Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design, Build, and Analyze: A Comprehensive Approach to Developing a Thermal Dehydrator Prototype

Authors: Manas Wagle, Shrikar Wadadare, Ved Rahangdale, Soham Kature

DOI Link: https://doi.org/10.22214/ijraset.2024.62606

Certificate: View Certificate

Abstract

Fruit and vegetable preservation commonly relies on drying methods, and dehydrators play a pivotal role in enhancing traditional sun-drying processes. This report delves into the intricate calculation and analysis of a specific household electric dehydrator model with a 5kg capacity. Employing a meticulously chosen 5 kg sample of grapes with an initial 80% w.b(wet basis). moisture content, the dehydrator was analysed at temperatures of 45, 50, and 60 degrees Celsius. The study scrutinizes the technical nuances of the electric dehydrator, aiming to provide a comprehensive understanding of its performance. By meticulously detailing the calculations and outcomes, this report contributes valuable insights into the efficiency of the dehydrator model, offering a foundation for future applications in fruit and vegetable preservation technologies.

Introduction

I. INTRODUCTION

Vegetables and fruits are not mere components of our diet; they stand as pillars of global agricultural food production and, more critically, as agents of health promotion and disease prevention. Numerous medical studies underscore their role in providing essential phytonutrients and bioactive compounds necessary for optimal health. The diverse array of nutrients, including phenols, polyphenols, vitamin E, ascorbic acid, phytoestrogens, flavonoids, isoflavones, terpenes, lignans, lycopene, and biotin, collectively contribute to a balanced and healthful diet. Despite being the world's second-largest harvester of vegetables and fruits, India faces a paradox—15% of the population goes hungry daily, around 23 crore people live below the poverty line, and 1 in 4 children is malnourished. Approximately 3000 lives are lost each day due to illnesses resulting from poor dietary choices.

One glaring challenge contributing to this paradox is the irregular availability of fresh produce throughout the year. The Portable Vegetable Dehydrator project seeks to address this issue by harnessing the power of dehydration—a time-tested and traditional postharvest method. By stabilizing and extending the shelf life of vegetables, dehydration ensures a consistent and cost-effective addition to the diet, irrespective of the season. Traditional drying methods, often conducted in open spaces, are not without drawbacks—hygiene concerns, contamination, temperature inconsistencies, and space requirements are persistent challenges. The proposed dehydrator aims to overcome these limitations by offering a portable solution with adjustable temperature settings, time controls, and an efficient tray system that maximizes capacity while minimizing space requirements. The incorporation of features such as removable trays with mesh and vents, coupled with an exhaust fan for moisture removal, ensures effective and hygienic drying.

In essence, the Portable Vegetable Dehydrator endeavors to revolutionize the traditional methods of drying fruits and vegetables, presenting an innovative solution to address issues of storage, spoilage, and cost-effectiveness throughout the year, contributing towards a more sustainable and nourished future.

II. LITERATURE REVIEW

Dehydration is a common method of preserving vegetables, as it can extend their shelf life and retain their nutritional value. Here is a literature review on dehydration of vegetables.

- Dehydration of vegetables: a review - K. J. Kadam and S. S. Salunkhe (1998)

This comprehensive review article provides an overview of the dehydration process, including factors affecting dehydration, methods of dehydration, and quality considerations. The article also discusses the nutritional aspects of dehydrated vegetables and their potential health benefits.

2. Nutritional quality of dehydrated vegetables - M. J. Ayala-Aponte, et al. (2017)

This study evaluated the nutritional quality of dehydrated vegetables, including carrots, sweet potatoes, and bell peppers. The researchers found that dehydrated vegetables retained most of their nutrients, including vitamins, minerals, and fiber. They concluded that dehydrated vegetables could be a good source of nutrients in diets.

3. Drying of vegetables by heat pump: a review - S. Y. Al-Zuhair and I. M. Al-Harahsheh (2009)

This review article focuses on the use of heat pump drying for vegetables. The authors discuss the advantages of this method, such as reduced energy consumption and improved product quality. They also provide an overview of the process and discuss the factors that affect the drying rate.

