Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and Construction of Hazardous Gas Detection and Control System for Electric Vehicle Cabin

Authors: Sonali Adhav, D. B. Salunke

DOI Link: https://doi.org/10.22214/ijraset.2023.54122

Certificate: View Certificate

Abstract

Electric vehicles (EVs) are a promising technology for achieving a sustainable transport sector due to their very low to zero carbon emissions, low noise, high efficiency, and flexibility in grid operation and integration. This chapter includes an overview of electric vehicle technologies as well as associated energy storage systems. Different types of electric-drive vehicles are presented. Also, if hazardous gas is detected inside of the cabin such as CO2 gas as a result of occupants of the vehicle, the system will open windows of the vehicle automatically. The advantage of this system is proper detection and faster response time leading to faster diffusion of the situation, compared with the manual methods. The gas sensor used in this project is MQ-7 and MQ-135 which detects the presence of hazardous gases both inside and outside of the vehicle cabin. These sensors will detect the concentration of the gas according to the voltage output of the sensor. To make the sensors operate in the control and data monitoring system, Arduino Uno was used as the microcontroller for the whole system. The circuit also includes Servo motor, buzzer, exhaust fan and LCD screen.

Introduction

I. INTRODUCTION

Electric vehicles (EVs) have played a significant role in reducing greenhouse gas emissions into the environment. It is not surprising that air quality in vehicle cabins found to be worse than that typically found in homes or workplaces, especially when so many exhaust pipes are only few centimeters away from adjacent vehicles. The quality of air in Ghana’s capital, Accra, remains a great concern. Hospitals in the cities are full of patients battling with cardiovascular, asthma and cancer ailments, due to pollutions in the form of nitrogen dioxide and hydrocarbons. Independent studies have shown that vehicle cabins commonly show concentrations of toxic gases such as carbon monoxide (CO), hydrocarbons (HC), volatile organic compounds (VOC), and oxides of nitrogen (NOx) higher than the threshold limits set by World Health Organization (WHO). Oxygen gas (O2) deficient environment has termed as “hazardous” by (WHO) when the O2 concentration is less than 19.5%. Low O2 levels can impair sense

of judgment, increases heart rate, and impair muscular coordination [2]. As experienced by most people, discomfort due to offensive smells is the prime concern regarding pollutants in vehicle cabins. However, more serious concerns are the adverse health effects that result. The most dangerous is the effect of fatigue. Driver fatigue is a primary concern in the efforts to decrease road fatalities. Fatigue is often associated with feeling of drowsiness or sleepiness, loss of alertness, inability to concentrate, and slowed reactions. Aside from lack of sleep, fatigue symptoms caused from vehicle exhaust pollutants such as CO, NOx, and HC’s causing headaches, nausea, and dizziness which induces poor hand-eye coordination that may increase the likelihood of an accident [3]. Further, in a confined environment, our natural breathing process can be impaired and aggravate the health hazard. While breathing, the occupants of the vehicle exhaled CO2, which can displace O2 in an indoor environment such as a vehicle cabin, and thus renders the environment with O2 deficiency. Such high CO2 and low O2 concentrations can cause adverse human health effects. For example, this situation geta amplified when vehicle occupants choose to operate the Air Condition system in the “closed/recycle” mode to prevent outdoor-polluted air from entering. To overcome these types of problems there is a need to monitor different pollutant gases and the oxygen level that ensures complete vehicle occupant comfort and safety.

A. Problem Statement

- Pollutant gases entering the vehicle cabin through the ventilation system.

- Lack of fresh airflow which results in low O2 and high CO2 concentrations due to occupant breathing process through the passages when the ventilation system is closed.

- Gaseous Pollutants entering the cabin from the external environment through window openings, imperfect seals, and other passages. In this project work, key features that addressed concerns of poor air quality in vehicle cabin will be implemented.

B. Objective

- To design and construct a system for toxic gases detection inside and outside the electric vehicle cabin.

- To develop a sensing system using a sensor array.

- To close windows and turn air condition of the vehicle on automatically.

