Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Development of Ragi Dosa Premix

Authors: Yash Hemant Shende, Sayali Shahuraj Makne, Koina Suresh Ramteke, Chetan Jabarsingh Yadav, Pricy Niruba P, Prashant Watkar

DOI Link: https://doi.org/10.22214/ijraset.2024.61999

Certificate: View Certificate

Abstract

Breakfast holds significant importance as it constitutes a vital component of daily nutrition. With the rising demand for nutritious and convenient food choices, there has been an emergence of premixes tailored for traditional recipes. This project specifically targets the creation of a Ragi Dosa Premix—a dry mix designed for effortless dosa preparation using ragi (finger millet), renowned for its nutritional richness and gluten-free properties. The objective of the premix is to offer a wholesome and convenient solution for health-conscious consumers. Enriched with fiber and protein, the premix is associated with positive effects on various aspects of health including appetite regulation, weight management, body composition, and overall well-being. Additionally, it aids in mitigating the risk of developing common conditions such as heart disease and diabetes, while also promoting lower blood pressure, improved weight control, and reduced instances of constipation. Combining the nutritional benefits of three different flours—ragi, urad dal, and rice—the product is further fortified with calcium and iron compounds. Sensory and microbial analyses were conducted to evaluate the product\'s attributes and safety. The proximate analysis revealed key nutritional parameters such as moisture content (8.8%), total fats (2.69g/100g), protein (14.19g/100g), carbohydrates (70.27g/100g), crude fiber (2.59g/100g), ash content (1.26), calcium (190.16mg/100g), and iron (3.02mg/100g). The microbial load was found to be within acceptable limits. Organoleptic assessment, encompassing attributes like color, flavor, texture, taste, and odor, indicated favorable reception by panelists, garnering a high rating score of 8. A packaging solution was chosen based on considerations of product properties and shelf-life requirements, with the product exhibiting a shelf life of 2 months from the manufacturing date. In conclusion, the developed product offers a nutrient-rich, fiber- and protein-packed breakfast alternative, catering to health-conscious consumers.

Introduction

I. INTRODUCTION

Today, the state of our day-to-day health is a significant concern. There is a high demand for nutritious products that promote health. Poverty plays a crucial role in causing malnutrition, affecting nearly 50% of children in India. Our research suggests a solution that addresses both ends of this issue. Millets, known for their health benefits, offer a cost-effective approach to combatting prevalent lifestyle diseases, especially benefiting economically disadvantaged populations. In India, staple cereals and millets, including rice, wheat, jowar, maize, bajra, and ragi, make up 78-80% of daily energy intake. For families with limited resources, these grains are the most affordable and widely available source of energy, becoming less significant as income levels rise. Finger millet is used in various dishes such as flour, pudding, porridge, and roti (Chaturvedi and Srivastava, 2008).

The dosa, a beloved South Indian dish, crafted from fermented rice and urad dal batter, stands out as a thin, crispy pancake commonly accompanied by coconut chutney and sambar. A breakfast or snack staple in Indian cuisine, dosa acquires a tangy flavor through the fermentation process. It can be filled with diverse ingredients like potatoes or paneer for enhanced taste. Easily digestible, dosa contributes to the diet as a source of protein, calories, and B-complex vitamins. Its versatility extends to various recipes incorporating cereals, lentils, millets, and vegetables. This study focuses on the development of a nutritious instant dosa premix, utilizing foxtail millet, oats, soya bean, and urad dal. The nutrient-dense premix offers a minimal preparation method as it comes in powder form (B Naimisha, M Niharika, Gujarat Agricultural Universities Research Journal, 223, 2020).

Today’s men and women find it difficult to cook many of our traditional recipes due to shortage of time. Hence, convenience foods such as ready-to- cook or ready to serve (instant mixes) normally in dry form need to be mixed with water before consumption and require only few minutes of cooking in boiling water or steaming or frying can suitably serve the purpose. The present study was undertaken to formulate an instant dosa batter with enhanced nutritive value. A study was undertaken by (Chaturvedi and Srivastava, 2008) that the traditional ingredients were replaced using brown rice, white rice, black gram, oats, finger millet, sorghum, foxtail millet to develop a novel breakfast dosa batter with enhanced taste and nutritional benefits.

