Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- References

- Copyright

Design and Analysis of Innovative Machine to Extract Banana Dietary Fiber

Authors: Murugapandi P, R. Soundararajan

DOI Link: https://doi.org/10.22214/ijraset.2023.53669

Certificate: View Certificate

Abstract

The project is aimed for study and design of an Innovative device to extract high quality dietary banana fiber from the banana pseudo stems. Banana dietary fiber is the fiber extracted from the center core stem of the banana pseudostem, it has high medicinal application as well as it is highly suitable for textile applications and recently lots of value added products are made from these dietary fiber. Still there is no device or machineries is available to extract the dietary fiber , our project aim is design a machine to extract the dietary fiber from the center core stem of the banana tree by using the software PTC creo 8.0.

Introduction

I. INTRODUCTION

In our earth lot of plants and plants waste materials are unused and remain waste and decomposed in the sand. Example banana, hemp, some grass, along with many trees bark, it contains valuable fibers. It is not only used for making fibers but also it contains natural medicinal properties along with skin friendly. We have visited many places after the rainy season we came across lot of plant leaf and plant waste has many valuable fibers. We have seen in uttarkhand state one type of nettle plant, it is very rough and course initially, after drying and beating the plant we saw that so much of soft fiber was present in the nettle plant. We are surprised with the soft and the spin ability and other quality of the fiber also. Banana fiber is environmentally friendly like jute fiber. It has large export demand from many countries like Japan, Australia, Germany and many. Fiber can be obtained from whole banana plant. After harvesting the banana bunch the remain portion of the tree becomes agriculture waste. This waste contains valuable dietary banana fiber. After the fruit is harvested the tree is thrown away or fires the entire area of the banana pseudo stem. It will be spreading the smoke with the entire area and create environmental problems. If they buried inside the land also create environmental problems. It also involves additional expenses to the banana farmers to clean the land to do next cultivation. Now due to this innovative device the banana farmers not only saving the land cleaning cost but also they are making profit by selling the banana pseudo stem.

A. Scope Of Innovation

This innovative device when come to the market all the banana farmers feel happy. This is the natural and chemical free fiber suitable for many applications. The banana fiber is tested for its properties in the lab as well as it is tested for some other product making just like eco friendly handmade paper making and it is very successful. 100% chemical free tissue paper also made. The banana dietary fiber is mostly liked by Japan and European people. The banana fiber longitivity is more than 700 years. In some countries banana fiber is being used for making currency paper. Even ladies can work on the machine and the state governments will give subsidy for the device.

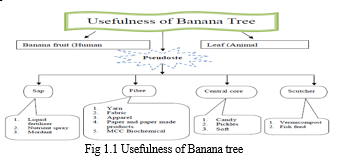

B. Usefulness Of Banana Tree

II. LITERATURE REVIEW

Banana has long been considered a food, fruit and fodder crop. In addition to this now a days, it is also gaining importance as a source of fibers. India is the largest producer of banana in the world with an estimated annual output of 3.5 million tones. Of which 80% is generated from 6 states, namely, Tamilnadu, Maharasthra, Karnataka, Kerala, Andhrapradesh and Gujarat. Annually about 1.5 million tons of dry banana fibers can be produced from the outer sheath of pseudo stem. With the increasing demand for banana in both the Indian and international markets. The acreage and production are expected to increase in the coming years, thus generating more of the pseudo stem biomass waste. Being a rich source of natural fibers, the pseudo stem can be profitably utilized for numerous applications and preparation of various products. Thus in order to get acquainted with the earlier reported details of banana fiber production and utilization and blending possibilities an extensive literature review was carried out. In order to have a clear picture of the banana fiber utilization the literature collected has been further classified under three categories. This consists of studies related to banana fibers and its applications.

Sinha(1973)69 studies on the use of banana plant fiber as a substitute for jute. Banana-plant fiber is strong, soft, and coarse and technique developed for processing the fiber on standard jute machinery is reported. In some trials the banana fiber was also blended with Mesta (cellulose fibers) the banana 82 fiber spin ability and weaving performance were invested, so that it can be used as a good substitute for jute in making of sacks and packaging materials . The yarn composed of entirely of banana fiber can be replace jute on weft, sacking warp yarn and still maintain the standard cloth characteristic Banana.

