Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and Manufacturing of EV Go-Kart

Authors: Kalam Tharun Reddy , Kotamarthy Sai Vishnu Teja , Pathireddy Kowshik Reddy, Shivarathri Hemanth Babu, Dr. B. Vijaya Kumar

DOI Link: https://doi.org/10.22214/ijraset.2024.61034

Certificate: View Certificate

Abstract

Go-karts are small-size and small-weight vehicles that were developed for racing. These are made with materials that are strong and durable. It consists of many parts which include a chassis, engine, steering and braking system, and electronic controls. The chassis is the main part that is responsible for the stability of the vehicle. Chassis is made with the material having greater endurance and rigidity. It was developed in the 1950s in the USA and now getting popular. These are now used in amusement parks as a recreational activity. Many researchers have done work on go-karts and improve their design. This project was intended to design and fabricate a reliable and durable go-kart. Its primary objective to build a go-kart using local resources and applying different techniques to limit the cost of vehicles. These objectives were achieved by going through a detailed literature review and studying different techniques which can be implemented. A reliable design was chosen which can be implemented and can be completed in our period. Critically evaluate the design of the vehicle and then different parts were designed. This paper presents an approach to a go-kart chassis design, vehicle dynamics calculation, Li-ion battery capacity analysis, and electric motor choice for optimized vehicle performance. The chassis analysis shown in this paper was performed using a CAD/FEA software package, SolidWorks Student Edition. Three highlights can be found in this paper: An original design was implemented; the basic analysis was composed of chassis optimization using beam elements and modelling such an optimized chassis “locally” with solid elements for sub-modelling purposes. The most stressed tube joint was sub-modelled to calculate the risk of tube wall stability. Vehicle dynamics were calculated for the case of braking on a curved path and the case of a collision with the front tire due to road imperfection. The authors intend to install a data acquisition system in the future to analyse the stress of local chassis tubes.

Introduction

I. INTRODUCTION

The general definition of any kart, a vehicle without suspension and differential. It is a vehicle specially designed for a flat track race. A wide range of engine karts were on track since the mid of the twentieth century. The Go-kart Vehicle is made with Four tires, seat, steering, brakes, and without suspension and differential. Go-kart structure refers to quadracycle vehicle that is used in sports and competition. Go-kart could also be called as the open-wheel car on land which could be made with or without the body-framework It has four harmonious wheels with the bottom, of which two of them assist for the turning of the vehicle with the control of steering and others would facilitate the transmit of the go-cart. Usually, the whole-body frame of the go-cart is made-up of steel pipes, apart from the other key components like engine and the wheels. There were some other parameters such as the types of materials used for the structure of the vehicle in-order to make it mechanically rugged and design of the chassis, these choices are very well concerned because they determine the safety of the vehicle and the structural analysis. now, due to the advancements in the technology and manufacturing materials go-carts are expected to be lighter, faster and should be more efficient in-terms of fuel consumption and overall performance as well. Due to road irregularities, engine loads, and other factors, lighter chassis structures can cause structural resonance as part of a rigid-body vibration. A result of this is riding discomfort and problems with ride control and safety. Finite element analysis is a proven method for designing and creating engineering products using computer-based analytical tools. Finite element modelling is already seen as a vital part of the style, as it can be used for analysing and predicting various structures with a dynamic performance within an engineering environment. Modality analysis is a common way to identify the modal parameter of a structure. In Go-kart, we divided it to four sub-divisions:

- Chassis

- Engine,

- Steering,

- Brake and Tire.