Control dosa batter was prepared using white rice and black gram in 4:1 ratio. According to their research, we took initiative and make ragi dosa and an enhanced level of various essential nutrients were observed.

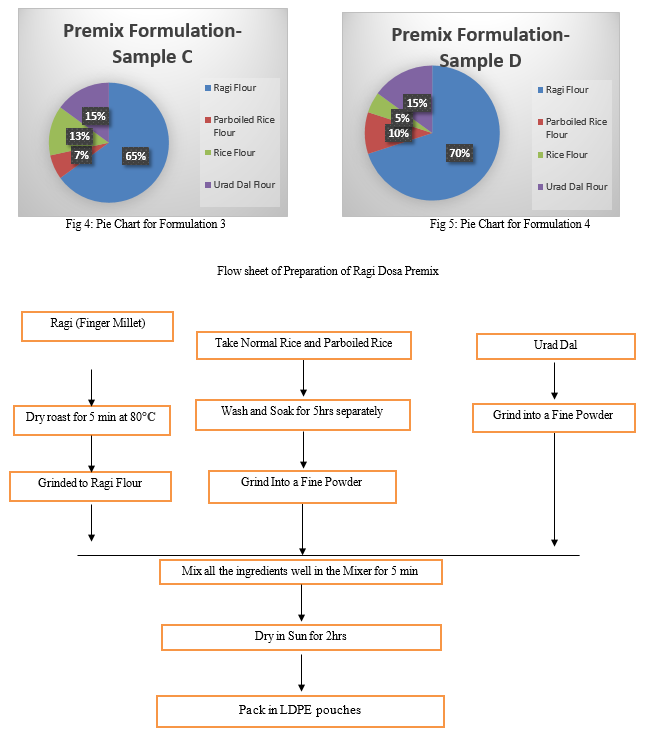

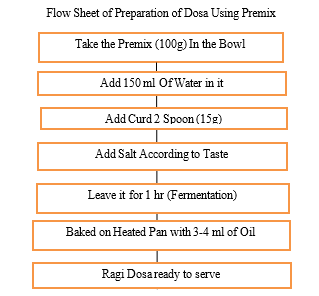

So According to study the increasing demand for nutritious and convenient food options has led to the development of premixes for traditional recipes, an attempt has been made in this regard to analyze the nutritional composition of newly released ragi variety KMR-204 and to assess the feasibility of ragi flour incorporation for the preparation of ready-to-cook mix, which can be used for the preparation of conventional products such as dosa with a prime objective to spread the awareness regarding nutritional qualities of ragi and to popularize the recipes that can be easily prepared and marketed by rural and urban mass using available resources. This study constituted of initial optimization of ragi flour to be added by means of sensory analysis. After which the method for preparation of Ragi premix was finalized and studies conducted to analyse the level of enhancement of the nutrition in the final sample. The Premix is made of Ragi flour, two different types of rice flour i.e normal rice and parboiled rice and urad dal. In 100g of Premix the ragi flour is 65g, normal rice flour is 6.6g, parboiled rice flour is 13.4g, urad dal is 15g. For dosa preparation, 100g of mix was added with 150 ml of water, 15g of curd and conditioned for 1 hr then add salt and baked on a heated Pan with 3-4 ml of oil. The premix thus prepared constituted of enhanced level of calcium (190.16mg), iron (3.02mg) and fibre (2.59g) when compared to the normal dosa. The shelf life according to sensory and microbial analysis was found to be 2 months.

II. MATERIAL AND METHODS

This chapter contains all the materials and methodology followed to prepare and test the product. The test methods for testing raw materials and products are also discussed. New product development work was carried out at the Department of Food Technology, Ballarpur Institute of Technology, Bamni, Ballarpur.

