Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Developing an Energy-Smart Retrofit to Less-Efficient Commercial Water Heaters

Authors: Emad Tanbour, M. C. Greenfield

DOI Link: https://doi.org/10.22214/ijraset.2025.66863

Certificate: View Certificate

Abstract

This paper is summarizing a pilot study to investigate the impact of retrofitting installed commercial water heaters with an energy smart capability. The theme of the retrofit applies algorithms to enable gas-fired commercial water heaters to adjust heating cycles based on detecting and continuously monitoring and learning the habits of end users and variations in the frequency of demand on hot water. The proposed pilot analysis is guided by US Department of Energy efficiency guidelines. The method to achieve the proposed energy smart retrofit is described in this paper as well as a pilot estimates of the impact of the retrofit on appliance efficiency is presented. Some basic and initial economic analysis is also presented including cost estimates of mass producing the proposed retrofit. .

Introduction

I. INTRODUCTION

Developing an energy-smart retrofit to less-efficient commercial water heaters is a new measure. The Algorithm of Energy-Smart water heating has many existing forms in some residential water heaters but is not available as a retrofit for less efficient commercial water heaters.

A. Proposed Solution to Problem

Less efficient gas fired commercial water heaters are currently at 57% overall Uniform Energy Factor rating (a measure of thermal efficiency) as maintained by major water heater manufacturers in North America, and other applicable industry standards. The energy-smart retrofit to the existing legacy less-efficient water heats installed in the field allows for higher overall efficiency. The proposed development of the retrofit regulates heating cycles to adapt to hot water usage behavior of the installation location and adjust heating cycle’s frequency to be right sized to hot water draw habits. This is expected to increase overall thermal efficiency of these commercial units and reduce fuel consumption cost

B. How Energy Conservation Is Proposed To Be Measured

Technical Description: Most less-efficient commercial gas waters heaters continuously burn fuel as long as the signal from the thermostat is asking for flame to on. It is possible to improve these heaters by considering a programmable thermostat that can be programmed to operate heating based on a preset schedule. This is not the optimal solution to achieve better efficiency. The proposed energy-smart measure will retrofit the gas water heater with a controller that adjust heating cycles based on the pattern of usage of hot water. This will not require continuous programming and adjust water heating cycles to the right frequency based solely of hot water usage patterns. By eliminating heating cycle’s high frequency, gas fuel consumption will be reduced. Furthermore, stand-by loss commonly faced in regular water heaters will be reduced during off peak demands of hot water as adjusted by the smart retrofit proposed. The proposed measure will serve the commercial and industrial markets where less-efficient commercial water heaters are installed. Installation of such less-efficient commercial water heaters are in hotels, large restaurants, hospitals, recreations outfits, and higher education institutions to name a few.

C. How the Proposed Technology Works

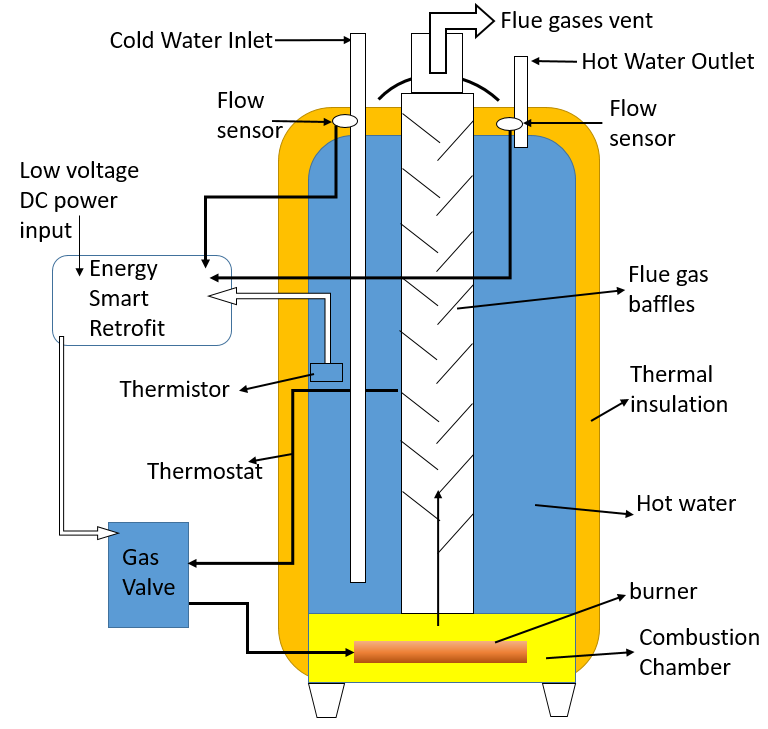

As illustrated in the schematic of Figure 1 above, the less efficient commercial water heaters are only controlled by the thermomechanical thermostat. To provide means to control the heating cycles, it is proposed to develop a controller for existing water heaters, an energy-smart controller.

