Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Comprehensive Study of Different Types of Cooling Towers

Authors: Shubham Dode, Rohan Sarode, Alan Abarahim, Saurabh Baviskar, S. V. Shinde, K. R. Pagar

DOI Link: https://doi.org/10.22214/ijraset.2023.56356

Certificate: View Certificate

Abstract

Cooling towers are essential components in a wide range of industries and processes, designed to dissipate excess heat generated during various operations. The efficient cooling of water or other heat transfer fluids is crucial for maintaining the optimal performance of machinery and equipment. This project presents a comprehensive study of different types of cooling towers, aiming to provide a thorough understanding of their functions, applications, and advantages. The study begins with an introduction to the fundamental principles of cooling towers, emphasizing the importance of heat exchange in industrial processes. It then digs into the various types of cooling towers, which include natural draft cooling towers, mechanical draft cooling towers, and hybrid cooling towers. Additionally, this study addresses showcasing successful applications of different cooling tower types in industries such as power generation, chemical manufacturing, and HVAC systems. Ultimately, the comprehensive study of different cooling tower types presented in this paper aims to provide engineers, industrial professionals, and researchers with valuable insights into selecting the most appropriate cooling tower design according to their needs.

Introduction

I. INTRODUCTION

Cooling towers are global wide array of industrial processes, power plants, and HVAC systems, playing a vital role in maintaining the operational efficiency of equipment and machinery. The efficient removal of excess heat is essential for ensuring the longevity and reliability of these systems. As such, the study of cooling towers holds immense significance in today's industrial landscape. This report embarks on a journey to comprehensively explore the various types of cooling towers. In a world where energy efficiency and environmental sustainability are increasingly prioritized, understanding the nuances of cooling tower technology is more critical than ever.

The ability to select the most suitable cooling tower type for a specific application can have a profound impact on operational costs, resource conservation, and carbon footprints.

From natural draft cooling towers that harness the power of nature to dissipate heat to mechanical draft cooling towers, which rely on mechanical systems to optimize heat exchange, and hybrid cooling towers, which blend the best of both worlds, we will go through each type's inner workings. By doing so, we hope to aid in the selection of cooling solutions that not only enhance operational efficiency but also align with sustainability and environmental responsibility.

II. OBJECTIVES

- To classify the cooling towers.

- To Analyse the performance of different cooling tower types.

- To Examine the environmental impact of different cooling towers.

- To Determine the suitability of different cooling tower types for various industries and applications.

A. AIM

The aim of this paper is to empower engineers, industrial professionals, and researchers with a comprehensive understanding of the various cooling tower options available.

III. LITERATURE SURVEY

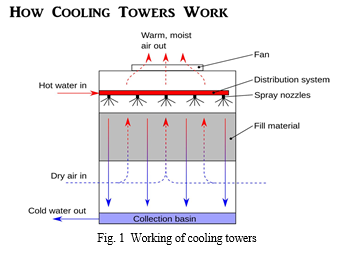

Cooling tower is a device which converts hot water into cold water due to direct air contact. It works on the temperature difference between the air inside the tower and outside the tower.

A. Literature review

Afshari, F. and Dehghanpour, H., 2019. A review study on cooling towers; types, performance and application. ALKÜ Fen Bilimleri Dergisi, in this study, a review study is carried out to investigate different types of cooling towers, their application, performance, usage and working principles, which can be useful in the field of nuclear plants as well as other energy stations. A number of investigations have been considered to reveal differences between the used cooling towers and finally a Fluent simulation has been carried out to examine major contours and flow field around the cooling tower.[1]

Cheremisinoff, N.P. and Cheremisinoff, P.N., 1981. Cooling towers: selection, design, and practice (pp. 114-122). Ann Arbor: Ann Arbor Science Publishers.[2]

