Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Development of a Mini Ginger Chopping Machine

Authors: Marjun E. Caguay

DOI Link: https://doi.org/10.22214/ijraset.2023.54760

Certificate: View Certificate

Abstract

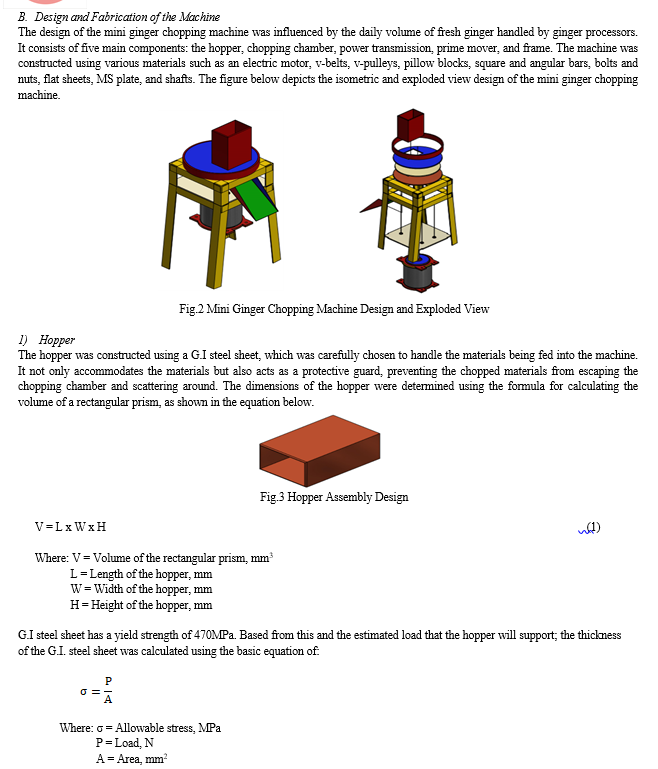

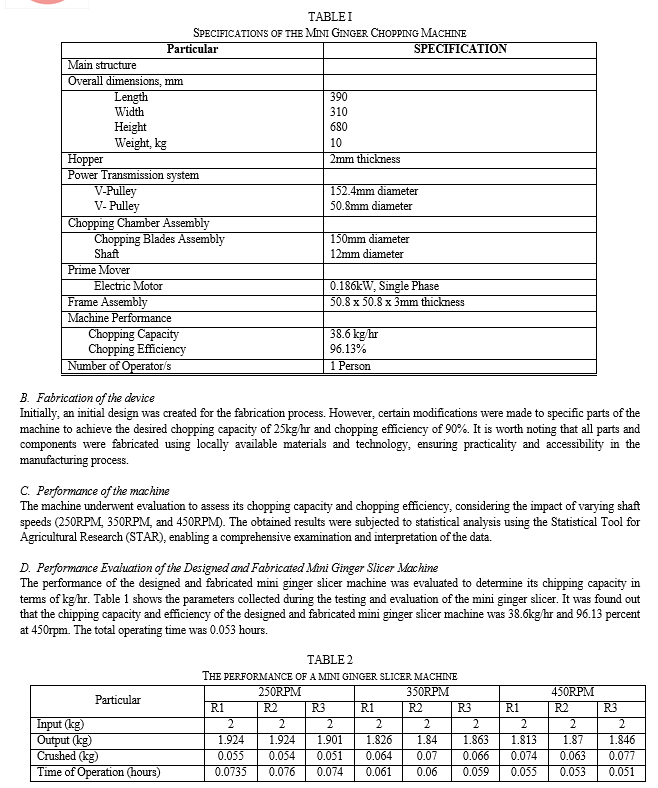

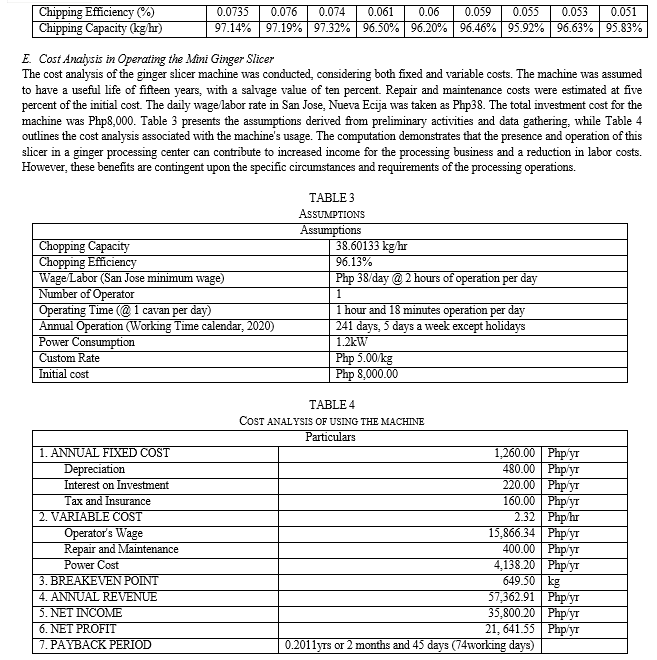

In the Philippines, ginger processing operations, especially in small and medium-scale processing centers, require significant time, financial investment, and effort. This is primarily due to the lack of affordable and cost-effective chopping machines specifically designed for ginger processing. Consequently, the objective of the study was to develop a mini ginger chopping machine that addresses these constraints and meets the requirements of local ginger processors and workers. The machine was composed of five major parts: the hopper, chopping chamber, power transmission system, prime mover, and frame. Locally produced ginger was used as test materials for the experiments, which included three treatment speeds: 250, 350, and 450 rpm. The experiment was conducted using a completely randomized design (CRD), and the performance parameters of the machine were analyzed using an analysis of variance (ANOVA) test. Furthermore, a least significant difference (LSD) test was employed to compare the means, with a 5% significance level. The results demonstrated that the highest chopping capacity of 38.6 kg/hr was achieved at a shaft speed of 450 rpm, with a chopping efficiency of 96.13%. However, a significant portion of the device\\\'s inefficiency stemmed from the presence of unchipped materials, amounting to 2.74% of the total inputted test materials. The majority of the product sizes ranged from 2 to 4 mm, indicating consistency in the chopping process. A cost analysis revealed that the machine needed to process a total of 649.5 kg of