Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and Fabrication of Solar Dryer

Authors: Katta Nikhil Kumar, Gorlakadi Shivaraj, Bandi Nishanth, Dharmarapu Swathi , Santosh Madeva Naik

DOI Link: https://doi.org/10.22214/ijraset.2024.59006

Certificate: View Certificate

Abstract

In a present modern busy life leading by the people, they are showing interest in eating readymade food items which can be instantly cooked and also save their time .In these readymade food items dried ingredients (fruits and vegetables) are used for long term preservative purpose .The drying of food products are done by traditional method which is called as \"Direct sun drying\". Which takes more time to dry with less efficiency and also due to open sun drying process hygiene is less due to dust particles present in the atmosphere. To overcome these circumstances solar dryer is one of the alternative method used for drying food products. A detailed study is done on the present Solar dryer on it’s performance & efficiency and also some developments of new technologies are done. So, that the factors like drying effect, performance, efficiency & temperature storing capacity can be increased and also innovative IOT temperature sensor are used to track the temperature readings according to the weather conditions.

Introduction

I. INTRODUCTION

In Food is the basic need of all human beings and to supply food for a long period is the biggest challenge the quality and quantity both are important in food. losses of fruits and vegetables are everywhere, most developing countries still facing this problem. about 30 to 40% of total production gets loss [1]. To protect fruits and vegetable from loss it is important to remove the moisture present in the fruits and vegetable to a certain extent. the moisture removal can be done by open sun drying which is one the oldest method. otherwise, fossil fuel dryer can be used for same. many industries are using electricity, natural gas, biomass, and solar energy for frying foods [2,3], There are different type of dryers and have their performance is differing as per the food and environment. the dryer can be used for many products like chilies, turmeric, peanut, grapes, copra, etc. the types of the dryer and possible improvement for better performance is studied [3]. Fossil fuels pollute the surroundings and not available in plenty. Solar energy is available free of cost and can be used for drying. Many researchers study solar energy and give their views by experimenting and reviewing the literature. Solar energy used by indirect solar dryer which is most prominently used by many researchers gives good quality products. Different techniques are incorporated for improving the performance of the dryer [4]. A new conception of the absorber in the collector of an indirect

dryer is used for thermal storage of solar energy. Two corrugated aluminium plates are used in the collector which gives the thermal efficiency of 11.11% [5]. Different types of dryers discuss with application [6]. To use a dryer of one type doesn’t provide high performance. A dryer with mixed-mode can give more efficiency than a single one. The efficiency of the dryer is mostly depending on the air temperature and its velocity, type of product solar radiation, and moisture content [7] Nabnean design a parabolic shape flat plate collector cover with a polycarbonate plate. The dryer was so designed that it can dry the banana from 72% W.B.9wet basis to 28% w.b in 4 days [8].

A box-type solar dryer is designed to dry the mango slices under controlled and protected conditions. The time taken to dry the 100kg of sliced mango is two days and moisture removal is from 81.4% to 10%. The dryer area was only 1.03m2[9]. The design procedure with all mathematical terms and conditions is studied for designing a solar dryer of any type [10]. The solar dryer with a 1 m2 area can dry many products like chilies, bit root, potatoes, and many more. The box-type dried was instructed to dry 20 kg of fresh vegetables from 89.6% to wb [11]. The dryer of mix mode types gives more variants in the drying of food items than other types.

The solar and wind energy combinations give the much easier and clean dryer[12]. A solar dryer can be made at a low cost and even cheap local material can be used to construct the dryer and this will be helpful to farmers and others also [13]. The solar dryer scope is not limited to the industries or agricultural land it can be used for household purposes also [14]. the dryer can be tested by many methods. The modelling techniques like CFD, ANFIS modelling, ANN modelling, fuzzy logic, and its application for understanding the drying concept [15]. There are various types of advancement are developed in the solar drying system [16] The objective of this paper is to explain the importance of solar drying and its application for industries and household products. Its major application is in a household.