4. Effect of pre-treatment on drying kinetics and quality of dehydrated vegetables - P. V. Shah and S. L. Sonawane (2014)

This study evaluated the effect of pre-treatment methods, such as blanching and chemical treatment, on the drying kinetics and quality of dehydrated vegetables. The researchers found that pre-treatment significantly affected the drying rate and the quality of the dehydrated vegetables. They recommended that pre-treatment should be optimized to achieve the desired quality.

5. Optimization of microwave dehydration conditions for carrot cubes using response surface methodology - M. A. Dehghani and M. R. Omid (2018)

This study used response surface methodology to optimize the microwave dehydration conditions for carrot cubes. The researchers found that the optimal conditions for microwave dehydration were a microwave power of 450 W, a sample thickness of 5 mm, and a dehydration time of 6 min. They also found that microwave dehydration retained the quality and nutritional value of the carrots.

6. Recent Advances in Drying and Dehydration of Fruits and Vegetables: A review. Sagar V. R. Suresh Kumar P. J Food Science Technol. Jan-Feb. 2010.

The paper discusses the challenges of traditional drying methods for fruits and vegetables and explores advanced techniques such as osmotic dehydration, vacuum drying, and freeze drying. Emphasizing the importance of energy efficiency and product quality, the review underscores the need for cost-effective and sustainable drying processes in post-harvest management.

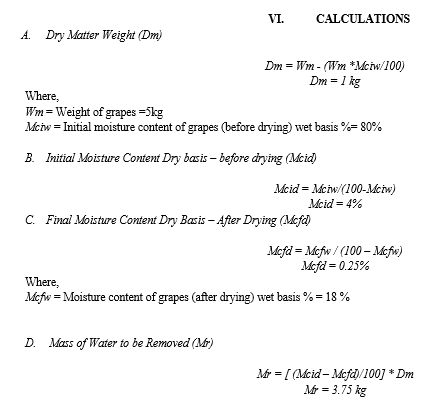

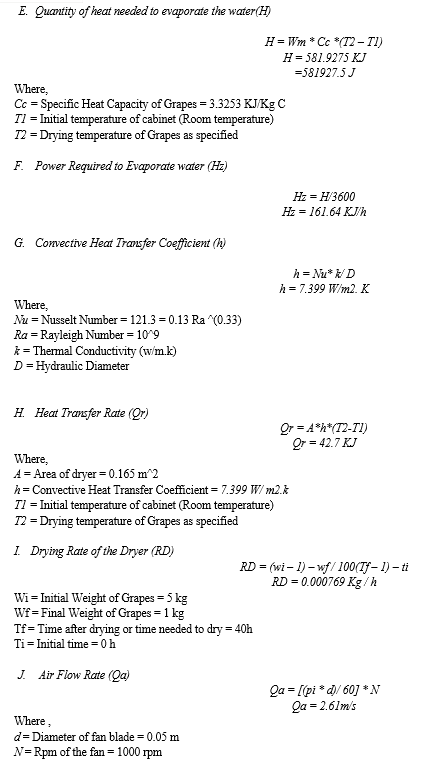

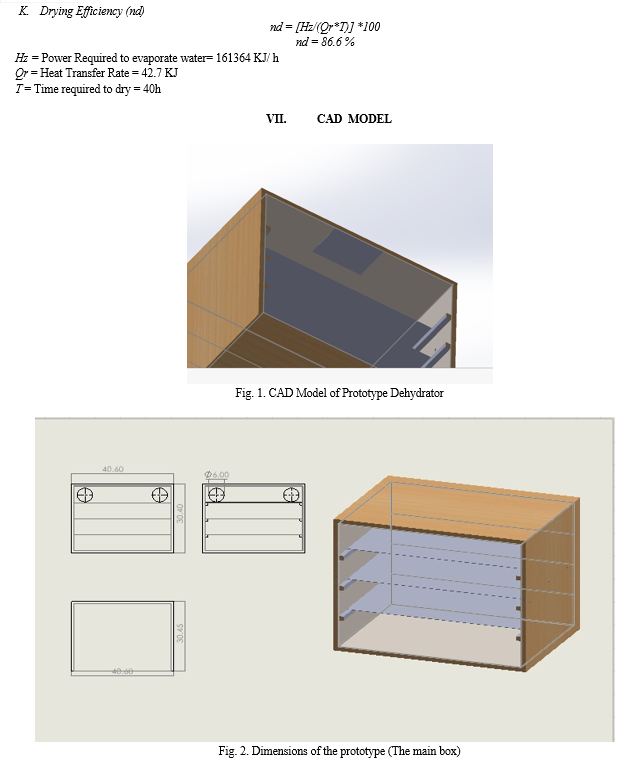

III. DESIGN AND MANUFACTURING

During designing process, the size and the shape of the prototype was taken into consideration. The main aim was to make the portable as well as the aesthetically pleasant. To minimise the shape used by the product is designed to be the square in shape and 2 trays are stacker inside it.