The study also affirmed that sacking fabrics woven with banana-fiber yarn as weft and with jute yarn in the other direction compiled with standard specifications and performed better than corresponding all –jute fabrics. Jute Technological research institute laboratories(JTR lab) Calcutta 73 carried out an experiment work,(1974) on rope making with banana plant fiber. It was concluded that banana fiber can replace certain percentage of Mesta, a cellulosic fiber in the composition of agricultural ropes.

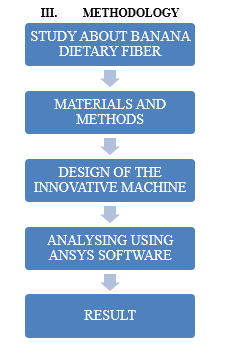

IV. STUDY ABOUT BANANA DIETARY FIBER

A. Characteristics Of Banana Dietary Fiber

The physical and chemical properties of banana dietary fibre are considered below:

The chemical composition of banana fiber is cellulose (50-60%), hemicelluloses (25-30%), pectin (3-5%), lignin (12-18%), water-soluble materials (2-3%), fat and wax (3-5%) and ash(15%) ,Its appearance is similar to that of bamboo and ramie fiber; however banana fiber has better fineness and spin ability.

It has shiny appearance depending upon the extraction and spinning process (Rao and Mohana,2007). It has very strong fiber with 3% elongation and light weight. Its average fineness is 2386 Nm, average strength is 3.93 cN/dtex and average length is 50 ~ 60 mm (or 38mm) (http://www.lifei.com/banana.htm). It absorbs and releases moisture easily. It can be spun by different methods like ring spinning, open-end spinning, bast fiber spinning, and semi-worsted spinning. It is bio-degradable and has no negative effect on environment and thus can be categorized as eco-friend fiber.

B. Different diameter untreated banana dietary fibers mechanical properties.

Table 4.1 Banana dietary fiber mechanical properties

|

Diameter Range In MM |

Dia meter In mm |

Young Modulus (GpA) |

Ultimate Strength Mpa |

Strain (%) |

|

0.07-0.05 |

0.0874 |

25.6 |

780.3 |

2.68 |

|

0.05-0.140 |

0.1328 |

13.7 |

300 |

1.93 |

|

0.140-0.175 |

0.1563 |

11.3 |

198.9 |

1.79 |

|

0.175-0.220 |

0.1925 |

6.6 |

222.3 |

3.27 |

C. Composition Of Banana Dietary Fibre

Table 4.2 Composition of Banana Dietary Fibre

|

Sr. No |

Component |

% Percentage |

|

1 |

Cellulose |

31.27 ± 3.61 |

|

2 |

Hemicelluloses |

14.98 ±2.03 |

|

3 |

Lignin |

15.07 ± 0.66 |

|

4 |

Extractives |

4.46 ± 0 .11 |

|

5 |

Moisture |

9.74 ± 1.42 |

|

6 |

Ashes |

8,65 ± 0 .1 |

D. Texture Of Banana Fiber

- Appearance of banana fiber is similar to that of bamboo fiber and ramie fiber.

- The chemical composition of banana fiber is cellulose, hemicelluloses, and lignin.

- It is a strong fiber.

- It has smaller elongation.

- It has somewhat shiny appearance depending upon the extraction.

- It is light weight.

- It has strong moisture absorption quality. It absorbs as well as releases moisture very fast.

- It is bio- degradable and has no negative effect on environment and thus can be categorized as eco-friendly fiber.

- Its average fineness is 4 to 15 tex.

E. Specification And Usage Of Banana Dietary Fiber

Banana fibers can be extracted by employing chemical, mechanical or biological methods. The chemical method causes environmental pollution, while mechanical method fails to remove the gummy material from the fiber bundle surface.