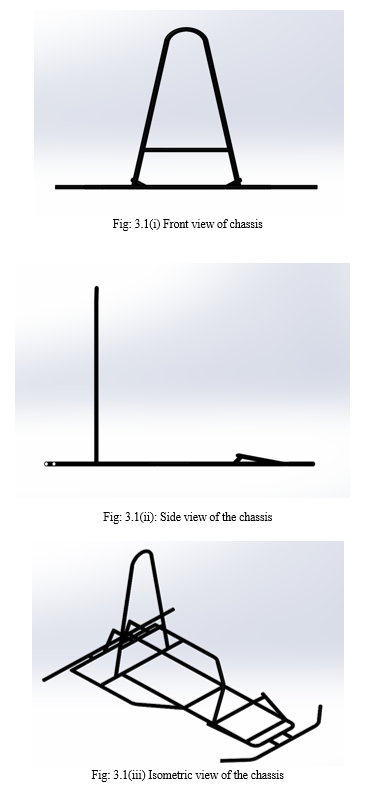

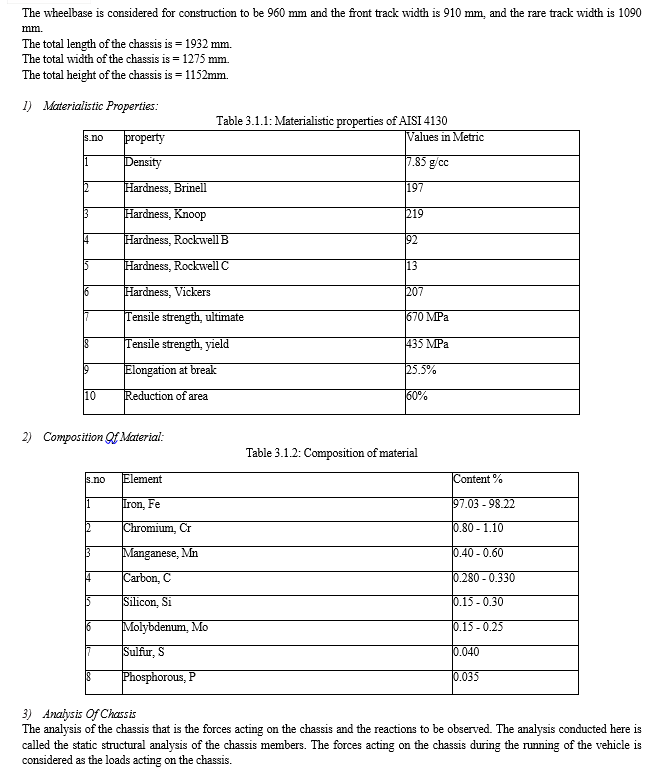

A. Design Of Chassis

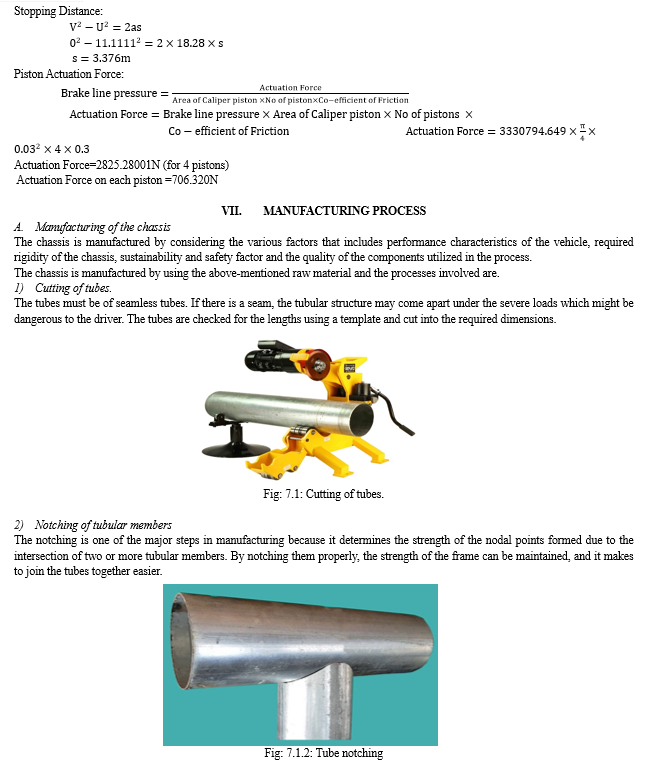

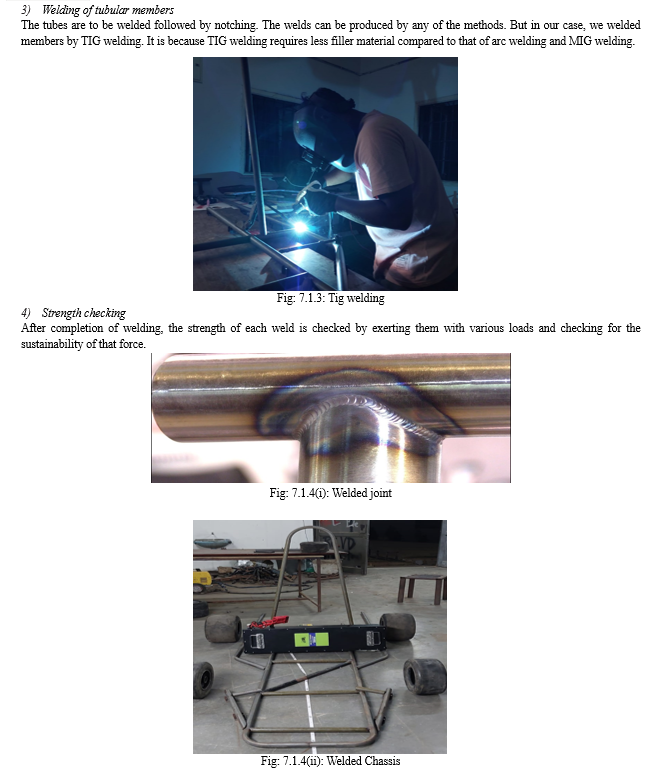

The chassis is made from a thick metal tube. The chassis type we used is a space frame which contains triangulation of tubes and forms nodes. The material used to make chassis is AISI 4130 graded steel which is also known as chromoly steel. And the chassis is held together by tig welding by notching the edges of the tubes.

- Chassis Material Selection

The foundation of any chassis lies in its accoutrements. Historically, sword tubing has been the go- to choose, but the arrival of advanced accoutrements has introduced new possibilities. High-strength sword blends and featherlight aluminum woofer compelling druthers, enabling contrivers to strike a balance between structural integrity and weight reduction. The pursuit of a featherlight yet robust lattice material is a central theme.

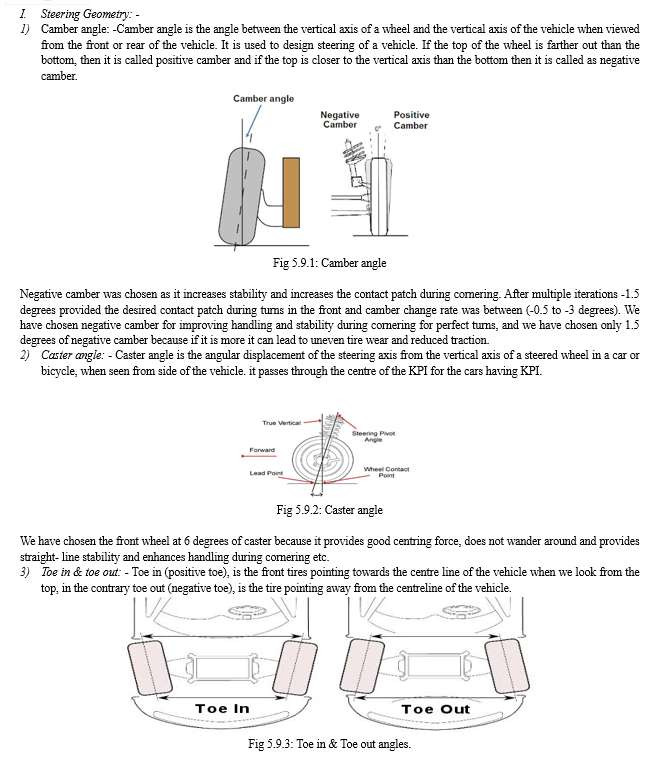

2. Chassis Figure And Dynamics

The chassis Figure plays a vital part in the kart's running characteristics. Variables similar as wheelbase, track range, and caster angle are strictly optimized to achieve the asked balance between stability and maneuverability. Similarly, considerations of Ackermann steering Figure and camber angles are integrated to enhance cornering performance, ensuring that the go-kart remains responsive and predictable during high-speed maneuvers.