The energy-smart controller collects information from a thermistor embedded in the hot water, a series of flow sensors on cold and hot water and (wireless Wi-Fi ability to facilitate remote control as an option).

Figure 1 Proposed Energy-Smart retrofit for less-efficient Commercial gas water heaters.

The energy-smart controller collects data on the pattern of hot water consumption over blocks of days, weeks or seasonal data to decide the frequency of heating cycles. Such ability to continuously adjusting the frequency of heating cycles based on demand of hot water patters provides the optimal setting to conserve energy by eliminating unnecessary heating cycles during low demand or no demand periods.

Common applications of the proposed energy-smart retrofit include commercial gas water heaters in new and existing construction sites of campus hotels, university buildings, university medical facilities and commercial and industrial building where storage type water heating in excess of 75 gallons capacities are in demand.

The Energy-Smart controller measure can be adopted as appropriate for New Construction (NC), Early Retirement (ER), or Replacement (R).

Energy-smart controllers are very common in a large number of residential electric water heaters. Retrofitting less-efficient commercial gas water heaters with energy-smart controllers will provide an opportunity to existing and new installation to benefit from the energy savings that can last over the life of these field units that spans 6 to 12 years and more in service.

|

Applicable Building Type(s) |

Applicable Sub-categories |

Applicable Fuel Type(s) |

Affected End-Use Load(s) |

|||||||

|

Electricity |

Natural Gas |

Space Heating |

Space Cooling |

Water Heating |

Lighting |

Appliance |

Process |

Other |

||

|

Commercial |

Restaurants, hotels, higher education campus buildings, recreations centers, catering companies and similar outfits |

ü |

ü |

|

ü |

|

ü |

ü |

|

|

|

Industrial |

Food processing, mass production bakeries, light chemical companies, automotive parts passivation and treatment industry and similar. |

|

ü |

ü |

|

ü |

|

|

ü |

|

D. Summary of Energy Conservation Measure

Specification of the Measure

Energy-Smart retrofit has one main construction of the following components:

-

- Energy-Smart Microcontroller to collect hot water use patterns supported by an algorithm to adjust heating cycle frequency to continuously adapt to optimal frequency for each specific installation.

- A set of sensors (two flow sensors for cold and hot water flows respectively), and a thermistor

- Connectors to wire the Energy-Smart Controller with sensors, gas valve and thermostat

- Optional wireless Wi-Fi connection to allow remote control of water heater.

- Targeted installation of the energy-Smart Retrofit includes a variety of commercial gas water heaters available in the MEMD field. The proposed Energy-Smart Retrofit is planned to target atmospherically-venter commercial Natural gas water heaters that are 100 gallon (379 liters) or more in capacity with Btu/hr input of 80,000 (23.4 kW) or more.

- Targeted commercial natural gas water heaters will be naturally vented types and direct-vented types of uniform energy factor ratings of the range of 57% and 64% respectively.

- Targeted commercial natural gas water heaters are these models have been tested according to DOE test procedures, and meet or exceed the thermal efficiency and standby loss requirements of current ASHRAE standards (Part of the federally mandated Energy Policy Act (EPact) and Adopted by US Department of Energy (DOE)). In specific to the 100-gallon storage tank type natural gas commercial water heaters, the DOE Uniform Energy Factor (UEF) range of units targeted will be approximately 64.75% on the low draw pattern to 78.8% on the high draw patterns[1].

- Starting June 12, 2017, EF rating was replaced with the new factor for measuring water heaters’ efficiency and it was called: Uniform Energy Factor (UEF). Definition of UEF will be detailed in section 6 not completed in this draft.