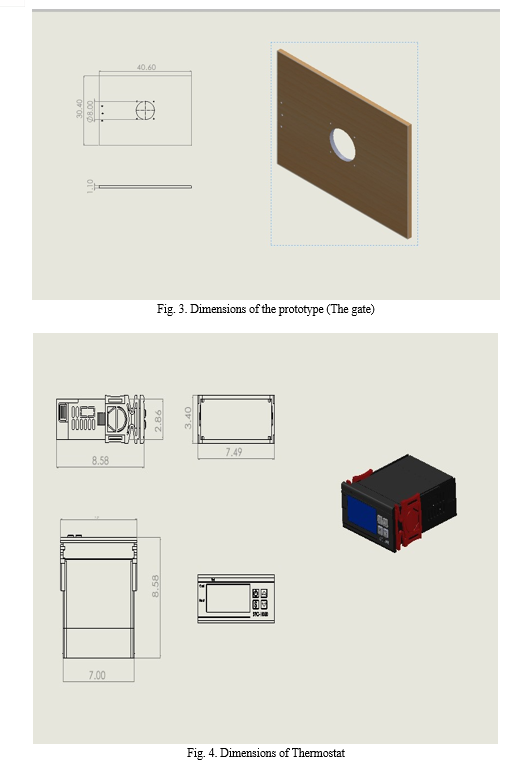

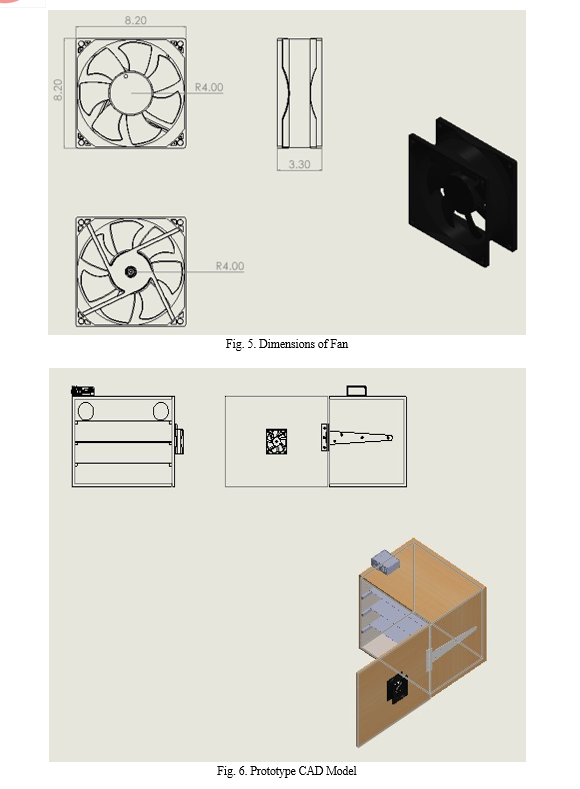

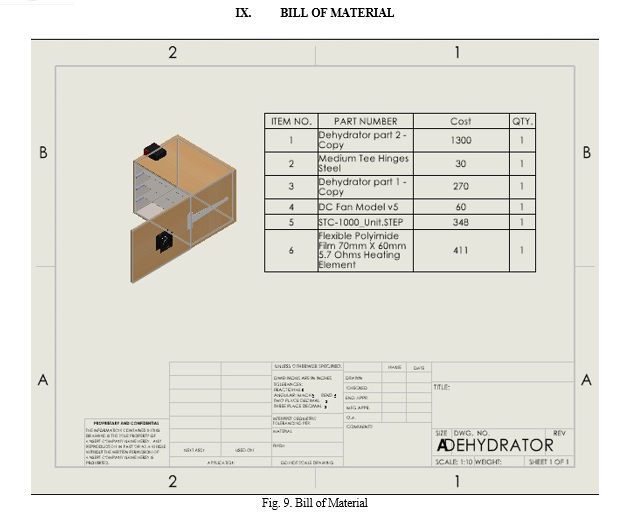

The drying compartment was constructed from plywood (10 mm thickness) coated with an insulating foil having the 0.1mm thickness and dimensions same as prototype dehydrator.. Three trays with stainless steel mesh were provided inside the drying chamber for loading the sample. The dryer is equipped with heating element (12 V), an axial flow fan (85 CFM), thermostat (range: 25C-80C)

