Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Review on Developing HiPER Bituminous Mix Using Existing Binder and Modifier

Authors: Er. Harsh Thakur, Er. Ajay Kumar Duggal

DOI Link: https://doi.org/10.22214/ijraset.2024.64069

Certificate: View Certificate

Abstract

Heavy commercial vehicles combined with high pavement temperatures induce higher stresses in base and surface courses layers resulting in premature pavement distresses such as rutting and cracking. Therefore, it\'s essential to create a binder that performs better in heat and is more elastic and rigid so that it may be utilized to bear heavy axle loads. For several years, efforts have been made in India and worldwide to develop new pavement materials and improve the specifications of paving mixes and their constituents. One of the emerging solutions is use of a French asphalt mix known as “Enrobé à Module Élevé (EME)” or “High-Modulus Asphalt (HiMA) Mix”. This mix offers unique performance characteristics such as high stiffness and durability, good resistance to permanent deformation and fatigue. Therefore, HiMA mixes also referred as High Performance (HiPER) Bituminous Mixes. EME mixes uses a hard grade binder (HB), have higher binder content and lower air voids. The unique challenges in preparation of HiPER bituminous mix is selection of bitumen, which shall be hard grade bitumen (stiffer than VG40). In India, binder stiffer than VG40 are not commonly available commercially. Also, selection of modifiers used to produce hard grade binders and to enhance the performance of the binders that provides higher resistance to permanent deformation as well as to cracking. The main focus of this study is to find potential of modifier(s) to develop hard grade binder (HB) and use of HB for the preparation of mixes at various binder content and evaluated with the target of producing HiPER bituminous mix. Marshall stability and indirect tensile strength (ITS) tests are conducted to assess the mixes for HiPER bituminous mix.

Introduction

I. INTRODUCTION

India stands out among developing nations due to its rapidly growing service sector and road transport plays a crucial role in the country’s economy, social integration and security needs of the country. Notably, India is having 98% flexible pavement out of its total road network, making them a critical asset. Hence, roads infrastructure needs to be designed with a long-term perspective, focusing on high quality in terms of load carrying capacity, performance and durability. On the other hand, due to severe environmental conditions and increasing traffic intensity especially more number of passing heavy vehicles with higher axle loads, service life of most of the flexible pavement reduced considerably. In many cases, premature pavement distresses such as rutting and cracking have occurred. For high traffic volumes and severe climatic conditions, it is essential to adopt binders and mixes which are capable of performing better than the conventional refinery produced binders and dense graded mixes. Numerous efforts were made in the past for the development of binders and bituminous mixes with improved performance. Bituminous mixes prepared using stiff unmodified binders may exhibit higher rutting resistance but less flexibility, leading to reduced resistance against cracking. Conversely, softer grade unmodified binders offer better fatigue resistance but may be less effective in resisting rutting. To achieve a balance between fatigue and rutting resistance, mixes can be prepared using modified binders or carefully select unmodified binders with suitable characteristics. Achieving a balanced mix with both properties is crucial for durable pavements and to enhance pavement performance. To address these issues, new design procedures and construction technologies have emerged globally. One of these technologies is “Enrobé à Module Élevé (EME)” or “High-Modulus Asphalt Mix (HiMA)” developed in the mid 1980's in France to address issues like rutting and premature fatigue cracking in flexible pavements. Its use has gained attention worldwide and has been successfully used in other countries like Australia and South Africa due to its unique performance characteristics, including high stiffness (modulus) and excellent resistance to rutting and cracking. HiMA mixes have high stiffness (modulus) values and are specifically engineered to outperform conventional bituminous mixes in terms of resistance to rutting and cracking (fatigue cracking and thermal cracking). Therefore, High Modulus Asphalt (HiMA) mixes can also be referred as High Performance (HiPER) Bituminous Mixes. HiMA mixes are mainly used in the binder course of a pavement structure. These mixes are appropriate for use in heavy duty pavements carrying high traffic volumes such as expressways, national highways and state highways.