Zamora, B. and Kaiser, A.S., 2011. Comparative efficiency evaluations of four types of cooling tower drift eliminator, by numerical investigation. Chemical Engineering Science, 66(6), The numerical model has been validated through comparisons with numerical and experimental results taken from the literature, including additional configurations of horizontal wave-plate mist separators. The effects of considering the turbulence dispersion of droplets are studied, as well as the influence of the inertial parameter and the aspect ratio of the eliminator sample channel. Finally, it is developed a procedure focused on establishing the overall efficiency for each type of eliminator, based in a key power function.[3]

Wenzel, P.M., Mühlen, M. and Radgen, P., 2023. Free cooling for saving energy: technical market analysis of dry, wet, and hybrid cooling based on manufacturer data. Energies, 16(9), the analysis reveals, for example, specific ranges of electricity demand from 0.01 to 0.06 kWel/kWth and highlights influencing factors, including type and operating point.[4]

Bhatia, A.J.C.E., 2001. Cooling towers. Continuing Education and Development, Inc Most industrial production processes need cooling waters to operate efficiently and safely. Refineries, steel mills, petrochemical manufacturing plants, electric utilities and paper mills all rely heavily on equipment or processes that require efficient temperature control. Cooling water systems control these temperatures by transferring heat from hot process fluids into cooling water. As this happens, the cooling water itself gets hot. Before it can be used again, it must either be cooled or replaced by a fresh supply of cool water.[5]

Ayoub, A., Gjorgiev, B. and Sansavini, G., 2018. Cooling towers performance in a changing climate: Techno-economic modeling and design optimization. Energy, 160, is paper presents a model of a natural draft wet type cooling tower, which is based on the conservation laws of thermodynamics. The model assesses the cooling abilities of a tower, the evaporation rate, and the amount of required make-up water, all represented as a function of the atmospheric conditions. The purpose of the model is to estimate the effects of extreme weather conditions on the thermodynamic efficiency of a natural draft wet type cooling tower.[6]

IV. METHODOLOGY

Methodology of the experiment considers different parameters such as energy efficiency, cost analysis, environmental impacts, design and operation, water usage and some other little things for selection of convenient and more efficient cooling tower. Through this paper Industries and large companies will get an overview about all types of cooling towers and how to select accordingly. For installation of cooling towers some types can be seen that are as follows:

Classification of cooling towers:

- Natural draft cooling towers.

- Mechanical draft cooling towers (including crossflow and counterflow designs).

- Hybrid cooling towers.

- Evaporative cooling towers.

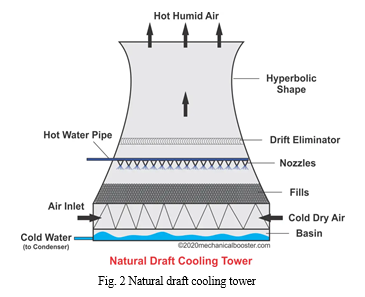

A. Natural Draft Cooling Towers

A natural draft cooling tower, is a type of cooling tower used in various industries to dissipate waste heat generated during industrial processes, power generation, or other applications. As their name implies, natural draft cooling towers rely on natural convection to circulate air throughout the tower, which then cools the water. As their name implies, natural draft cooling towers rely on natural convection to circulate air throughout the tower, which then cools the water. Unlike mechanical draft cooling towers, natural draft towers do not require mechanical fans for air circulation, reducing energy consumption and operating costs.

As natural draft towers do not require mechanical fans for air circulation, they reduce energy consumption and operating costs. And hence due to reduced number of some components natural draft cooling towers are easy to maintain. They are commonly used in power plants, refineries, and other large industrial facilities to dissipate the substantial amounts of heat generated by these processes. These towers are often preferred when large heat dissipation capacity is required these cooling towers release warm, moist air into the atmosphere, which can result in visible plumes during cold weather. Care must be taken to prevent environmental concerns related to plume formation. While natural draft cooling towers can be more water-efficient than some other types, they still consume water due to evaporation and drift losses. Water management and conservation are important considerations while selecting these types of cooling towers. As a conclusion after this research, it is found that natural draft cooling towers can be a good choice. However, they do require careful environmental management, especially in colder climates where visible plumes can be a concern.

