. Introduction To Anasys

ANASYS is analysis software. It is used to check design feasibility of the design almost in all aspect. ANASYS as a software is made to be user-friendly and simplified as much as possible with lots of interface options to keep the user as much as possible from the hectic side of programming and debugging process.

B. Analysis Diagram Of Connecting Rod Using Titanium

A. Result And Analysis

B. Analysis Diagram of Connecting Rod using Forged Steel

VII. MERITS

- We can easily identify the mechanical deformation of connecting rods.

- Easily identify the stress analysis.

- Comparison between different types of materials used in connecting rods.

A. Software Used

- CATIA

- ANASYS

B. Future Scope

- Vibrational analysis can be done at ANASYS for minimizing the premature failure.

- Dynamic analysis of connecting rod can also be performed on ANASYS to get the better analysis.

- Thermal analysis can be done of connecting rod to minimize the thermal stress effect on connecting rod.

- Torsional analysis can be done due to presence of small amount of torsional moment at the end points.

- Design modification can be done to minimize the weight of connecting rod and the inertia force.

- Work on the internal coating of hard material inside the both ends can be done to minimize the wear failure in connecting rod.

C. Acronyms

N = No. of cycles

σe = Endurance Limit

????????= Ultimate Tensile Stress

???????? ′ = Endurance limit for variable axial stress

k a = Load correction factor for reversed axial load = 0.8

ksr = Surface finish factor = 1.2

ksz = Size factor = 1

f.o.s = factor of safety

σm = mean stress

σy = yield stress

σv = variable stress

σe = endurance stress

VIII. CALCULATION FOR WEIGHT AND STIFFNESS FOR TITANIUM ALLOY

Density of titanium alloy = 4.6×10−6 kg/mm3

Volume = 41050 mm3

Deformation = 0.0048301 mm

Weight of Titanium Alloy = Volume ×Density

=41050×4.6×10-6

= 0.188kg

= 0.188×9.81

= 1.8524 N

Stiffness = weight/deformation

= 1.8524/0.0048301

=383.51 N/mm

Fatigue Calculation Result For Fatigue Of Connecting Rod

N=1000(sf/ (0.9σu)) 3/ (log (???????? ′/ (0 .9×????????)))

Where,

N = No. of cycles

σe = Endurance Limit

????????= Ultimate Tensile Stress

???????? ′ = Endurance limit for variable axial stress

k a = Load correction factor for reversed axial load = 0.8

ksr = Surface finish factor = 1.2

ksz = Size factor = 1

???????? ′ = σe×ka×ksr×ksz

????????= (????.o.????x σv)/(1−(????.????????????/????????))

For titanium alloy

???????? =962.5 Mpa

σe = ????????×0.5

= 962.5×0.5

= 481.25 Mpa

????? ′ = σe×ka×ksr×ksz

= 481.25×0.8×1.2×1

= 462 Mpa

sf = (f.o.sxσv)/(1−(f.o.s×σm)/σu))

=(17.69×16.708)/(1− ((17.69×16.708)/962.5))

= 426.54 Mpa

N = 1000(sf/0.9σu) 3/log (???????? ′/ (0 .9×????????))

=1000(426.54/(0.9×962.5))3log(462/(0.9×962.)

N = 2405.03× 103cycles

IX. CALCULATION FOR WEIGHT AND STIFFNESS FOR BERYLLIUM ALLOY

Density of beryllium alloy = 8.36×10-6kg/mm3

Volume = 41050 mm3

Deformation = 0.0043489 mm

Weight of beryllium alloy = volume ×density

=41050×8.36×10-6

= 0.3431kg

= 0.3431×9.81 = 3.36 N

Stiffness =weight/deformation

= 3.36/0.0043489

=772.609N/mm

Fatigue Calculation Result For Fatigue Of Connecting Rod

N=1000(sf/(0.9σu))3/(log (???????? ′/(0 .9×????????)))

Where,

N = No. of cycles

σe = Endurance Limit

????????= Ultimate Tensile Stress

???????? ′ = Endurance limit for variable axial stress

ka = Load correction factor for reversed axial load = 0.8

ksr = Surface finish factor = 1.2

ksz = Size factor = 1

???????? ′ = σe×ka×ksr×ksz

???????? = (????.o.????×σv)/ (1− ((????.o.????×????????)/????????))

???????? =370Mpa

σe = ????????×0.5

= 370×0.5

= 185 Mpa

???????? ′ = σe×ka×ksr×ksz

= 185×0.8×1.2×1

= 177.6Mpa

s???? = (????.o.????×σv)/ (1− ((????.o.????×????????)/????????))

= (4.747×18.9575)/(1−((4.747×18.9575)/370))

= 118.91Mpa

N = 1000(sf/0.9σu) 3/log (???????? ′/ (0 .9×????????))

= 1000(118.91/ (0.9×370)) 3log (177.6/ (0.9×370))

N =1000.186× 103 cycles.

