Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and Simulation of Robot Gripper and Conveyor System for Workstations

Authors: Anjaiah Madarapu, Jai Sai Ganesh Singh Rajaputra, Tirupati Sai Hitesh, Yadavalli Phani Bhaskar

DOI Link: https://doi.org/10.22214/ijraset.2023.56055

Certificate: View Certificate

Abstract

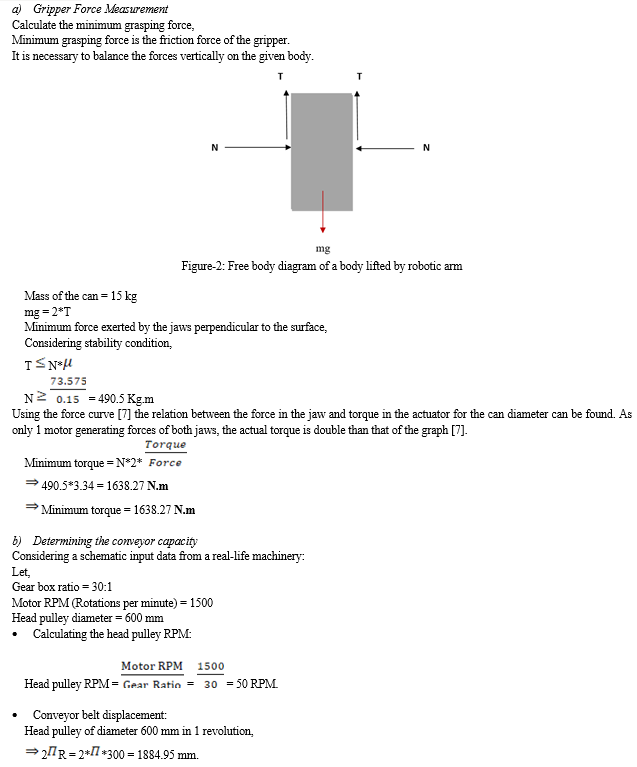

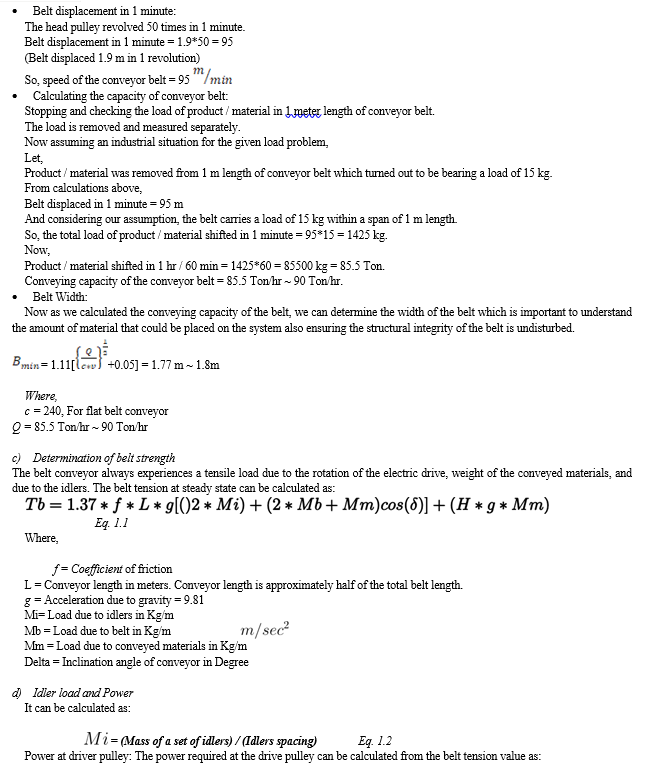

Intelligent manufacturing is going to boom in the upcoming years. The characteristic features of Industry 4.0 are fully automated production facilities where all processes are controlled in real-time and take into account the changing external conditions. The core of the Industry 4.0 is made up of digitalization and robotics, in particular, the use of collaborative robots and MES. MES (Manufacturing Execution System) is a specialized system designed to solve the problems of synchronization, coordination, analysis, and optimization of production. It involves the use of conveyor belts for rapid transportation of products. Industries where conveyor belt systems are excelling include automotive, computer, good, packaging, print finishing, bottling and canning, chemical, pharmaceutical, aerospace and food processing The safety conditions in fundamental industrial jobs are dangerous and harmful combined with ineffective manual work as a result of rising need for mass manufacturing. In industries, automation is the use of technology to jobs that were previously handled by humans. It is a potent instrument that can aid companies in enhancing quality, production, and efficiency. A typical type of mechanical handling equipment that transports things from one place to another is a conveyor system. These systems consist of conveyor belts that are designed to work seamlessly with robotic arms and other automated equipment. Increased automation and mass production rate reduces the lead time and increases the profit of a firm. The deployed robotic arms are immensely capable of handling various tasks with increased flexibility. Using a robotic arm with an end effector as a gripper to hold/pick and place the material from the conveyor belt improves the product flow process. The project comes with the NodeMCU firmware and an integrated Wi-Fi chip, the ESP8266 12E. To connect with the controller via a mobile phone, a web page would be constructed using HTML and coded using the Arduino IDE\\\'s C language. At either end of the conveyor belt, 2 robotic arms with 2 degrees of freedom (D.O.F.) would be placed. Using one arm to place the product on the belt and a second to pick it up at the other end. Also calculating the analytical data of the system that is involved in real-life industrial processes along with the simulation of entire system for the UR10 industrial robot, using the RoboDK simulation software. Through the usage of this system, productivity is boosted with improved safety of the working environment, become more effective, be more flexible, and have higher levels of job satisfaction.

Introduction

I. INTRODUCTION

