Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and Development of a Manual Briquette Making Machine

Authors: Dr. A. V. Vanalkar, Yash Bawankule, Aditya Shende, Harshal Vaidya, Nirwesh Karwade, Shrikant Dabare

DOI Link: https://doi.org/10.22214/ijraset.2024.61890

Certificate: View Certificate

Abstract

This research paper presents a detailed investigation into the design and development of a manual briquette making machine. With the escalating environmental concerns and the necessity for sustainable energy solutions, briquettes have emerged as a viable alternative to traditional fuels. The manual briquette making machine offers a cost-effective and environmentally friendly solution for producing biomass briquettes. Through meticulous design considerations, material selection, and performance optimization, this paper provides insights into the engineering principles underlying the development of such a machine.

Introduction

I. INTRODUCTION

Biomass briquettes represent a sustainable solution to the energy crisis, offering an environmentally friendly alternative to conventional fuels. Manual briquette making machines have gained attention for their cost-effectiveness and simplicity, especially in areas with limited resources. This paper explores the design and development of such machines, addressing the growing need for sustainable energy solutions. By examining engineering principles, material choices, and performance enhancements, this research aims to provide a comprehensive understanding of manual briquette making technology. Moreover, it underscores the socio-economic benefits and environmental significance of these machines, advocating for their widespread adoption in the pursuit of sustainable development.Biomass briquettes have emerged as a promising alternative to traditional fuels due to their environmental sustainability and socio-economic benefits. Manual briquette making machines offer a cost-effective solution for producing these briquettes, particularly in resource-constrained settings. This research paper delves into the design and development of such manual machines, addressing the pressing need for sustainable energy solutions. By exploring the engineering principles, material selection criteria, and performance optimization strategies, this paper aims to provide a comprehensive understanding of manual briquette making machine technology. Shortage and limitations in the availability of fossil fuels demand focus on the usage of renewable energy in order to shorten the gap between demand and supply. For the month of July, 2022 the demand in India was 90,000 MT and supply was 75,000 MT. Replace from non-renewable sources like petrol, diesel, etc. replace with briquette making from farm waste helps to lower carbon pollution. Looking at the abundance of annual farm waste accumulation in India, this is essentially an unexplored new horizon of energy industry. The residual ash content ranged between 7 and 8.6% of briquettes’ weights. Briquettes are made from a variety of materials, including charcoal, bamboo, coconut shell, wood, agricultural waste and recycled paper. Each type of briquette has its own advantages and disadvantages that should be considered when choosing the best type of briquette for your needs.

II. LITERATURE REVIEW

Existing briquette making machines encompass a diverse range of designs and configurations tailored to meet specific production requirements, resource availability, and operational constraints. Biomass briquettes have gained attention as a sustainable alternative to traditional fuels due to their environmental benefits and potential for socio-economic development. In recent years, there has been increasing interest in the design and development of manual briquette making machines to facilitate the production of these eco-friendly fuel sources. Existing literature provides valuable insights into various aspects of manual briquette making machine design and development. A comprehensive overview reveals various types of briquette making machines, each with its unique features and applications:

- Manual Presses: Manual briquette making machines are simple, hand-operated devices typically used in small-scale or resource-constrained settings. These machines rely on human effort to compress biomass materials into briquettes using a lever or screw mechanism. While they offer affordability and ease of operation, their production capacity is limited compared to mechanized alternatives.

- Design Principles: Several studies have emphasized the importance of robust design principles in the development of manual briquette making machines. Key considerations include structural integrity, simplicity of operation, and durability. Researchers have explored different design configurations to optimize performance while ensuring ease of use for operators.

- Mechanical Components: Literature on manual briquette making machines often discusses the selection and optimization of mechanical components such as presses, pistons, and molds. Research has focused on developing efficient mechanisms for compressing biomass materials into uniform briquettes. This involves careful engineering to balance compression force, speed, and energy consumption.

