Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and Fabrication of Automated Water Tank Cleaner

Authors: Mr. Sowdager Moin Ahmed, B. Sai Swapna, T. Srinivas, K. Sainath, A. Shiva Kumar, B. Mohammad Khan, Y. Varun Sai

DOI Link: https://doi.org/10.22214/ijraset.2024.59715

Certificate: View Certificate

Abstract

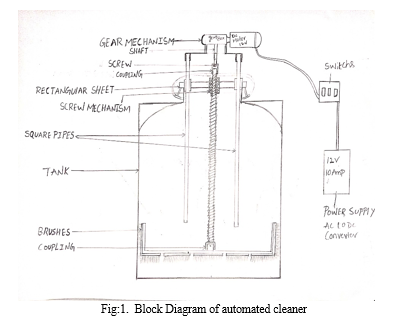

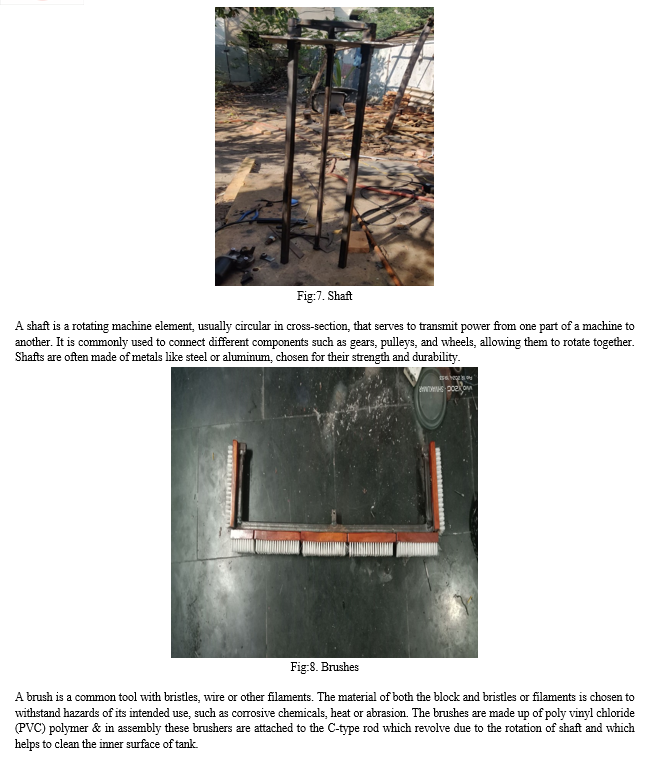

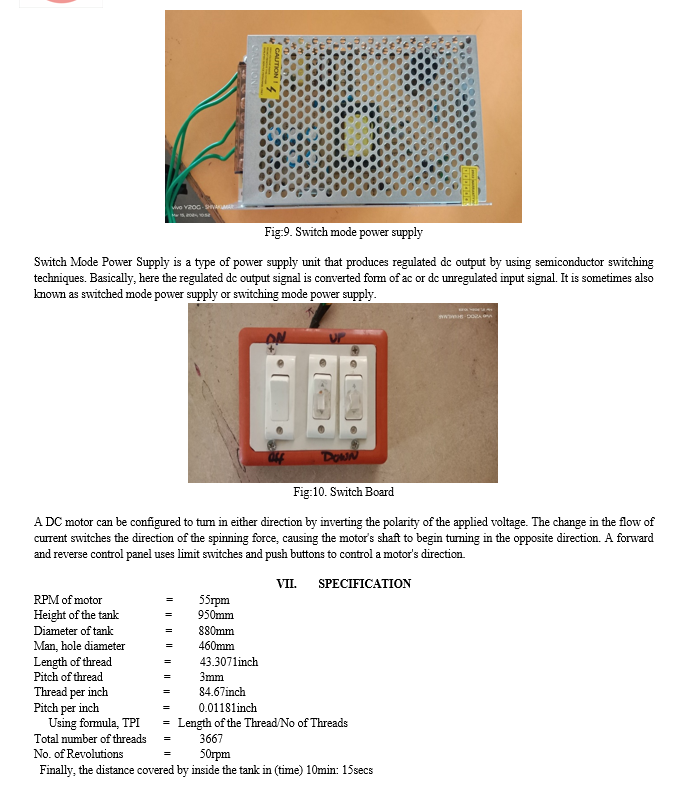

To develop a mechanical system for cleaning automatic cylinder water tank. The mechanical system consists of water tank, electrical motor, shaft, handle for supporting frame and converter. Converter is used to supply the required voltage to the motor. As the power input is given to the electric motor. The mechanical system includes screw mechanism. A screw mechanism is a mechanical device that converts rotational motion into linear motion. It consists of a threaded shaft, known as a screw, and a nut with matching threads that engage with the screw. When the screw is rotated, the nut moves along the screw axis, resulting in linear motion of the nut. This arrangement is used to transport the entire mechanical system up and down for cleaning cylinder water tank. Brushes are connected to the shaft through coupling. When motor gets starts the energy transfers into the shaft. It cleans the interior surface of the cylinder water tank. The purpose of this project is to reduce the human efforts and to avoid the chemical influence on health of person entering the tank for cleaning. To overcome this cleaning tanks overhead manually is a critical job. So, we designed an automated cleaner with provide a high safety, better efficiency, and to reduce the time for cleaning.

Introduction

I. INTRODUCTION

Every day the water stored in the tank is used for Domestic and industrial purpose. Water tanks are used to provide storage of water to be used in lots of applications, drinking water, irrigation agriculture, fire suppression, agricultural farming, [1] each for vegetation and livestock, chemical manufacturing, meals education in addition to many different uses. Water tank parameters include the overall layout of the tank, and preference of production materials, linings. [2] Various materials are used for creating a water tank: plastics (polyethylene, polypropylene), fiberglass, concrete, stone, steel (welded or bolted, carbon, or stainless). Water tanks are a green way to assist developing nations to save clean water. [3] Safe drinking water is one of the fundamental factors for people to maintain a healthy life. In recent research it was discovered that no robot-based machine is used as part of cleaning the upper tank. This is the result of the unpredictable