|

Sr. No |

Component Name |

Specification |

|

1 |

Plywood |

10 mm thick |

|

2 |

Insulating Foil |

0.1mm thick |

|

3 |

Heating Element |

12 V |

|

4 |

Axial Flow Fan |

85 CFM |

|

5 |

Thermostat |

Range 25C- 80 C |

IV. WORKING OF DEHYDRATOR

In the operational context, the dehydrator operates on the principles of forced convection and drying, constituting a complex interplay of heat and mass transfer processes. The heat transfer occurs through forced convection, where the heating coil, when activated, elevates the air temperature within the dehydrator to the specified drying temperature of the material. Simultaneously, the fan facilitates the circulation of heated air over the material on the drying trays, promoting the transfer of heat from the air-food interface.

This convective heat transfer process is integral to the dehydration mechanism, wherein water diffuses from the interior of the food material to the air-food interface and is subsequently carried away by the convecting air stream. The vents strategically placed at the dehydrator's end serve as outlets, allowing moist air to escape, thereby aiding in the overall drying process.

For analysis purposes, the study focused on the fundamental principles of heat transfer through convection, assuming a constant air flow and temperature during the process. The dehydrator continues its operation until a consistent weight of the sample is achieved, indicating the completion of the dehydration process. This systematic approach ensures effective dehydration of the sample within the specified parameters.

V. METHODOLOGY

In the methodology, a 5kg sample of grapes with an initial moisture content of 80% underwent analysis. The drying process aimed to achieve a moisture content of 18% at a drying temperature of 60°C over a period of 40 hours.

The analysis commenced by calculating the dry matter weight, determining the amount of water to be removed. Subsequently, the heat energy and power required for water evaporation were computed. This involved the calculation of the heat transfer rate of the dryer and the coefficient of thermal conductivity.

To delve deeper, two key terms were introduced: Wet Basis and Dry Basis Moisture Content. Wet Basis Moisture content (Mw) was defined as the percentage ratio of water weight (Ww) to the total material weight (Wi). On the other hand, Dry Basis Moisture Content (Ma) represented the percentage ratio of water weight (Ww) to the weight of dry matter (Wa). Dry Basis moisture content is commonly used in describing moisture changes during drying processes.

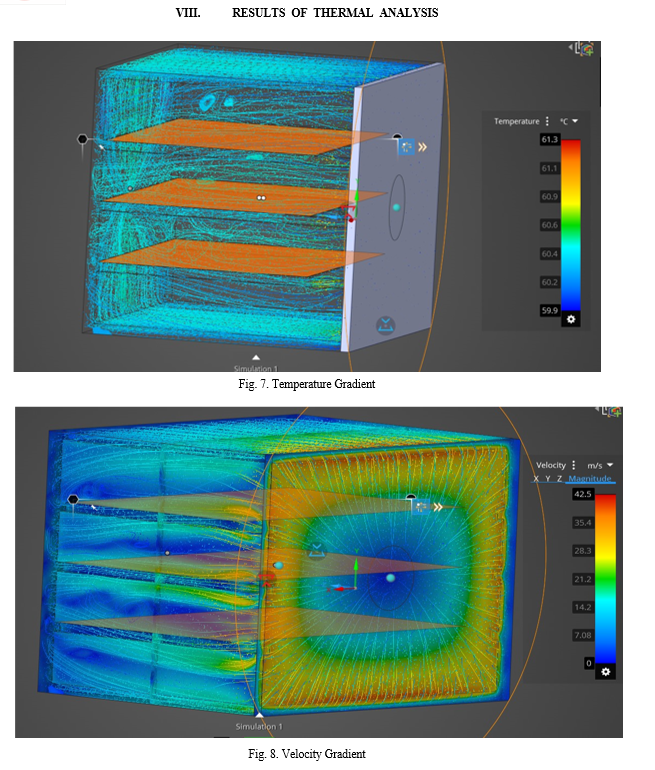

The methodology also included the calculation of film coefficient and associated factors like the Nusselt number. Subsequently, thermal analysis was conducted using ANSYS to comprehensively understand the heat transfer dynamics during the dehydration process. This multifaceted approach ensures a thorough investigation into the thermal aspects of the grape dehydration, encompassing both theoretical calculations and practical simulations.