ginger to reach the breakeven point, considering a custom rate of Php 2/kg. With an initial investment cost of Php 8,000, the machine could recoup this investment in just 3.36 months (equivalent to 74 working days), and additionally provide a net income of Php 21,641.55 per year to ginger processors.

Introduction

I. INTRODUCTION

Ginger (Zingiber officinale) is a globally renowned spice cultivated in various countries worldwide, including China, India, Nigeria, Nepal, Bangladesh, Japan, Thailand, Philippines, Cameroon, Sri Lanka, Korea, and Fiji. It is widely utilized in both its fresh form (Green Ginger) and dried form (Dry Ginger). In many Asian cultures, both types of ginger are commonly added to teas to enhance flavor and for their associated health benefits. Ginger possesses essential oils, namely Oleoresin and Gingerol, which contribute to its distinct characteristics. These oils make ginger highly valuable in the food industry as a spice for flavoring curries, as well as in the beverage, perfume, and medicinal industries. The versatility of ginger and the presence of these unique oils have established its widespread use and demand across various sectors [4]. Freshly harvested ginger typically contains a moisture content ranging from 80% to 85%. However, for the purpose of storage, ginger is dried to achieve a moisture content of approximately 10% to 12%. This drying process helps to prolong its shelf life and maintain its quality during storage [1] [2]. The harvest of ginger takes place approximately 8-9 months after planting, specifically for the purpose of processing it into dried ginger. Once harvested, the fresh ginger undergoes several post-harvest processes, including washing, peeling, killing (a process to prevent sprouting), and finally, either slicing or dicing. These steps are crucial in preparing the ginger for further processing and storage [5][7].