- To open windows and turn off the air condition system of the vehicle automatically for fresh air to enter

C. Scope of the Study

Automatic sensor sensitivity control via software implemented on microcontroller to continuously detect pollution levels, Automatic operation of a ventilator or air conditioner in the vehicle to keep air quality standard Automatic opening and closing of air inlet or windows due to high concentration of hazardous gases in and outside the electric vehicle.

II. LITERATURE SURVEY

The main aim of this research work is to detect the vehicle exhaust pollutants such as CO, NOx, and HC’s and CO2 in and outside of the vehicle cabin in order to design and construct an intelligent air quality monitoring and controlling system. At the heart of the Arduino, are the gas sensors and the microcontroller. Here, a review of various works related to sensing technologies for various applications presented in the following section. There are numerous ways to sense gases in a vehicle cabin. Gas sensor and its propagation in the sensor system is modelled and experimentally validated. It is shown that even with the simple set-up of the system the infrared radiation can be used to detect indoor relevant CO2 concentrations in the range of 1000 ppm with the IR system part. They reported that corresponding to the design and operation of the metal oxide gas sensor it detects explosive or toxic gas concentrations or volatile organic compounds in indoor applications.

P. Fau et al., (2001),[6] proposed nanosized tin oxide sensitive layer on a silicon platform for domestic gas applications. Micromachined silicon platforms have been specially created and are coated with a drop of tin oxide sensitive layer by a novel drop deposition technique. Tin dioxide powder, prepared by laser ablation, in suspension with water is dropped between electrical paths onto an alumina substrate.

They reported that the sensors are extremely sensitive to carbon monoxide and methane and are very stable to baseline resistance and gas sensitivity over time.

J. Gerblinger et al., (1994), [7] studied on cross sensitivity of various doped Strontium Titanate films to detect CO, CO2, H2, H2O and CH4 in high temperature oxygen sensor. The cross-sensitivity investigations are conducted in the temperature range of 4000 - 11000C and reported that the reactive gases such as CO and CO2 have only a reducing effect when present in concentrations of 1% in oxygen containing gas mixtures and remaining being N2. The H2, H2O, and CH4 shown reducing effect instead of oxidizing effect. They reported that the Strontium Titanate films are cross sensitive to above gases limited range and then the results are compared. They reported that the response time at the optimal working temperature of 420 °C is sufficiently low to predict good applicability of these sensors as CO detectors.

G. W. Hunter et al., (1998),[9] proposed the use of micro fabricated chemical sensors for safety and emission control applications. Conditions that include operation in harsh environments, high sensitivity, minimal size and weight, and power consumption cannot be addressed by commercial sensors. They reported that the micro fabrication is being used to fabricate miniaturized sensors to measure hydrogen, hydrocarbons, etc., to overcome these drawbacks.

H.S. Hong et al., (2006),[10] studied the filter layers to suppress cross-sensitivity of NO and SO2 in electrochemical (SnO2) CO2 sensors. The solid-state galvanic cell of Na2CO3-SnO2, Na2CO3-SnO2-Cu, Na2CO3-SnO2 -CuO is adopted as filter material adjacent to the sensing electrodes which were investigated at 673K and 773K. They reported that CuO added filters brought not only enhanced NO filtering but also SO2filtering ability in a limited range in the detection of CO2.

III. METHODOLOGY

The project is divided into two parts which includes hardware and software. for the software implementation, it involves writing code and programming the arduino. meanwhile, hardware implementation involves designing the circuit of the project and pcb development. after the completion of both parts, the next was the testing and debugging process.

The block diagram is about the connection of the gas detector implementation. In this project, output voltage from the gas sensor

will be delivered to the Arduino board. The heart of the system is the Arduino. All the inputs and the outputs will be connected to the Arduino. When the gas sensor MQ7 or MQ135 detect the presence of gas, it will send analogue signal to an analog digital converter (ADC) inside the Arduino. An Arduino will process this signal and analyze it the signal according to the threshold value of gas concentration. The gas concentration value will determine which action should be taken by the system. If external gases such as carbon Monoxide and others are detected, the system shall trigger the buzzer to warn the users of gas concentration in the dangerous level and then close windows and turn on air condition automatically. If internal gas such as CO2 is detected, the system shall open windows automatically for fresh air to enter the vehicle cabin. A Vehicle Air Quality Monitor System using gas sensors for improved safety.” In this project work, carbon monoxide (CO) and oxygen (O2) gas sensors was used for the design of the Vehicle air quality monitoring system. The system designed for continuous monitoring of oxygen and carbon monoxide gases. It has alarms feature that could be set off when dangerous gas concentrations are reached, preventing driver fatigue and drowsiness.