Biological procedures yield more fiber bundles than the other two procedures without any harm to the environment. The extraction of banana fibers using biological natural retting has already been reported. After extracting the fibers, degumming is essential prior to the utilization of fibers. The removal of heavily coated, non-cellulosic gummy material from the cellulosic part of plant fibers is called degumming.

Banana fiber is multiple celled structures. The lumens are large in relation to the wall thickness. Cross markings are rare and fiber tips pointed and flat, ribbons like individual fiber diameter range from 14 to 50 microns and the length from 0.25 cm to 1.3 cm, showing the large oval to round lumen.

The extraction of fiber from the pseudostem is not a common practice and much of the stem is not used for the production of fibers. The buyers for banana fibers are erratic and there is no systematic way to extract the fibers regularly. Useful applications of such fibers would regularize the demand which would be reflected in a fall in the prices.

A high cellulose content and low microfibril angle impart desirable mechanical properties for bast fibers. Lignins are composed of nine carbon units derived from substituted cinnamyl alcohol; that is, coumaryl, coniferyl, and syringyl alcohols. Lignins are associated with the hemicelluloses and play an important role in the natural decay resistance of the lignocellulosic material.

- Banana Fiber Extraction

Banana fibre is extracted, not on a commercial worthwhile scale anywhere in the country. For extraction of fibres from the pseudo stem, the most common method followed in Indian villages is hand scrapping, i.e. to scrap the stem with blunt metal edge. The drawback of hand scrapping is that the fibre output is very low. The essentially hand driven process of extracting banana fiber is now set to change with the invention of the Banana Fiber Separator Machine. An easier and quicker way of extracting fibres is to use a machine extractor, called Raspador, Banana Fiber is extracted from Banana pseudo stem sheaths. Some efforts to extract the fibre by conventional methods like Hand extraction are being made in state of Kerala but the quantity of fibre produced is quite small. In some banana growing countries of the world like Philippines, Uganda, China, and Indonesia systematic extraction of banana fibre is being carried out.

The plants are cut down as soon as the fruits are harvested. The trunk is peeled. Brown-green skin is thrown away retaining the cleaner or white portion which will be processed into knotted fibers. To extract the fibre, the pseudo stem is cut at the bottom at an angle, and its sheaths are removed, as each series of leaf sheaths produces different grades of fibers. It would be desirable to separate them according to the classification mentioned above prior to the cleaning or stripping that would enable the artisans to market the fibres advantageously. The fibers are extracted through hand extraction machine composed of either serrated or non serrated knives.

The peel is clamped between the wood plank and knife and hand-pulled through, removing the non- fibrous material. The extracted fibers are sun-dried which whitens the fiber. Once dried, the fibers are ready for knotting. A bunch of fibers are mounted or clamped on a stick to facilitate segregation. Each fiber is separated according to fiber sizes and grouped accordingly. To knot the fiber, each fiber is separated and knotted to the end of another fiber manually. The separation and knotting is repeated until bunches of unknotted fibers are finished to form a long continuous strand. This fiber can now be used for making various products. One more interesting fact associated with the development of this machine is that it uses the agriculture waste of banana harvests to produce silk grade fiber. These silk grade fibers are of immense help to the handicrafts and textile industry. What was previously considered an agricultural waste is now converted to a raw material for good quality silk like yarn.