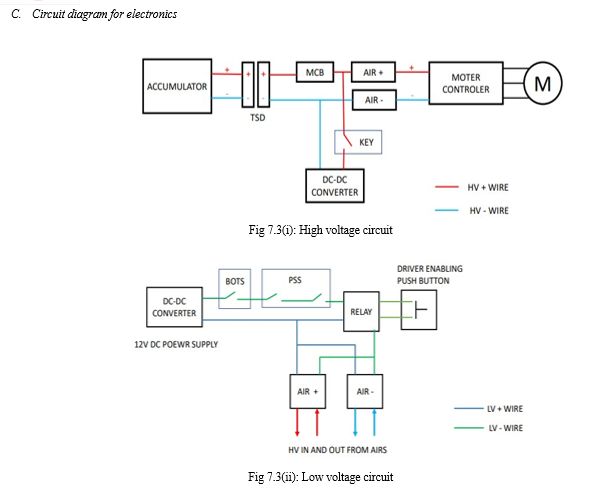

B. Powertrain Design

EVs have a single-speed transmission which sends power from the motor to the wheels. The motor is powered by a battery or by multiple batteries which store the electricity required to run an EV. The higher the kW of the battery, the higher the range.

We have used chain drive type Transmission Between motor and drive shaft.

The main advantage being its lightweight, highly efficient, low maintenance characteristics.

The E-power train system has the following objectives are:

- To have a combustion free vehicle.

- To have agility in the performance.

- To achieve flexibility on the road.

- Motor

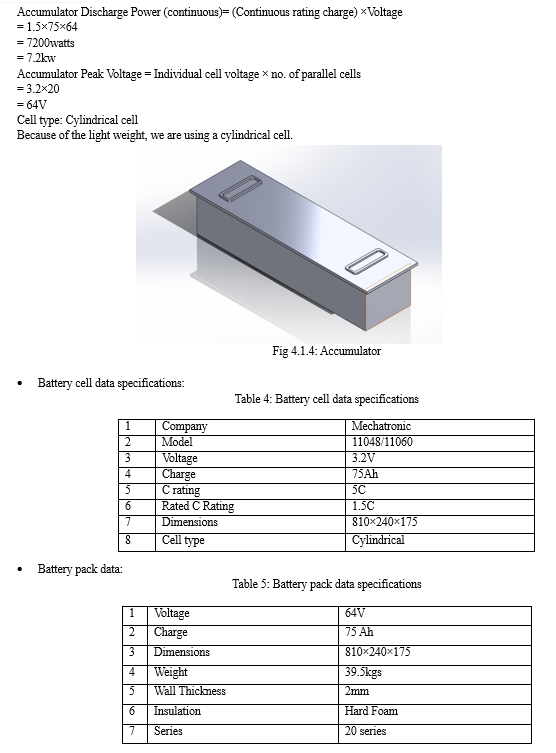

An electric motor is a device used to convert electrical energy into mechanical energy. Scientifically speaking, the electric motor is a unit used to convert electric power into motive energy or electrical energy into mechanical energy.

The most important feature of the Permanent Magnet Synchronous Motor (PMSM) is its high efficiency, given the ratio of input power after deduction of the loss to the input power. Permanent Magnet Synchronous Motors have the potential to provide high torque-to-current ratio, high power-to- weight ratio, high efficiency, and robustness. Due to the above favourable points, PMSMs are commonly used in latest variable speed AC drives, particularly in Electric Vehicle applications.

2. Accumulator

An accumulator is an energy storage device that accepts, stores, and releases energy as needed. Based on our requirements, we chose a 64V And 75 amps lithium-ion phosphate battery, which consists of 5 cells connected in parallel and 20 cells connected in series, where each cell has 3. 2volt.Dimensions of the Accumulator: 810×240×175mm.

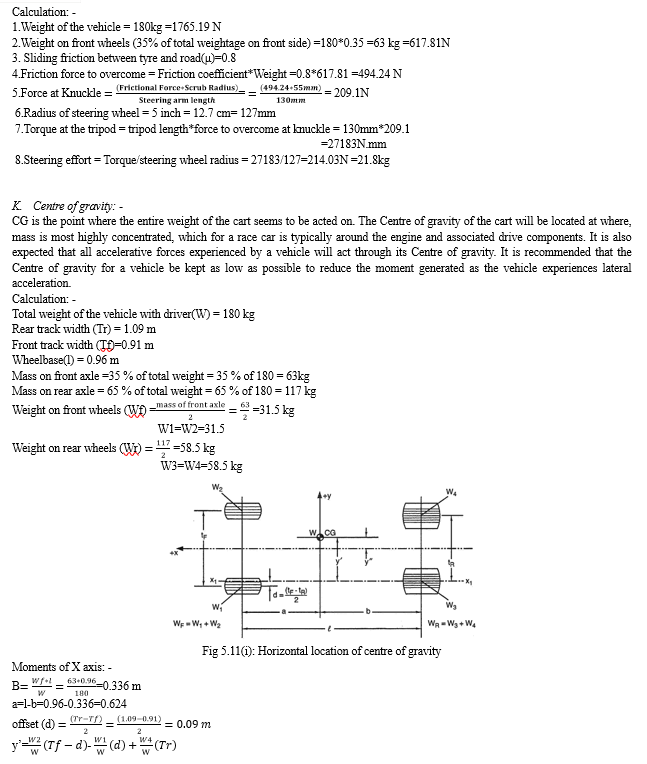

C. Vehicle Dynamics

Vehicle dynamics is the application of classical mechanics in physics to cars to predict and control motion. The understanding of various types of Forces, moments and their effects on the vehicle is a critical study to understand and predict the behaviour of the vehicle in dynamic conditions.