- The more recent DOE proposed ruling is even asking for further requirement of UEF of storage water heaters as in the Energy Conservation Program: Energy Conservation Standards for Consumer Water Heaters[2]

E. Requirements

- Commercial and industrial locations where a less-efficient commercial natural gas water heater is installed and/or planned to be installed can qualify to receive the proposed Energy-Smart retrofit.Preference is proposed for all commercial natural gas water heaters that are at 80% thermal efficiency or having UEF of 0.57 to 0.65. The thermal efficiency is defined as the ration between the thermal energy in the delivered hot water and the amount of energy in the fuel consumed in the water heater. The UEF has different adopted formulas based on storage tank capacity and draw patterns as per DOE ruling. The details of these formulas will be discussed in the detailed section of the Methodology section 6 not completed in this draft.

- A condensing commercial water heater with microcontroller may not qualify for the proposed Energy-Smart retrofit.

- The proposed Energy-Smart retrofit measure is not specific to climate zone or location so it is applicable throughout Michigan. It is also applicable to outside Michigan with approval of the utility sponsor if needed.

F. Savings Methodology (From Workpaper)

Existing Baseline or Baselines

Table below shows an example for values of Uniform Energy Factor (UEF) for a typical storage tank natural gas commercial water heater with 100-gallon rated capacity:

|

Commercial Natural Gas Water Heater Rated Storage Volume |

Draw Pattern |

Uniform Energy Factor for the case of rated volume ???????? = 100 gallons |

|

Less than or equal 100 gal |

Very Small |

0.5352 − (0.0007 * ????????) = 0.4652 |

|

Low |

0.7375 − (0.0009 *???? ????) = 0.6475 |

|

|

Medium |

0.7704 − (0.0010 * ????????)= 0.6704 |

|

|

High |

0.7980 − (0.0010 * ????????) = 0.6980 |

The following table summarized natural gas energy savings potential when installing the proposed (Please notice that these numbers reflect the 2017 DOE ruling and may be higher than the current Michigan Building Code that is based on ASHRAE/ANSI/IES 90.1 and its 2013 addenda). More efficient newer installations of commercial gas water heaters may provide less savings compared to less-efficient installed legacy units.

Energy-Smart retrofit for a typical commercial water heater with 100-gallon storage capacity and 80,000 Btu/hr. rating. Numbers are estimated using equation 1 shown below the table and will be verified through development testing.

|

For the case of a commercial gas water rated volume 100 gallons and 80,000 Btu/hr rating. |

|||

|

Draw Pattern |

Uniform Energy Factor |

Natural Gas Energy Saving Potential (Therm/year) by increasing UEF by potential 0.05 |

Natural Gas Energy Saving Potential (Therm/year) by increasing UEF by potential 0.1 |

|

Very Small |

0.4652 |

652 |

1,240 |

|

Low |

0.6475 |

481 |

938 |

|

Medium |

0.6704 |

466 |

910 |

|

High |

0.698 |

449 |

878 |

The following equations assumes 23 hours per day operation in commercial applications in the field.

Energy Savings (Therms per year) = UEFBTUHR1UEF-1UEF+?UEF23 HR/day365dayyr100,000 BTU/Therm

Energy Savings (BTU/day) = UEFBTUHR1UEF-1UEF+?UEF23 HR/day

Where ( ?UEF= improvement of the uniform energy factor ).

In the table above, ?UEF=0.05 and ?UEF=0.1 where used to calculate values in column 2 and column 3.

II. BASELINE TECHNOLOGY

Baseline equipment is a typical atmospherically vented natural gas fired commercial tank-type water heater of storage capacity of 75 to100 gallons or more and input energy rating of 80,000 Btu/hr. or more.

- New Construction: Newly installed light to medium duty atmospherically (naturally) vented commercial gas tank-type water heaters certified under the DOE requirements of June 12, 2017 UEF. Newer construction of higher efficiency commercial gas water heaters may get slight improvement than less-efficient water heaters.

- Existing Equipment Replacement: Similar to new construction targeted water heaters or retrofit application to earlier water heaters governed by DOE requirements preceding June 12, 2017 ruling.

III. IMPROVED TECHNOLOGY

The improved Energy-Smart retrofit measure provides a solution to field installed and new construction installation of less-efficient atmospherically vented tank type commercial gas water heaters. The proposed technology employs microcontroller, sensors and algorithm to learn and adjust heating cycles based the usage habits of hot water. The proposed measure is expected to cur standby losses due to firing losses of natural gas, heat loss through walls as well as significantly cut standby losses through the flue tube of targeted heaters. Proposed technology has a potential to increase UEF by an estimated 10 percentage points or more.