X. FUTURE SCOPE

- Optimization of Tray Configuration: Investigating the optimal number of trays and the spacing between them could significantly improve heat transfer efficiency. Conducting experiments or simulations to find the configuration that maximizes productivity while maintaining optimal drying conditions is a promising avenue for future research.

- Development of MATLAB Models: To enhance the accuracy of calculating film coefficients, the integration of MATLAB models could provide a sophisticated tool for in-depth analysis. These models can consider various parameters, simulate heat transfer processes, and aid in refining the understanding of the drying mechanism.

- Air Filtration Integration: Incorporating air filtration systems in the input air can be explored to improve the quality of the drying environment. This addition could minimize the introduction of contaminants, ensuring a cleaner atmosphere for the drying process. Research into the types of filters, their efficiency, and their impact on overall dehydration quality would be beneficial.

These advancements not only contribute to the optimization of the dehydrator but also align with contemporary trends in precision and sustainability within food processing technologies. Investigating these aspects could pave the way for a more efficient, accurate, and environmentally friendly dehydration process

Conclusion

In conclusion, the exhaustive thermal analysis conducted on the fruit dehydrator unveils a project marked by meticulous design and impressive efficiency. The uniform temperature distribution, characterized by a minimal variation of less than 2°C, speaks to the precision embedded in the dehydrator\'s construction. This critical feature ensures a consistent and thorough drying process for an array of fruits, affirming the practicality and versatility of the equipment. The effectiveness of the drying process is a standout aspect, with the dehydrator demonstrating its ability to reduce moisture content to below 10% within a relatively brief duration. This not only attests to its efficiency but also positions the equipment as a practical solution for both domestic and commercial fruit drying needs. Beyond the technical achievements, the dehydrator\'s user-friendly interface and straightforward maintenance add a layer of practicality and accessibility. The simplicity of controls, coupled with ease of cleaning, contributes to the overall user experience and makes the equipment adaptable to a diverse user base. In essence, this project represents a harmonious amalgamation of theoretical knowledge and practical application. The fruit dehydrator, emerging from this endeavor, stands as a testament to thoughtful engineering, efficient functionality, and user-centric design. It not only advances our understanding of heat transfer dynamics in the context of dehydration but also presents a tangible solution that bridges the gap between theory and real-world application in the realm of food processing technology.

References

[1] AS Mujumdar - Handbook of Drying Vegetables and Vegetable Products [2] Sonawane, AkashBalasaheb, et al. \"Analysis of solar drying system for the applications like fruits and vegetables (Onion and Potato).\" Journal homepage: www.ijrpr.com ISSN 2582: 7421. III. [3] Hallak, H., I. Deeb, And J. Hillal. \"Physical Characteristics Of A Fruit And Vegetable Solar Dryer.\" Bethlehem University Journal (1991): 41-57. [4] Babagana, Gutti, Kiman Silas, and B. G. Mustafa. \"Design and construction of forced/natural convection solar vegetable dryer with heat storage.\" ARPN Journal of Engineering and Applied Sciences 7.10 (2012): 1213-1217. [5] Kumar, Ankit, et al. \"Design and Fabrication of Solar Dryer System for Food Preservation of Vegetables or Fruit.\" Journal of Food Quality 2022 (2022). [6] Sharma, V. K., A. Colangelo, and G. Spagna. \"Experimental performance of an indirect type solar fruit and vegetable dryer.\" Energy conversion and management 34.4 (1993): 293-308. [7] Pangavhane, D. R., and R. L. Sawhney. \"Review of research and development work on solar dryers for grape drying.\" Energy conversion and management 43.1 (2002): 45-61.

Copyright

Copyright © 2024 Manas Wagle, Shrikar Wadadare, Ved Rahangdale, Soham Kature. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62606

Publish Date : 2024-05-23

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online