Table 1: Material Required for New Product Development

|

Material Required |

Collection Of Raw Material |

|

Ragi Flour |

Jio Mart |

|

Urad Dal |

Super Market |

|

Normal Rice |

Home |

|

Parboiled Rice |

Super Market |

|

Curd |

Dairy Shop |

|

Oil |

Home |

|

Water |

Mineral Water |

|

Salt |

Home |

|

Grinder |

Processing Lab |

|

Weighing Machine |

Processing Lab |

|

Measuring cylinder |

Processing Lab |

|

Pan |

Processing Lab |

|

LDPE |

Stationary Shop |

A. Packaging Material

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. The packaging material for the product was selected according to the Food Safety and Standard (Packaging) Regulation, 2018 (schedule IV – List of suggestive packaging material. The packaging of the final product was done in LDPE, a thermoplastic made from monomer ethylene which is a soft, flexible and lightweight. It has high clarity, heat-seal ability, high elongation and softness. This allows the consumer to have a greater experience in seeing the contents and product level as well as holding and squeezing the packaging. LDPE is the most inexpensive material for plastic films. LDPE (resin identification code 4) is recycled in the United States. (Team Xometry April 29, 2022). The above explained were the resons for which LDPE was chosen as a packaging material for the developed ragi dosa premix.

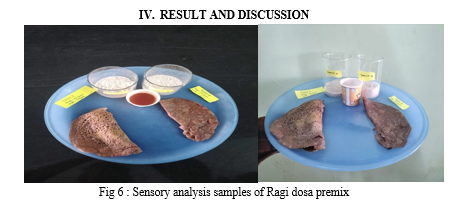

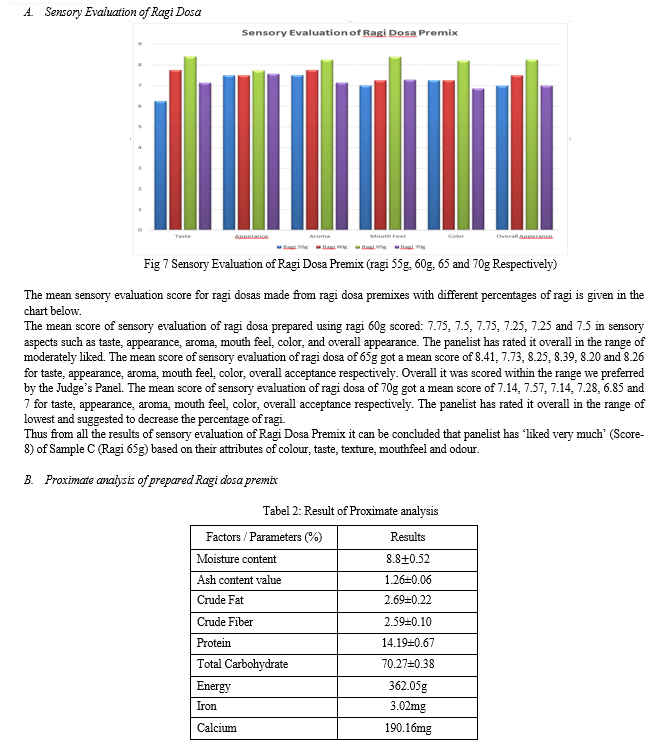

C. Sensory Analysis

Sensory analysis was conducted in the campus of Ballarpur Institute of Technology by a sensory panel consisting of 10 panelists. The panelist observed color, appearance, flavor, texture, taste and overall acceptability of product and rated them in a scale of 0 to 10 with 0 as the minimum and 10 as the maximum.

D. Proximate Analysis

- Estimation of Moisture

Moisture content was determined using the Oven drying method. Approximately 5 grams of the sample were weighed (W2) on pre-weighed petri plates (W1) and placed in an oven at 105º C for 3 hours. After drying, the samples were cooled in airtight desiccators to prevent moisture exchange with the environment. The drying process was considered complete when two consecutive weighings, taken an hour apart, showed variations of no more than 5 mg. Moisture content was calculated by subtracting the dried weight from the initial sample weight and expressed as a percentage. [Adya Yadav, et al, 2016]

% Moisture = (Loss in weight×100)/(Weight of sample)