- Weight Distributionb And Balance

Weight distribution is the linchpin of kart dynamics. Achieving a harmonious distribution of weight among all four tires is essential for maintaining traction, reducing understeer or oversteer tendencies, and optimizing cornering performance. Inventions in chassis design allow for precise weight distribution adaptations to acclimatize to varying track conditions and motorist preferences.

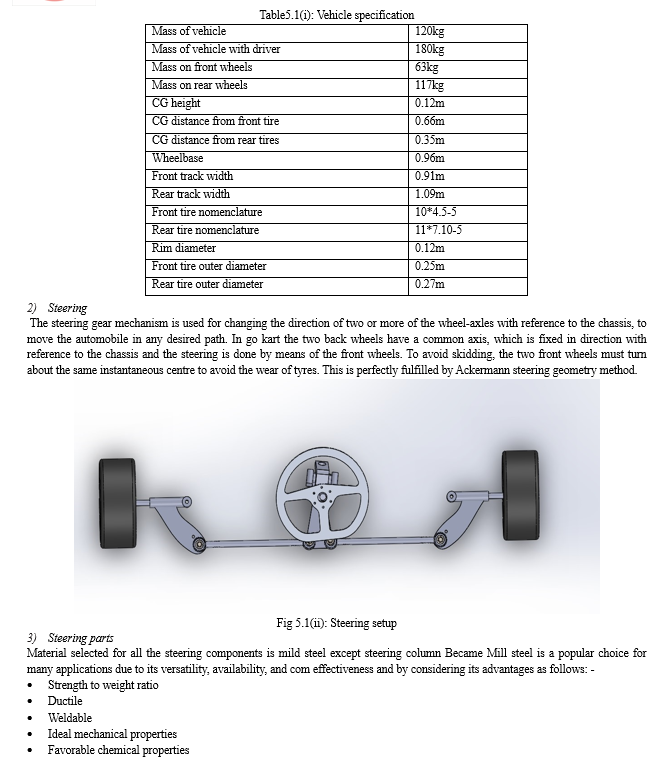

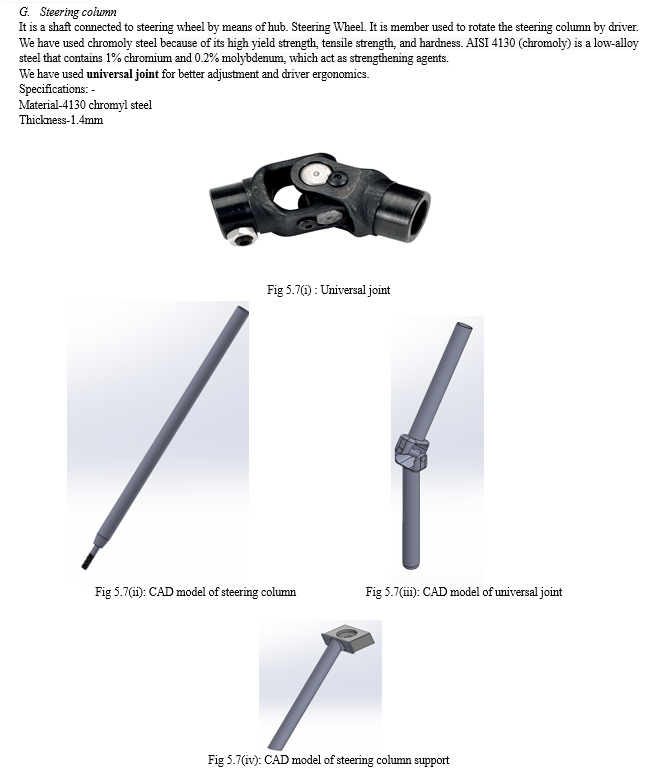

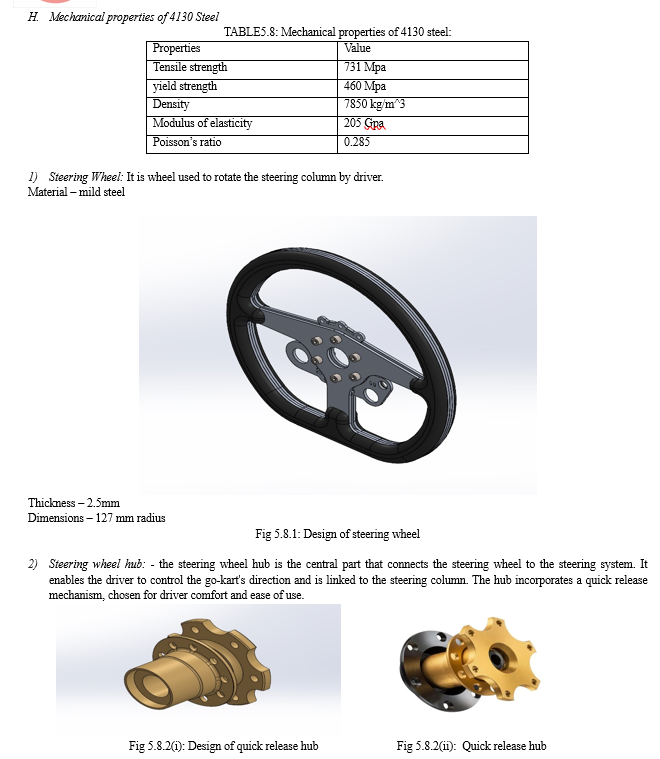

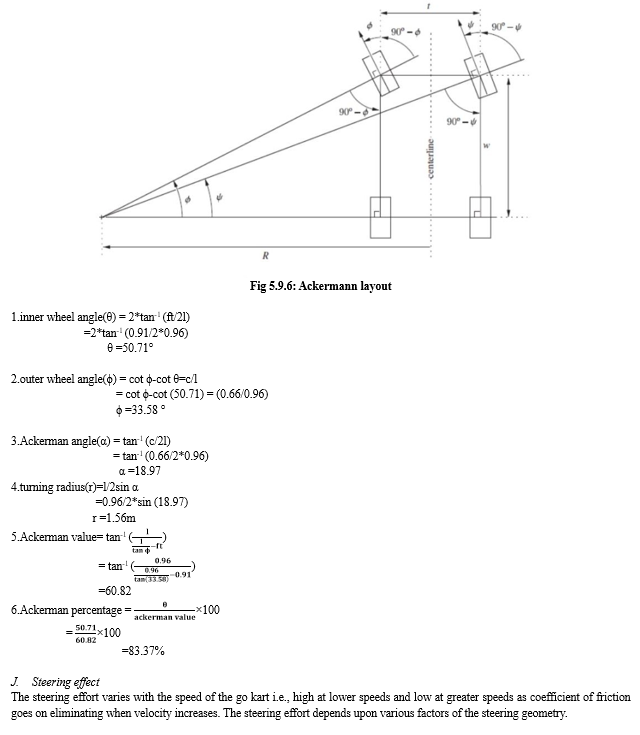

2. Steering

The steering gear mechanism is used for changing the direction of two or more of the wheel-axles with reference to the chassis, to move the automobile in any desired path. In go kart the two back wheels have a common axis, which is fixed in direction with reference to the chassis and the steering is done by means of the front wheels. To avoid skidding, the two front wheels must turn about the same instantaneous centre to avoid the wear of tyres. This is perfectly fulfilled by Ackermann steering geometry method.

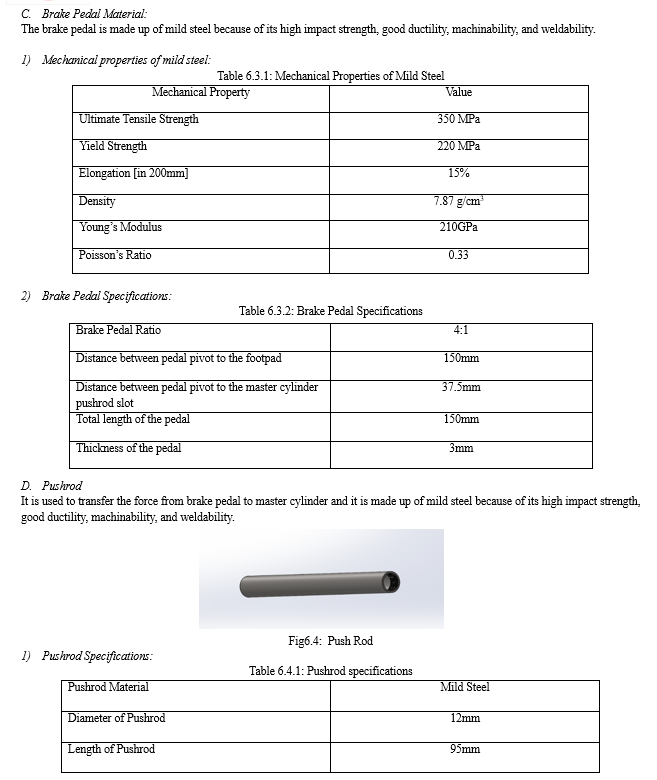

D. Braking System