A. Enrobé à Module Élevé (EME)

The EME or HiMA mixes are a relatively new type of mixes which is modified with increased amount of copolymers. HiMA mix characterized by higher stiffness modulus (usually > 14,000 MPa), along with higher durability, good rutting and fatigue resistance. These mixes were developed in 1980’s at Laboratoire Central des Ponts et Chaussées (LCPC), France. High Modulus Asphalt (HiMA) mixes prepared using hard grade binders (HB) i.e., High Performance Binders (HiPB) and designed with low air void content (3%) to incorporate more bitumen, such that fatigue resistance of mixes will be increased and HiMA mixes can perform satisfactorily under severe traffic and climatic conditions. The distinctive feature of the HiMA mixes is the use of higher content of hard paving grade bitumen which increases the resistance to cracking and rutting.

???????B. EME Binder

Generally, HiMA mixes are produced using hard grade binders (HB) and designed with low air void content. Overloading, high pavement temperatures and traffic volume are some of the challenging issues of Indian highways and these issues can be addressed with the use of hard grade bitumen in bituminous base layer. These binders typically have penetration value in the range of 10 to 25 at 25°C. Hard grade bitumen (stiffer than VG40 grade) obtained either by modification of neat binders or produced in the refinery by Propane De-Asphalting (PDA) method.

???????C. Ideal Bitumen Modifier

Bitumen modification improves bitumen's temperature sensitivity to keep it flexible at lower pavement temperatures while staying stiffer at higher pavement temperatures. The main goal of the modification is to increase bituminous mixes' resistance to permanent deformation at high temperatures without degrading their low temperature performance.

???????D. Evaluating Bitumen Modification: A Dual Perspective

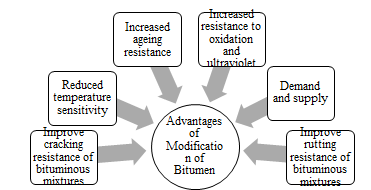

1) Advantages of Modification of Bitumen

Fig. 1: Advantages of modification of bitumen

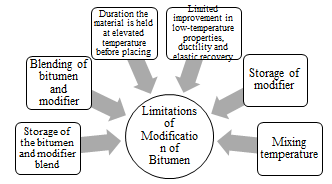

2) The Flip Side: Limitations of Modification of Bitumen

Fig. 2: Limitations of modification of bitumen

II. NEED AND SCOPE OF STUDY

Modification of bitumen can form a protective layer that acts as a barrier to oxygen and polymers have UV absorbing properties, which help shield the bitumen from the harmful effects of UV radiation. This can reduce the gradual loss of visco-elastic properties of bitumen due to ageing which enhances the performance of bitumen and mixes prepared using them. Also, HiPER bituminous mixes require hard binders with penetration of 10/15 or 15/25. In India, binders stiffer than viscosity grade VG40 are not available easily and the use of modifier(s) (single or composite modifiers) to produce hard binder has received far less attention and these would result in mixes with excellent resistance against distresses such as cracking, rutting and better durability. To meet demand and supply constraints effectively, we need to explore the alternative binders and mix designs to enhance performance while managing supply limitations. This study is to develop a HiPER bituminous mix by blending modifiers at different dosages to the base binder and examines their potential in improving the overall performance of base binder to produce a hard grade binder for HiPER bituminous mix. This study is beneficial for engineers and road sector engineering companies, with the use of HiPER bituminous mixes pavement performance will be enhanced.

III. LITERATURE REVIEW

The following is a description of some of the relevant research that is important to this topic's area of study:

Panda, M., & Mazumdar, M. (1999) [1] reported that the penetration, ductility, and specific gravity of EVA modified bitumen decreases as compared conventional bitumen, conversely softening point and viscosity increases. The minor variations in temperature and blending time do not significantly affect the bitumen properties. Also, the use of EVA with conventional bitumen results in higher Marshall stability value up to 14KN. The flow values and air voids are also within acceptable ranges, as the use of EVA increases both stability and air voids while reducing the flow value and unit weight. EVA modification also enhances the tensile strength at test temperature (5 ºC to 50 ºC).