shape and the different dimensions of the tank areas. [5] With previous reviews it has affected the effort to build a machine through the mechanization process to clean the tank. [6] Over the period of time residues sludge and scale deposition gets formed on the inner walls and floor of the tank. [7] The sediments contaminate the water make it unfit to use. Bacterial growth in water can cause infection and can spread diseases. Hence, Cleaning and maintenance of water tank regular is absolutely necessary. [8] The traditional methods of manual scrubbing have become redundant and are labor intensive. Therefore, in this pare alternative efficient method has been attempted with the aim of reducing human effort involved in cleaning the water tank. This not only improves the health and safety of the water supply but also extends the lifespan of the storage tanks by preventing corrosion and damage associated with sediment buildup and microbial growth.

II. LITERATURE SURVEY

- Shubham Srivastava "Cleaner Cylindrical Water Tank Design and Production," January [2016]. They build mechanical system in this work consists of two main mechanisms which are gear mechanism and reciprocate four bar connection mechanism. The gear used is worm gear which is used according to the height of the cylindrical tank to reciprocate the entire mechanical system up and down.

- Pramod B jacket "Computerized robot to clean water tank underwater" [2016]. Cleaning up water tanks for storage is a tedious job. Entire work needs to be done manually, and this is a risky task when manual work is considered. Considering the height of water tanks, oxygen shortage can be a big problem. Therefore, the need for the use of robotic systems underwater has become more apparent.

They create a program in which the user navigates the robot remotely as he wants, as well as monitors other operations such as washing, brushing, sucking, etc.

3. Rohit R. Dabhade1, Shubham V. Lasankute, Sanket P. Wankhade, Shubham G. Darokar, Prof. Vikram Singh R. Parihar Automatic Overhead Water Tank Cleaning System. This method was more effective and safer than the conventional methods. The future scope of the project is to extend it with auto feeding mechanism by which the manpower involved in feeding gets removed. Through the help of the auto feed mechanism, it is easy to clean the tanks without excess man power.

4. Mr. Yogesh, K. Chaudhary, Mr. Nitesh B. Patil, Mr. Sachine A. Khangal, Mr. Nisar S. Shaikh, Mr. Shrikant, U. Nagare Design & Fabrication of Water Tank Cleaning Machine. This equipment was found to be effective in cleaning cylindrical water tanks. This method is capable to clean water tanks within less time and human efforts.