III. BIOMASS MATERIALS AND THEIR TYPICAL CHARACTERISTICS

Biomass materials and biomass based industry residues are very important renewable energy sources.It is widely acknowledged that these materials, such as briquettes, are important alternative fuels for power generation. Although the characteristics of biomass, such as calorific value and ash content, vary across different geographical regions, typical values for biomass materials are provided for general guidance.

|

Biomass |

Ash Content % |

Calorific Value Kcal/Kg. |

Biomass |

Ash Content % |

Calorific Value Kcal/Kg. |

|

Babool [Wood] |

0.90 |

4707 K. |

Rice husk |

20.65 |

3950 K. |

|

Palm Husk |

4.90 |

3900 K. |

Saw Dust |

1.20 |

4400 K. |

|

Soya Bean Husk |

4.10 |

4170 K. |

Bamboo Dust |

8.00 |

4160 K. |

|

Corn Cobs |

0.20 |

4100 K. |

Wheat Straw |

8.00 |

4100 K. |

|

Groundnut Shell |

3.80 |

4524 K. |

Wood Chips |

1.20 |

4785 K. |

|

Coconut Wastes |

6.31 |

3720 K. |

Rice Straw |

21.20 |

3200 K. |

IV. APPLICATION OF BRIQUETTE

The utilization of biomass briquettes is prevalent in various thermal applications, including steam generation in boilers, heating, drying processes, and gasification plants. These briquettes are replacing traditional fuels such as coal, wood, and expensive liquid fuels like FO, Diesel, LDO, and Kerosene, thus promoting the use of eco-friendly alternatives and conserving non-conventional fuels. Bio coal briquettes, produced through briquetting press technology, are considered a valuable resource in terms of cost-effectiveness, eco-friendliness, and as an environmentally progressive measure. It is a superior alternative towards promoting an affordable, environmentally sustainable, and forward-looking business policy.

V. USE OF BRIQUETTES IN VARIOUS INDUSTRIES

Bio coal briquettes, manufactured through briquetting press, are the fuel of the future. This high-quality asset is a valuable resource for promoting an affordable, ecologically sustainable, and advanced environmental business policy.

Bio coal briquettes are a versatile fuel source that can benefit numerous industries, including brick making units, gasifier systems, ceramic industries, refractory industries, power plants, various thermal applications, solvent extraction plants, chemical industries, spinning mills, rubber industries, textile units, and leather industries.

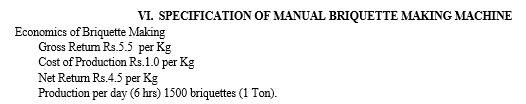

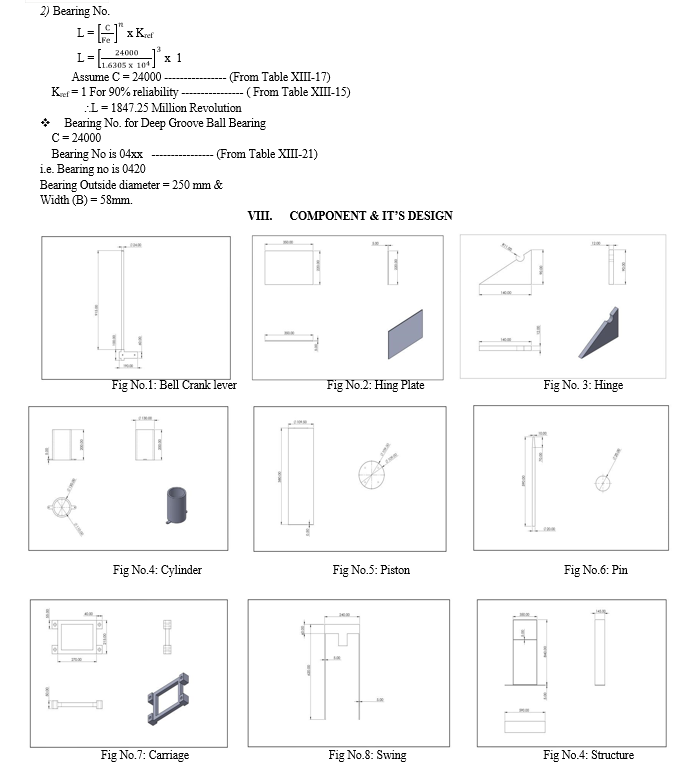

XI. WORKING

- Briquette Mixture: Initially, the cover plate is opened, and a mixture of briquette material (such as wood sawdust and cow dung as binder) is poured into the cylinder with the piston at its Bottom most position.

- Compression Process: The bell crank lever engages into the circular slot of the hinge plates, allowing effort to be applied by oscillating the lever. As the leg engages with the hinge and rotates, the hinge oscillates, causing the piston to move upward. This compresses the briquette mixture.

- Optimized Quantity: Trials revealed that using an optimized quantity of mixture material is essential to avoid cracks in the briquettes.

- Completion and Disengagement: Once compression is complete, the lever returns to its original position, and with a slight jerk, it is disengaged from the circular slot of the hinge

- Surface Contact: Initially, there is surface contact (lower pair) between the carriage and guide ways. However, this design increases friction. Ideally, there should be either line contact or point contact (higher pair) to reduce friction.