Automated systems can operate more quickly and accurately. Automation in the workplace refers to the control of robotic equipment, computers, and software. Automation systems typically include sensor software and feedback loops that can manually alter activities to achieve a desired result, compared to human employees. Since a robot can accomplish a task for less money than human labour and will perform better once it has been programmed, robotics has become more important in the modern day. Today's industry is moving towards computer-based job monitoring, mostly because it needs to boost productivity and produce final goods of the highest quality. Automation is currently a widespread term for the use of robotics and machines to reduce or replace previously performed work by employees. But there are other ways that automation works in the manufacturing sector besides robotics. Robotics, such as three- or six-axis robotic arms, can be used for material handling and pick-and-place activities, completing them more rapidly and efficiently than through labour alone. These industrial robotic applications can improve high-volume, repetitive tasks like putting an item on a conveyor belt and lifting big things. Controls engineers can program robotics to always execute the same task in the same way, or they can train them to be more adaptive using more advanced technology.

The material handling system is a subject on which many industrialists and academic experts have conducted research, and it has always been an intriguing one to think about.

The ESP8266 12E Wi-Fi chip and NodeMCU firmware are both included with the project. An HTML- and C-coded web page would be created in order to establish a connection with the controller via a mobile device. Two robotic arms with two degrees of freedom (D.O.F.) would be mounted at either end of the conveyor belt. putting the item on the belt with one arm and picking it up with the other. Using the RoboDK simulation programme, the UR10 industrial robot's full system is simulated, including with the analytical data of the system that is involved in actual industrial processes.

II. LITERATURE REVIEW

Priyambada Mishra et al. [15] - In this paper, they employed four servo motors to create the robotic arm's joints, and a potentiometer has been used to govern movement. The used controller is UNO Arduino. The Potentiometer received the analogue input signals from the Arduinos. Cardboard was used to construct the arm, and each component is fastened to the appropriate servo motor. The arm was designed primarily to pick up and set down light objects. When programming, Arduino 1.6.10 was used.

Thus, the paper's main focus is on building a robotic arm out of ineffective materials and using it for productive goals such as lifting objects.

Puran Singh et al. [16] – In this paper, gripper had been employed in the robotic arm's two degrees of freedom, which was used for spot welding. An arrangement of spur gears, threaded shafts, and an AC motor made the end effector.

End effectors were employed in the end effector assembly, one of which was permanent and the other of which was moveable, at the wrist and end effector assembly points.

The center of mass for each linkage in the robotic arm's two D.O.F., which execute the lifting function, was acting at half of its length. The robotic arm could be arranged in a variety of ways, so the maximum rotation of each joint is 180 degrees.