IV. HARDWARE IMPLEMENTATION

In the vehicle cabin air quality monitoring system of gas detector, there are a few parts of hardware involved. This section will discuss on the design and function of each component that are connected to the Arduino to build the project. It also explains how the circuitry connection between the components and microcontroller is made. This includes the sensor circuit and the output circuit which comprises of LCD, servo motor, fan and a buzzer.

A. Carbon Monoxide Sensor - MQ-7

Resistance value of MQ-7 is difference to various kinds and various concentration gases. So, when using these components, sensitivity adjustment is very necessary. we recommend that you calibrate the detector for 200ppm CO in air and use value of Load resistance that (RL) about 10 KΩ (5KΩ to 47 KΩ). When accurately measuring, the proper alarm point for the gas detector should be determined after considering the temperature and humidity influence.

The sensitivity adjusting program:

- Connect the sensor to the application circuit.

- Turn on the power, keep preheating through electricity over 48 hours.

- Adjust the load resistance RL until you get a signal value which is respond to a certain carbon monoxide concentration at the end point of 90 seconds.

- Adjust another load resistance RL until you get a signal value which is respond to a CO concentration at the end point of 60 seconds.

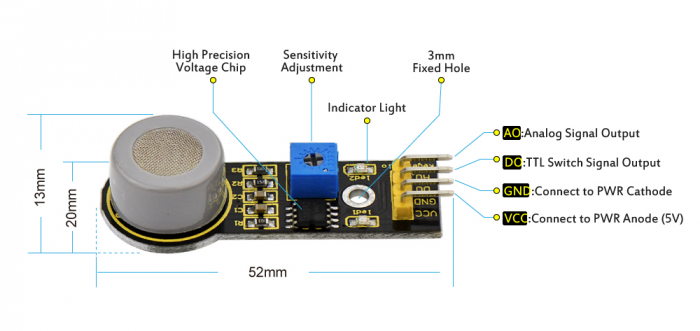

Fig 3. MQ-135 Air Quality Gas Sensor

Fig 4. MQ-135

Sensitive material of MQ135 gas sensor is SnO2, which with lower conductivity in clean air. When target pollution gas exists, the sensor’s conductivity gets higher along with the gas concentration rising. Users can convert the change of conductivity to correspond output signal of gas concentration through a simple circuit.

MQ135 gas sensor has high sensitivity to ammonia gas, sulfide, benzene series steam, also can monitor smoke and other toxic gases well. It can detect kinds of toxic gases and is a kind of low-cost sensor for kinds of applications.

B. DHT11 Temperature Sensor

Once DHT detects the start signal, it will send out a low-voltage-level response signal, which lasts 80us. Then the programmer of DHT sets Data Single-bus voltage level from low to high and keeps it for 80us for DHT’s preparation for sending data. When DATA Single-Bus is at the low voltage level, this means that DHT is sending the response signal. Once DHT sent out the response signal, it pulls up voltage and keeps it for 80us and prepares for data transmission. When DHT is sending data to MCU, every bit of data begins with the 50us low-voltage-level, and the length of the following high-voltage-level signal determines whether data bit is "0" or "1"

C. Arduino Uno R3

The Arduino UNO R3 is one of the most important tools used in this project. It was tool used to test and program our ATmega328P. It’s hardware consists of an open- source hardware board designed around an 8-bit or 32- bit Atmel AVR microcontroller. It requires an integrated development environment (IDE) to program the chip. See picture below.