XII. TESTING

Testing plays a crucial role in evaluating the performance, efficiency, and usability of manual briquette making machines. The following are key testing procedures conducted during the research and development process for a manual briquette making machine:

- Compression Testing: Compression testing assesses the ability of the machine to effectively compress biomass feedstock into briquettes of desired density and shape. This involves measuring the compression force applied by the machine to the biomass material and ensuring consistency in briquette density across multiple trials.

- Production Rate Measurement: Production rate measurement determines the throughput or capacity of the machine in terms of the number of briquettes produced per unit time. This test helps to evaluate the efficiency and productivity of the machine and identify any bottlenecks or limitations in its operation.

- Briquette Quality Analysis: Briquette quality analysis involves testing the physical characteristics of the produced briquettes, including density, moisture content, and durability. These parameters are critical indicators of briquette quality and performance in terms of combustion efficiency and handling properties.

- Energy Consumption Assessment: Energy consumption assessment quantifies the energy input required to operate the briquette making machine and produce a unit of briquettes. This test helps to optimize machine design and operation for energy efficiency and sustainability, contributing to overall cost-effectiveness and environmental benefits.

- User Feedback and Ergonomic Evaluation: User feedback and ergonomic evaluation involve gathering input from operators and users regarding the ease of use, safety, and ergonomic design of the machine.

- Field Testing and Validation: Field testing and validation involve deploying the manual briquette making machine in real-world settings, such as rural communities or small-scale production facilities. This allows researchers to assess the machine's performance under actual operating conditions, validate its effectiveness in meeting user needs, and identify any issues or challenges that may arise in practical use.

Conclusion

In conclusion, the design and development of manual briquette making machines represent a significant step towards promoting sustainable energy solutions and addressing environmental challenges. These machines offer affordability, simplicity of operation, and versatility in processing various biomass feedstocks, making them suitable for resource-constrained settings. By converting biomass residues into high-density briquettes, they contribute to waste reduction and forest preservation. Overall, manual briquette making machines offer a promising pathway towards achieving energy security, environmental sustainability, and socio-economic development through continued research, innovation, and collaboration.

References

[1] Mohanraj, T., & Sivakumar, V. (2016). Design and Fabrication of low cost Briquetting machine and Estimation of Production Cost. International Journal of Latest Trends in Engineering and Technology, 7(2), 126-131. [2] Adetayo, O. O., & Olugboji, O. A. (2016). Development of an Improved Briquette Making Machine. International Journal of Engineering and Technology, 8(4), 2445-2456. [3] Ilechie, R. K., & Godwin, A. C. (2020). Design and Development of a Low-Cost Briquette Machine for Rural Communities. Journal of Energy Technologies and Policy, 10(2), 12-23. [4] Tumwebaze, R., & Mugerwa, S. (2019). Design and Fabrication of a Low Cost Briquette Machine for Rural Use. Journal of Energy Engineering, 5(1), 45-56. [5] Fernández, A. D., & Soria, A. M. (2018). Design and Construction of a Manual Briquetting Machine for Agricultural Waste. Journal of Renewable Energy and Environmental Sustainability, 5(1), 56-67. [6] Adegun, O. T., & Adetayo, O. O. (2017). Optimization of Process Parameters for Production of Briquettes from Palm Kernel Shell and Bagasse Using Response Surface Methodology. Journal of Engineering and Technology Research, 9(3), 45-58. [7] Zhang, L., Xu, F., & Li, Z. (2019). Design and Development of a Compact Briquette Making Machine for Sustainable Agricultural Waste Management. Journal of Cleaner Production, 209, 567-578. [8] Amankwah, E. O., & Frimpong-Mensah, K. (2018). Performance Evaluation of a Hand Operated Briquetting Machine. International Journal of Engineering Research and Applications, 8(6), 45-54. [9] Biswas, K., & Ghosh, P. (2020). Design and Development of a Manual Screw Press Briquette Making Machine. Journal of Energy Conservation and Management, 15(3), 78-89. [10] Obi, S. N., & Okafor, J. C. (2017). Fabrication and Performance Evaluation of a Manual Briquette Making Machine for Agricultural Residues. Journal of Sustainable Energy Technologies and Assessments, 5, 34-45.

Copyright

Copyright © 2024 Dr. A. V. Vanalkar, Yash Bawankule, Aditya Shende, Harshal Vaidya, Nirwesh Karwade, Shrikant Dabare. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET61890

Publish Date : 2024-05-10

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online