This project helped in increasing the productivity of spot welding with its end effector as a 2 DOF robotic arm.

V. K. Banga et al. [17] – In this paper, a 4 DOF robotic arm with flexible joints that uses soft computing has been employed and developed the techniques for robotic mobility that is under control. With the use of fuzzy logic (FL) and genetic algorithms (GAs), arm and trajectory planning. The architectural design is employed to reduce problems with component motion, friction, and settling time in robotic arms. For this four D.O.F. robotic system, the best joint angles are discovered using genetic optimization.

Thus, the lengthy process of trial and error in search of a better combination of joint angles, which are legitimate according to inverse kinematics for robotic arm movement, has been replaced by this kind of optimization.

Anughna N et al. [18] - This paper used an Arduino Atmega328 controller and accelerometers. Flex and gyro sensors track the movements of the human arm and send signals to the Arduino ATmega328, which in turn manages the servo motors and causes the arm to move. Near the fingers were the Flex and Gyro Sensors.

The controller processes the data from both sensors if a change is noticed.

The paper's future work would use more gyros and up to five flex sensors close to the fingers for the simplest operation feasible.

Shamsheer Verma [19] – This paper involves a manipulator with 3 DOF that could be operated with hand motions was created. A glove serves as a transmitter, while a robotic arm serves as a receiver that responds to signals from the transmitter. The hardware in the glove is made up of an Arduino Mega 2560, which is programmed to send and receive data from the robotic arm through an APC220 Module. The hand is assigned three angles, alpha, beta, and gamma. The gyroscope and accelerometer take care of these, as well as the acceleration in the three directions, by delivering the signal to the Arduino Mega by wires, where all the information is combined and analyzed. Additionally, the signals for the movement were sent using a flex sensor.

This project can be used in the remote sensing and signals processing applications.

T. Sunil Kumar et al. [20] – This paper involves servos that were used to power the joints in the robotic arm, resulting in a manipulator with increased accuracy. CATIA software has been used to design the robotic arm. The method for choosing the servos used to drive each joint of the arm is covered in detail in the project.

In the project, the torque acting at each of the joints have been calculated, and a servo with the necessary torque rating has been chosen for each joint. Microsoft's programming language is used to construct the robotic arm's control software and choose an appropriate servo controller.

Rahul Kumar et al. [21] – In this paper, two classifiers for object recognition and detection, as well as the modelling and implementation of the feature extraction approach have been used. Making the test subjects comply with the classifier parameters was the main difficulty in designing the image processing system, as scaling the photos resulted in the loss of pixel data. A centered image approach method was therefore used. The techniques for feature extraction and classification are also covered in the work.

The paper discusses object position determination in further detail and shows all of the outcomes obtained during algorithm development.

R?ducan Elena et al. [22] – This paper presents a speed regulation method of a conveyor system from sintering process. The method consists in developing a mathematical model based on the temperature difference between different measuring points situated along the sintering bed. The adjustment of the model was made on site taking into consideration the temperature limits in order to not cause any major damage to the equipment or to endanger the whole process. The algorithm was developed by using real data and the model was simulated using Maple. After the simulation, an approximation of the complete combustion for the raw material was estimated and the automated speed regulated of the belt conveyor was resulting by using the Lagrange interpolation method.

Following the implementation of the mathematical model in the PLC, the speed of the machine changes automatically based on the process temperatures. The sintering process it is followed better and there is not major fluctuation in operation, as in manual mode.

Considering the outcome of the paper, it can be state that for the most efficient positioning of BTP in sintering process the data from the carbon monoxide analyzer are very important.

Jacob Nichols Cook et al. [23] – This paper involves facile fabrication strategy by 3D-printing thermoplastic polyurethane (TPU) employed to fabricate the soft tri-gripper consisting of 9 capacitive tactile sensor-laden phalanges. The 3D-printed TPU itself was used as a sensory dielectric for the fabricated tri-gripper. The sensor and interconnect electrodes have been designed to have minimum cross-sensor capacitive coupling with stretchable interconnects to ensure robust integration. The designed sensors were patterned as copper electrodes on top of flexible polyimide film and embedded within the gripper during the 3D-printing process.

