Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and CFD Analysis of Electric Car Battery Cooling System

Authors: R Ragavendiran, P. Amirthalinagm

DOI Link: https://doi.org/10.22214/ijraset.2022.41601

Certificate: View Certificate

Abstract

Electric cars are initially developed as an alternative option for existing gas powered car. It also shows good results in both performance and energy utilization. Usage of electric cars are encouraged due to its effect over global warming as there is no emission of harmful gases like CO, CO2, NOX. The electric car is an automobile that is propelled by one or more electric motors, using energy stored in rechargeable batteries. This idea was coined in later 18th century. But it was initiated in 20th century to roll on roads. Even though we use battery as the energy source, we need a cooling system. It isnecessary to ensure the proper dissipation of heat which is emitted from the battery while transmission. Here we discuss about the cooling system of battery in an electric car. We use three different liquids to analyze its effectiveness. Those fluids are Glycol, Fluorinert FC72 and NOVEC7200 (Ethoxy nonaflurobutane). We have designed and drawn the model using CATIA V5 software and analyzed using ANSYS FLUENT software. Then analyzed best Coolant for the battery coolingsystem.

Introduction

I. INTRODUCTION

Automobiles throughout the world are the primary consumers of fossil fuels, which emit toxic gases when burnt such as CO, CO2 and NOX. This results in increase of Global Warming. To reduce this factor Electric Vehicles were invented. Electric cars are a variety of electric vehicle(EV). The term "electric vehicle" refers to any vehicle which utilizes electric motors for propulsion. Low-speed electric vehicles classified as NEVs in the United States in terms of weight, power and maximum speed that are allowed to travel on public roads and city streets up to a certain posted speed limit.

Thus, an electric car that derives its power from an on-board battery pack is a form of battery electric vehicle(BEV).Although it is an electric vehicle, it needs a cooling system. It is due to its optimal usage of battery which dissipates heat heavily. So we analysis different types of fluids and its performance in this script.

II. LITERATUREREVIEW

A. Electric Vehicle Operation

The vehicles emitting organic compounds, Pd, nitrogen oxide and carbon monoxide have done significant pollution of air. World population is growing in extremely high rate so that the vehicle usage is also rising with the rise of the population. The main energy source of the vehicle is fossil fuel. After inventing the lead acid batteries and the electric motors in late 1800s, the first electric vehicles were invented. In the early 1900s, electric vehicles were very popular and that period is called golden period of electric vehicles. After the arriving of gasoline powered vehicles almost every electric vehicle was disappeared due to limitation of range, long charging time, heavy weight and poor durability of batteries (Young, K., Wang, C. and Wang, L.Y., 2013) (Kulkarni.A, Kapoor. A, and Arora. S,2015). Owing to gas emission laws and air pollution, automobile manufactures were forced to manufacture less carbon emission vehicle and so the electric vehicle manufacturing is increasing today (Sagar. A.D, 1995) (Kulkarni. A, Kapoor. A, and Arora. S, 2015). Electric vehicles provides an excellent alternative to the current fossil fuel powered vehicles due to several reasons. Low noise and zero emission are some main reasons why people buy electric car now days.Electric vehicle are perfectly suitable for urban environment thus they are very compact, not as wasteful as internal combustion engines in traffic and the limited range is not matter in the urban environment (Sagar. A.D, 1995).Internal operation of electric vehicles is similar to the internal combustion vehicles. Like in combustion vehicles, electric vehicles have an electric motor, an ECM, a battery, battery management system with regenerative braking system a charger and a cooling and heating system.

There are two types of motors used in electric vehicles AC motors, and DC motors. DC motors are easily controlled when comparing with AC motors and also less expensive than AC motors. However, DC motors are larger and heavier than the AC motors. Hence the electric motors have high torque and acceleration of an electric vehicle is quicker than the internal combustion engine.

