Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design of Castellated Column in Finite Element Analysis

Authors: Tejaswini C. Patil, Prof. S. S. Mohite, Prof. V. M. Patil

DOI Link: https://doi.org/10.22214/ijraset.2023.48957

Certificate: View Certificate

Abstract

Castellated columns have been utilised extensively in steel constructions and structures. When compared to conventional I-section structural components, castellated structural components have a greater capacity for bending along their primary axes and can withstand greater flexural buckling. With the aid of FE analysis, the study sought to examine the strength and buckle behaviour of axially loaded tapered castellated cruciform steel columns. Although there is a sizable amount of study on the failure of various columns, no suitable standard has been developed to recognize the point of buckling in the equilibrium path of a deficient column. The analysis discussed in this manuscript takes into description a multiplicity of useful geometric dimensions and fix to fix ends conditions by the application of ABAQUS softwares

Introduction

I. INTRODUCTION

A cellular column's larger group of steel sections is with web apertures results in a higher moment of inertia to weight ratio. Utilized as floor beams, open-web sections are a type of floor system that enables the integration of building services inside the structural depth of the floor. For heavily serviced office towers, there are typically only two options: either integrates the structural members and service providers inside the same horizontally zone, or lower the structural zone to allow the building services to flow under. Integrated floor systems include thin floor systems, trusses, stub girders, produced beams with tapering webs, hunched beams, and beams with one or more web openings. Because the depth that may be used for assembly in these systems is almost equal to the depth of the floor, a dramatically lower height of the arrangement can be reached, which lowers sheathing costs. The majority of the time now, when designing floor beams with web apertures, consideration is given to the composite action of the steel beam and the concrete slab that sits on top of it.

Steel members can have one or more web apertures, each of which can have a distinct shape. The elements are referred to as cellular when these apertures are round and evenly spaced. Other aperture shapes, such as square, rectangular, hexagonal (typical castellated section), even eight shapes, are feasible depending on the production technique.

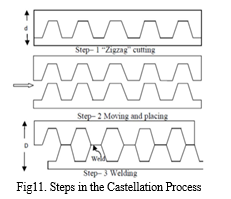

A. Production Methods

A diversity of steel producers use their own patented procedures to create cellular beams. The method used is to weld profiled steel plates together to create the flanges and the web of the specimen. The web plate has an opening made in it before the wedding ceremony. Although all dimensions are adjustable, there is no positive fillet weld effect. Another method, which is more frequently used, involves cutting the web of an existing hot-rolled section into a H or I form before tip-to-tip welding the pieces back together. The steel mills repurpose the material that is removed during the two-way flame cutting process.

CMC Metals is a manufacture of cellular beams in other nations; hence the design is not governed by dead load deformations. Cellular beams are produced entirely by some firms, although they are only a small portion of their overall product line for other companies. The top and bottom parts do not necessarily have to match when creating cellular spans using flame cutting and welding; alternatively, it is feasible to create an asymmetric cellular section by employing separate base sections. The height of the final segment can be greatly modified during both project stages. The creator's criteria are followed in the manufacture of every beam. The web is sliced at an angle to the centroidal line to create tapered cellular beams. By changing the cutting pattern to produce different bottom and top tees, curved beams can be manufactured. These trees are then bent to the necessary radii and joined together using welding. It is also feasible to curve the plan, although caution must be used because the torsional stiffness is very low.

II. LITERATURE REVIEW

- Ebrahim Faraj pourbonab, Hossein Showkati, Sunil Kute 2018. The ANSYS programme is worn in the study known in the publication to account for a broad diversity of practical geometric dimensions and various end situations. In the guise of a ductility curve, a streamlined approach for determining the buckling capacity in castellated columns is developed. A summary of the findings is provided for about 224 sample of castellated cruciform I-shaped specimen. The current work also uses numerical analysis to examine the axial compressive properties of those steel sections. According to the findings of a nonlinear analysis of these pillars, castellated cruciform steel columns are best suited and have a much higher ability for carrying loads than conventional cruciform steel columns. New geometrical criteria that can properly reflect different column types have been provided in the present article. Column critical loads are shown for together elastic as well as inelastic behaviour. This learn can be worn as a position for practical engineering purposes, as design strategy for steel structures with castellated shaped sections, and as a physical benchmark for calculating the buckling stress of actual pillars. Column critical loads are shown for both elastic in addition to inelastic behaviour. This revise can be worn as a reference for practical engineering reason, as plan guidelines for steel structures with castellated shaped sections, and as a physical standard for scheming the buckle stress of actual pillars.