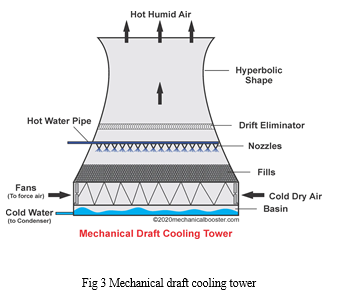

B. Mechanical draft cooling towers

These cooling towers employ mechanical fans to create airflow, allowing for greater control over cooling efficiency. Warm water from industrial processes or HVAC systems is pumped into the cooling tower and distributed over the fill material. Mechanical draft cooling towers come in various shapes and sizes, but they typically consist of an enclosure or casing containing heat exchanger surfaces, known as "fill" or "packing. Mechanical fans, often axial fans, located near the top of the tower, draw air through the tower and over the fill material. This induces the evaporation of water and facilitates heat transfer from the water to the air. The cooled water is then collected at the bottom of the tower and circulated back to the industrial process or HVAC system. Fans: Mechanical draft cooling towers use mechanical fans to create airflow, allowing for precise control over the cooling process. Variable Speed: Fan speed can often be adjusted, making it possible to modulate cooling capacity as needed. Mechanical draft cooling towers are known for their efficiency in heat dissipation. They are widely used in power plants, petrochemical refineries, HVAC systems, and industrial processes where precise temperature control is necessary. Mechanical draft cooling towers require regular maintenance, including fan inspection, lubrication, and cleaning of the fill material. Maintenance schedules are essential to ensure optimal performance. Mechanical draft cooling towers release warm, moist air into the atmosphere, but their efficiency can help reduce the overall environmental impact compared to other cooling methods. Drift eliminators are often used to minimize water loss due to drift. While these cooling towers consume water due to evaporation and drift losses, they are generally designed to be water-efficient. Modern designs incorporate features to minimize water wastage. Mechanical draft cooling towers generate noise due to the operation of the fans. Noise control measures, such as acoustic enclosures or silencers, may be required in noise-sensitive environments.

C. Hybrid cooling tower

A hybrid cooling tower is a type of cooling system that combines the principles of both wet (evaporative) and dry cooling methods. This hybrid approach allows for efficient heat dissipation while reducing water consumption, making it particularly suitable for applications where water conservation is a concern. A hybrid cooling tower typically consists of two separate cooling sections: A dry cooling section, which uses air to cool water without direct contact, similar to an air-cooled heat exchanger and A wet cooling section, which operates like a traditional evaporative cooling tower, using water evaporation to dissipate heat. Hybrid cooling towers provide flexibility and efficiency by using the dry section for primary cooling and the wet section for supplementary cooling when needed. Water usage is reduced compared to a traditional evaporative cooling tower because the wet section is used as a backup, primarily during hot weather or high heat loads. Dry cooling sections are also capable of operating during cold weather without water use, further enhancing water conservation. Hybrid cooling towers are designed to be more water-efficient and energy-efficient than traditional evaporative cooling towers. They are often employed in industries where water scarcity or environmental regulations require water conservation, such as power generation, data centres, and industrial processes. Maintenance requirements for this cooling towers are similar to those of traditional cooling towers, including routine checks on fans, fill materials, and water distribution systems.

Hybrid cooling towers offer advantages in water conservation, which can lead to lower environmental impact and in accordance with water use regulation these systems are generally designed to be energy-efficient, as they primarily use the dry section when weather conditions allow, reducing fan energy consumption. Hybrid cooling towers offer an effective solution for cooling applications where both water conservation and energy efficiency are priorities. They provide the flexibility to adapt to varying weather conditions and cooling demands, making them a suitable choice for industries that require efficient heat dissipation with minimal environmental impact.