In conclusion, a sensor-array laden soft gripper that can be used to lift and grasp delicate objects has been developed. A representative tactile sensor in the sensor array exhibited a non-linear characteristic with a maximum sensitivity of 2.87%/kPa.

Andrija Milojevi? et al. [24] - This paper presents a further investigation of a novel adaptive soft robotic gripper with integrated active elements, i.e., sensors and actuators. In many contemporary robotic applications, there is a great need to grasp differently shaped and sized objects as well as objects of different stiffness or soft objects. Sensors are formed by using conductive graphite foam. The machine learning models of tactile foam sensors are presented. Actuators are formed by using a shape memory alloy wire nitinol.

In this paper, it is demonstrated that the developed soft gripper concept with integrated active elements can realize multiple grasping patterns. Many potential applications in robotics are foreseen for the novel smart adaptive gripper.

Sandro G.A. Sobreira et al. [25] – This work proposes the development of machine-learning techniques to estimate the mass flow of ore in a conveyor belt that is not equipped with a belt weigher. The virtual sensors were designed using current, torque, and motor speed data from a conveyor belt and iron ore flow measurements from a belt weigher installed on a different conveyor. Two of the proposed virtual sensors were implemented in a programmable logic controller of a belt conveyor in a mining area, where it was possible to verify the performance of the virtual sensors in a real situation. As a result, the proposed virtual sensors were able to measure the ore flow with an acceptable error rate compared to a physical belt weigher. The accounting of the production of the proposed sensors also proved to be close to the total production accounted for the physical belt weigher.

The work showed the development of virtual sensors, using machine-learning techniques, which could estimate the mass flow of ore in a belt conveyor that is not equipped with a belt weigher.

Yunfeng Ni et al. [26] – This paper involves a new energy saving control method of belt conveyor based on fuzzy algorithm is proposed. This method analyzes the composition and structure of the control system for belt conveyor, selects frequency control method to reducing energy consumption, at the same time, matches belt conveyor speed and transportation capacity. On the basis of the above, through the formula of speed of induction motor, combined with fuzzy algorithm, energy saving control System of mine belt conveyors is completed.

The simulation results show that the proposed method can effectively match speed and transportation capacity of the belt conveyor and reduce speed of the belt conveyor and energy consumption. The maximum economize energy is thirty percent. The practical application shows that this method has a certain effect of energy saving.

Vladislav Ivanov et al. [27] – This work focuses on developing a self-learning robotic system which can replicate the human learning capabilities in a handing-over task. The proposed system consists of two submodules Vision analysis and environment monitoring, which provides accurate global and local information about the area in which the robot has to hand over the specific object Safe and flexible bin-picking gripper, which handles various objects with complex geometries.

Fredrik Ore et al. [28] - This research proposes a HIRC workstation design process. The novelty of this design process is the methodology to evaluate the HIRC workstation design alternatives by considering both performance and safety characteristics through computer-based simulations. As a proof of concept, the proposed HIRC design process is applied on an industrial manufacturing case from a heavy-vehicle manufacturing company.

The research concerns human–industrial robot collaboration (HIRC) in manufacturing industry. Although this concept is very promising in terms of productivity and profitability, industrial practitioners currently have many apprehensions regarding its applicability in an industrial context, especially due to human safety considerations. In order to address this, several simulation-based methodologies have been presented in the literature to evaluate HIRC workstation design characteristics.