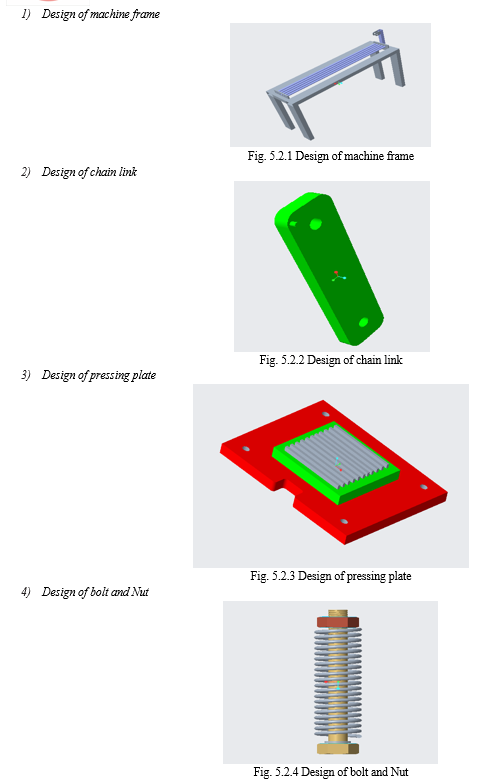

D. Working Procedure

The banana dietary fiber is available in the centre core stem of the pseudostem, so Initially we have to remove the centre core stem of the banana tree, After cultivation of the fruits the stem remains as a waste by extracting the dietary fiber we can make lots of value added products from it.

After removing the centre core stem, cut it into pieces about 2 feet.

Keep the centre core stem piece inside of the machine that is above the blade.

By pressing the press plate on that it get loaded and immersed inside of the blade gaps.

Its making the centre core stem into number of small pieces.

The machine blade is then expanded by pulling the lever using hands. It get expanded with the principle of the chain linkage mechanism.

After expansion of the blades we can see the dietary fiber in between the each gap of the blades.

It is in the wet condition, to remove the sap blow the air in the controlled way to get it dry, after drying we can get the good quality dietary fiber.

Take away the fiber from the machine using stirrer mechanism with the comb.

The remaining immersed centre core stem pieces are removed and it can be used for fertilizers, and other usages also.

VII. OBSERVATION

A. Observation Of The Product

With increasing demand on eco-friendly materials, banana fibres are now used to make garments, ropes, mats, carpets, cushions, cushion covers, bags, baskets, table cloths, curtains, rugs, matresses, pillows, wallets, wallets, yoga mats, sausage casings, tea bags, vacuum bags, cigarette papers, fishing nets, packaging sheets, base material for growing of mushrooms, cardboards, string threads, socks etc. It is used to make currency papers, bond papers, envelopes, tissue papers, filter papers, decorative papers and writing papers. Banana fibre is an alternative for wood pulp in paper industry due to its high cellulose content. In composite materials, banana fibres can be used as alternative to fibre glass and thus it finds application in automobile industry. Due to the high resistance to salt water, banana fibres are the most preferred ones in making marine ropes that are used in boats and ships, Use of cloths based on banana fibres originated in Japan during 13th century. Since water is absorbed and released quickly, fabrics made from banana fibres are considered as comfortable summer wear. Banana fabrics are beautiful and similar to silk. Although the raw fibres are not as soft as silk, it is possible to create silk like fabric from these fibres. Pseudo-stem of Cavendish varieties of banana is useful for paper making. Papers made from banana fibres are known to have resistance to water and also stronger than the wood pulp-based paper.

D. Application Of Banana Dietary Fiber

The use of banana stems as a source of fibre declined after other convenient fibres such as cotton and silk became popular. But in recent years the commercial value of banana fibre has increased and it is used all over the world for multiple purposes from making tea bags and sanitary napkins to. By explaining in detail its use in ancient times, its characteristics, From our extraction process and the possible uses of the eco-friendly fibres in the textile industry.

It is one of the strongest natural fibres, This biodegradable natural fibre from the bark of the banana plant is so durable that if we make currency notes from it, the notes can be used for more than a hundred years.

Banana stem, generally considered a complete waste, is now is now being made into banana-fibre cloth which comes in differing weights and thicknesses based on what part of the banana stem the fibre was taken from. The innermost sheaths are where the softest fibres are obtained, and the thicker and sturdier fibres come from the outer sheaths. It can be used to make silk grade saris.

E. Advantages Of These Project

- This project will give additional income to the banana farmers.

- After cutting the banana bunch to do next cultivation works the farmer will clean the land it will take around Rs.2000 per acre.

- The farmer will fire the banana tree waste it leads to atmospheric pollution; it is increasing the global warming also.

- Now the farmers are reducing the cleaning expenses and atmosphere also healthy.

- This project will generate lot of rural employment opportunities and it will improve the income level to the rural people.