Braking system helps slow down the rotation of the wheels when the brake pedal is pressed, ensuring a vehicle comes to deceleration. Brakes work on the principle of Pascal's law. According to this law when some pressure is applied on fluid it will travels uniformly in all the directions. when we apply some pressure on brake fluid it will transmit that pressure to the pistons of the calliper which actuate the brake pads which makes the disc to stop, so that the kart slow down.

II. LITERATURE REVIEW

- William F. Milliken and Douglas L. Milliken

Written for the engineer as well as the race car enthusiast, Race Car Vehicle Dynamics includes much information that is not available in any other vehicle dynamics text. Truly comprehensive in its coverage of the fundamental concepts of vehicle dynamics and their application in a racing environment, this book has become the definitive reference on this topic.

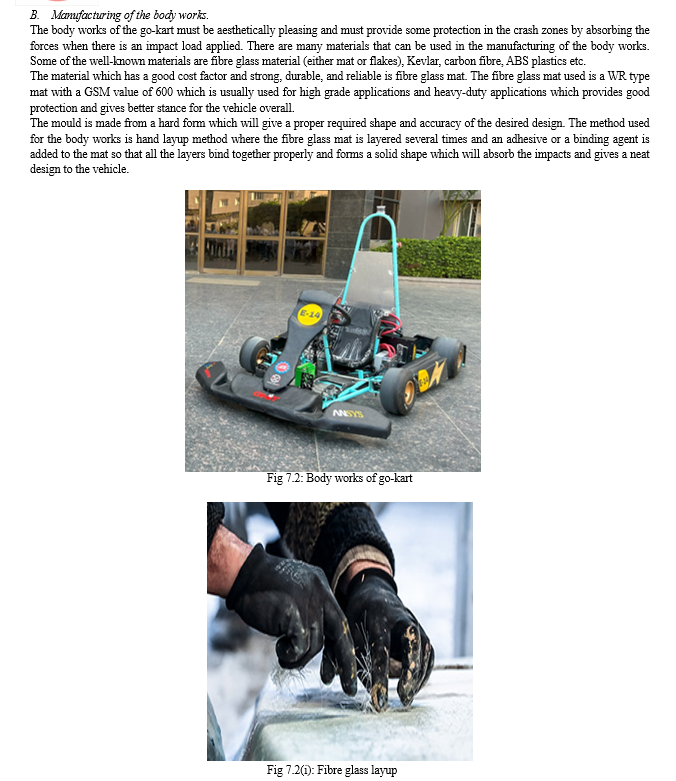

2. Dr. B. Vijaya Kumar

Tungsten Inert Gas (TIG) welding, a widely utilized fusion welding process, plays a pivotal role in various industrial sectors due to its ability to create high-quality welds. The mechanical properties of TIG-welded joints, such as hardness and tensile strength, are intricately linked to several key parameters: welding current, filler materials, groove design, and bead dimensions.