Electric vehicle also has a feature called regenerative breaking using which the vehicle can generate electricity by own kinetic energy that can be stored in super capacitors. Electric vehicles sales are increasing rapidly when we compare the sales data for previous years. That shows that the demand for electric vehicles are higher now days.

B. Available Battery Varieties for EV’s

A cell of a battery consists of an anode and a cathode and all the chemical process happen between those two. Other than the electrodes a battery has separators, terminals, electrolyte and a case (Dhameja, S. and Dhameja, eep, 2000). A battery has one negative terminal and a one positive terminal. The electrolyte can be a gel, solid or liquid according to the battery type and it can be acidic or alkaline (Dhameja, S. and Dhameja,eep, 2000). For an example electrolyte of a lead-acid battery is sulphuric acid and the negative terminal is made by pure lead and the positive terminal is made by lead- dioxide.In late 80’s there were electric vehicles but failed, in early 90’s due to lack of battery technology (Kulkarni. A, Kapoor. A, and Arora. S, 2015). Nevertheless, in 1990s due to climate change governments looked forward to develop electric vehicle.

For example, the U.S. Advanced battery consortium (USABC) was formed to develop electric vehicle batteries (Dhameja, S and Dhameja,eep, 2000). Therefore, the electric vehicle battery technology was developed up to now passing so manystages.

Electric vehicle batteries should have some special properties such as high energy density to travel long range. The battery should give a stable output with different acceleration and it should have a higher C rate. Long life cycle is more important for electric vehicle battery and the maintenance cost also should be low. Besides the battery must be environmental friendly and recycling must be possible (Dhameja, S. and Dhameja,eep, 2000).There are a vast range of EV vehicle battery available on the market. Most of the electric vehicle manufacturers are using Li-ion or Ni-MH batteries for their EV’s. Normally Ni-MH battery is used in electric vehicles as a secondary power source. Ni-MH batteries are safer than the Li-ion battery but Li-ion is preferred as the power source of electric vehicles (Kulkarni. A, Kapoor. A, and Arora. S,2015).

III. BATTERY COOLING SYSTEM

Air-cooling battery thermal management systems can be simply classified according to different air sources, one is an air-cooling system that uses only external air, while the other uses pre- conditioned cabin air for battery cooling systems. Considering different cooling requirements for cabin and battery pack, there is another battery thermal management system, which uses a second evaporator to especially cool battery. The three air cooling systems mentioned above are already used in commercial vehicles.

A. Liquid Cooling Battery Management System

Liquid cooling system is considered to be an effective cooling method, which can control the battery maximum temperature and the temperature difference between battery cells within a reasonable range, and extend the life cycle. Liquid cooling system can be divided into direct contact mode and indirect contact mode according to the battery surface. According to different control solution of the system, it can be divided into active cooling and passive cooling. In the liquid cooling system, the passive cooling has low cooling efficiency and poor control on temperature, and is only suitable for battery packs with low power, At present, domestic and foreign researchers have done a lot of numerical simulation and experimental research on this cooling method, in order to find a high- performance, low-cost liquid cooling method that meet the needs of market.

Heat pipe has a high thermal conductivity, which can make up for the low heat conduction of pure PCM. The coupling of HP and PCM as a BTMS is a new and effective way to improve the BTMS cooling performance more efficiently, which has become a very popular BTMS in recent years. The hybrid PCM-based BTMS can further improve the heat dissipation capability of the PCM The PCM-HP coupled battery thermal management system not only takes advantage of the high thermal conductivity of HP, but also make full use of PCM latent heat. HP can enlarge the operating temperature range of the PCM, and improve the BTMS cooling performance. WU designed a BTMS based on heat pipe assisted phase change material (PCM). It has been found that the maximum temperature can be controlled below50°C, when operating at a 5°C discharge rate, and the temperature fluctuation can still be more stable and lower after the cycle. It is important to reduce the energy consumption and improve the performance of the hybrid BTMS active part. An appropriate type of cooling plate is an effective method to improve the cooling performance. DENG found that the cooling plate was suitable for square and pouch batteries, and can also be used as a jacket for cylindrical batteries. WANG designed and developed a new liquid cooling solution, which based on thermal silica gel plates to overcome the large amount of heat generated by high-capacity batteries under high temperature and rapid charging/discharging conditions. Combining the good thermal conductivity of silica gel plates with excellent cooling of water, resulting in a feasible and effective composite liquid cooling system.