Airey (2002) [2] reported that modifying bitumen with EVA enhances its rheological properties. The EVA copolymer enhances the bitumen by forming rigid three-dimensional crystalline networks within it. Conventional tests like penetration, softening point, ductility and viscosity test shows that EVA PMBs exhibit increased stiffness and improved temperature susceptibility.

Gonzalez O., Muno M. E., Santama A. Garc??a Morales M., Navarr F. J., & Partal P., (2004) [3] revealed that when blended with recycled or virgin EVA copolymer that has an equivalent vinyl acetate (VA) content, the visco-elastic characteristics of 60/70 penetration grade bitumen are improved. This modification minimizes the possibility of rutting in hot weather and cracking in cold weather. Bitumen modified with recycled EVA exhibits superior visco-elastic properties, this is probably because carbon black, which serves as a filler is present. Overall, the test results indicate that the performance of bitumen as a binder for the pavement is notably improved with the addition of recycled EVA or virgin EVA.

Garc??a-Morales M., Partal P., Navarro F. J., Mart??nez-Boza F., Gallegos C., González N., González O., Muñoz M. E., (2004) [4] reported that the viscous properties of bitumen at high temperature can be enhanced by adding recycled EVA copolymer, with the amount added depending on the bitumen’s grade. Additionally, as the polymer concentration increases, notable microstructural changes occur, leading to the development of a polymer rich phase within the bitumen. These microstructural changes significantly impact the binder’s flow behavior and its performance during service.

Kumar Praveen, Khan Tanveer, Singh Maninder (2013) [5] determined the ideal dosage, the physical characteristics of EVA (Ethyl Vinyl Acetate) modified bitumen, and the impact of aging on the binder made with the ideal dosage. The findings demonstrated that the inclusion of polymers enhances bitumen's physical properties including penetration and softening point. Lower penetration value, greater softening point value, and higher viscosity are obtained with the EVA modified binder in relation to plain bitumen and the aging impact on the modified EVA binder are within allowable bounds.

Claudio Brovelli, LoicHilliou, YacineHemar, Jorge Pais, Paulo Pereira, Maurizio Crispino (2013) [6] stated that compared to normal bitumen, EVA modified bitumen has a higher resistance to rutting in hot mix asphalt. It also offers greater compatibility, safer handling, and increased workability than SBS and SBR modifiers. Additionally, certain grades of EVA improve resistance to fuel spill damage and don't cause problems for the material's future recycling. However, the vinyl acetate (VA) monomer concentration, crystallinity, chain length and molecular weight of the EVA polymer can all affect its characteristics. When determining particular properties, for EVA, the VA concentration and melt flow rate (MFR) are just as important as the styrene content and the linear or radial structure in SBS. Additionally, EVA modified bitumen is more heat stable and deteriorates less quickly at high storage temperature compared to SBS and SBR modified bitumen, results in better storage stability.

Zhu J., Birgisson B. & Kringos N. (2014) [7] revealed that bitumen polymer modification for road construction has seen significant advances, but it also faces several challenges. While these polymers generally improve bitumen properties, there are drawbacks that hinder further development such as high costs, low aging resistance and poor storage stability. Also, it is still challenging to perfectly achieve all expected properties at the same time. It is also suggested that future modification research of bitumen should concentrate more on function development to improve adhesion with aggregates, long-term performance, and recyclability.

Kishan K.Vachhani, Prof. Mishra C.B. (2014) [8 revealed that the bitumen's (VG30) elastic recovery rises as the proportion of EVA increases, reaching 4%. A higher elastic recovery number denotes greater binder flexibility and will increase the pavement's lifespan. The environmental parameters under which each EVA modified binder should be used effectively are stated. They can be utilized in high temperatures and high traffic locations.