Size reduction is a critical step in the processing of fresh ginger as it reduces the time required for drying and minimizes energy consumption. Slicing and dicing are the primary methods employed for pulverizing ginger rhizomes. When ginger is sliced, it can be dried in a cross-flow drier within 5 to 6 hours, whereas drying scraped whole ginger using the same equipment and conditions takes approximately 16 to 18 hours. This significant difference in drying time makes sliced ginger a preferred choice, especially for the export market, due to the high demand for value-added products in the international market [3][9]. The mechanization of the slicing procedure is imperative to address the challenges posed by labor shortages in the ginger processing industry. However, existing vegetable slicers available in the market are not suitable for ginger slicing due to certain limitations and drawbacks. One of the key factors to consider is the unique morphological characteristics of ginger rhizomes, which contain long and sturdy fibers in their flesh. These fibers possess the ability to withstand the cutting forces applied during slicing, making it necessary to develop specialized machines tailored specifically for ginger slicing [10][11]. The vegetable cutters currently available in the market are primarily designed for non-fibrous vegetables like potatoes and carrots, which require relatively lower cutting forces. If these cutting machines were to be used for ginger, the blades would be susceptible to damage and would need frequent replacement. Additionally, the cost of these available machines is typically high. As a result, small-scale industries may face limitations in investing in such expensive equipment, leading them to rely predominantly on manual labor for ginger processing operations.

Based on the benchmarking conducted, it has been observed that the vegetable cutters available in the market are specifically designed for non-fibrous vegetables such as potatoes and carrots, which necessitate lower cutting forces. However, when these cutting machines are used for ginger, the blades are prone to damage and require frequent replacement. Furthermore, the high cost of these machines poses another challenge. Small-scale industries often lack the capacity to invest in such expensive equipment, leading them to rely predominantly on manual labor for ginger processing operations.

After conducting preliminary activities, it was identified that processing centers face two major challenges that require attention: manual washing and manual chopping or slicing of ginger produce. According to interviews conducted, daily production levels fluctuate between 50 and 200 kg of fresh ginger when slicing is performed manually. Currently, laborers rely on kitchen knives for these tasks, resulting in low productivity and efficiency, inconsistent sizes of cuts, and an increased risk of harm or injuries to workers. These issues highlight the pressing need for improved methods and equipment to enhance productivity and ensure worker safety in ginger processing centers.

The limited quantity of ginger that can be processed manually each day directly affects the income of both the workers and the processing center. Introducing mechanical slicing of ginger can address the challenges associated with manual labor and transform it into a commercially viable production process. By automating the slicing task, the machine can significantly reduce the time required for slicing the product before it is subjected to the juicer machine, thereby lowering labor costs. Additionally, the machine is designed to be user-friendly and safe, ensuring a more efficient and secure processing experience.

Therefore, the objective of this study is to develop a mini ginger chopping machine with the aim of enhancing production and increasing the income of processing centers engaged in ginger processing and production. By introducing this innovative machine, it is anticipated that productivity levels will rise, leading to improved financial outcomes for the processing centers.

II. OBJECTIVES OF THE STUDY

The general objective of the study was to develop a mini ginger chopping machine. Specifically, the study aimed to:

- Design a mini ginger slicer using locally available materials;

- Fabricate the machine using local manufacturing technology;

- Evaluate the performance of the device in terms of chopping capacity and chopping efficiency;

- Analyze the cost of using the machine.

III. MATERIALS AND METHODS

A. Conceptualization of the Study

The design conceptualization of this study was driven by the feedback and concerns expressed by the turmeric and ginger processing centers during interviews. Based on the information gathered, it was observed that the processing centers typically resort to manual chopping of the produce before subjecting it to the juicer machine. This manual process is time-consuming and labor-intensive. To overcome these challenges, the study aimed to design and develop a mini ginger slicer machine that utilizes locally available materials and machine technology. By introducing this machine, the goal is to streamline the processing operations and improve efficiency in ginger slicing, addressing the concerns raised by the processing centers.

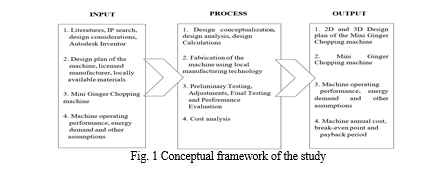

Figure 1 illustrates the conceptual framework of the study, utilizing the input-process-output method. The framework revolves around the overarching objective of developing a mini ginger slicing machine. This serves as the foundation for the study, guiding the input variables, the processes involved in designing and developing the machine, and the desired outputs or outcomes to be achieved.

