Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and Fabrication of Friction Floor Cleaner for Cattle Shed

Authors: Arun Kedar, Jayesh Vairagade, Khushal Walde, Sakshi Chavhan, Swarnim Patil

DOI Link: https://doi.org/10.22214/ijraset.2024.61436

Certificate: View Certificate

Abstract

In the world of advanced technology and scientific evolution our one vision should be there in the health and hygiene of domestic animals. Domestic animals like cows and goats are the source of revenue in the form of milk. Hence it is essential to take care of the health and hygiene of cows as unhygienic surroundings may lead to various diseases among the cattle and can also affect productivity. There also lies the probability of diseases being transmitted to human beings who consume this milk. So considering all these factors we aim to design and fabricate a machine for the cleaning of cowshed. The proposed system uses 4 different arrangements which are friction cleaning arrangement, water distribution arrangement, disinfectant spraying arrangement, and left and right (1-D) movement arrangement of the complete system. The friction cleaning system uses a rotating brush arrangement to make the complete ground surface of cowsheds dirt-free. A watering arrangement is used to distribute water on the ground surface. Disinfectant distribution arrangement uses sprinkler arrangement to distribute disinfectant to make cowshed bacteria-free. 1-D movement arrangement uses rack and pinion arrangement to make the complete system move in one-directional movement.

Introduction

I. INTRODUCTION

In animal husbandry, maintaining the health and hygiene of domestic animals is of ultimate importance. Cows and goats, in particular, play a pivotal role in generating income through milk production. Therefore, cowshed and farm owners are deeply concerned about the health and hygiene of these animals as they constitute the primary source of income. Hence in this project, "Design and fabrication of friction floor cleaner for cattle shed" an advanced solution for maintaining clean and hygienic cowsheds, crucial for the well-being of domestic animals and public health is proposed. The machine involves a sophisticated cleaning system with rotating brushes, efficient water distribution, and disinfectant distribution to combat contaminants. The system's left and right or one-directional moving arrangement ensures thorough coverage. The successful implementation of this advanced layered friction cleaning system with integrated pesticide distribution has the potential to revolutionize the way cowsheds and farms are maintained, promoting animal health and hygiene, enhancing productivity, and safeguarding cattle and human health. In the world of animal husbandry, maintaining the health and hygiene of our livestock is critical. Cows and goats, in particular, generate significant income through milk production. Cowshed and farm owners have a vested interest in keeping these animals healthy because their welfare directly affects their livelihood. This project proposes a revolutionary solution: designing and manufacturing an advanced friction floor cleaner specifically for cattle sheds. This machine promises to keep these domestic animals' living spaces clean and hygienic, benefiting both their health and the public's. The proposed system includes a sophisticated cleaning mechanism with rotating brushes, efficient water distribution, and an integrated disinfectant application to combat contaminants. The machine's design, whether left and right moving or unidirectional, ensures full floor coverage. The successful implementation of this advanced layered cleaning system with built-in pesticide distribution has the potential to revolutionize the way cowsheds and farms are managed. This innovation has the potential to improve animal health and hygiene, increase productivity, and eventually protect the health of both cattle and humans. Rotating brushes effectively clean the entire floor, removing dirt, debris, and stubborn contaminants. Efficient water distribution provides even rinsing across the floor, removing dirt and contaminants for complete cleanliness. Sprinkler systems effectively distribute pesticides, preventing the spread of harmful bacteria and diseases. The system moves left and right using a rack-and-pinion mechanism, covering the entire cowshed floor The successful implementation of this advanced layered friction cleaning system with integrated pesticide distribution has the potential to revolutionize the way cowsheds and farms are maintained, promoting animal health and hygiene, enhancing productivity, and safeguarding human health.

Unsanitary Cowsheds and their Detrimental Effects on Animal Health, Human Health, and Production Efficiency Traditional cowshed cleaning methods are plagued by several shortcomings, including:

- Manual labor: Requires significant time and effort.

- Ineffective cleaning: Often relies on manual scrubbing and water rinsing, failing to remove stubborn dirt, debris, and bacteria.

- Limited functionality: Lacks comprehensive cleaning mechanisms, neglecting crucial aspects like pesticide distribution for bacterial control

- Environmental concerns: Inefficient water usage and potential for chemical contamination from pesticides. These shortcomings collectively contribute to a vicious cycle of unhygienic cowsheds.