2. Estimation of Fat

5 gm sample was weighed and packed in a thimble the prepared thimble was weighed to cross- check the weight of the sample. The thimble was then enclosed in a big cellulose thimble and then it was placed in a Soxhlet extraction tube, 250 ml, of petroleum ether, was added to the Soxhlet extraction tube containing the sample. The heating mantle was turned on and the temperature was set at 60°C. Petroleum ether gets evaporated and condensed and falls over the sample drop by drop and the speed of dropping should be 150 drops per minute. When clear color petroleum ether was seen in Soxhlet after 6-12 hours, the assembly was turned off. The round bottom flask containing the solvent was separated from the assembly to recover the solvent. The solvent was recollected by using the downward distillation unit for the next use and the round bottom flask holding the extracted fat sample was dried in a hot air oven at 105 "C until all the solvent was removed after drying the RBF was cooled in a desiccator and the weight was taken until the last three successive reading shows the difference less than 0.001 gm. A 5-gram sample underwent initial weighing and was then enclosed within a thimble. Subsequently, the thimble, now containing the sample, underwent an additional weighing to verify the sample's weight. The thimble, housing the sample, was then inserted into a larger cellulose thimble. This combined setup was carefully positioned within a Soxhlet extraction tube. To facilitate the extraction process, 250 ml of petroleum ether was introduced into the Soxhlet extraction tube containing the sample. Upon activating the heating mantle and setting the temperature to 60°C, the petroleum ether underwent a cycle of evaporation, condensation, and dripping over the sample at a controlled rate of 150 drops per minute.

Once the petroleum ether, now visibly clear, was observed in the Soxhlet after 6-12 hours, the entire assembly was deactivated. The round bottom flask, holding the solvent, was then separated from the apparatus to recover the solvent. The reclaimed solvent underwent further processing using a downward distillation unit for subsequent use. Meanwhile, the round bottom flask containing the extracted fat sample underwent a drying process in a hot air oven set at 105°C until all the solvent was completely removed. Following drying, the round bottom flask was cooled in a desiccator, and its weight was measured until three successive readings showed a difference of less than 0.001 grams [AOAC (1995)].

Percent crude fat was calculated as under:

% Crude Fat=(Weight of Fat)/(Weight of sample) ×100

3. Estimation of Protein

The protein content of the samples was determined utilizing the Kjeldahl method. Initially, 2 grams of the sample underwent digestion with 5 grams of a digestion mixture, comprising 10 parts potassium sulfate and 1 part copper sulfate, along with 20 ml of concentrated sulfuric acid. This digestion process continued in a Kjeldahl flask until the contents achieved a state of being carbon-free. The resulting digested sample was then adjusted to a final volume of 100 ml. A 10 ml aliquot of the digested sample was subjected to distillation with 20 ml of 30 percent sodium hydroxide. The liberated ammonia from this process was collected in a solution containing 20 ml of 2 percent boric acid, enriched with 2-3 drops of a mixed indicator. This indicator was a combination of 0.1% methyl red and 0.1% bromo-cresol green, dissolved in 95 percent ethyl alcohol, with a ratio of 1:5, respectively.

The entrapped ammonia was subsequently titrated against 0.1N hydrochloric acid. The nitrogen content in the sample was then calculated using the following expression:

% Nitrogen = (14×N of HCL×Titre value (ml)×Dilution factor×100)/(Weight of sample(g)×1000)

4. Estimation of Total Ash

To determine the ash content, a 2-gram sample was placed in a silica crucible and ignited on a heater. Subsequently, the crucible was transferred to a muffle furnace and maintained at a temperature of 550º C ± 15º C until a clean ash was obtained. The weight of the resulting residue was then recorded, and the percentage of ash was calculated using the following formula:

% Ash = (Weight of residue×100)/(Weight of sample)

5. Estimation of Carbohydrate

The percent carbohydrates were calculated by subtracting the sum of moisture, protein, fat, ash and fiber from 100.

% CHO = 100 - (% Moisture + % Protein + % Fiber + % + Ash)

6. Microbial Analysis

The Total bacterial count and fungal load was estimated by serial dilution method.

7. Shelf Life Testing

Shelf life was estimated based on microbial and sensory analysis at intervals of 15 days.