II. LITERATURE REVIEW

- PRAVIN M.GUPTA (2017) International research journal of engineering and technology Design and construction of solar drying agricultural product The solar dryer designed constructed expressed sufficient ability to dry agricultural produce most especially food items to an appreciably reduced moisture level. And affordable for farmers. And also reducing food wastage, since it can be used extensively for majority of the agricultural food crops.

- A REYES (2015) the fifth international renewable energy congress irec control system in a hybrid solar dryer this resulted in an increase of thermal efficiency of the process during 11 hours of drying, the moisture content of slices mushroom diminished from 93% to 6% the communication system based on open platform communication technology works in a very good way for programming fuzzy logic control implemented in mat lab with the date acquisition program.

- MOHAMMEDABDELBSSITKHERRAFI(2023) applied energy and thermal laboratory department of mechanical engineering ABOU BEKR BELKAID UNIVERSITY, Algeria, performance Enchancement of indirect solar dryer with offset strip finish this paper publication they performed an experiment by using offset shaped find in place of flat fin plate collectors in order to Enchance the drying effect of solar dryer in this experiment they used freshly harvested to dry using the solar dryer by using flat fin collector and offset fin collector in a clear Sunday condition. after completion of the experiment the says that the has dryed in 20H18MIN by using offset fin collector & 35H 45MIN using flat fin collector.

- DARWAN HARUN (2016) (International Annual Engineering Seminar (In ASE), Indonesia Experimental investigation on open sun drying and solar drying system of bilimbi THE experiment is carried out on drying the bilimbi using two different methods, direct sun drying and solar drying process by performing this experiment they concluded that the bilimbi which dryed using the solar dryer has dryed has taken the time of (24 hrs) where has direct sun drying took (40hrs) to dry completely. and also the bilimbi is protected by the surrounding which can eliminate the fungus and bacteria

- HASEEB UR REHMAN,FAWAD NASSER & HAFIZ MUHAMMADALI (2023) mechanical engineering department, king FAHD university of petroleum and minerals, Saudi Arabian experimental case study of solar dryer with thermal storage using phase change material (pcm)in this paper publication they performed an experiment on indirect solar dryer to increase the heating effect for longer period of time by using phase changing material (pcm) such as "paraffin wax" they used thermal storage chamber in which paraffin wax is employed.at the mid of the day due to heat released by the sun the paraffin wax changes its state from solid to liquid and stores the heat in it these heat is released during the night time i.e in the absence of sun so that the drying of the product can be continued throughout the day.

- COSKUN YUKSELMURAT OZTURK & ERDEM CIFTCI (2023) graduate school of natural and applied SCIENCE GAZI UNIVERSITY, TURKEY analysis of a novel v-grooved double pass photovaltic thermal solar dryer including thermal storage this experiment show the manufacturing of v-grooved double pass solar dryer and improving its performance by including a thermal storage unit and result is the two dryers had v-grooved type absorber surface in one of the dryer collector a paraffin based thermal energy storage unit was added to the photovaltic pannel inside the collector golden apple slices are choose has a product to be dryed.

- SHOBHANA SINGH, SUBODH KUMAR (2012) Centre for energy studies, Indian institute of technology, delhi testing method for thermal performance based rating of various solar dryer design the study states about the heat balance concept of different solar dyer based on the design, where no load is applied to identify the dimensionless parameter called no load performance index(nlpi) . under the conditions of natural and forced air circulation and then finally concluded that the proposed parameters nlpi of any solar dryer operating for given air flow condition is more or less independent of absorbed thermal energy and ambient temperature.

III. METHODOLOGY

A Selection of Dryer for Industry and Household

- Initial Selection: The first step is the type of solar dryer i.e. direct, indirect, mixed, or hybrid. The free convection or forced convection. The types should best suit the wet material and the continuity of the process.