- Ebrahim Farajpour bonab 2018 Under axial and lateral cyclic stresses, the rigidity dynamic hysteresis behaviour of steel castellated and common cruciform columns has been investigated. The main benefit of the castellation mechanism is that makes the much more effectual application of more expensive or bulky building project steel while also facilitating right of entry to the required services. It does this by raising the web height to an advanced moment capacity from the initial league of the same burden of plain webbed members, growing the hardness of I-sections. The impacts of various steel section types, web & flange increases, and specimen length variations have all been explored together along with bend, comportment aptitude, hysteresis loops, ductility, with energy dissipation capacities. Numerical simulation analysis is performing using geometric nonlinearity and early numerical imperfection. The findings of numerical simulation studies, which are in good agreement with the experimental findings, demonstrate that castellated cruciform steel columns have a substantially greater and better LCC than ordinary cruciform steel pillars. The study found that CPE steel components might be utilized in seismic regions. This revise could give an early examination of the engineering applications and specifications needed to construct CPE steel sections.

- Miss R. R. Huddar, Prof. A.V. Sagade 2019 Research on castellation has shown that when the horizontal tube's width expands, the radius of gyration also increases and the slenderness ratio lowers without affecting the columns self-weight. Furthermore, shock waves, particularly those close to web openings, have the potential to reduce the load-bearing capacity of castellated columns, which could lead to a number of different failure types. In the analysis, the use of hollow square columns with various castellation geometries, suitable for various loading situations under buckling, is taken into account. Castellation is typically provided Software study indicate that the hexagonal castellation is appropriate for castings because it has a greater capacity to withstand stress. Since cellular columns have more stress-bearing capacity as well as less deflection, they are also useful. They do have a lot of jobs. Square sections have less deflection but have a lower stress carrying capability due to the edges' ability to accommodate freight. To validate projects for comparative analysis, analytical solutions, experimental solutions, and commercial tools like ANSYS Evaluation are being established.

IV. FINITE ELEMENT SIMULATION

To decide the critical elastic buckling load & the related mode of failure, castellated columns are numerically modelled and simulated by the finite elements programme summary software ABAQUS. Three-dimensional (3D), six- and eight-noded structural solid components with 3 translational degrees of freedom at every node are utilized to simulate the geometric aspects of the columns under examination. The usual geometry of modelled castellated columns is exposed in Figure. In just this image, the typical castellation spacing is seen to be 1.5d c/c, wherein d is the diameter of the circular enclosing the hexa perforations.

C. Submission For Analysis And Visualization Of Results

The model is now ready for examination after meshing is finished. This is done by creating a job and submitting it in the job module. The visualisation module presents the analysis's results. We are particularly interested in Von-misses stresses and deflection in the Y-direction, which are denoted in the results drop-down menu as S-Misses and U2, respectively. Figure shows the findings of the deflection of a sample castellated beam from a visual standpoint.

V. VALIDATION OF SOFTWARE

Paper: FE Analysis of Composite Beams and Columns with Castellated Members, (Serene K T, Aswathy P, 2019)

A study conducted concentrated on a paper that uses finite elements to analyse composite beams and columns with castellated members that contain full height web holes. Numerical analysis of composite beams and columns was carried out using the ANSYS16.1 tool. This article considered several web opening forms in partial and full concrete encasings, such as rectangular, hexagonal, and elliptical ones. The elliptical web opening is effective for the better behaviour, according to the results collected.