- Animal waste accumulation: Breeds bacteria and parasites, leading to diseases, reduced productivity, and potentially mortality.

- Disease transmission: Contaminated milk and airborne pathogens pose health risks to both animals and humans.

- Environmental degradation: Excessive water usage and improper disposal of cleaning chemicals pollute water sources and harm soil health.

Therefore, a need exists for a revolutionary cleaning system that addresses these challenges by:

- Enhancing hygiene: Effectively remove dirt, debris, and bacteria to create a healthy environment for cattle.

- Improving efficiency: Reduce reliance on manual labour and automate cleaning processes.

- Integrating multiple cleaning functionalities (friction cleaning, disinfectant distribution, water distribution) for comprehensive hygiene.

Developing such a system is vital to ensure the health and well-being of animals, safeguard human health through safe milk consumption, and foster sustainable farming practices for a healthier planet.

The current research in similar area depicts only arrangement of water sprinkler, friction floor cleaning and pesticide sprayer. Traditional research extended towards disinfectant distribution via manual arrangement having vessel with air pumping arrangement. By combining friction based cleaning with water and disinfectant sprinkle system which is an under-explored area. There is a lack of comprehensive research that investigates the synergistic effects of friction-based cleaning alongside a simultaneous water and disinfectant sprinkler system

II. AIM

- To study the requirement for Cow Shed cleaning after Cow dung is manually removed from the floor.

- To Design friction cleaning arrangements using brush, coupling, and motor arrangements for effective cleaning.

- To Design various elements of a combined friction-based cleaning machine for water spraying, cleaning, and disinfecting.

- To provide support for cattle shed owners to experience an advanced cleaning process unlike the traditional methods.

III. METHODOLOGY

The following flow chart shows the steps to fabricate the prototype. The process to start the prototype fabrication starts with the chassis fabrication followed by the fabrication of rotating brushes for friction cleaning. After that, the fabrication of a water and disinfectant distribution arrangement is planned which is followed by the fabrication of a water and disinfectant tank. Once all these arrangements are fabricated, the motor and piping will be placed in a specific position to ensure proper distribution of water and disinfectant. The prototype fabrication will be concluded with the fabrication of a one-directional horizontal movement arrangement which will act as the driving mechanism for the machine.

The cleaning system utilizes a high-torque DC motor to rotate a friction brush in both clockwise and anti-clockwise directions. These brushes are connected to the motor through a flange coupling. In addition to friction cleaning, the system incorporates a disinfectant distribution setup with a dedicated tank and sprinkler mechanism. The disinfectant is pumped from the tank to the sprinkler. Furthermore, the machine includes a water distribution system with a mini water tank and a layered water distribution setup. Water is pumped from the tank to the layered water distribution arrangement. The overall system features a cleaning mechanism that includes a rotating friction brush, disinfectant sprinkler, and water distribution components. Following are the arrangements and components used in it:

- Rack and Pinion Mechanism: The pinion gear is connected to a motor with a rating of 12 V and variable current rating of 2 to 8 A that drives the mechanism for one directional horizontal movement. When the motor turns, the pinion gear rotates along its axis. As the pinion gear rotates, its teeth come into contact with the teeth of the rack. Since the rack is fixed, the force exerted by the rotating pinion gear pushes against the rack's teeth. This pushing force causes the entire machine to move in a straight line along the direction of the rack. This arrangement includes a high torque dc motor, a spur gear rack and a geared pinion to provide horizontal movement. This rack and pinion with motor mechanism acts as the driving force for the whole system.

- Water and Disinfectant Tanks:

- Water Tank: This tank is made of mild steel sheet and has a volume of approximately 8.4 litres (based on the calculations proposed further). Its purpose is to store clean water used for rinsing and potentially diluting disinfectant. The water is pumped from this tank to the sprinkler arrangement, which sprays it onto the floor of the cattle shed.

- Disinfectant Tank: Like the water tank, this tank is also made of mild steel sheet and has approximately the same volume (8.4 litres) as of the water tank. This tank stores the disinfectant solution used to eliminate bacteria and on the floor. A pump draws disinfectant from this tank and delivers it to the sprinkler system, which sprays it onto the floor after the water application.

3. Shaft mounted on vertical wall: The proposed machine will be designed in such a way where a vertical wall will be used as a support. But where a cattle shed without the presence of such wall is present, a shaft can be used for the same purpose. Hence a shaft of length 5 feet is used for this purpose.