- The banana cloth made by the banana cotton is very soft nature and it has very good export potential it will bring lot of foreign exchange also.

- The banana cotton separated stem pieces are very good nutrient vegetables

VIII. RESULT

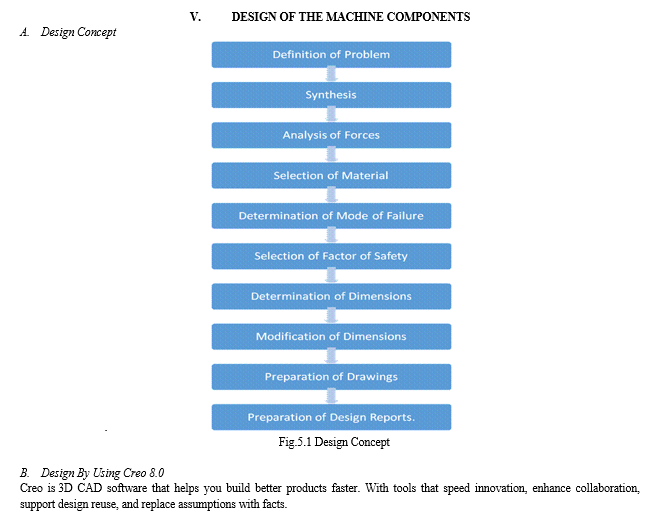

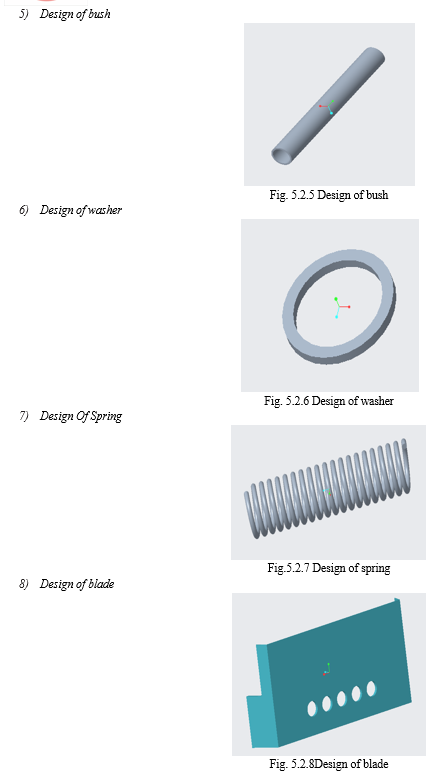

In many agricultural farms, the pseudo-stem of banana plants after harvest are disposed as landfill waste or burnt after drying. There exists a high potential for converting this waste into wealth. One metric ton of the pseudo-stem (contributed by 50 plants approximately) can yield about 1.5-2.0 kg of banana dietary fibres. Compared to other natural fibres, production of banana fibres is less expensive since the raw material is cheap and abundantly available in banana growing regions. Although many products based on banana fibres are available in the market, banana fibres are not yet explored completely. Cellulose nanocrystals obtained from banana fibres is an emerging field which has a greater potential to find additional applications for banana fibres. Low cost fibre extraction machines established at the village level can not only help in recycling this banana biomass into fibres but also provide employment opportunities to the rural poor and additional income to the farmers. For Extraction we have successfully designed the machine by using the software creo 8.0 .