III. METHODOLOGY

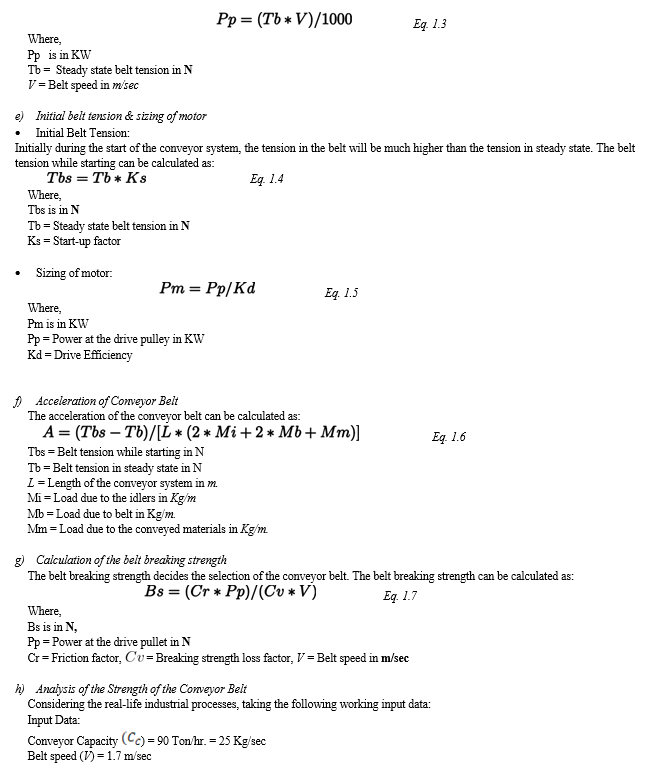

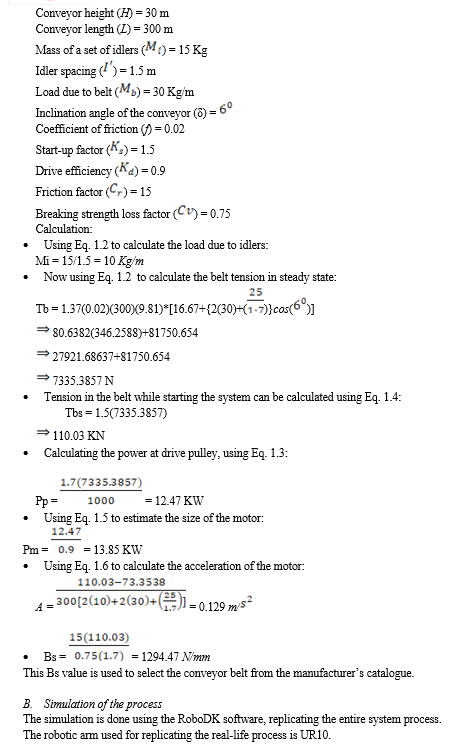

To understand the requirement for necessary needs, the design of gripper along with the conveyor system has been done.

Proper design values of gripper and conveyor are important to ensure whether the system meets our needs such as the capacity / amount of product to be transported in 1 hour, the load to be lifted by the gripper etc.