5. G. Bhaskar, Y. Chandu, S.B. Fazul Rehman, V. Ganesh, R. Sai Lokesh. Design and development of automatic water tank cleaning machine. Water splashes everywhere along the dividers in the tank and the rotating brushes clean the external separators. The future scope of the project is to extend it with auto feeding mechanism by which the manpower involved in feeding gets removed. Through the help of the auto feed mechanism, it is easy to clean the tanks without excess man power.

III. WORKING PRINCIPLE

The Water tank cleaning Mechanical system consists of water tank, electrical motor, shaft, brushes, handle supporting frame and converter. The main purpose of supporting frame is to place the motor and to control the vibrations. A Rotating handle along with brush is coupled to the bottom of the shaft. Converter is used to supply the required voltage to the motor. As the power input is given to the electric motor, screw driven apparatus is moved along all the areas of the tank. The screw shaft consists of helical shape which allows it to rotate and move water and dirt particles along its path. As the screw rotates the helical shapes causes to push the water and debris towards an exit point. At exit point the water and other dirt particles are removed from the tank through outlet provided in the tank. The up and down motion of the handle depends on the rotation of the screw and it is controlled by electrical switches. The rotation of screw driven shaft has to ensure that all areas of tank cleaned effectively. Which includes side walls and bottom of the tank.

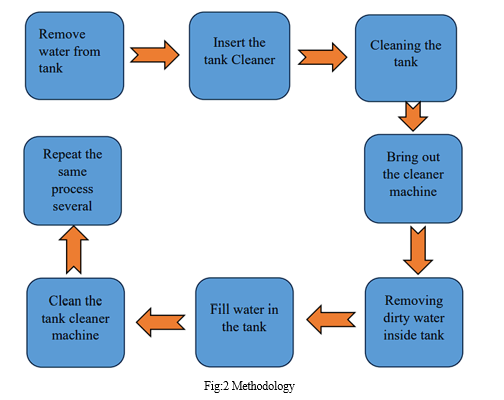

IV. METHODOLOGY

The working of a system is shown in the above methodology, the very first step is the removal of water. The water is removed from the tank to initiate the process. After the water is removed, the machine is inserted into the tank. The machine should be carefully inserted and check whether it is placed properly inside the tank.

Now when the machine is inserted and placed properly, one should open the folding and start cleaning the tank. It has to open in such a way that the brushes are in contact with the surfaces of the tank.

After the tank is cleaned properly, close the folding and remove the machine from the tank. Remove the dirty water which was being cleaned from the tank. After purification, fill purified water with inside the tank and then clean the tank cleaning machine once more properly. Repeat the same method a few times. Automatic cleaning of the water tank saves time and money. If you are cleaning your tanks manually or using the fill and empty method, you may be surprised at how much you can save through automation. Automated tank cleaning is best suited for apartment complexes and businesses or buildings installed with large water tanks. Nowadays, professionals and companies working with automatic tank cleaning equipment arrive at their doors with their equipment to clean the water tanks in a few hours. The advantage of automated tank cleaning equipment is that it saves you time. In addition, you do not need to enter the water tank to clean it. Companies that offer automatic tank cleaning equipment usually offer a demonstration of their products that allows them to choose the right product they need for tank cleaning. The process of automatic tank cleaning begins with the cleaning of the manhole and dirt, mud and surrounding algae. After cleaning the water tank, the water tank is disinfected using chlorine or antibacterial agents. Some professional cleaning service providers use the UV radiator to kill the remaining bacteria. The cleaning process ends with the residual chlorine test left in the tank.

V. DESIGN

Designing in mechanical engineering involves creating plans, specifications, and drawings for machines, structures, and mechanical systems. This process includes conceptualizing, modeling, and detailing components or systems to meet specific requirements, such as functionality, safety, and cost-effectiveness. Mechanical engineers use principles of physics and material science to design products and systems that are efficient, reliable, and durable. They often use computer-aided design (CAD) software to assist in the design process. In AutoCAD, users can draw lines, shapes, and text to create precise technical drawings. The software provides a range of tools for drawing, editing, and dimensioning objects. Users can also apply colors, textures, and materials to their drawings to create realistic renderings. One of the key features of AutoCAD is its ability to create and edit drawings with a high degree of precision. Users can specify exact dimensions, angles, and other parameters to ensure that their drawings are accurate.