3. T.Z Quazi

Taking part in a run Over the last 50 times, go- kart racing has developed into one of the most competitive forms of motor racing in the United States. Kart racing has acted as a turning gravestone for numerous motorists seeking careers in NASCAR and Formula One; all began their careers in this less expensive but high- octane style of motorsports contending.

4. Koustubh Hajare, Yuvraj Shet

The drivers in these are very professionals and accurate. They can drive it very fast. But there are also motor sports which do not need professional drivers and need not much speed. The vehicles used are also fewer amounts Such a motor sport is Go-kart. They resemble to the formula one car, but it is not as fast as F1, and cost is very less. The drivers in go-kart are also not professionals.

5. Ammar Qamar Ul Hasan

A go-kart is a small four wheeled vehicle. Go-kart, by definition, has no suspension and no differential. 'Carting is commonly perceived as the stepping stone to the higher and more expensive ranks of motor sports. Kart racing is generally accepted as the most economic form of motor sport available.

6. Shubham Kolhe, Vrushabh U. Joijode

A Go Cart also spelled as Go-Kart is a four wheeled vehicle designed and meant for racing only. It is a small four-wheeler run by I.C Engine. It is a miniature of a racing car. This report documents the process and methodology to produce a low-cost go-kart.

7. Kiral Lal, Abhishek O S

The chassis is an extremely imported element of the kart, as it must provide, via flex, the equivalent of suspension to give good grip at the front. Karts have no suspension and are usually no bigger than is needed to mount a seat for the driver.

8. Prof. Alpesh V. Mehta

The fibre to take load in the form of a structural element, but the matrix phase only sustains small amount of applied load. In addition, beside the matrix material is ductile; it also protects the individual fibres from mechanical abrasion or chemical reaction with the environment which will cause surface damage.

9. Mat and Ghani's

This research is conducted in 2012 carried out a light chassis development for "Eco-Challenge" race cars that could safely withstand loads and compulsions. Chassis analysis was carried out by addressing normal carloads such as engine and driver weight, acceleration, braking and cornering forces.

10. Tsirogiannis E, Stavroulakis GE

In the 2019 study conducted by Tsirogiannis and his friends, an integrated methodology of developing an electric car chassis was demonstrated.

The main criteria for the development of the electric car chassis are the elimination of cost and time, as well as an increase in hardness and strength, which is subject to mass reducing.

11. Joel.Ja, Kalaiarassan Ga

A structurally balanced chassis was designed for an electric motorcycle in a 2018 study by Joel et al. simulated the real-time forces on the chassis and suspension geometries. Cost and weight of the chassis to determine the material most suitable for the chassis.

12. S. Arshibad

He went on to show that a vehicle's chassis is crucial to preserving its speed and performance, making it necessary to do static and dynamic analyses of go-kart chassis. Electric go-karts are replacing conventional go-karts due to all the benefits they provide, which include less pollution and environmental friendliness.

13. N.A.Z. Abdullah et al.

The model update approach is crucial for enhancing the dynamic features of the go-kart chassis structure. By handling the record of dynamic reactions from test structures to have an accurate model for any reenacted examination and limited component, they showed that model refreshing is concerned with the remedy of limited component models.

14. Santosh Kumar et al.

He comprised the study on the frame of go-karts; at times, researchers were concerned with material selection, simple structural analysis, safety, and structural stability. He offered a detailed examination of the systems used in a go kart, including the steering and braking, transmission and consideration fostering selection.

15. Mr. Nikunj (2011)

The fibre to take load in the form of a structural element, but the matrix phase only sustains small amount of applied load. In addition, beside the matrix material is ductile; it also protects the individual fibres from mechanical abrasion or chemical reaction with the environment which will cause surface damage.

16. Raghunanda, A. Pandiyan, Shajin Majeed,

The chassis material is considered depending upon the various factors such as maximum load capacity, absorption force capacity, strength, rigidity. The material selected for the chassis building is AISI 4130

17. Prof. Nirmal Chohaun

He written report on “DESIGN AND FABRICATION OF ELECTRIC GO-KART” published on IRJET. Year of publication: 15 SEP 2020. The goal of this report is to design and build a working model of an electric go-kart.

18. Karale, S. Thakre

The EV's chassis was designed and developed based on assumptions about the vehicle's gross weight for carrying a suitable size of sprayer attachment, considering the agronomical requirements of the field crops available in the region, and validated using the Finite Element Method (FEM) with ANSIS software.

19. Rahul Thavai, Quazi Shahezad

The chassis is made up of AISI-1018 which is a medium carbon steel. This material was selected due to its good Combination of all the typical traits of Steel – high tensile strength, ductility, light weight, better weldability, and comparative ease of machining.

20. Abhinay Nilawar, Harmeet Singh

The Go-kart, by definition, has no suspension and no differential. They are usually raced on scaled down tracks but are sometimes driven as entertainment or as a hobby by non-professionals.

21. P. Bhatt, Hemant Mehar

A comparison of the most common kinds of electric motors in use across time is offered, along with their efficiency, power density, reliability, and size. An article published by RATHEESH NAIR in Ev reporter-e-magazine on.