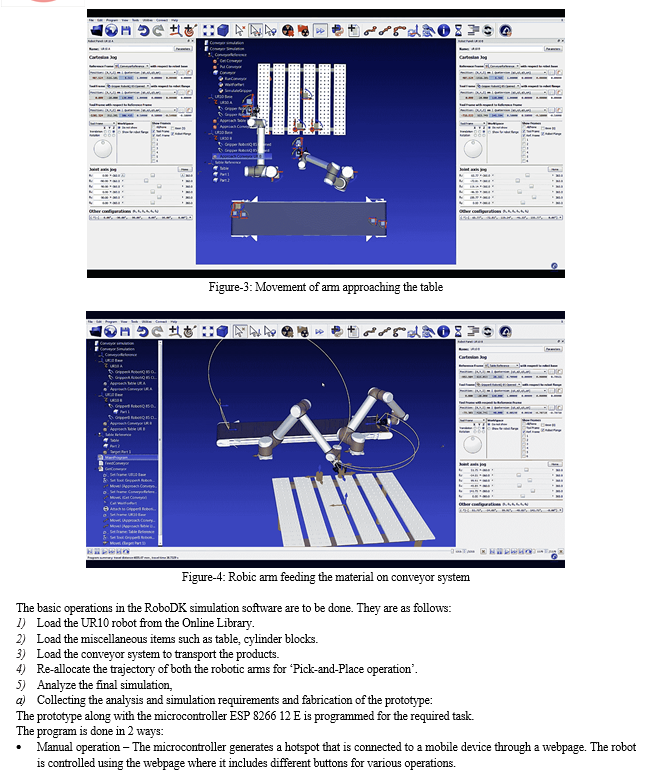

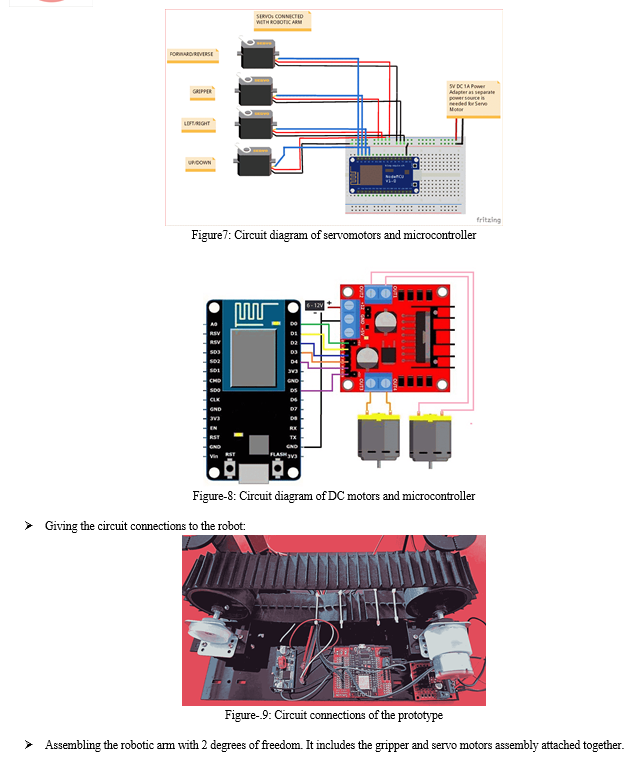

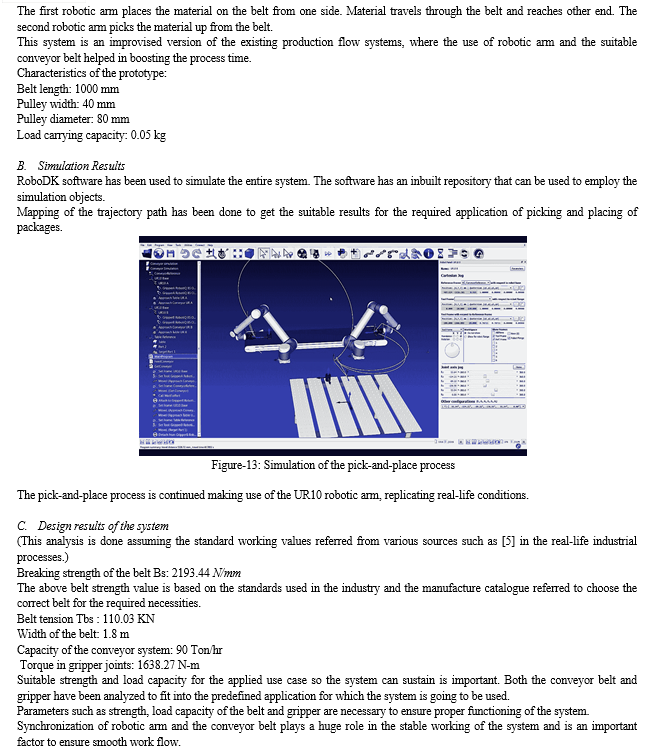

After the design of gripper and conveyor, to integrate both together, a simulation of the real-time industrial process has been created for the UR10 industrial robot using the RoboDK software.

The simulation created is to visualize the real industrial process and for the path planning of the trajectory of the UR10 industrial robot.

A prototype of the similar system has been created using the microcontroller NodeMCU ESP8266 12 E.

The project involves wide arena of details as mentioned below:

The required outcome has been achieved as the designed system completes the assigned task the way it is supposed to be. This in-turn has the potential to increase the production flow.

Prototype has been created to replicate the process using ESP8266 12 E microcontroller. It is a model of the designed system and is capable of transporting small volumes of material.

Similar type of design can be modified to match the requirements of a different problem such as different loads, different objectives with the end effector such as welding etc.

Above discussed process can be applied in various real-time processing and product flow applications such as –

- Package delivery through E-commerce industries such as Amazon.