- Initial comparison: The selected dryer in step is needed to evaluate the cost, space, and performance.

- Solar Drying Test: Now test the dryer selected according to steps 1 & 2 for small scale and concluded the result for alternatives experimental readings. Based on the result and conclusion made a design of dryers for said capacity, cost, operating cost, product quality, dryer operability, and available space.

- Final Selection of Solar Dryer: Based on step 3 final selection dryer is made for types and capacity. the dryer can be select on following points.

The dryer can be select on the following points.

a. Physical Features: Types, size, shape collector area.

b. Thermal Performance: Solar insolation, drying time/drying rate, efficiency.

c. Properties of Material: Physical characteristics, acidity, toxicity, etc.

d. Drying Characteristics of the Material: The type of moisture (bound, unbound, or both), initial moisture, final moisture drying temperature.

e. The flow of Material to and from the Dryer: Quantity to be handled per hour, continuous or batch operation, prior and post-process.

f. Product Qualities: Shrinkage, contamination over drying, appearance, flavour.

g. Facilities were Available at the Site of Proposed Installation: Space, Temperature, humidity, available fuels, exhaust gas outlets.

h. Economics: The cost of dryer and drying.

i. Other Parameters: Maintenance, safety, etc.

A. Material Selection

The material selection is depending on the climatic conditions and the availability of the material at that location. Most of the dryers are built by using a steel frame. For a low-cost dryer, Mild Steel is used or sometimes wood, plastic, or PVC pipes can be used. The cost of the dryer depends on the application product. What type of product quality needed to be based on that the product cost and material are selected?

B. How To Predict The Moisture Content

Moisture in the food items needs to remove but how much that is the question arises. Before removing what is the amount of moisture present in the item to the dryer is to be known. Measuring moisture content allows controlling the drying process. This helps to dryer the product to a specific level of moisture content rather than for a fixed period. Following are the methods of finding the moisture content [18].

- Moisture content can be predicted by measuring the weight of the product before and after drying.

- Electrical resistance type meters operate on the principle of electrical resistance, which varies minutely by the moisture content of the item measured. Resistance meters have an average accuracy of + 1% MC over their operating range.

- Dielectric moisture meters rely on surface contact with a flat plate electrode that does not penetrate the wood. Similar to resistance meters, the accuracy of dielectric meter in measuring average MCis+1% moisture content

- The Modern portable moisture balances are available with built-in infrared heaters, which directly measure the moisture content of the product and gives a profile of moisture content variations with time.

- The advanced method of meaning the moisture content is radio frequency capacitance method. the instrument measure the loss, or change, in RF

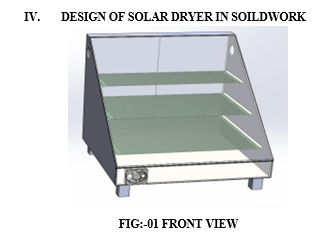

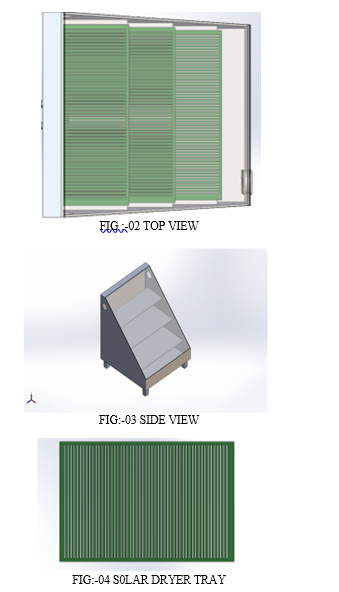

V. DESIGN CONSIDERATION

Several structural design considerations should be taken into account for economical and efficient manufacturing. Many of these apply to other joining methods, and all apply to both subassemblies and the complete structure.

- The device should be suitable for local manufacturing capabilities.