As a result, it was found that when the water flow rate was increased to 4 ml/s, the maximum temperature was lowered to 48.70C, the temperature difference was kept within 50C, and the pump energy consumption only accounts for 1.37% of the total energy. JIAQIANGE proposed a BTMS using rectangular channels and cold plates. Set the circulating liquid passage as a rectangle, which between two cooling plates, and battery is sandwiched between two cooling plates, next group cooling channel is set on the other side of the cooling plate.

B. Thermal Management System PCM-BASED Battery Cooling Management System.

It is one of the types of Phase Change Material based cooling system. Compared with traditional thermal management methods such as air cooling and liquid cooling, the research on applying phase change materials to battery thermal management system started late. However, PCM battery thermal management system has broad application prospects and outstanding comprehensive performance. Many related scholars have made in-depth research on this technology. Initially proposed using phase change materials in battery thermal management system, and found that the temperature in the battery module controlled by PCM is more uniform than that cooled by air at different discharge rates which proved that PCM has effective control over temperature. RAO found that PCM with a melting point below 45°C is more effective in decreasing battery temperature. JAVANI studied the cooling performance of PCM in batteries with various volumetric heat production rates. They found that PCM can decrease the peak temperature and obtained a better performance. However, the low thermal conductivity of phase change materials leads to heat saturation. BTMS based on pure phase change materials cannot operate for a long time in high- power batteries, and cannot effectively control the battery temperature. Many researchers have further improved the performance of PCM. Adding other materials with high thermal conductivity and porous materials in PCM, such as metal foam, expanded graphite, carbon nano tubes, can produce composite energy storage materials with high thermal conductivity. MILL supplied a phase change material (PCM) in passive battery thermal management system for lithium-ion laptop battery pack. With the PCM impregnated expanded graphite (EG), significantly improved the low thermal conductivity of the PCM. Improving the properties of the PCM composites have the potential to significantly reduce the volume of increase in temperature in comparison to the original battery pack volume. WU developed a copper mesh (CM) reinforced paraffin/expanded graphite(PA/EG) composite material for composite PCM battery thermal management system. LV uses expanded graphite, paraffin and low density poly-ethylene to form ternary composites. It has good heat dissipation performance, and effectively dissipates a large amount of heat accumulated by the PCM to external air environment. This shows that combining the PCM with the fins can not only take advantage of the PCM high latent heat value, but also increase the thermal conductivity by fins, ZHAO found that battery surface temperature reached 39°Cafter running the pure paraffin BTMS for 1800 times, and about 25°C for the copper mesh/paraffin BTMS with the same situations. After adding foamed copper, battery surface temperature decreased by 14°C,the temperature was stabilized within a certain range, and there was no temperature difference between battery cells. It indicates that thermal management performance of pure PCM is insufficient. In order to improve the cycle stability and thermal management capability of the PCM- based BTMS, many researchers have coupled other cooling methods with the PCM-based BTMS. Especially in extreme environments, PCM-based hybrid BTMS can effectively reduce temperature rise and temperature difference and maintain battery performance. HÉMERY proposed a cooling system coupled PCM with liquid cooling plate, which can solidify the PCM while the car is charging. FATHABADI coupled air cooling with PCM cooling into a hybrid battery thermal management system. The results showed that the temperature profile a system, the passive cooling has low cooling efficiency and poor control on temperature, and is only suitable for battery packs with low power, At present, domestic and foreign researchers have done a lot of numerical simulation and experimental research on this cooling method, in order to find a high- performance, low-cost liquid cooling method that meet the needs of market. In recent years, exploring cooling plates types, passage geometry, fluid flow distribution, etc. is the research emphasis of liquid cooling systems. Considering the battery structure, exploring parameters of this battery pack are significantly superior to other battery packs. LING proposed a hybrid BTMS that coupled PCM and forced air to dissipate heat for a lithium-ion battery. The results showed that the hybrid BTMS can improve their liability of the PCM-based BTMS without increasing the system complexity, it can avoid excessive heat accumulation, and control the temperature at 50°C in each cycle. At present, improving the thermal conductivity of PCM, improving the cycle stability and thermal management capability is the research emphases of the PCM-based BTMS. The PCM is coupled with other active thermal management systems, and combined them into a hybrid thermal management system, which can improve the cycle stability of the PCM-based BTMS. It is a new and efficient battery thermal management system. In practical applications, more attention should be paid to the PCM packaging. Design details such as leakage, volume change of PCM, and proper quality of PCM based on load should be taken into consideration. The breakthrough of these practical problems is crucial for the PCM-based BTMS future development.