- Production flow system of pharmacy industries, milk production industries etc.

- Automobile industries

- Food processing industries etc.

Conclusion

1) The project employs the use of conveyor system and a robotic arm with a gripper as an end effector. This system is useful in industries as more effective equivalent of a human hand. Robotic arm use in manufacturing decreases production process delays and aids in task completion more quickly and effectively. The processes can be completed faster than a manual process. 2) The project includes an amalgamation of software (where the programming of the robot has been used), hardware (development of the prototype), simulation (that has been done using the RoboDK software for the UR10 robot) and design construction characteristics, integrating all the major necessities in the design of an industrial automated processing system. 3) This attempt has been made to bring out the result-oriented approach in the project, a model has been prototyped that can run using the microcontroller NodeMCU ESP 8266 12 E. This concept can be scaled-up to industrial standards to adjust to larger domain of works, such as packaging or storage industries that employ such systems to boost the process.

References

[1] S. M Automated Pick And Throw Robotic Arm From Conveyer Belt – IRJET; Volume: 07 Issue: 06 , June 2020, e-ISSN: 2395-0056. [2] Pick and Place Robotic ARM using PLC – IRJET; Vol. 8 Issue 08, August-2019, ISSN: 2278-0181. [3] Arduino Based Product Sorting Machine – Hirode Baswa Raj, Dr. K. Sudhakar Reddy; Vol 11, Issue 1, JAN/2020, ISSN NO:0377-9254 [4] Experimental investigation of speed checker monitoring system for conveyor using microcontroller - Siti Khadijah Idris, Hazura Haroon, Hanim Abdul Razak, Muhammad Shahriezan Omar; Proceedings of Mechanical Engineering Research Day 2020, pp. 194-196, December 2020. [5] Design of a Belt Conveyor for iron ore - Pelayo López García; Ljubljana, June 2016. [6] Conveyor Belt Technique. Dunlop-Enerka b.v [7] Takashi Yoshimi, Naoyuki Iwata, Makoto Mizukawa and Yoshinobu Ando, Member, IEEE,” Picking up Operation of Thin Objects by Robot Arm with Two-Fingered Parallel Soft Gripper”, Proceedings of the 2012 IEEE International Workshop on Advanced Robotics and its Social Impacts, Technische Universität München, Munich, Germany, May 21 - 23, 2012. [8] Anusha Ronanki , M. Kranthi,”Design and Fabrication of Pick and Place Robot to Be Used in Library”, International Journal of Innovative Research in Science, Engineering and Technology (An ISO 3297: 2007 Certified Organization) Vol. 4, Issue 6, June 2015. [9] Design and Fabrication of Pick and Place Robot to Be Used in Library Anusha Ronanki. Vol. 4, Issue 6, June 2015 [5] Design Analysis of a Remote Controlled Pick and Place Robotic Vehicle B.O. Omijeh, RUhunmwangho and M Ehikhamenle, Volume 10, Issue 5 May 2014. [10] Object detection and recognition for a pick and place Robot by Rahul Kumar ; Sunil Lal ; Sanjesh Kumar ; Praneel Chand published in Asia-Pacific World Congress on Computer Science and Engineering. [11] Pang, Y., & Lodewijks, G. (2006, June). A novel embedded conductive detection system for intelligent conveyor belt monitoring. In 2006 IEEE International Conference on Service Operations and Logistics, and Informatics (pp. 803-808). [12] Salawu, G., Bright, G., & Onunka, C. (2020). Modelling and simulation of a conveyor belt system for optimal productivity. International Journal of Mechanical Engineering and Technology, 1(11), 115-121. [13] People in Control: An International Conference on Human Interfaces in Control Rooms, Cockpits and Command Centers 21 - 23 June 1999, Conference Publication No. 463, O IEE, 1999. [14] Tabisz, Jovanic, & Lee,; \\\"Present