4. Geared rack: This is a straight bar with teeth machined along one flat face, designed to mesh with the teeth of the pinion gear. As the pinion gear rotates, its teeth come into contact with the teeth of the stationary rack which as discussed above gives the driving force to the whole mechanism.

5. Piping arrangement for water distribution: A pipe is used for even distribution of water which will be pumped via a water pump. This piping and motor arrangement is linked to the tank which will contain water. A pipe of length 2 feet with very minute holes of 1 mm diameter having such 10 holes is used to ensure the water is sprayed thoroughly on the cattle shed floor. Such minute diameter is proposed so that the water is sprayed with pressure to ensure full surface coverage.

6. Water pump motor: The water pump motor is a DC type with a voltage rating of 12V and a current rating of 4 Amps. The motor is constructed using fibre material and operates at a speed of 2000 RPM. Its inlet diameter is 12 mm, while the outlet diameter is 10 mm.

7. Brushes: The brushes are characterized by a width of 6 inches and a thickness of 0.5 inches. They have a circular appearance and the bristles are made from nylon material. Bristles made from nylon are commonly used for scrubbing regular surfaces and hence the same are proposed in our invention. 2 such brushes are used in this case so that no spot on the surface remains unattended and unclean assuring proper scrubbing. These brushes are then coupled to the motor which is characterized by a voltage of 12 volts and 2 amperes to ensure proper rotation of brushes in anti-clockwise and clockwise sense. A multi layered switchboard is used for the clockwise and anti-clockwise rotation of the brushes.

8. Piping arrangement for disinfectant distribution: This mechanism is operated on the same principle as of the water distribution piping arrangement. A pipe characterized by a length of 2 feet having holes of 1 mm diameter is proposed for proper distribution of disinfectant on the cattle shed floor to achieve a bacteria free surface. A motor pump is used to pump the disinfectant liquid from the disinfectant tank to the pipe for its even distribution.

9. Spur Gear: Geared pinions like these are commonly utilized in various mechanical systems for precise transmission and control of rotational motion. This spur gear is paired with the rack to provide the driving force to the system. The geared pinion has a diameter of 40 mm, thickness of 30 mm and consists of 25 teeth. This arrangement provides enough torque which is needed for the operation.

VI. ACKNOWLEDGMENT

We would like to express our sincere gratitude to Yeshwantrao Chavan College of Engineering, Nagpur, India, for providing the resources and facilities necessary to conduct this research project on a cattle shed floor cleaner design.

We are particularly grateful to our esteemed guide, Dr. A.P. Kedar, for his invaluable guidance, support, and encouragement throughout this project. His expertise and sincere support were extremely beneficial to us, and his insights significantly improved the quality of our work.We are thankful for the opportunity to learn from him and appreciate his patience in reviewing our work and providing constructive feedback.

Encouragement, understanding and unwavering support from our family and friends kept us motivated throughout this project.