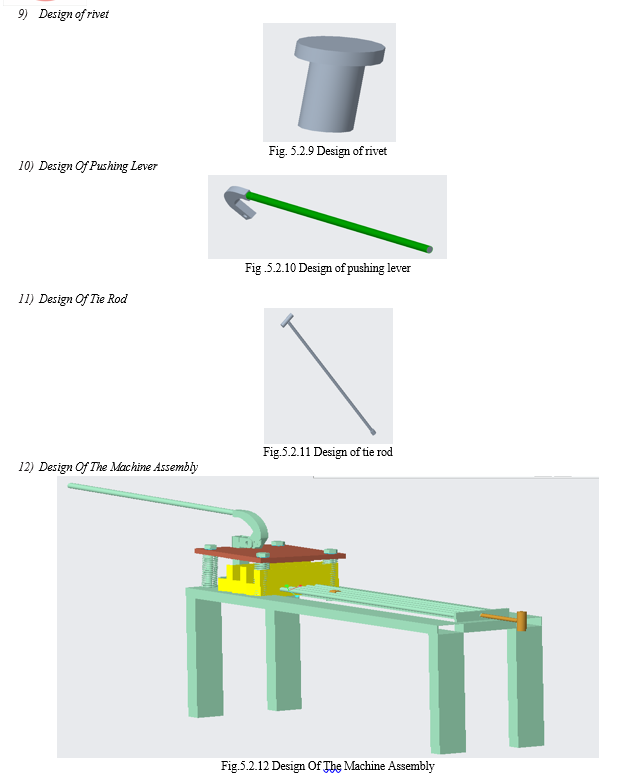

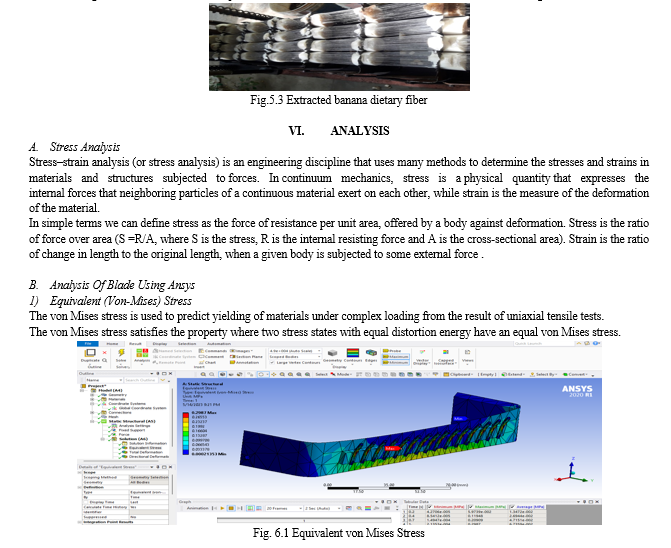

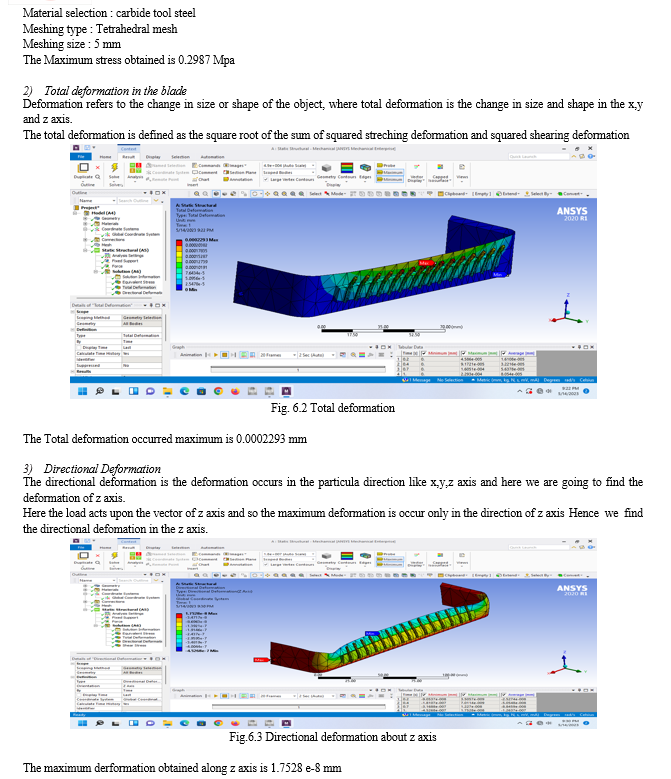

The analysis of the machine design by using Ansys is also done and the chosen material is viable and feasible the result obtained in the Ansys are mentioned below as