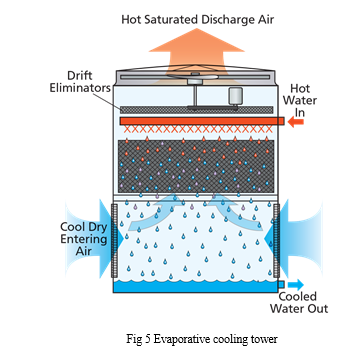

D. Evaporative Cooling Towers

Evaporative cooling towers are a type of cooling system used to dissipate heat from various industrial processes, HVAC systems, and power generation plants. These towers operate by using the principle of water evaporation to remove heat from hot water or other process fluids. Evaporative cooling towers consist of a large tower structure that contains a fill material, typically made of plastic or other materials with a high surface area. Evaporative cooling towers provide efficient cooling by using the latent heat of water evaporation to remove heat from the process fluid. They are capable of maintaining a relatively constant cooling water temperature, making them suitable for applications with varying heat loads. Evaporative cooling towers are known for their energy efficiency in heat dissipation and are commonly used in power plants, manufacturing facilities, and HVAC systems. They are particularly effective in areas with dry and hot climates, where they can provide substantial cooling benefits. Maintenance of evaporative cooling towers includes cleaning the fill material, checking the water distribution system, and ensuring proper fan operation. Routine maintenance is essential to maintain cooling efficiency.

Evaporative cooling towers release warm, moist air into the atmosphere, which can result in visible plumes during cold weather. Care must be taken to prevent environmental concerns related to plume formation. Drift eliminators are often used to reduce water loss due to drift, which can contain chemicals used in the cooling water. their water usage is generally lower than that of other cooling methods. Evaporative cooling towers generate noise, primarily due to the operation of fans. Noise control measures may be needed in noise-sensitive environments. Evaporative cooling towers are an effective and energy-efficient solution for cooling in various industries. They rely on the cooling power of water evaporation to dissipate heat from industrial processes, power generation, and HVAC systems. The choice of an evaporative cooling tower depends on factors such as climate, cooling requirements, and water conservation goals. Proper maintenance and consideration of environmental factors are essential to their successful operation.

Conclusion

Our comprehensive study of different types of cooling towers has provided valuable insights into the critical components and operational characteristics of these essential industrial systems. Through this project, we have gained a deeper understanding of the various cooling tower designs, their advantages, limitations, and the factors influencing their performance. This research has also highlighted the pivotal role of cooling towers in addressing the challenges of environmental sustainability and energy efficiency. As the global focus on reducing carbon footprints and conserving resources is increasing, the insights gained from this study can guide engineers and decision-makers in making informed choices. Considering concerns over energy efficiency and environmental impact continue to grow, given findings are not only insightful but also timely.

References

[1] Afshari, F. and Dehghanpour, H., 2019. A review study on cooling towers; types, performance and application. ALKÜ Fen Bilimleri Dergisi, pp.1-10. [2] Cheremisinoff, N.P. and Cheremisinoff, P.N., 1981. Cooling towers: selection, design, and practice (pp. 114-122). Ann Arbor: Ann Arbor Science Publishers. [3] Zamora, B. and Kaiser, A.S., 2011. Comparative efficiency evaluations of four types of cooling tower drift eliminator, by numerical investigation. Chemical Engineering Science, 66(6), pp.1232-1245. [4] Wenzel, P.M., Mühlen, M. and Radgen, P., 2023. Free cooling for saving energy: technical market analysis of dry, wet, and hybrid cooling based on manufacturer data. Energies, 16(9), p.3661. [5] Bhatia, A.J.C.E., 2001. Cooling towers. Continuing Education and Development, Inc. [6] Ayoub, A., Gjorgiev, B. and Sansavini, G., 2018. Cooling towers performance in a changing climate: Techno-economic modeling and design optimization. Energy, 160, pp.1133-1143.

Copyright

Copyright © 2023 Shubham Dode, Rohan Sarode, Alan Abarahim, Saurabh Baviskar, S. V. Shinde, K. R. Pagar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET56356

Publish Date : 2023-10-29

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online