C. Heat PIPE-BASED Cooling Management System

As an efficient heat transfer element, heat pipe is favored by the energy industry due to its high thermal conductivity and low thermal resistance. It is widely used in aerospace, military industry, micro- electronics heat dissipation, building materials, metallurgy, solar energy and other fields. The heat pipe can move a large amount of heat inside the battery pack to keep the battery within the required operating temperature range. The temperature difference inside the battery pack can also be significantly reduced. It can also significantly reduce the temperature difference inside battery cells. The aforementioned PCM-based BTMS has problems, such as difficulty in controlling the volume change during solidification. Single heat pipe for BTMS becomes an effective temperature control method. So far, the types of heat pipes used in large quantities mainly includes pulsating heat pipes, sintering heat pipes, and flat ring heat pipes. The battery releases heat during the charging/discharging, and then transmits it to the heat pipe which is in direct contact with the bottom or side of the battery. Finally, the heat is removed by the heat dissipation system at cold end of heat pipe. When cooled by water with a 25°C inlet temperature and a 1liter/minute (lit/min)flow rate, the system dissipates heat about 50W and keeps temperature below 55°C. GAN proposed a BTMS based on heat pipe with a cylindrical battery module as the research object. It was found that the battery temperature can be significantly reduced by 14 °C in the 50C discharge rate, which compared with a naturally air-cooled BTMS. RAO designed a BTMS equipped with a heat pipe, which is according to the heating characteristics of the power battery. It was found that the maximum temperature can be controlled below 50°C when the heat is less than 50 W. Therefore, the maximum temperature and temperature difference can be kept within the desired range under unstable operating conditions and cyclic test conditions. TRAN compared the thermal performance of the flat-plate heat pipe BTMS with the conventional heat sinks under different conditions(including various cooling conditions and several inclined positions). It was found that using heat pipes can reduce thermal resistance of conventional radiators by 20% in natural convection, and 20% in low wind velocity. The battery temperature can be kept below 50°C. The flat heat pipe has a large flexibility in space, and is suitable for various practical working conditions. In addition, the layout of BTMS will have a great impact on thermal conductivity of the heat pipe. SAHA proposed that embedded heat pipes can delay or prevent thermal runaway due to excessive heat in the battery. WANG placed L-shaped sintered heat pipe between adjacent cells, and battery surface temperature can be controlled below40°Cwhen the battery power is less than 10 W/cell. Heat pipe has a high thermal conductivity, which can make up for the low heat conduction of pure PCM. The coupling of HP and PCM as a BTMS is a New and effective way to improve the BTMS cooling performance more efficiently, which has become a very popular BTMS in recent years. The hybrid PCM-based BTMS can further improve the heat dissipation capability of the PCM The PCM-HP coupled battery thermal management system not only takes advantage of the high thermal conductivity of HP, but also make full use of PCM latent heat. HP can enlarge the operating temperature range of the PCM, and improve the BTMS cooling performance. WU designed a BTMS based on heat pipe assisted phase change material (PCM). It has been found that the maximum temperature can be controlled below50°C, when operating at a 5°C discharge rate, and the temperature fluctuation can still be more stable and lower after the cycle.