Conclusion

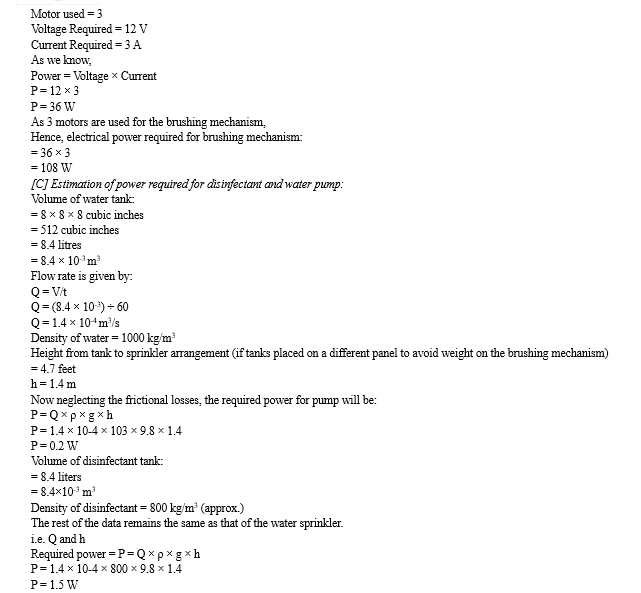

This project investigated the feasibility and performance of a layered friction cleaning system designed for a cattle shed. The power required for effective cleaning, considering the given parameters and calculations, is approximately 0.1 HP. This indicates the amount of power needed to rotate the cleaning mechanism at the desired velocity and torque. For the brushing arrangement, with three motors each consuming 36 W, the total power required for the brushing arrangement is 108 W. This accounts for the power needed to drive the brushing mechanism effectively. The power required to lift and distribute water from the tank to the sprinkler arrangement, neglecting frictional losses, is approximately 0.2 W. Similarly, the power required to distribute disinfectant from the tank to the sprinkler arrangement, again neglecting frictional losses, is approximately 1.5 W. In conclusion, the calculations provide an estimate of the power requirements for various components of the cleaning and disinfecting system. These calculations are crucial for determining the power supply needs and ensuring the effective operation of the cleaning and disinfecting apparatus. Further development and optimization efforts will focus on analysing battery specifications, improving system efficiency, and exploring sustainable cleaning methods. This includes integrating smart agricultural technologies for automation and data analysis, developing self-learning algorithms for adapting cleaning strategies, and investigating low-water and chemical-free solutions. These advancements will enhance the system\'s capabilities and promote its wider adoption in the agricultural industry, contributing to improved hygiene, animal welfare, and environmental protection.

References

[1] K. MURUGAN, B. J. SHANKAR, A. SUMANTH, C. V. SUDHARSHAN, and G. V. REDDY, \"Smart Automated Pesticide Spraying Bot\" 3rd International Conference on Intelligent Sustainable Systems (ICISS), Thoothukudi, India, 2020, pp. 864-868. [2] E. Ramya, J. Anand, R. Renugha Devi, N. A. Issac, and K. Roshni Prasenth, \"Solar Grass Cutter with Water Spraying Vehicle\", 2021 International Conference on Advancements in Electrical, Electronics, Communication, Computing and Automation (ICAECA), Coimbatore, India, 2021, pp. 1-6. [3] L. M. Thakur, R. Abdulla, S. K. Selvaperumal and C. Nataraj, \"Pesticide Sprayer for Agricultural Purpose based on IoT Technology\", 2022 3rd International Conference on Smart Electronics and Communication (ICOSEC), Trichy, India, 2022, pp. 414-421. [4] K. Saravanan, E. Siva Prasanna, R. Sattish, R. Udhaya Abinesh, and P. Anandakumar, \"Automatic Floor Cleaning Robot\", IEEE International Conference on Data Science and Information System (ICDSIS), Hassan, India, 2022, pp. 1-5. [5] Varsha P.H., Lavanya V., Meghana K., Rohan P.S., Sneha R., \"Sweepy – The Smart Floor Cleaner\", 2018 International Conference on Design Innovations for 3Cs Compute Communicate Control (ICDI3C), Bangalore, India, 2018, pp. 124 126 [6] J. S. John, S. M. Dash, A. Sharma, A. Kashyap, and V. Yadav, \"Design and Analysis of Solar powered Automated Lawn mower with Vacuum Cleaner\", 2022 International Conference on Advances in Computing, Communication and Applied Informatics (ACCAI), Chennai, India, 2022, pp. 1-5 [7] Humayun Rashida, Akash Mahmoodb, Sarjahan Shekhac, S M Taslim Rezad, Md. Rasheduzzaman, “Design and Development of a DTMF Controlled Room Cleaner Robot with Two Path - Following Method” 19th International Conference on Computer and Information Technology, December 18-20, 2016, North South University, Dhaka, Bangladesh, pp 484- 489 [8] Adeel Saleem, Atif Iqbal, Adnan Sabir, Adil hussain, “Design and Implementation of an Intelligent Dust Cleaner Robot for Uneven and Nonstructural Environment” 2019 International Conference on Computing, Mathematics and Engineering Technologies – iCoMET 2019 pp 1-2 [9] Lei Mai, Yongyi Cui, Fang Qu, Fan Wu, “Studies on water distribution characteristics of sprinkler in sprinkler systems” Sixth International Conference on Intelligent Systems Design and Engineering Applications, 2015 [10] Pranali S. Bhoite, Nisha U. Gurav, Onkar K. Nagarkar, Reshama R. Chaudhari, “SEKTROO: Smart Automated Pesticide Sprinkling Bot” Proceedings of the 35 Third International Conference on Trends in Electronics and Informatics (ICOEI 2019), Virar,India, pp 1420-1423

Copyright

Copyright © 2024 Arun Kedar, Jayesh Vairagade, Khushal Walde, Sakshi Chavhan, Swarnim Patil. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET61436

Publish Date : 2024-05-01

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online