A. Implementation

Although the proposed measure is to be developed as per the description, its major components are well defined given the experience of the research team and past industry practice. The proposed measure of the Energy-Smart retrofit is expected to contain the following major components:

- A potential switch of the thermomechanical thermostat into a thermistor

- An energy-smart microcontroller with energy-smart algorithm

- Two flow sensors (one for cold and one for hot water) + fittings

- Casing for the Energy-Smart retrofit kit

- Connectors and wiring

- Optional Wi-Fi communication enablers

- Installation and user manual

- Amortized tooling and certification cost by a third-party (most likely ANSI approved third party lab)

- Field installation estimated cost. We assume the kit will be designed so it is easy to install in the field by one technician in less than one hour.

If the Energy-Smart retrofit measure is developed for over-the-shelf commercial cost will depend on the expected annual volume (quantities). Below, the table list projected cost of the proposed measure for two cases with annual volume of 1000 kits and 10,000 kits respectively.

|

Projected Cost of the Proposed Measure for two annual volume cases |

||

|

Major Component |

Assume 10000 quantity |

Assume 1000 quantity |

|

$1.50 |

$3.00 |

|

$5 |

$10.00 |

|

$5 |

$10.00 |

|

$2 |

$4.00 |

|

$2 |

$4.00 |

|

$4 |

$8.00 |

|

$2 |

$4.00 |

|

$4 |

$8.00 |

|

$70 |

$70 |

|

Grand total |

$97.50 |

$141.00 |

Comparing project mass-produced cost of the Smart-energy kit to the projected annual savings in section 7, the proposed measure is of great potential for a return on investment in less than one year.

B. Recurring Costs

It is expected that the proposed Energy-Smart retrofit measure, once installed on the less-efficient water heater, to incur no further recurring cost.

C. Estimated Baseline Energy Use For Relevant Systems

Based on the workpaper, the plan is to develop the proposed measure of Energy-smart retrofit to be installed on baseline commercial gas water heaters of 80,000 Btu/hr rating or more up to 200,000 Btu/hr. with thermal efficiency rating of 80% or less.

Conclusion

It is estimated that the proposed measure will cost (upon commercialization) between $97.5 to $141 per kit including field installation cost. The measure is expected to save $426 to $1,178 per commercial water heater receiving the proposed measure’s kit depending on hot water demand/draw pattern.

References

[1] DEPARTMENT OF ENERGY, 10 CFR Parts 429, 430, and 431, [EERE-2015-BT-TP-0007], RIN: 1904-AC91 [2] 10 CFR Part 430 [EERE–2017–BT–STD–0019] RIN 1904–AD91, Energy Conservation Program: Energy [3] Oumaima Laguili, Julien Eynard, Stéphane Grieu, \"Nonlinear Model-Based Predictive Control of Electric Water Heaters in Individual Dwellings\", 2024 IEEE Congress on Evolutionary Computation (CEC), pp.1-8, 2024. [4] Juan Carlos Laurencio-Molina, Carlos Salazar-Garcia, \"Design of an Artificial Neural Network Controller for a Tankless Water Heater By Using a Low-Profile Embedded System\", 2018 IEEE International Work Conference on Bioinspired Intelligence (IWOBI), pp.1-9, 2018. [5] Tobias Lübkert, Marcus Venzke, Volker Turau, \"Appliance commitment for household load scheduling algorithm: A critical review\", 2017 IEEE International Conference on Smart Grid Communications (SmartGridComm), pp.527-532, 2017. [6] M. Rastegar, M. Fotuhi-Firuzabad and F. Aminifar, \"Load commitment in a smart home\", Applied Energy, vol. 96, pp. 45-54, 2012. [7] P. Du and N. Lu, \"Appliance Commitment for Household Load Scheduling\", IEEE Transactions on Smart Grid, vol. 2, no. 2, pp. 411-419, Jun. 2011. [8] Samar Abbas, Abu Bakar, Yasra Chandio, Khadija Hafeez, Ayesha Ali, Tariq M. Jadoon, et al., \"Inverted HVAC: Greenifying Older Buildings One Room at a Time\", ACM Trans. Sen. Netw., 2018, [online] Available: https://doi.org/10.1145/3229063.

Copyright

Copyright © 2025 Emad Tanbour, M. C. Greenfield. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET66863

Publish Date : 2025-02-06

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online