V. ACKNOWLEDGMENT

First and foremost, the author would like to express heartfelt gratitude to the Almighty God, the ultimate source of wisdom and strength. Special thanks are extended to Engr. William Salasa Jr., Engr. Apple Joy Cobrador, and Engr. Melba Denson, M.Sc., for their invaluable suggestions and encouragement throughout the research process.

The author would also like to acknowledge and appreciate all the individuals who may not be mentioned by name but have provided prayers, assistance, and support. Without their presence and contributions, this study would not have been possible.

Thank you sincerely to everyone involved, and all glory and praise be to God.

Conclusion

Based on the objectives and findings of the study, several conclusions can be drawn. Firstly, the developed mini ginger chopping machine has proven to be highly effective in reducing labor, time, and expenses associated with ginger processing. It also offers the potential for generating additional income for ginger and turmeric processors. Moreover, the machine can be fabricated using locally available materials and local manufacturing technologies, making it easily accessible and feasible for implementation. In terms of performance, the machine has demonstrated satisfactory results based on its chopping capacity and efficiency. While the chopping efficiency decreases as the shaft speed increases, higher shaft speeds also result in a higher shredding capacity for the machine. The cost analysis of utilizing the machine indicates its financial viability. Local ginger and turmeric owners could potentially increase their profits by Php 21,641.55 per year when operating the machine for 2 hours per day to chip/slice their products. The cost of fabricating the machine was Php 8,000, and the projected annual operating cost was Php 21,562.7123. The computed breakeven weight and payback period were determined to be Php 255.07 kg per year and 74 working days, respectively. These results highlight the economic benefits and relatively short timeframe for recovering the initial investment.

References

[1] Ajavi E. A. and Ogunlade C. A. Physical Properties of Ginger (Zingiber officinale), Global Journal of Science Frontier Research: D Agricultural and Veterinary, 2014; 14(1): 1- 8. [2] Alakali, J. S. and Satimehin, A. A. Moisture adsorption characteristics of Ginger (Zingiber officinale) Powders, Agricultural Engineering International. The CIGR Ejournal. Manuscript 1289. 2009; 10: 1 - 19. [3] Aniyi, S. O. Design and Evaluation of a Ginger Slicing Machine, Journal of Agricultural Engineering and Technology (JAET), 2006; 14(1): 12 – 17. [4] Emehute, J. K. U. Eds. Proceedings of Three Training Workshops on Ginger Production, Processing, Utilization and Marketing held at the National Roots Crop Research Institute, Umudike. 2002; 46 – 50 [5] Emmanuel, L. Technology and Ginger Farm Performance, Path of Production 237 Efficiencies Overtime, Agriculture Economics Journal. 2008; 2: 297 - 306. [6] Ettannil, J. and Rangaru, V. (2012). Mechanical and thermal properties of ginger (Zingiber officinale Rosc.). Journal of Spices and Aromatic Crops. TathQeef Scientific Publishing. Retrieved from https://www.researchgate.net/journal/Journal-of-Spices-and-Aromatic-Crops-0971-3328 [7] Food and Agriculture Organization Statistics, (FAOSTAT) Production Quantity of Ginger 241 in the World Total 2011-2016. 2016; Retrieved from www.factfish.com/statistics/. 31 October, 2018. [8] Philippine Agricultural Engineering Standard. 2003. Agricultural Machinery – Chipping Machinery – Method of Test. PAES 223:2004 [9] Silva, F. H. C. A. and Jayatissa, D. N. Design and Development of a Ginger Slicer for Small Scale Spice Processors, International Journal of Trend in Research and Development, 2017; 4(1):385 – 389 [10] Simonyan, K. J., Eke, B. N., Adama, A. B., Ehiem, J. C., Onwuka, J. C., Okafor-yadi, U. N., … Okapara D. A. Design and Development of a Motorized Ginger Rhizomes Splitting Machine, Journal of Applied Agricultural Research. 2014; 6(1): 121 – 130. [11] U. N., … Okapara D. A. Design and Development of a Motorized Ginger Rhizomes Splitting Machine, Journal of Applied Agricultural Research. 2014; 6(1): 121 – 130

Copyright

Copyright © 2023 Marjun E. Caguay. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET54760

Publish Date : 2023-07-13

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online