The ABAQUS software was used to assess a full height rectangular aperture castellated steel beam made from a parent section with dimensions of height 150mm, flange width 75mm, flange thickness 7mm, web thickness 5mm, and yield strength 278MPa. The perpendicular and horizontal cutting patterns were made using holes that were 130 mm wide, 264 mm deep, and a total height of 278 mm, or nearly twice as tall as the beam's original height of 150 mm, in castellated steel beams through full height rectangular openings. The entire length of the beam was 2990mm. The beam featured a hinge at one end and a roller at the other, and it used a two-point loading mechanism. After analysis, the maximum load value and the journal values were compared.

Conclusion

Compared to regular cruciform strengthen columns, castellated cruciform steel pillars have a significantly lower strength reduction ratio. Therefore, it is advised that castellated pillars be utilised in high-rise buildings, industrial halls, or tower columns as fixed terminated, long pillars. Compared to ordinary cruciform steel columns, castellated cruciform steel columns have a significantly lower durability reduction ratio. In high-rise buildings, industrial halls, or tower columns, it is therefore recommended to utilise castellated pillars as fixed terminated, long pillars. An formula was developed to estimate the weight limit of castellated cruciform steel columns when they are compressed axially. Additionally, the numerical outcomes of the nonlinear analyses are unswerving with the reported analytical formulas in the latest research. The analytical results showing the load capability capacities of steel column sections under loading and those found in the study papers using software are found to differ by 5.64% in terms of load bearing capacity. This leads to the conclusion that the technology-based study report\'s findings validate the ABAQUS results.

References

[1] Amr M.I. Sweedan, Khaled M. El-Sawy, and Mohamed Ikbal Martini, \"Identifying The Buckling Capacity Of Axially Loaded Cellular Columns,\" Thin-Walled Structures, Vol. 47, pp. 442-454, 2009. [2] Anwar Badawy Badawy , Abu-Sena, Mohamed Wahied Fares, and Hanan Hussien El-TobgY \"Experimental And Numerical Investigation Of The Behavior Of Castellated Steel Beam-Columns,\" International Journal Of Scientific & Technology Research, Vol. 10, Issue 04, April 2021 [3] Delphine Sonck, Jan Belis, “Strong?Axis Flexural Buckling of Cellular & Castellated Members”, Structural Stability Research Council Or lando, Florida, April15, 2016. [4] Delphine Sonck, Jan Belis, “Weak-Axis Flexural Buckling Of Cellular And Castellated Columns”, Journal of Constructional Steel Research, Vol. 124 2016. [5] Ebrahim Faraj pourbonab, Hossein Showkati, Sunil Kute, “Castellated Cruciform Steel Columns”, World Journal of Engineering 2018. [6] Ebrahim Farajpourbonab, “Castellated And Common Cruciform Steel Columns Under Axial And Lateral Cyclic Loading”, Asian Journal of Civil Engineering 2018. [7] E. Farajpourbonab, S. Kute, and V. Inamdar, \"An Experimental Study On The Strength Of Cft Columns Reinforced With Castellated Cruciform Steel Sections,\" Asian Journal Of Civil Engineering (Bhrc), Vol. 18, No. 2, 2017. [8] Jinsong Lei, Boksun Kim, and Longyuan Li, \"Dynamic Instability Analysis of Axially Compressed Castellated,\" International Journal of Steel Structures 2020, [9] Jin-Song Lei, Wei-Bin Yuan, and Long-Yuan Li, “Axial Compression Buckling of Castellated Columns”, International Journal of Structural Stability and Dynamics Vol. 16, 2016. [10] Jian-zu Gu and Shanshan Cheng, \"Shear Effect On Buckling Of Cellular Columns Subjected To Axially Compressed Load,\" Thin-Walled Structures, vol. 98, pages 416-420, 2016.

Copyright

Copyright © 2023 Tejaswini C. Patil, Prof. S. S. Mohite, Prof. V. M. Patil. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET48957

Publish Date : 2023-02-01

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online