Espersson M. (2014) [9] done a study to calculate the percentage of reduction in thickness of the base course in airport pavements while using High Modulus Asphalt Concrete (HMAC) compared to conventional bitumen mixtures, also considering the temperature variations. In order to determine the thickness reduction based on temperature and the use of HMAC, tests were performed at various temperatures: -20°C, -10°C, 0°C, 10°C, and 20°C. The result indicates that HMAC had a higher complex modulus and higher viscosity at all elevated temperatures. The results suggests that HMAC can effectively reduce asphalt layer thickness. Specifically, the base layer thickness could be reduced by 24.77% at 20°C and by about 1.24% at -10°C. However, at lower temperatures HMAC was less effective in terms of thickness reduction. Additionally, dynamic Young’s modulus at high temperatures is 50% higher than that of conventional bitumen mixes. HMAC also exhibits twice the rutting resistance and 5-10 times greater fatigue resistance compared to conventional bitumen mixes.

Keymanesh, M. R., Ziari, H., Damyar, B., & Shahriari, N. (2017) [10] used waste polymer EVA at three levels (3%, 5% and 7%) and waste crumb rubber at three levels (2%, 4% and 6%) as modifiers for Iran 85/100 refinery bitumen. The impact of these additives on bitumen properties was examined to evaluate the low temperature performance and compared with low temperature performance of conventional bitumen. The test results revealed that these additives improved the low temperature performance. Specifically, increasing the EVA content up to 3% and crumb rubber content up to 4% resulted in decreased creep stiffness and increased creep rate. Additionally, other test results demonstrated that the samples exhibit proper elastic recovery and acceptable efficiency.

T. Parmar, Thummar Milan Sureshbhai, Sohaliya Kaushik Kalubhai, Kakadiya Jigarkumar Harasukhbhai, Shiyani Dhaval Rajubhai & Rathod Rohit Bharatbhai (2017) [11] did an investigation on VG 30 grade bitumen's physical characteristics both with and without the addition of ethylene vinyl acetate copolymer. The elastic recovery rises as the proportion of EVA does and seen at 4%. A higher elastic recovery value will extend the pavement's life at low temperatures by indicating that the binder is more flexible. The environmental parameters under which each EVA modified binder should be used effectively are stated. They can be utilized in high temperatures and high traffic locations.

Ibrahim Elnam, Momen Mousa, Marwa M. Hassan, Ipshit Idris, and Louay Mohammad (2022) [12] prepared a blend of 10% crumb rubber, 20% RAP, and SBS-modified binders was used to create an HMAC (High Modulus Asphalt Concrete) that effectively complied with LaDOTD and French mix design requirements. HMAC mix performed better in terms of dynamic modulus, resistance to rutting, and resistance to cracking than the control Superpave mix. Furthermore, depending on traffic volume, this HMAC combination might lower the needed asphalt thickness by 1.5 or 2 inches. Furthermore, it might lessen the volume of discarded tires that are disposed of in landfills, this mixture is ecologically benign.

IV. GAPS IN LITERATURE REVIEW

These gaps represent areas where limited or insufficient information is available:

- The selection and inclusion of modifiers poses a significant challenge, as there is lack of research on this subject.

- To produce HiPER bituminous mix, no specific binder is available in India.

- Research is needed to find out the impacts of employing different modifiers in various binders. This can help in determining the ideal modifier that offers the greatest results in terms of strength and durability.

- HB produced using polymers comprises of higher polymer content has been not explored.

- It is unusual to create hard binder via composite modification (more than one modifier or additive).

- Not much sustainable material has been developed for HiPER bituminous mix. Research required for recycle and reuse of modifiers to make hard grade binders.

V. EXPECTED OUTCOMES

Based on the work done above, we will:

- Ascertain suitability of base binder in preparation of suitable binder for HiPER bituminous mix.