D. Servomotor SG90

Tiny and lightweight with high output power. Servo can rotate approximately 180 degrees (90 in each direction) and works just like the standard kinds but smaller. You can use any servo code, hardware, or library to control these servos. Good for beginners who want to make stuff move without building a motor controller with feedback & gear box, especially since it will fit in small places. It comes with 3 horns (arms) and hardware. Servo motors have three wires: power, ground, and signal. The power wire is typically red and should be connected to the 5V pin on the Arduino board. The ground wire is typically black or brown and should be connected to a ground pin on the Arduino board. The signal pin is typically yellow, orange or white and should be connected to pin 9 on the Arduino board [19].

E. LM7805 Voltage Regulator

LM 7805 is a series of 78XX voltage regulators. It is a standard; from the name, the last two digits 05 denote the amount of voltage that it regulates. Hence a 7805 would regulate 5v and 7806 would regulate 6V and so on. It comes with the provision to add heat-sink. The maximum value for input to the voltage regulator is 35V DC. It can provide a constant steady voltage flow of 5V DC for higher voltage input till the threshold limit which is 35V DC. For voltages close to 7.5V DC, the LM7805 does not produce any heat but from input voltages higher than 9V DC, the excess electricity is liberated as heat [21].

The LM7805, like most other regulators, is a three-pin IC used as a voltage regulator. Below is the description of the pins of the voltage regulator:

Pin 1 (Input Pin): The Input pin is the pin that accepts the incoming DC voltage, which the voltage regulator will eventually regulate down to 5 volts.

Pin 2 (Ground): Ground pin establishes the ground for the regulator.

Pin 3 (Output Pin): The Output pin is the regulated 5 volts DC.

F. Liquid Crystal Display (LCD)

The LCD display used is a 2x16 character display unit. The following pins of the display unit are used to establish a parallel connection with the microcontroller.

- A register select (RS) pin: it controls the LCD’s memory locations where data written is to.

- A read/write (R/W) pin. This pin is used to select either a reading mode or a writing mode. Reading mode is when data is read from the registers of the LCD and writing mode is when data is writing to the registers.

- An Enable pin (E): it enables writing to the registers.

- 8 data pins (D0 – D7): The states of these pins (high or low) are the bits that are written to a register when in a write mode, or the values read, when in a read mode.

- A display contrast pin (Vo): It is used to control the display contrast through a potentiometer.

- Power supply pins (+5 v and Gnd): Used to power the LCD.

- LED Backlight pins: Used to turn on and off the LED backlight.

The LCD is controlled in a 4-bit mode where only seven I/O pins from the microcontroller is used. The following configuration is used for the connection.

a. LCD RS pin connected to digital pin 12.

b. LCD Enable pin connected to digital pin 11.

c. LCD D4 pin connected to digital pin 5.

d. LCD D5 pin connected to digital pin 4.

e. LCD D6 pin connected to digital pin 3.

f. LCD D7 pin connected to digital pin 2.

G. Buzzer

This is a piezo buzzer that has built in circuitry that produces the audible buzzer tone.It can operate from a voltage between 3 to 28V and draws only 4mA of current at 12V. When the current drawn by the buzzer was measured at 5V, it was found that it only drew about 1.1mA which is well within the drive capability of an Arduino Uno pin.

- RW Series Relay covers switching capacity by 10A is spite of miniature size to comply with user’s wide selection.

- RWH is approved C-UL & TÜV safety standard.

- The employment of suitable plastic materials is applied under high temperature condition and various chemical solutions.

- Complete protective construction is designed form dust and soldering flux. If required, plastic sealed type is available for washing procedure.

- 12A at 120VAC for RW & 12A at 240VAC for RWH are UL approved.

I. ESP8266

ESP8266EX offers a complete and self-contained Wi-Fi networking solution; it can be used to host the application or to offload Wi-Fi networking functions from another application processor. When ESP8266EX hosts the application, it boots up directly from an external flash. In has integrated cache to improve the performance of the system in such applications. Alternately, serving as a Wi-Fi adapter, wireless internet access can be added to any micro controllerbased design with simple connectivity (SPI/SDIO or I2C/UART interface). ESP8266EX is among the most integrated Wi-Fi chip in the industry; it integrates the antenna switches, RF balun, power amplifier, low noise receive amplifier, filters, power management modules, it requires minimal external circuitry, and the entire solution, including front-end module, is designed to occupy minimal PCB area.