A. Results For Factors

Table.No:5 Result Factor

|

MATERIAL |

FOS |

WEIGHT |

STIFNESS |

|

Titanium Alloy |

17.69 |

1.8524 |

383.51 |

|

Beryllium Alloy |

4.747 |

3.36 |

772.609 |

Conclusion

It is the conclusion of this study that the connecting rod can be designed and optimized under a load range comprising compressive load as one extreme load and tensile load. Furthermore, the existing connecting rod can be replaced by optimization with a new connecting rod made of lighter in weight (approx. 15%).From the above analysis we can conclude that stresses of all the materials are almost comparable and also in safe limit, i.e., well below the yield stress. The section modulus of the connecting rod should be high enough to prevent high bending stresses due to inertia forces. 1) Solid modelling of connecting rod was made in fusion 360 according to production drawing specification and analysis under the effect of tensile and compressive loads in terms of pressure is done in ANSYS Workbench. 2) From analysis it is observed that the minimum stresses among all loading conditions, were found at crank end cap as well as at piston end. So the material can be reduced from those portions, thereby reducing material cost. For further optimization of material dynamic analysis of connecting rod is needed. 3) After considering dynamic load conditions once again finite element analysis will have to be performed. It will give more accurate results than existing. 4) It is the conclusion of this study that the connecting rod can be designed and optimized under a load range comprising compressive load as one extreme load and tensile load. Furthermore, the existing connecting rod can be replaced by optimization with a new connecting rod made of lighter in weight (approx. 15%). 5) From the above analysis we can conclude that stresses of all the materials are almost comparable and also in safe limit, i.e., well below the yield stress. 6) The section modulus of the connecting rod should be high enough to prevent high bending stresses due to inertia forces. Weight of connecting rod is reduced, Thereby reduces the inertia force by comparing the results of three different materials used for connecting rod analysis it is found that equivalent von mises stress for all the materials is approximately same. 7) From the static analysis the stress is found maximum at the small end of the connecting rod. 8) Carbon steel as a connecting rod material is less stiff and having more weight than forged steel and other material taking in consideration. 9) Forged steel connecting rod is having more weight than Aluminum, magnesium and beryllium alloys connecting rod. 10) Aluminum alloy connecting rod is having more weight and displacement than magnesium and beryllium alloys. So, aluminum connecting rod show more shaky behaviour.Maximum von mises stress, 11) Maximum von mises strain and Maximum displacement are minimum in connecting rod of Beryllium alloy. 12) Comparing the different data it is observed that stress, strain and displacement is minimum in beryllium alloy connecting rod. So, beryllium alloy can be used for production of connecting rod for longer life. 13) Vibrational analysis can be done at ansys for minimizing the premature failure. 14) Dynamic analysis of connecting rod can also be performed on ansys to get the better analysis. 15) Thermal analysis can be done of connecting rod to minimize the thermal stress effect on connecting rod. 16) Torsional analysis can be done due to presence of small amount of torsional moment at the end points. 17) Design modification can be done to minimize the weight of connecting rod and the inertia force. 18) Work on the internal coating of hard material inside the both ends can be done to minimize the wear failure in connecting rod.

References

[1] Kuldeep B, Arun L.R, Mohammed Faheem “ANALYSIS AND OPTIMIZATION OF CONNECTING ROD USING ALFASiC COMPOSITES”, ISSN: 2319-875, International Journal of Innovative Research in Science, Engineering and Technology, Vol. 2, Issue 6, June 2013 [2] Prof. N.P.Doshi, 1 Prof .N.K.Ingole “ANALYSIS OF CONNECTING ROD USING ANALYTICAL AND FINITE ELEMENT METHOD” INTERNATIONAL JOURNAL OF MODERN ENGINEERING RESEARCH” (IJMER) www.ijmer.com Vol.3, Issue.1, Jan-Feb. 2013, ISSN: 2249-6645. [3] Webster.w.d, coffell R, and Alfaro D. “Modelling and analysis of two wheelr connecting rod while using ansys software” IOSR Journal mechanical and civil engineering. [4] Yoo et al., M.M. Rahman, M.M. Noor, K. Kadirgama and A.K. Amirruddin “DESIGN OF CONNECTING ROD OF INTERNAL COMBUSTION ENGINE: ATOPOLOGY OPTIMIZATION APPROACHM” National Conference in Mechanical Engineering Research and Postgraduate Studies (2nd NCMER 2010)3-4 December 2010, pp.155166 [5] FOLGAR Analysis of Connecting Rod Using Analytical and Finite Element? International Journal of Modern Engineering Research (IJMER), JanFeb. 2013, Vol.3, Issue.1, pp-65-68 [6] SERAJ, Mohammad Reza Asadi, Masoud Mohammadi, Ahangari Heidar., 2011, Fatigue Analysis of Connecting Rod of Samand Engine by Finite Element Method, Australian Journal of Basic and Applied Sciences, ISSN 1991-8178, 5(11): 841-845. [7] SARIHAN and SONG, Design Evaluation and Optimization of Connecting Rod Parameters Using FEM International Journal of Engineering and Management Research, Vol.-2, Issue-6, December 2012.

Copyright

Copyright © 2022 Anand. M, S. Raghukumar . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET42153

Publish Date : 2022-05-02

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online