- Ascertain suitable modifier dosage that can be used in modifying base binder to develop suitable binder in development of HiPER bituminous mix.

- Ascertain variation in performance of HiPER bituminous mix with addition of modified base binder.

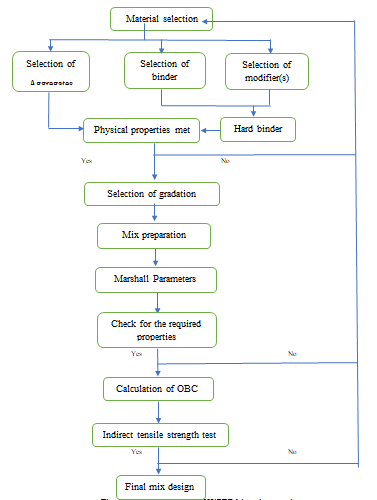

VI. RESEARCH METHODOLOGY

???????

???????

Fig. 3: Design procedure of HiPER bituminous mix

Conclusion

Following conclusions has been derived after reviewing various research works: A review of prior studies on the HiPER bituminous mix was conducted. This study aims to investigate the possible advantages of using modifiers in bitumen and how it influences performance of bitumen. A number of research studies have focused on bitumen modification, but far less emphasis has been paid on producing a hard grade binder. Based on a review of the many studies conducted, it has been determined that the tests have been carried out with various additives, including EVA, SBS, SBR, crumb rubber, etc. According to the study the physical properties of bitumen such as penetration and softening were improved with addition of polymer, but not all additives are capable of enhancing every desired bitumen property of bitumen and effectiveness of modification depends on the properties of base binder, proportion of modifier used and compatibility between bitumen and modifier. Also, using this modified bitumen results in higher values for both Marshall Stability and Indirect Tensile Strength. This study concluded that modified bitumen gives lower penetration value and higher softening point value as compared to neat bitumen, but there is high need to study the impacts of employing different modifiers in various binders. This can help in determining the ideal modifier that offers the greatest results in terms of strength and durability to develop a hard grade binder (HB) and use that hard grade binder for HiPER bituminous mix. Further research in this field involves the preparation of specimens with varying percentages of modified bitumen and evaluated with the target of producing HiPER bituminous mix. Marshall stability and indirect tensile strength (ITS) tests are conducted to assess the mixes for HiPER bituminous mix. The results obtained from these tests are statistically analyzed, in the attempt to develop the HB and HiPER bituminous mix.