- It should be accessible and affordable by low income groups, and should fulfill their basic need for mechanical power

- It should be simple to manufacture, operate, maintain and repair.

- It should be as multi-purpose as possible, providing power for various agricultural implements and for small machines used in rural industry.

- It should employ locally available materials and skills. Standard steel pieces such as steel plates,

- Use the metal for absorber usually coated with a black colour.

- The frame can be manufactured using wood or metal.

- A dryer should be reliable it should be design such as air is circulated inside the chamber and uniform drying should be obtained.

- A dryer should durable and have a long life.

- The dryer should possess good mechanical properties.

- The dryer should not be too heavy in weight so that it is used to move it around.

VI. RESULT

The performance of existing solar food dryers can still be improved upon especially in the aspect of reducing the drying time and probably storage of heat energy within the system. Also, meteorological data should be readily available to users of solar products to ensure maximum efficiency and effectiveness of the system. Such information will probably guide a local farmer on when to dry his agricultural produce and when not to dry them. Solar radiation can be effectively utilized for drying of agricultural produce in our environment if proper design is carried out. This was demonstrated and the solar dryer designed and constructed exhibited sufficient ability to dry agricultural produce most especially food items to an appreciably reduced moisture level. This will go a long way in reducing food wastage and at the same time food shortages, since it can be used extensively for majority of the agricultural food crops. Apart from this, solar energy is required for its operation which is readily available in the tropics, and it is also a clean form of energy. It protects the environment and saves cost and time spent on open sun drying of agricultural produce since it dries food items faster. The food items are also well protected in the solar dryer than in the open sun, thus minimizing the case of pest and insect attack and also contamination.

Conclusion

Open sun drying is not a valid and hygienic technique for drying food, marine agriculture, and non-agriculture products. Solar drying is the new method of open sun drying and its scope is not limited to drying but also to supplying the hot air. The rate of the drying depends on the volume of the solar dryer, airflow rate, moisture content in the item, humidity in the air as per the environment conditions, and of course the average amount of solar radiation available during the drying season. The dryer has a huge scope in drying the products and providing hot air to many areas of application.

References

[1] Nwaokocha, C.N and Adunola, O. 2010. Design and construction of a domestic passive solar food dryer, Leonardo Journal of Sciences. [2] Adegoke, C.O and Bolaji, B.O. 2000. Performance evaluation of solar-operated thermosyphon hot water system in Akure, International Journal of Technology. [3] Akinola, AO; and Fapetu, O.P. 2006.Exergetic analysis of a mixed-mode solar dryer. Journal of Solar Energy and Applied. Science [4] Bahnasawy AJ and Shenana J.R. 2004. Evaluation of a solar crop dryer for rural applications in Botswana. Botswana Journal Technolog [5] Bena, B and Fuller, R.J. 2002. Determination of the average coefficient of internal moisture transfer during the drying of a thin bed of potato slices. Journal of Food Engineering. [6] Ericson, J. 1980. Global solar radiation measurements in England. Renewable Energy [7] Ghazanfari, A and Sokhansanj, S. 2002. Experiments on solar drying of Pistachio nuts. Energy Conversion Management [8] Bolaji, B.O. 2005. Performance evaluation of a simple solar dryer for food preservation. Proc. 6th Ann. Engineering. Conf. of School of Engineering and Engineering Technology, Minna, Nigeria [9] Janjaia, S; Srisittipokakuna, N; and Balab, B.K. 2008. Experimental and modelling performances of a roof-integrated solar drying system for drying herbs and spices. Journal of Energy [10] Karathanos, K and Belessiotis, L. 2002. Natural convection solar dryer with biomass backup heater, Solar Energy

Copyright

Copyright © 2024 Katta Nikhil Kumar, Gorlakadi Shivaraj, Bandi Nishanth, Dharmarapu Swathi , Santosh Madeva Naik. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59006

Publish Date : 2024-03-14

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online