22. Babaarslan's

In 2014 study investigated the design and production of an optimal vehicle for an M1-class electric sports vehicle with the help of analyses and tests. This vehicle design is planned to be a faultless, world-class vehicle by carrying out production controls.

III. CHAPTER 3

A. Design Of Chassis

The chassis is made from a thick metal tube. The chassis type we used is a space frame which contains triangulation of tubes and forms nodes. The material used to make chassis is AISI 4130 graded steel which is also known as chromoly steel. And the chassis is held together by TIG welding by notching the edges of the tubes.

VIII. FUTURE SCOPE

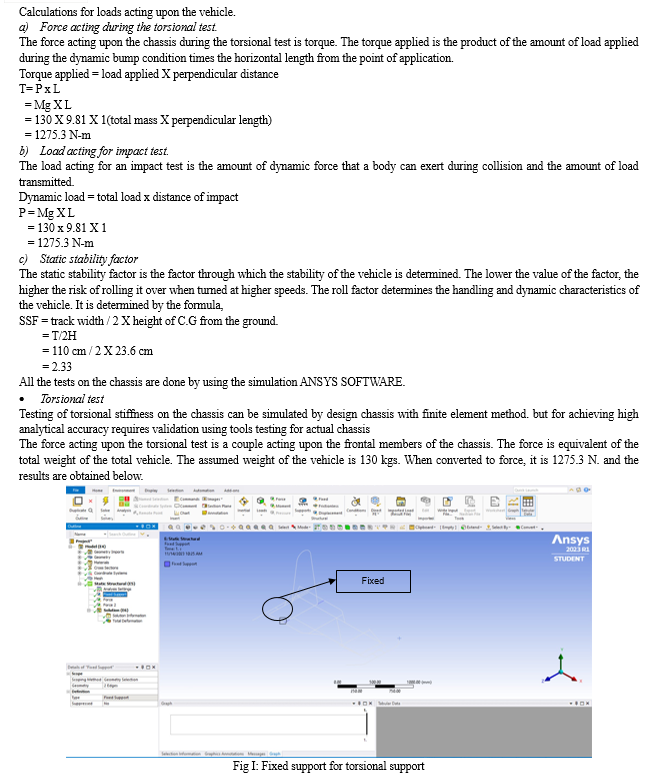

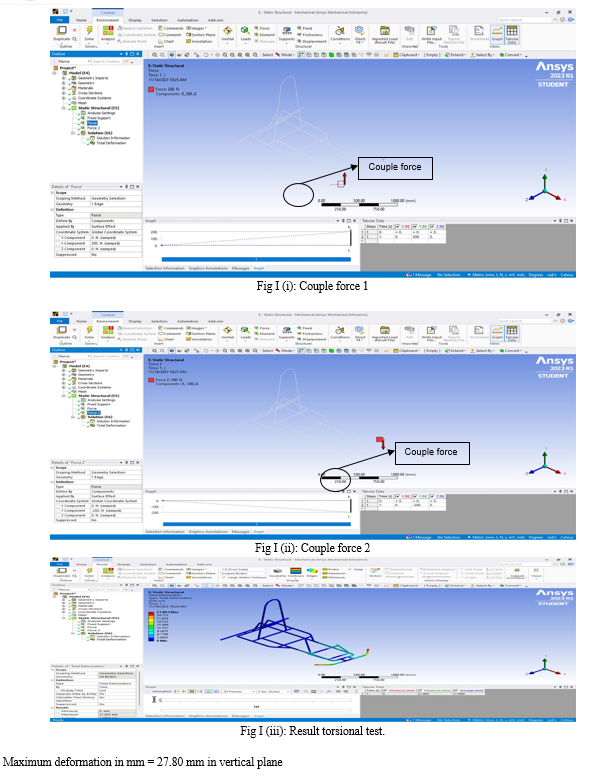

There are several factors to be considered that are common to all or any engineering vehicles. With an approach of engineers can come up with the most effective possible product for the society. The chosen design is the safest & the foremost reliable car for any racing vehicle. All the parameters like Reliability, safety, Cost, Performance, aesthetics, ergonomics, Standard dimensions & material were also taken in consideration on an equivalent time. Wherever possible finite element analysis was done on the regularly loaded parts & modifications were done accordingly to avoid any sort of design failure. The designing of Go-kart can develop many skills. The training of 3-D modelling software like Solid works is important to get desire design. The analysis of design determines the stresses developed within the chassis which plays a crucial role in factor safety. From the analysis we can predict the chassis is safe or not and by seeing the deformation and stresses modification within the kart chassis is feasible.

IX. ACKNOWLEDGMENT

We owe our immense thanks to Dr. B. VIJAYA KUMAR our guide, Professor and Head of the Mechanical Engineering, & COE Guru Nanak Institute of technology for the sustained interest, constructive criticism, and constant encouragement at every stage of this endeavour.

We extend our deep sense of graduate to Dr. B. VIJAYA KUMAR, Professor & Head of the Mechanical Department & COE.

We owe our immense thanks to Dr. S. SREENATHA REDDY, Principal and the management of the Guru Nanak Institute of Technology for providing us the best amenities which enabled us to complete our project in the stipulated time.

Finally, yet importantly, we are very thankful to our parents, friends, and other faculty of Mechanical Engineering department for their constant support in completion of this project.

Conclusion

Overall goals for the chassis included, increasing torsional rigidity and decrease weight, deformation. Chassis should perform at an optimum level. The results gained in this section show that the chassis will experience very minimal deflections under race conditions. This is also going to allow the chassis to perform at an optimum level in conjunction with the rest of the vehicle setup. Like any vehicle, the chassis is the backbone of the system. Every critical component relies on the chassis either directly or indirectly. The driver of the vehicle also relies on the chassis for protection in the event of an accident. This dissertation covers the procedures that were used to successfully design and construct a functional chassis.