J. Li-Ion Rechargeable Battery Roofer 2500 mAh

Output Voltage Range: 11.1v - 12.6 by test conditions (e.g., temperature, wire loss, test equipment, test parameters, etc.), please perform multiple tests and take the average of the results to reduce the deviation. At a temperature of 25 ° C, the deviation between the pure resistance discharge test result and the nominal data is controlled within ±10%, which is normal. Charging - Charge mode: CC CV - Use a S Lithium-ion battery dedicated charger to charge up to 8.4v - Charge current 2A max Discharge - Continuous discharge current 5A - Instantaneous discharge current 7A.

V. PCB DEVELOPMENT

For the PCB development, donut board is used in this project. Before soldering all the components on the board, bread board was first used to ensure that the connection between each component is functional for this project. Donut board does not have connection to each hole like the strip board. In order to make the connection, solder method is used to connect all components.

A. Software Details

This section will specifically discuss the methodology to interface the sensor and hardware module. The most important part is to enable the analog sensor to send analog data to Arduino so that hazardous detected gases can be control by the system automatically.

B. Arduino Programming

Arduino programming is the heart of this project. This is because, all the data from sensor, LCD, Arduino controls servo motor, fan and Buzzer of the system. The entire process includes in the gas sensor MQ 7 for detecting the LPG concentration level.

C. Code

void trigger_buzzer(int duration);

void external_detect_gas();

void close_windows();

void open_windows();

void on_air_con();

void off_air_con();

void internal_detect_gas();

#include <Servo.h>

Servo myservo; // create servo object to control a servo int pos = 0; // variable to store the servo position

#include <LiquidCrystal.h>

// initialize the library with the numbers of the interface pins

LiquidCrystal lcd(12, 11, 5, 4, 3, 2); int buzzer=8;

int servor_motor=10;

int air_con=9;// dc motor

int external_gas_level=0;

int external_minimum_accepted=310;

int external_maximum=980;

int internal_gas_level=0;

int internal_minimum_accepted=310;

int internal_maximum=980;

void setup()

{

lcd.begin(16, 2);// set up the LCD's number of columns and rows:

lcd.clear(); lcd.print("Loading...");

pinMode(buzzer, OUTPUT);

//pinMode(servor_motor,OUTPUT);//servor motor-- close/open windows

pinMode(air_con, OUTPUT);// pinMode(A0, INPUT);// internal pinMode(A2, INPUT);// external

digitalWrite(buzzer,LOW);

digitalWrite(air_con,LOW);

//digitalWrite(servor_motor,LOW);

delay(2000);

lcd.clear();

lcd.print("System ready");

myservo.attach(10);

delay(3000);

lcd.clear();

}

void loop()

{

lcd.clear(); lcd.print("Internal: ");

lcd.print(analogRead(A0));

lcd.setCursor(0,1);

lcd.print("External: ");

lcd.print(analogRead(A2));

delay(150);

external_detect_gas();

internal_detect_gas();

}

void trigger_buzzer(int duration)

{

int the_duration= duration *1000;

digitalWrite(buzzer, HIGH);

delay(the_duration);

digitalWrite(buzzer, LOW);

}

//********************************************

********************** void external_detect_gas()

{

external_gas_level=analogRead(A0);

if(external_gas_level < external_minimum_accepted )

{

}

else if (external_gas_level > external_maximum )

{

trigger_buzzer(5);

close_windows();

on_air_con();

lcd.clear();

lcd.print("Int:hazarduous");

lcd.setCursor(0,1);

lcd.print("gas detected !!!");

delay(3000);

}

}

//********************************************

********************* void internal_detect_gas()

{

internal_gas_level=analogRead(A2);

if(internal_gas_level < internal_minimum_accepted )

{

}

else if (internal_gas_level > internal_maximum )

{

trigger_buzzer(5);

open_windows();

off_air_con();

lcd.clear();

lcd.print("Ext: hazarduous");

lcd.setCursor(0,1);

lcd.print(" gas detected !!!");

delay(3000);

}

}

void close_windows()

{

for(pos = 0; pos < 180; pos += 1) // goes from 0 degrees to 180 degrees

{ // in steps of 1 degree myservo.write(pos);

// tell servo to go to

position in variable 'pos'

delay(15); // waits 15ms for the servo to reach the position

reach the position

}

VI. RESULTS AND ANALYSIS

Show the output result of the project design of air quality monitoring and control system. Green LED is turned on because of power supply through the system and the LCD displays the activities of the system. The servo motor demonstrates the closing and opening of the vehicle windows or air inlet and the Dc motor serves as the ventilation or air conditioning system in the cabin.