It is important to reduce the energy consumption and improve the performance of the hybrid BTMS active part.

IV. RESULTS AND DISCUSSION

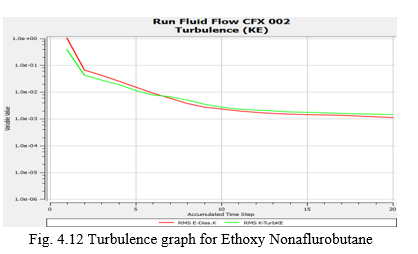

The Results of the CFD Analysis of a single battery in a container (fluid flow surface)for all three fluids were compared with various aspects. Single battery is used here for analyzing convenience.

???????

???????

Conclusion

This project work has provided us an excellent opportunity and experience, to use our limited knowledge. We gained a lot of knowledge about electric cars, its working techniques, charging methods and cooling systems. We had used Ethylene Glycol, Fluorinert FC72 and Ethoxy Nonaflurobutane fluids for analysing. We used ANSYS FLUENT for the analysis. Finally the Ethoxy Nonaflurobutane, an Engineering Fluid had shown enormous result compared to the other fluids. It had a greater heat conduction when compared to other fluids. So it is concluded that the ETHOXY NONA FLURO BUTANE as the best coolant fluid.

References

[1] X. Na, H. Kang, T. Wang, et al., Reverse layered airflow for Li-ion battery thermal management, Appl. Therm. Eng. 143 (2018) 257–262. [2] X. Li, F. He, G. Zhang, et al., Experiment and simulation for pouch battery with silica cooling plates and copper mesh based air cooling thermal management system [J], Appl. Therm. Eng. 146 (2019) 866–880. [3] L.H. Saw, Y. Yes, A.A.O. Tay, et al., Computational fluid dynamic and thermal analysis of Lithium-ion battery pack with air cooling, Appl. Energy 177 (2016)783–792. [4] R.Mahamud, C. Park, Reciprocating airflow for Li- ion battery thermal management to improve temperature uniformity, J. Power Sources 196 (2011)5685–5696. [5] E.Jiaqiang, M. Yue, J. Chen, et al., Effects of the different air cooling strategies on M. Lu, et al. Journal of Energy Storage 27 (2020) 10115514 [6] S. Hong, X. Zhang, K. Chen, et al., Design of low configuration for parallel air-cooled battery thermal management system with secondary vent, Heat Mass Transf. 116 (2018) 1204–1212. [7] K. Chen, S. Wang, M. Song, et al., Configuration optimization of battery pack in parallel air-cooled battery thermal management system using an optimization strategy, Appl. Therm. Eng. 123 (2017) 177–186. [8] K. Chen, M. Song, W. Wei, et al., Design of the structure of battery pack in parallel air-cooled battery thermal management system for cooling efficiency improvement, Int. J. Heat Mass Transf. 132 (2019) 309–321. [9] T. Wang, K.J. Tseng, J. Zhao, et al., Thermal investigation of lithium-ion battery module with different cell arrangement structures and forced air- coolingstrategies,Appl.Energy134(2014)229–238. [10]Y. Fan, Y. Bao, C. Ling, et al., Experimental study on the thermal management performance of air cooling for high energy density cylindrical lithium- ionbatteries,Appl.Therm.Eng.155(2019)96–109. [10] Parush Bamrah, Manish kumar Chauhan and Basant Singh Sikarwar., conference series,volume2178,international symposium on fluid and thermal engineering Uttar Pradesh , India

Copyright

Copyright © 2022 R Ragavendiran, P. Amirthalinagm . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET41601

Publish Date : 2022-04-19

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online