The Maximum stress obtained is 0.2987 Mpa,

The Total deformation occurred maximum is 0.0002293 mm,

The maximum derformation obtained along z axis is 1.7528 e-8 mm,

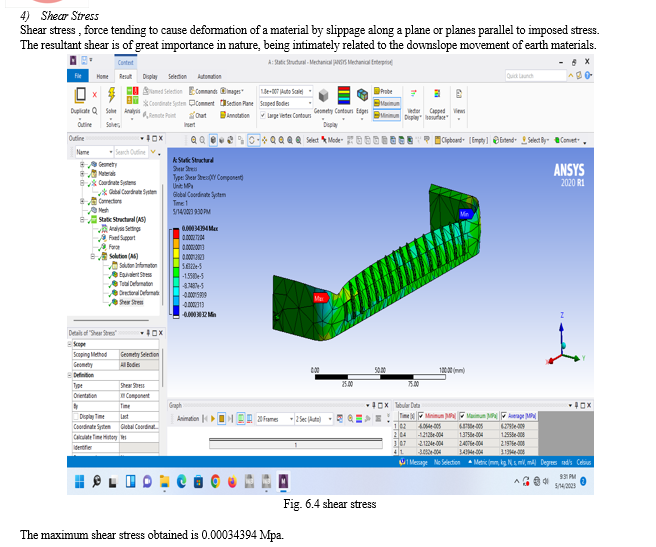

The maximum shear stress obtained is 0.00034394 Mpa.

References

[1] O. A. Adeboye, R.A. Iyanda, K.A. Yusuf, A.M. Olaniyan, and K.O. Oje, “Effects Of Temperature, Pretreatment And Slice Orientation On The Drying Rate And Post Drying Qualities Of Green Plantain (Musa Paradisiaca)”, International Journal Of Technology Enhancements And Emerging Engineering Research, 2 (7): 92-99, 2014, [2] Ankita and Prasad K., “Studies on Spinach Powder as Affected by Dehydration Temperature and Process of Blanching”’, Int. J. of Agri. & Food Sci. Technol., 4(4):309-316, 2013. [3] Dawn C.P. Ambrose, Laxman, R. and Ravindra Naik, “Studies on the drying kinetics and quality assessment of Banana pseudo stem waste for effective utilization as a value added product”, International Journal of Farm Sciences, 6(2): 276-285, 2016. [4] T. Garware, N. Sutar., and B. Thorat,, “Drying of tomato using different drying methods: comparison of drying kinetics and rehydration ratio,” in Proceedings of the 16th International Drying Symposium(IDS ’2008), pp. 1427–1432,Hydrabad, India, 2008 [5] J.M Gould, B.K Jasberg and G.L Cote, “Structure-function relationships of alkaline-peroxide treated lignocellulose from wheat straw”, Cereal Chem., 66:213–217,1989. [6] L.H Ho, A.A Noor Aziah and Rajeev Bhat,”, Mineral composition and pasting properties of banana pseudo-stem flour from Musa acuminata X balbisiana cv. Awak grown locally in Perak, Malaysia”, Intl. Fd. Research J., 19(4):1479-1485,2012 [7] R. Lakshman, D. C. P Ambrose, D. Chelvame, “Studies on the on the quality of banana centre core flour prepared by different drying methods”, Curr Agri Res 3(1): 55-59, 2015 [8] Muhammad Aslam Shad, Haq Nawaz, Mazhar Hussain and Beena Yousuf, “Proximate composition and functional properties of rhizomes of lotus (nelumbo nucifera) from Punjab, Pakistan”, Pak. J. Bot., 43(2): 895- 904, 2011 [9] J. P. Natt and M. S. Narasinga, “Functional Properties of Guar Proteins”, J. Food. Sci., 46:1255, 1981 [10] S. Ranganna, Handbook of Analysis and Quality Control for Fruit and Vegetable Products; 2nd ed. Pp.589, Tata Mc Graw Hill Publishing Company Ltd., New Delhi, India,1986.

Copyright

Copyright © 2023 Murugapandi P, R. Soundararajan. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET53669

Publish Date : 2023-06-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online