and Future of Distributed Power Systems,\\\" APEC Proceedings, February 1992. [15] Priyambada Mishra, Riki Patel, Trushit Upadhyaya, Arpan Desai “Review of Development Of Robotic Arm Using Arduino UNO”, International Journal on Recent Researches in Science, Engineering and Technology, ISSN: 2348-3105 Volume 5, Issue 5, May 2017. [16] Puran Singh, Anil Kumar, Mahesh Vashishth “Design of Robotic Arm with Gripper and End effector for spot welding”, Universal Journal of Mechanical Engineering 1(3); 92-97, 2013, DOI: 10.13189/ujme,2013.010303 [17] V. K. Banga, Jasjit Kaur, R. Kumar, Y. Singh “Modeling and Simulation of Robotic Arm Movement using Soft Computing”, International Journal of Mechanical And Mechatronics Engineering, Vol:5, No:3,2011 [18] Anughna N, Ranjitha V, Tanuja G “Design and Implementation of Wireless Robotic Arm Model using Flex and Gyro Sensor”, International Journal of Recent Technology and Engineering (IJRTE) ISSN: 2277-3878, Volume-8 Issue-5, January 2020. [19] Shamsheer Verma “Hand Gestures Remote Controlled Robotic Arm”, Advance in Electronic and Electric Engineering. ISSN 2231-1297, Volume 3, Number 5 (2013), pp. 601-606. [20] Dr.T.Sunil kumar, K.sarath, Sd.Famil, A.V.S.Bhagyesh and Sk.Althaf “Design and fabrication of pick and place robotic arm”, 2nd National Conference on Recent Trends in Mechanical Engineering, GIST, Nellore. Conference Paper · August 2020. [21] Rahul Kumar, Sunil Lal, Sanjesh Kumar and Praneel Chand “Object Detection and Recognition for a Pick and Place Robot”. [22] R?ducan Elena, Viorel Nicolau, Nov?cescu Andreea “Aspects of modeling and speed control of belt conveyors in sintering processes” - 2020 7th International Conference on Control, Decision and Information Technologies (CoDIT’20) | Prague, Czech Republic / June 29 - July 2, 2020. [23] Jacob Nichols Cook, Abhishek Sabarwal, Harley Clewer, William Navaraj “Tactile sensor array laden 3D-printed soft robotic gripper” - 978-1-7281-6801-2/20/$31.00 ©2020 IEEE. [24] Andrija Milojevi?, Heikki Handroos, Miša Tomi?, Žarko ?ojbaši? “Novel Smart and Compliant Robotic Gripper: Design, Modelling, Experiments and Control” - 978-1-5386-9301-8/19/$31.00 ©2019 IEEE. [25] Sandro G. A. Sobreira; Pedro H. Gomes; Geraldo P. Rocha Filho; Gustavo Pessin “A Data-Driven Soft Sensor for Mass Flow Estimation” – IEEE Sensors Journal, Published: 2021, Volume 72, Article Sequence Number: 2515309, DOI: 10.1109/TIM.2023.3273658. [26] Yunfeng Ni; Li Chen “Research of energy saving control System of Mine belt conveyors” - IEEE Transactions on Intelligent Transportation Systems; Published: 2020, DOI: 10.1109/ICITBS53129.2021.00147, Published in: 2021 International Conference on Intelligent Transportation, Big Data & Smart City (ICITBS). [27] Vladislav Ivanov; Angel Aleksandrov; Mohamad Bdiwi; Aleksander Popov; Aquib Rashid, Zhanna Pershina, , Aleksey Kolker, Lubomir Dimitrov – “Bin Picking Pneumatic-Mechanical Gripper for Industrial Manipulators” - IEEE Robotics and Automation Letters, Published: 2023, Published in: 2021 IV International Conference on High Technology for Sustainable Development (HiTech), DOI: 10.1109/HiTech53072.2021.9614215. [28] Fredrik Ore, Bhanoday Vemula, Lars Hanson, Magnus Wiktorsson & Björn Fagerström – “Simulation methodology for performance and safety evaluation of human–industrial robot collaboration workstation design” - International Journal of Intelligent Robotics and Applications volume 3, pages269–282 (2019).

Copyright

Copyright © 2023 Anjaiah Madarapu, Jai Sai Ganesh Singh Rajaputra, Tirupati Sai Hitesh, Yadavalli Phani Bhaskar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET56055

Publish Date : 2023-10-08

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online