Conclusion

A High Fiber High Protein product was developed and its proximate and nutritional analysis were carried out. From the results, it is evident that the product is rich in protein having 14.19g/100g. (According to FSSAI regulations for Advertising and Claims, 2018, the product must contain 20% of RDA per 100g of solid product), rich in crude fiber having 2.59g/100g and contains carbohydrate, iron and less amount of fat. The product has a shelf life of two months. A feedback obtained from the sensory analysis showed that the product was ‘liked very much’ (Hedonic Score- 8) based on their attributes of colour, taste, texture, mouthfeel and odour. Thus, from all the results it can be concluded that, the formulated product is rich in fiber, rich in protein and contains other nutritive qualities. It also possesses good organoleptic properties. Hence, the developed product is acceptable and can be a part of the daily diet of consumers owing to the health benefits it imparts.

References

[1] Abdul-Hamid, A., Sulaiman, R. R. R., Osman, A., & Saari, N. (2007). Preliminary study of the chemical composition of rice milling fractions stabilized by microwave heating. Journal of Food Composition and Analysis, 20, 627–637. [2] Abe, T., & Afzal, T. (1997). Thin-layer infrared radiation drying of rough rice. Journal of Agricultural Engineering Research, 67(4), 289-297 [3] Amerine, M.A. Pangborn, R.M and Roessler E.B. (1965). Principle of sensory evaluation of foods. Academic Press, New York, :349. [4] ANONYMOUS, 1995, Official methods of analysis. Association of official Analytical Chemists, International 14th Edn, Washington DC, 22 : 113 - 208. [5] ANONYMOUS, 2001, Annual Report, All India Coordinated Small Millets Improvement Project, Bangalore. [6] ANTONY, HILU AND DE WET,1976, Effect of fermentation on the primary nutrients in finger millet (Eleusine coracana). J. Agric. Food Chem., 44: 2616 -2618. [7] AOAC, 1995. Official Methods of Analysis.13th Edition. Association of Official Analytical Chemist, Washington, D.C [8] AOAC. (1990). Official Methods of Analysis, 14th ed. Washington DC: Association of Official Agricultural Chemists. [9] APAARI (Asia Pacific Association of Agricultural Research Institutions). 2000. National agricultural research systems in the Asia-Pacific Region—a perspective. Bangkok (Thailand): APAARI. 37 p. [10] B Naimisha, M Niharika, Gujarat Agriculture Universities Research Journal : 223 – 2020 [11] Battacharya, S. and Bhat, K K. (1997). Steady shear rheology of rice black gram suspensions and suitability of rheological models. Journal of Food Engineeering.32:241–250. 50 [12] BHATT, A, SINGH V, SHROTRIA, P. K. AND BASKHETI D. C., 2003, Coarse Grains of Uttaranchal: Ensuring sustainable Food and Nutritional Security. Indian Farmer’s Digest. [13] CGIAR (Consultative Group on International Agricultural Research). 1998. The international partnership for food security and sustainable agriculture. Third System Review of the CGIAR. Washington (D.C.): CGIAR Secretariat. [14] CHATURVEDI, R. AND SRIVASTAVA, S., 2008, Genotype variations in physical, nutritional and sensory quality of popped grains of amber and dark genotypes of finger millet. J.Food Sci. Technol., 45 (5) : 443 - 446. [15] DE WET AND HUCKABAY, 1966, Genotype variations in physical, nutritional and sensory quality of finger millet. [16] Gopalan et al., 2004, Chemical composition and protein in hybrid varieties of finger millet. https://pharmeasy.in/blog/ayurveda-uses-benefits-side-effects-of-urad-dal/ - :~:text=Urad%20dal%2C%20scientifically%20called%20Vigna,and%20Urad%20dal%20in%20Hindi [17] https://pharmeasy.in/blog/ragi-health-benefits-and-tasty-recipes-for-losing-weight/ [18] https://plants.usda.gov/home/classification/24211 [19] https://www.medicalnewstoday.com/articles/318699 [20] https://youtu.be/XB0YiIIm2pM?si=Fea78bCET8X6eiIK

Copyright

Copyright © 2024 Yash Hemant Shende, Sayali Shahuraj Makne, Koina Suresh Ramteke, Chetan Jabarsingh Yadav, Pricy Niruba P, Prashant Watkar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET61999

Publish Date : 2024-05-12

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online