References

[1] William F. Milliken and Douglas L. Milliken, “RACE CAR VEHICLE DYNAMICS\", Society of Automotive Engineers Inc., pg. 673-667, 1995. [2] Dr. B. Vijaya Kumar, Professor, Head of Mechanical Engineering & Coe Guru Nanak Institute of Technology, Hyderabad, Study of unique limitations on gas tungsten arc welding, https://scholar.google.com/citations?user=d5x1HjYAAAAJ [3] T. Z. Quazi, Omkar Jalvi, Sameer Shinde, Rohan Kamble, Tushar Sargar, “A Review on Design and Analysis of Go-kart Chassis”, IJRESM, Volume-1, Issue-10, October-2018, ISSN: 2581-5782. [4] Koustubh Hajare, Yuvraj Shet, Ankush Khot,“A Review paper on Design and Analysis of a Go-kart Chassis”, IJETMAS, February 2016, Volume 4, Issue 2, ISSN: 2349-4476. [5] Ammar Qamar Ul Hasan, \"SIMULATION OF ATV ROLL CAGE TESTING\", IOSR-JMCE, ISSN: 2278-1684, P-ISSN: 2320-334x, Volume 12. Issue 3 Ver. li, Pp 45-49, May. Jun. 2015 [6] Shubham Kolhe, Vrushabh U. Joijode, \"ROLL CAGE DESIGN AND ANALYSIS FOR FORMULA STUDENT RACE CAR\", IJESRT, ISSN: 2277- 9655, July 2016. [7] Kiral Lal, Abhishek O S, Design, Analysis and Fabrication Of Go-Kart, International Journal of Scientific & Engineering Research, Volume 7. Issue 4, ISSN 2229-5518, April-2016. [8] Prof. Alpesh V. Mehta, Mr. Nikunj Padhiar, Mr.Jaydip Mendapara, Design and Analysis of Hybrid Go-Kart, International Journal of Advanced Engineering Technology, Vol 2, Issue 1, E-ISSN 0976-3945, /January-March 2011 [9] Mat MH and Ghani ARA. Design and analysis of ‘ECO’ car chassis. International Symposium on Robotics and Intelligent Sensors (IRIS 2012), Procedia Engineering 2012 41: 1756-1760. doi: 10.1016/j.proeng.2012.07.379 [10] Tsirogiannis E, Stavroulakis GE and Makridis SS. Electric car chassis for shell eco marathon competition: design, modelling and finite element analysis, World Electric Vehicle Journal.2019;10(1) 8 21. doi:10.3390/wevj10010008 [11] Jeyapandiarajan Pa, Kalaiarassan Ga, Joel.Ja et al. Design and analysis of chassis for an electric motorcycle. Materials Today: Proceedings 2018;5(5):13563–13573 [12] Ashirbad sahu, Manas Ranjan Panda, Mahendra Khara, Soumya Ranjan Senapati, Samika Parida, Bijaya Rao (2020) Design and Analysis of Electric Go-Kart Chassis Journal of Xi\'an University of Architecture & Technology Volume XII, Issue III, pp 4739 [13] N.A.Z. Abdullah, M.S.M. Sani, N.A. Husain, M.M. Rahman and 1. Zaman (2017) Dynamics properties of a Go-kart chassis structure and its prediction using model approach Journal of Automotive and Mechanical Engineering Volume 14, Issue 1 pp 3887-3897 https://doi.org/10.15282/ijame.14.1.2017.6.0316 [14] R. Santosh Kumar, R. Rohith, S. Srinivas (2019) Design of a compact go kart vehicle International Research Journal of Engineering and Technology (IRJET) Volume 06, Issue 09 hjdghf. [15] Mr. Nikunj (2011), Mr.Jaydip Mendapara, Design and Analysis of Hybrid Go-Kart, International Journal of Advanced Engineering Technology, Vol 2, Issue 1, E-ISSN 0976-3945, /January-March 2011 [16] D. Raghunanda, A. Pandiyan, Shajin Majeed, \"Design and Analysis of Go-Kart Chassis\"International Journal Of Engineering Sciences & Research Technology November,2016, Issn:2277-9655. [17] Prof. Nirmal Chohaun has written report on “DESIGN AND FABRICATION OF ELECTRIC GO-KART” published on researchgate.com. [18] D. Karale, S. Thakre, M. Deshmukh “DESIGN AND ANALYSIS OF ELECTRIC VEHICLE”, IJOI vol.4, 1 OCT 2020. [19] Rahul Thavai, Quazi Shahezad, Mirza Shahrukh, Mukri Arman, Khan Imran, “STATIC ANALYSIS OF GO-KART CHASSIS BY ANALYTICAL AND SOLID WORKS SIMULATION”, IJMER, ISSN: 2249–6645, Vol. 5, Issue 4, Apr. 2015. [20] Abhinay Nilawar, Harmeet Singh Nannade, Amey Pohankar, Nikhil Selokar, “DESIGN OF GO-KART”, Maharashtra, India, IJFEAT, ISSN: 2321-8134. [21] “Electrical Motors for Electric Vehicle – A Comparative Study” by P. Bhatt, Hemant Mehar, M. Sahajwani published on SSRN Electronic Journal, 3 April 2019. [22] Babaarslan N. A new chassis design and manufacture for the M1 category electric sports vehicle. (Master\'s thesis). Hacettepe University, Mechanical Engineering Department Ankara, Turkey, 2014

Copyright

Copyright © 2024 Kalam Tharun Reddy , Kotamarthy Sai Vishnu Teja , Pathireddy Kowshik Reddy, Shivarathri Hemanth Babu, Dr. B. Vijaya Kumar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET61034

Publish Date : 2024-04-26

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online