Conclusion

The water tank cleaner was used to clean the cylindrical water tanks. During cleaning the rotating brush needs to move up and down manually for complete cleaning with the help of brush. This method was more effective and safer than the conventional methods. This method is capable to clean water tanks within less time and human efforts. By using that water tank cleaning machine, we can reduce the time consumption for water tank cleaning. That water tank cleaning machine is easy to operate as compare to manual cleaning. The weight of that machine is low and as compare to manual cleaning cost for cleaning is low. Through the help of the auto feed mechanism, it is easy to clean the tanks without excess man power. An automated water tank cleaner provides a high safety, better efficiency, and to reduce the time for cleaning. The purpose of this project is to reduce the human efforts and to avoid the chemical influence on health of person entering into the tank for cleaning.

References

[1] Shubham Shrivastav, Hari Om Kumar, “Design and Development of Cylindrical Water tank cleaner”, IEEE Trans. Common, vol.6, no. 1, pp. 1-7, Feb. 2016. [2] Brown J. A., “vacuum tanker for cleaning storage tanks,” Process Engineering, vol. 21, no. 5, pp.138- 180, Sep. 1989. [3] Thonge Suraj D., Shelke Prasad K., Wakte Vaibhav B., Thonge SharadA., Prof. Shinde R.S, “Automatic Water Tank Cleaning Machine”, Published in International Journal of Engineering and Advanced Technology, Vol. 04 Issue 02, February 2017. [4] Rohit R. Dabhade, Shubham V. Lasankute, Sanket P. Wankhade, Shubham G. Darokar, Prof.Vikramsingh R. Parihar, “Automatic Overhead Water Tank Cleaning System: A Review and an Approach”, Published in International Journal of Advanced Engineering Research and Science, Vol. 5 Issue 10, January 2018. [5] Paper Kumar, W. Deotus, S. Kathir, T. Prasad, Dr.K.Karthikeyan, “Autonomous Water Tank Cleaning Robot for Indian Household”, Published in International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering, Vol. 7 Issue 3, March 2018, DOI:10.15662/IJAREEIE.2018.0703017. [6] Ramya R, Lokesha H, Nitheesha T S, Yashwant C M4, Vitthal R, “Water Tank Cleaner”, Published in Journal of Emerging Technologies and Innovative Research, Vol. 6 Issue 5, May 2019. [7] Ashwin Chander, G. Siddharth, E. Krishna Kanth, Kevein Shadrack, P. Vetrivezhan, “Design and Fabrication of Water Tank Cleaning Machine”, Published in International Journal of Innovative Technology and Exploring Engineering, Vol. 8 Issue 9, July 2019. [8] Yogesh Kumar S R, Naveen Kumar, GowthamNaik, Venkatesh A, Hanumanth Araya R, “Fabrication of Water Tank Cleaning Machine”, Published in International Journal of Scientific & Engineering Research, Volume 11 Issue 6, June 2020 [9] Vardaan Mittal, etc. al, (2016) “Automatic Water Level Controller”. International Journal of Science and Research, Vol 06, Issue No 05, pp.136-138. [10] Abhishek “design and fabrication of automatic system overhead tank cleaning” April 2017. In this work present a concept of the mechatronics system consists of a grooved gear rod attached to two arms with brushes at ends. The two arms are connected to the gear rod by nut. By rotating the gear rod, the up and down motion of the two arms is achieved. The gear rod is rotated with the help of a D.C gear motor. The main grooved shaft is powered by an A.C motor. The motor and the shaft are connected by a rubber belt. The clockwise rotation of the main shaft will make the arms move and vice versa. The whole operation is controlled by a circuit consisting of relay switches, buttons, and PIC microcontroller. The number of times for the operation to repeat can be fed into the circuit. He concludes that advanced model for tank cleaning system is cleaning the tanks thus making the operation user friendly.

Copyright

Copyright © 2024 Mr. Sowdager Moin Ahmed, B. Sai Swapna, T. Srinivas, K. Sainath, A. Shiva Kumar, B. Mohammad Khan, Y. Varun Sai. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59715

Publish Date : 2024-04-01

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online