References

[1] Panda, M., & Mazumdar, M. (1999). Engineering Properties of EVA-Modified Bitumen Binder for Paving Mixes. Journal of Materials in Civil Engineering, doi:10.1061/(asce)0899-1561(1999)11:2(131) [2] Airey, G.D. (2002), “Rheological Evaluation of Ethylene Vinyl Acetate Polymer Modified Bitumens”, Journal of Construction and Building Materials, Elsevier Science Ltd. doi:10.1016/s0950-0618(02)00103-4 [3] Gonzalez O., Muno M. E., Santama A. Garc??a Morales M., Navarr F. J., & Partal P., (2004), “Rheology and Stability of Bitumen-EVA Blends”, European Polymer Journal, 40(10), 2365-2372. doi:10.1016/j.eurpolymj.2004.06.001 [4] Garc??a-Morales M., Partal P., Navarro F. J., Mart??nez-Boza F., Gallegos C., González N., González O., Muñoz M. E., (2004), Viscous properties and microstructure of recycled eva modified bitumen. Fuel, 31–38. doi:10.1016/s0016-2361(03)00217-5 [5] Kumar Praveen, Khan Tanveer, Singh Maninder (2013), “Study on EVA modified bitumen” Elixir Chem. Engg. [6] Claudio Brovelli, LoicHilliou, YacineHemar, Jorge Pais, Paulo Pereira, Maurizio Crispino (2013), “Rheological characteristics of EVA modified bitumen and their correlations with bitumen concrete properties”, Construction and Building Materials. doi: https://doi.org/10.1016/j.conbuildmat.2013.07.032 [7] Zhu J., Birgisson B. & Kringos N. (2014), “Polymer modification of bitumen: Advances and challenges”, European Polymer Journal. [8] Kishan K. Vachhani, Prof. Mishra C.B. (2014), “Assessing the impact of VG30 grade bitumen with and without additive (EVA) on short term aging”, IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE). [9] Espersson M. (2014), “Effect in the high modulus asphalt concrete with the temperature”, Construction and Building Materials, doi:10.1016/j.conbuildmat.2014.08.088 [10] Keymanesh, M. R., Ziari, H., Damyar, B., & Shahriari, N. (2017), Effect of waste EVA (Ethylene Vinyl Acetate) and Waste CR (Crumb Rubber) on characteristics of Bitumen Petroleum Science and Technology, doi:10.1080/10916466.2017.1384840 [11] T. Parmar, Thummar Milan Sureshbhai, Sohaliya Kaushik Kalubhai, Kakadiya Jigarkumar Harasukhbhai, Shiyani Dhaval Rajubhai & Rathod Rohit Bharatbhai (2017), Influence Of VG30 Grade Bitumen With And Without Additive (Eva) On Short Term Aging [12] Ibrahim Elnam, Momen Mousa, Marwa M. Hassan, Ipshit Idris, and Louay Mohammad (2022), “Development of Cost-Effective High Modulus Asphalt Concrete Mixtures Using Crumb Rubber and Local Construction Materials in Louisiana”, Transportation Research Record Journal of the Transportation Research Board, doi:10.1177/03611981221074377 [13] Gupta S. & Duggal A. K. (2022) ‘A Review on Behavioural Similarity Between Marshall Stability and Indirect Tensile Strength Values for D.B.M. using VG-30 & VG-40 Grade Binder’, International Journal for Research in Applied Science and Engineering Technology. [14] Drakos C. G., Birgisson B., and Roque R. (2005), “Guidelines for use of modified binders”, Florida Department of Transportation, University of Florida. [15] Moghaddam T. B., “Development of High Modulus Asphalt Concrete Mix Design Technology for Use on Ontario’s Highways”, 2019, Waterloo, Ontario, Canada. [16] MoRTH (Ministry of Road Transport and Highways), “Specifications for road and bridge works”, (Fifth Revision), Indian roads congress, New Delhi, India, 2013. [17] ASTM D 6927 (2015), “Standard Test Method for Marshall Stability and Flow of Bituminous Mixtures”, 2015, American Society for Testing and Materials International, United States. [18] ASTM D 6931 (2017), “Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures”, 2017, American Society for Testing and Materials International, United States. [19] IRC:SP:139-2023,“Guidelines for High Performance Bituminous Mixes for High Volume Roads”, Indian Roads Congress, New Delhi, India, 2013. [20] IS:73-2013, “Paving Bitumen - Specification”, (Fourth Revision), Bureau of Indian Standards, New Delhi. [21] IS:15462-2019, “Polymer Modified Bitumen (PMB) - Specification”, (First Revision), Bureau of Indian Standards, New Delhi. [22] IS:17079-2019, “Rubber Modified Bitumen (RMB) - Specification”, Bureau of Indian Standards, New Delhi. [23] IS:15462-2004, “Polymer and Rubber Modified Bitumen - Specification”, Bureau of Indian Standards, New Delhi [24] IS 1203 (1978), “Methods for Testing Tar and Bituminous Materials, Penetration test”, Bureau of Indian Standards, New Delhi. [25] IS 1205 (1978), “Methods for Testing Tar and Bituminous Materials, Softening Point Test”, Bureau of Indian Standards, New Delhi.

Copyright

Copyright © 2024 Er. Harsh Thakur, Er. Ajay Kumar Duggal. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64069

Publish Date : 2024-08-24

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online