VII. PROJECT DISCUSSION

Project done is based on the objectives started before which is analyzing a sensor circuit for the gas sensor. This sensor node will detect the level of concentration of the gas exposed and convert it into analog voltage and directly sending it into Arduino. After transferring the data, Arduino will read the data into the digital format. Arduino processes analog to digital converter (ADC) from 0 to 1024 which are in 10 bits. Voltage output from the gas sensor (0-5) V will be read as (0-1024) decimal output in Arduino. Furthermore, this system will trigger an alarm as a result of concentration of hazardous gases. If CO gas and other external gases from the vehicle cabin is detected, the system will close windows of the vehicle and turn on the ventilation automatically. Also, if the system detects gas in the cabin such as  , windows of the vehicle will be open automatically to allow fresh air in the vehicle. Al activity of the system is displayed on the LCD.

, windows of the vehicle will be open automatically to allow fresh air in the vehicle. Al activity of the system is displayed on the LCD.

VIII. RECOMMENDATION

For further improvement, the research can add some features that will enables user to easily get the information about the air quality in their vehicle cabin by monitoring the wirelessly. In addition, this system was able to monitor and control air condition for various implementations with some system alterations.

The toxic gas release alarm system safety features can also be improved by adding another function to check the sensor’s condition in case the sensor is not working properly or if the sensor’s calibration has been displaced. A power saving features, and power supply back-up would also be an essential addition to the system in case the main power supply is down. The alarm system can also be hooked up to a timer and a phone that dials directly to the owner and the authorities if the dangerous CO concentration levels are detected continuously for more than one or two hours.

Conclusion

As a conclusion, reading of the output voltage from the gas sensor shows the value of concentration and level of dangerousness in LCD. Control system that reacts with the servo motor as the window control or air inlet of the vehicle, the dc motor controlling the fan as air condition of the cabin and the alarm system has been design based on the indicator for user. This system is built to help user to feel comfortable and safe when using road transport and it is easy to monitor the range of air quality in the environment of the vehicle cabin from their own figure via LCD, servo motor, dc motor and buzzer. This system device also gives an advantage to the user to easily help reduce road fatal accident as a result of driver fatigue.

References

[1] Incorporated, C. T., Technologies, C., & Technologies, C. (2021). Cytron USB to UART Converter User ? s Manual, (June), 1-23. [2] Dissanayake, S. D., Karunasekara, P. P. C. R., Lakmanaarachchi, D. D., Rathnayaka, a J. D., &Samarasinghe, a T. L. K. (2020). Zigbee Wireless Vehicular Identification and Authentication System. 2008 4th International Conference on Information and Automation for Sustainability, 257-260. [3] F. He, Z. Du, and Y. Sun, “Indoor Dangerous Gas Environment Detected by Mobile Robot,” [4] J. Anderson, Transport Ministers Attack Driver Fatigue. Media Release—Australian Commonwealth [5] Somov, A., Baranov, A., Savkin, A., Spirjakin, D., Spirjakin, A., & Passerone, R. Development of wireless sensor network for combustible gas monitoring.Sensors & Actuators: A. Physical, 1-8. [6] Datasheet MQ-7 Semiconductor Sensor for LPG 1- 2. [7] Datasheet MQ-135 Semiconductor Sensor, 2-3. [8] Datasheet DHT11 Sensor. [9] Datasheet ESP8266NodeMCU. [10] Datasheet SG90 Servomotor.

Copyright

Copyright © 2023 Sonali Adhav, D. B. Salunke. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET54122

Publish Date : 2023-06-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online